However, this is not always possible to achieve, especially if we are talking about an object built from panels.

If the walls do not cope with their task of maintaining a comfortable air temperature, they need to be insulated. Read the article on how to do this.

When is it necessary to insulate inside?

to insulate walls made of panels inside a house when external thermal insulation has proven to be ineffective . In addition, it is not always possible to carry it out, for example, installation of insulation from the outside cannot be carried out if the house is a panel high-rise, or the walls border technical spaces, for example, an elevator shaft.

Reasons for insulating walls from the inside:

- The apartment is corner. In such a room, a large area of the walls comes into contact with frosty air, which is why it warms up worse and cools down quickly.

- Due to high heat loss, mold begins to grow in the corners of the walls.

- There is no external insulation, or it does not cope with its main task.

- The apartment is located on the ground floor or on the basement, which is why it is always cold in it.

If the panels quickly give off heat, then heating devices will not be able to cope with maintaining a comfortable temperature inside the room. At the same time, costs for heating, gas or electricity will increase. Frozen walls are the source of many troubles, ranging from mold to colds.

When is this not needed?

to insulate panel walls if the building has high-quality external thermal insulation .

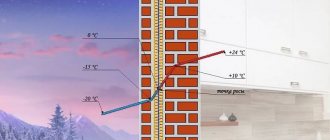

This means the dew point does not move closer to the living space, and the wall does not freeze. The dew point is understood as the conditional boundary at which water vapor cools to the condensation temperature. This is especially true during the cold season.

If the cooling is below the dew point, then the process of vapor condensation starts : the windows begin to fog up, and the room becomes damp. However, if the house is built and insulated according to the standards, then the dew point will pass through the center of the facade panel and it will always be warm inside the building.

Detailed instructions for doing the work yourself

After preparation is completed, you can begin installing the ventilation gap. This procedure is combined with the stage of laying waterproofing. Some forums publish opinions that insulation can be done without organizing a ventilation gap. However, this scheme leads to the accumulation of moisture between the surface of the wall and the insulation.

The ventilation gap is arranged according to the following scheme:

- Wooden slats with a thickness of 2 cm or more are attached to the walls. They need to be fixed horizontally in increments of 1 m. Dowel nails are suitable for fixing. Before laying, the slats are treated with protective impregnation.

- Further, several vents are made in the wall for normal air exchange. This is done by drilling holes with a diameter of about 20 mm. To prevent them from clogging, you need to provide a protective mesh.

- Then a vapor barrier film is attached to the resulting frame. It is installed tensioned to form a ventilation gap.

Diagram of the ventilation gap.

The next stage involves installing a frame of vertical posts. They are fixed in increments equal to the width of the insulation boards. For denser material, you can reduce the step by 1 cm.

Insulation is attached to the finished frame. If the design is done correctly, the mineral wool slabs will be held in place without additional fixation. But to eliminate cold bridges, you need to fill the voids between the studs and the wall with thermal insulation material. Drywall is used to cover the frame.

Materials

To insulate panel walls from the inside, various materials are used. There are many possible solutions. To make the right choice, you need to understand for which panels this or that type of insulation is suitable, what features it has, and more. Here's what you need to pay attention to:

- Minvata. It can be used to insulate panel walls, but it is recommended to use it only as a last resort, for which there are 2 reasons. Firstly, it flakes off, and its particles in a free state can cause harm to health if they enter the respiratory tract.

Secondly, mineral wool absorbs moisture, which over time leads to a deterioration in its thermal insulation properties. The film will not help to cope with this problem; the water will still end up inside. In addition, the installation of insulation will require the construction of a frame structure. If you still decide to use mineral wool, then you need to choose a certified product that is approved for indoor use.High-quality material retains heat well, meets fire safety requirements, and is lightweight. It is also recommended to cover the layer of wool with particle boards (OSB), and then proceed to finishing. The cost of the material is 580 rubles for 8 layers of mineral wool measuring 1200*600*50 mm.

- Regular non-pressed polystyrene foam .

It is mounted with glue and additionally reinforced with dowels; a fiberglass mesh is attached on top, which is embedded in the plaster. However, this material also has its drawbacks: it burns and melts, releasing toxic substances into the air, it is fragile and can be damaged by rodents. It is used as insulation when work needs to be done quickly and inexpensively. If possible, the use of expanded polystyrene in apartments and private houses is avoided and non-residential premises are lined with it. The price of a slab measuring 1000*1000, 20 mm is 40 rubles. - Extruded polystyrene foam . Panel houses are often insulated with this modern material. It is stronger than ordinary polystyrene foam, although in conditions of internal insulation this indicator is not decisive. The main thing is that EPPS has a lower level of water absorption - 0.2% versus 2.0 for conventional PSB. The price of a slab measuring 118.5*58.5 cm, 50 mm is 170 rubles.

Styrofoam . It is rarely used to insulate interior walls in houses. It is flammable, very fragile and can be damaged by rodents, so it is not recommended to use it in a private home.- Keramoizol or liquid thermal insulation. This material is applied to the wall by type of painting: with a brush or spray gun.

The main advantages of spraying include: moisture resistance, elasticity, environmental safety, and no load on the structure.This insulation will be an excellent option for panel walls in a high-rise building. It does not reduce the usable area of the room and has good thermal insulation characteristics. One millimeter of liquid spray gives the same amount of heat as 50 mm thick basalt wool.

- Cork wallpaper .

They are often used to insulate walls in corner rooms, as well as in apartments located on the ground floor. In appearance, they resemble non-woven wallpaper, but have a greater thickness, reaching 1 mm. To install them you will need special glue. The main advantages of cork wallpaper: environmental friendliness, preventing the formation of mold, ease of gluing. However, they cannot retain heat as well as other thick materials, creating a kind of “pie” that prevents the room from cooling down. The cost of 1 square meter is 1,700 rubles. - Penoizol .

This material is an analogue of polystyrene foam, but it is produced in liquid form. It is rarely used for self-insulation of walls, since it is difficult to use in domestic conditions. Most often, they insulate walls during the construction stage by pouring penoizol into hollow structures. Its main advantages: low thermal conductivity, long service life, environmental friendliness, non-flammability. The cost of insulating walls with foam insulation starts from 200 rubles per meter. - Astratek . This is a microporous liquid insulation that is used to create a seamless coating that prevents the room from cooling down. The material does not corrode and adheres well to walls, which is why it is often used when working in panel houses. Its cost is 8300 rubles per 20 liters.

- Penoplex . This insulation is a type of expanded polystyrene. It is represented by tiny bubbles, isolated from each other. Low thermal conductivity is ensured precisely by the porous structure of the material. Penoplex does not absorb water, has a long service life, but is destroyed upon contact with solvents. The cost of a panel measuring 3000*1500*10 mm is 990 rubles.

- Warm paint . Its manufacturers position the product as insulation and waterproofing material. It protects panel walls from corrosion and mold. Its ability to retain heat indoors is achieved through the inclusion of special granules in the composition. The paint is easy to apply, but it cannot significantly eliminate heat loss. Price – 3500 rubles per 10 liters.

Features of insulating a cold wall from the inside

The cold penetrates from the outside through the seams in panel houses. If it is not possible to fill them due to certain circumstances, insulation should be carried out from the inside. For this you can use polystyrene foam or mineral wool. These materials are supplemented with foil insulation or insulation paint is used separately. Typically, the work involves installing a frame, inside which additional insulating layers are laid, covered with plasterboard on top.

If you plan to load the walls with something heavy, then you can apply plaster over the insulation, saving money. When there is no desire to install drywall, you can plaster with polystyrene foam, as well as mineral wool. In the latter case, the material must have a high density. If you want to prefer mineral wool for insulating a panel house from the inside, then it is better to choose its basalt variety, which is also called stone. This material is good because it is not afraid of moisture and tolerates heat well. In this case, it is possible to exclude the use of a membrane, which, during external thermal insulation, acts as a vapor and water barrier.

Consumables and tools

The tools and consumables that will be required during the work differ, depending on the type of insulation .

If installation is carried out from sheet material, it will not be possible to do without the following devices and tools:

- Tile adhesive.

- Primer.

- Insulation.

- Sealant.

- Reinforcing mesh.

- Spatula.

- Brushes.

- Drill.

- Dowels.

- Glue and container for diluting it.

When using wallpaper or paint as insulation, some tools, such as a drill or tile adhesive, will not be needed. For some materials, for example, mineral wool, beams will be required to construct the frame.

Wooden

In the case of a wooden building, the choice of insulation depends on the following factors:

- ventilation system;

- heat protection;

- humidity level.

When assembling wooden walls, inter-crown insulation is done. The thermal insulation material is placed in the grooves, and after the shrinkage of the house is completed, a further insulation process is carried out.

Materials that are suitable for providing thermal insulation in a wooden house must be resistant to fire, in addition to a high level of thermal insulation properties. The list of insulation materials is as follows:

- felt materials;

- interventional insulation;

- mineral wool;

- expanded polystyrene;

- ecowool.

Read about the internal insulation of a wooden house here.

Technology

To insulate panel walls inside a house or apartment yourself, you need to follow the instructions. The step-by-step algorithm of actions is as follows :

- Calculate the required amount of material and purchase it.

- Prepare the surface for upcoming work. To do this, the walls are thoroughly dried.

- Remove old coverings in the form of wallpaper, paint and other decor. If plaster has been applied to the wall, it is removed down to the concrete panel.

- Clean the wall from dust and other contaminants.

- Prime the surface using a deep penetration solution. It is recommended to apply at least 2 coats of primer.

- Leave the walls until completely dry.

- Formwork is installed into which layers of insulation, for example, mineral wool, are installed.

- If formwork is not needed, insulation is attached. There is a specialized adhesive for each material.

- Seal the joints with sealant.

- Cover the structure with slabs or other finishing material.

If all technologies are followed, a comfortable temperature will be maintained inside the room. Wall insulation is good not only because it prevents its deterioration in winter, but also helps to maintain coolness in summer.

Important ! You can start insulating walls only in summer or early autumn. During the cold season, this work is not done.

Vapor barriers Ondutis

These thermal insulation films are presented in the form of membranes that do not allow water and air to pass through. Ondutis is used to protect the internal elements of the roof, walls, and insulation from moisture.

Various types of membranes of this brand are produced, each of which is intended for different corners and rooms. The advantages include long service life and the ability to protect against:

- ultraviolet rays;

- formation of fungus and mold;

- rotting of a wooden structure;

- rust of metal elements.

One of the significant advantages is the affordable cost. Ondutis films are considered to be quite good thermal insulation products and leaders in this group of materials in terms of price and quality ratio.

Difficulties and errors

When insulating panel walls, novice repairmen often make the following mistakes :

- They begin work in the cold season.

- They do not pay enough attention to the quality preparation of the wall.

- The glue is applied incorrectly (it is applied to the slabs along the perimeter in the form of strips about 4 cm wide, and dotted along the rest of the surface).

- The seams between the insulation are left empty.

- Install the insulation on an undried wall.

Consequences of errors

Mistakes made during the process of wall insulation lead to serious consequences:

- If the walls are cold or poorly prepared, the glue between the insulation and the wall will dry out quickly, which will impair its adhesion. As a result, the entire structure will be unreliable, and there will be a risk of mold and mildew growing.

- If the glue is applied to the insulation incorrectly, the material will deform, bending in one direction or another.

- If the seams between the slabs are not filled with sealant, cold bridges will form in the wall, through which warm air will escape.

- If the wall is wet, then soon a fungus will appear under the insulation.

Finishing stage

The glue must be applied to the surface of the top sheet, its width must correspond to the reinforced mesh;

- it is necessary to apply a mesh and hide it under a layer of mixture;

- the wall must be allowed to dry and only then begin finishing work.

Attention! There should be no folds on the mesh; they dry out very poorly in the future.

Thanks to this insulation, the apartment will become noticeably warmer and more comfortable. You should not skimp on materials; the main thing is to choose the right foam for insulation and all the components for its installation.

How to choose insulation

When choosing insulation for outdoor use, you should consider the following factors:

- Climate of the region in which the panel house is located

- Wind rose and precipitation

- Available budget

- Local features, for example, the design project of the building facade.

To calculate the estimate and create a project, you must contact the management company or the HOA, while a team of industrial climbers will directly handle the insulation

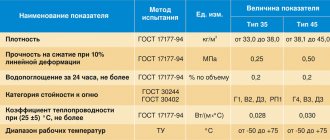

Thermal conductivity diagram for building insulation

Vapor permeability

In a residential building, the vapor permeability of walls should increase towards the street. The main reason lies in the different humidity levels inside and outside the house in winter. The reasons for high humidity in the house are:

There are people living in the house who breathe, cook, wash floors and dishes, and do laundry.

All these habitual operations make the air more humid. And when the windows are closed, the exchange of air is difficult and is carried out only by the forces of the ventilation system. From the course of physics, we know that heated air is capable of holding more moisture compared to cool air. For this reason, condensation occurs from “excess” moisture as the air cools.

Foggy windows and dampness in the corners of a building are a practical example of this. But water vapor leaves the house not only through ventilation, but also through the pores of the wall. If the wall outside is more permeable to steam, then it can pass through it without difficulty. Otherwise, having encountered an obstacle, water vapor begins to condense directly in the wall, which leads to its dampness.