Today, cork is actively used to insulate walls and ceilings in apartments. The products are environmentally friendly, allow for additional insulation of the room, and are water-repellent, however, if exposed to excessive amounts of water, they can lose their original performance properties and become deformed.

Characteristics and advantages of cork covering

Cork has unique characteristics. Thus, during operation the layer does not deform and retains its original shape. This is especially true if you plan to soundproof the walls. Cork is also good because it does not come into contact with chemicals and is not destroyed by them. With increasing thickness of the sound insulation layer, it is possible to achieve higher efficiency.

If you need to soundproof your floor, cork is perfect because it is lightweight. This characteristic is important when strict weight requirements are imposed on the material, for example, if work is carried out in a loggia, where the concrete slab cannot be overloaded. Such sound insulation does not rot, is durable, and eliminates the emergence and development of biological formations.

The physical properties of the material do not change over time. When soundproofing an apartment, the fire safety characteristics of the material are important. Cork flooring meets these requirements. When smoldering, the material does not release harmful substances. Which is especially important for residential premises and children's rooms.

When choosing a plug for sound insulation, you can familiarize yourself with its technical characteristics. Thus, the specific gravity of the material is 150 kg/m3, but the deviation from the linear dimensions does not exceed 0.3%. The moisture content of the material is low, and the maximum is 7%. Thermal conductivity, which is equal to 0.038 W/m oC, may also be important for the consumer. The cork resists sound shock at a level of 12 dB.

Video

The correct use of cork coverings simultaneously for the floor, walls and ceiling ensures the creation of an effective sound barrier from external sounds. When carrying out work, it is important to understand the sources of noise and ways to reduce it.

Cork is used to insulate walls, ceilings and floors in an apartment or house. This material is made from cork oak bark, which has a cellular structure, does not allow sounds to pass through and does not get wet. Therefore, cork backing for wallpaper is great for complete sound and noise insulation of an apartment.

Kinds

Cork soundproofing is offered for sale in many types. Among them are:

- wallpaper;

- rolls;

- technical jam;

- tiles;

- liquid coating;

- panels.

As for wallpaper, it is based on paper, which is what makes the coating so thin - no more than 1 mm. Panels and tiles are convenient because they have different size variations, allowing the consumer to choose the products to suit their needs.

Cork panels

Soundproofing walls with cork can be done using panels that are available for sale in a variety of colors. The panels can be combined with other decorative materials or the walls can be finished locally. The product is glued to PVA, which makes sound insulation completely environmentally friendly. The panels can have a textured surface, and their appearance can even imitate stone.

Liquid coating

Liquid cork is also called spray cork and at one time became a real technological breakthrough in the field of construction. It is based on granulated bark, which acts as sound and heat insulation. The composition is environmentally friendly and may additionally include:

- acrylic resins;

- vegetable fats;

- water.

If we compare liquid cork with panels, the first has one important advantage, which is ease of application, because the material only requires a spray gun, and you no longer have to cut and cut the material. This design of the cork allows you to level out minor unevenness in the walls.

Technical coverage

Technical cork coating is a substrate that is used for specific construction purposes, but not for decoration. This material is usually used as a rough covering under laminate or parquet. The substrate is usually presented in the form of rolls or sheets of different thicknesses. The coating not only provides sound and heat insulation, but also shock absorption, which is important when laying floor coverings.

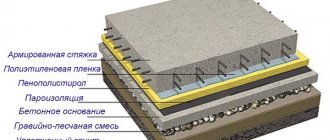

When laying the underlayment on a concrete floor, it is important to ensure that its humidity does not exceed 5%. But if there is a wet room under the floor, polyethylene is placed under the cork with an overlap. Bitumen-cork chips on paper face up if installation is carried out in a non-residential area with high humidity. Additional waterproofing is not required in this case. If you plan to install a heated floor, the underlay should be rubber-based. This coating is suitable for wooden floors. Sound insulation is fixed with tape at the joints.

Which plug to choose

The highest quality cork is produced in Portugal. It is better not to buy Chinese products. Thin coatings are very easy to check. To do this, they should be looked at through the light. If the sun's rays break through the layer, it is better not to take the material, its quality is low.

The largest range of cork coverings is represented by (Portugal). The Ibercork brand produces technical cork, as well as wall and floor coverings. Interesting design solutions are presented. Multilayer floating floor coverings are produced by Baumtex, but they are expensive. Panels with solid veneer are also expensive.

Adhesive panels are cheaper than those connected under locks. The agglomerate has the lowest prices and is mostly used as a substrate.

Soundproofing the floor

Cork floors are not necessarily a substrate for a decorative coating. You can also soundproof this part of the room using other types of cork, for example: cork veneer, MDF panels with cork, cork laminate, cork tiles.

The floor system can be floating or glued. It is recommended to work with the material in the warm season or keep the plug at room temperature before installation. Surface preparation consists of leveling and drying the base. If you have to work with concrete, it is important to make sure it has the right moisture content. Leveling can be done using a liquid composition, for example, a self-leveling floor.

You can soundproof the floor using cork laminate, which is laid on the prepared surface. The base must be covered with film, gluing the joints with tape. Laying the covering begins from the far corner, and each subsequent row should be formed with the seams shifted by a third of the length of the board.

It is necessary to cover the technical hole between the cork floor and the wall with a plinth made of the same material, which is attached with glue to the wall. You can walk on this floor right away.

Using insulation as a sound insulator

If you look hard enough, you can find heat insulators that act very well as sound insulators.

Among these insulation materials, the most popular are:

- mineral wool;

- expanded polystyrene;

- expanded clay;

- perlite

In first place, of course, is mineral wool. It does not burn, does not evaporate allergens, does not shrink during installation and insulates well.

The main areas of use of mineral wool:

- insulation of air noise in the frame partition;

- limits impact noise in a floating field;

- in a sound-absorbing structure - wall cladding.

One type of mineral wool is ecowool. This material insulates well and insulates from unnecessary sounds. It also protects against condensation. It needs to be sprayed using special blowing machines and fill the voids. This creates a continuous wall of sound insulation. For the full effect, you need to use sound reflectors and sound-absorbing materials. Such materials can be double plasterboard or concrete screeds.

Stone wool will help achieve the same effect. It is very easy to install:

- Mount the frame posts every 500-600 millimeters.

- Place mineral wool slabs between the posts to cover the gaps. The thickness of the slabs should be 50-100 millimeters.

- Cover the frame with heavy material (for example, drywall).

- Plaster the seams.

Might be interesting

Soundproofing walls

You can soundproof the walls in your apartment with decorative or technical cork. In the latter case, the sheets are fastened to the ceiling. In your work, you can use acrylic glue, which simplifies and speeds up the process. It is applied to both surfaces. If you plan to use decorative cork to soundproof the walls, it can be attached to a plasterboard structure, which is supplemented with another layer of insulation inside.

Advantages of soundproofing panels with decorative coating

@PaneliZvukoizolyatsii

Decorative soundproofing boards have a lot of advantages, thanks to which the material, despite its recent appearance, quickly gained popularity among buyers.

- Panel thickness. When decorative sound insulation is installed in an apartment, the space used is reduced by installing a frame and covering it with panel sheets. This soundproofing structure takes up at least ten centimeters from each wall. If we sum up all the values, then there would be enough space to install a refrigerator or washing machine. Decorative panels provide a high degree of sound protection without compromising the available space.

- Mass of material. The weight of the product is relatively small, which makes it possible to carry out installation work independently, even without the involvement of specialists and assistants. The mass of one slab is 4 kilograms, and it covers one and a half squares.

- Functionality. The soundproof decorative panel consists of different materials. The panel includes: a sound-proofing layer, a heat-insulating layer and decorative finishing. One panel performs three functions simultaneously.

- Installation features. It is worth noting that with the use of decorative insulating panels you will not have to take out a lot of construction waste, use many different tools, and also prepare the wall surfaces to be treated. Thanks to these characteristics, you can significantly save on sound insulation and repairs in general.

- Variety of design options. During renovation, everyone wants their room to be unlike any other. The abundance of texture options and materials used in finishing allows you to recreate your fantasies in real form. Among all the abundance, everyone can find what they need.

- Universal material. Unlike different soundproofing materials, which differ in structure and characteristics, decorative panels are suitable for any room. Starting from the kitchen and ending with public canteens. The panels can be installed on any surface, including the ceiling, while the performance characteristics of the structure do not change.

Ceiling soundproofing

A cork ceiling can be installed by first preparing the surface - covering it with putty. It fills potholes and cracks. The material is left to dry, and then the surface is sanded until smooth. The ceiling should be coated with primer. If the cork will be glued to drywall, the seams between the sheets should be treated with putty. She needs to go through the places where the screws are located. The primer is important in any case, and it must be applied in two layers, with time between them to allow the liquid to dry.

The cork is glued to a water-based contact compound. The composition can be distributed with a notched trowel or roller. It will be possible to adjust the position of the soundproofing panels while the glue is still wet, so it is recommended to mark the location of the panels in advance.

Getting a technical plug

Waste cork bark is crushed and then pressed and steamed. Sometimes binders are used, but you can do without them, since the cork contains natural glue.

The technology for making cork products is called agglomeration. Moreover, they differ in color: dark is obtained from the bark of the trunk, and light is obtained from the bark of the branches.

Dark and light agglomerate

Note! The cellular structure of the material provides high sound insulation and also does not allow gas and water to pass through.

Eliminating structural noise

It is necessary to take care of reliable insulation and get rid of strong structural hum even during the construction of the building. For this purpose the following are used as standard:

- Elastomeric building materials;

- Special sealant (vibroacoustic);

- Fiberglass.

It is advisable to do work in 3 directions to ensure the best insulation from noise.

Of course, the best option for getting rid of annoying noises is decent neighbors, but this is not up to you. In other cases, you can resort to one of the methods given above, or use the latest options offered by modern technology.