The rating of soundproofing materials for an apartment presented in this article will help you choose the best option for soundproofing walls specifically for your specific case. But if you think that I will tell you one of the best or most popular soundproofing materials, then I will have to disappoint you a little. The fact is that there is no material that is ideal for different situations. Much depends on the type of penetrating noise, its intensity, the design of the walls, and the permissible thickness of the soundproofing material. Based on this, one or another material is selected.

Reasons for use

Thin insulating material is used to improve the acoustics in a room, making the walls inaccessible to sounds. Other factors for using such material in residential buildings or apartments include:

- The desire to preserve existing square meters, which is important for small spaces.

- Residents want to maintain the ceiling height and room area.

- The need to create a hard surface in order to obtain walls suitable for pasting and painting.

- The desire to protect yourself from annoying neighbors above or to the side, who can move furniture, drill, jump, etc. This causes irritation, so residents want to get rid of the noise coming from their neighbors.

- It is not possible to use complex multilayer structures consisting of soundproofing material and rigid plasterboard layers.

- The need to replace the structure with a modern thin material that protects against the penetration of internal and external sounds.

- The need to make interior spaces silent. Partitions are made inside the apartments that do not absorb noise, but allow you to hear everything that is happening in the next room.

- During the construction of the house, mistakes were made in sealing seams and interior spaces, so there is a need to strengthen protection from noise.

- Over time, buildings, especially high-rise buildings, sag and the sound protection system deteriorates.

Thin sound insulation of the walls in the apartment is carried out with materials such as polyurethane foam, cork, gas-foamed polyethylene, and thermosound insulation. Their special feature is their thickness. It should not exceed 10 mm. Similar sound insulation is produced in the form of rolls, liquid materials, plates, tiles, panels, which have the ability to both insulate from sounds and absorb and reflect them.

Polyurethane boards

Polyurethane foam panels are widely used in recording studios and residential areas.

Photo: polyurethane boards

Pros:

- light weight;

- simple installation;

- non-flammability;

- non-toxic;

- resistant to alkalis and acids;

- not hygroscopic;

- durable.

Minuses:

- darkens during use;

- susceptible to sunlight.

Main categories of thin insulation

The following types of thin soundproofing materials are used in construction and renovation:

- Viscous substance "Green Glue Compound". Used in conjunction with drywall on which the substance is applied. The total thickness of the structure is 50 mm, which allows for excellent sound dampening.

- Loaded vinyl, the thickness of which is 2.5 mm. Made from aragonite and barite.

- The membrane is also made from aragonite. The thickness is 3.6 mm. Apply to walls, ceilings and floors.

- Soundproofing pad, which is made of foamed polyethylene and thermo-laminated paper. It is recommended to use for interior walls to remove whispers, sounds, and defects on the wall surface.

- Pressed balsa wood chips or regular cork. Used with soft, liquid or rigid insulation, which helps make the room ideally soundproof. In addition, cork under wallpaper and on wet walls can prevent the formation of mold.

- Plates made from fiberglass or mineral wool. The thickness is 30 mm. Inserted into rigid structures made of plasterboard and gypsum fiber.

- Foamed polyurethane, the thickness of which varies from 35 to 100 mm.

- Liquid substances that are applied to the surface in a layer of 30 mm.

Basaltine

Very thin basalt fiber of staple weaving, stitched with glass thread or basalt rope. It is resistant to temperature changes, therefore it is often used in baths and saunas for sound and heat insulation.

Photo: basaltine

Pros:

- elastic and elastic material;

- good thermophysical characteristics (l= 0.036);

- application in the temperature range from – 260°C to 700°C;

- resistant to mechanical stress;

- durable.

Minuses:

- dusty;

- considerable cost.

Popular materials

- Isoplaat tiles, for the production of which pine wood fibers are used. The thickness of the tile is 10 mm, dampens sounds up to 23 decibels. The tiles are attached to the wall using glue. Recommended for final finishing.

- ZIPS panels, consisting of plasterboard facing sheets and sandwich panels. They are made of dense and soft layers. The thickness of the material depends on the chosen model and can vary from 40 to 130 mm. Sound insulation is 10 decibels. They are attached to the surface using structural units, and for installation to walls it is recommended to use soundproofing gaskets.

- Kraft wall panels are made from wood fibers, included in the boards, wax paper (on the front side), corrugated paper (on the back side). The thickness is 12 mm, dampens sound up to 23 decibels. You can paste over the walls in the apartment, and then attach wallpaper to the panels, as well as for final finishing.

- EcoZvukIzol panel made of 7 layers of cardboard profiles and quartz sand. The thickness is 13 mm, and the sound insulation level is 38 decibels. The panels are attached to the wall with ordinary adhesive for installing drywall.

- Isotex tiles and panels made from softwood fibers. The products have two types of thickness - either 12 mm or 25 mm, but the noise insulation level is 23 decibels. They are mounted using connections called tongue-and-groove.

Article on the topic: Soundproofing plaster for walls

Craft

Kraft cardboard with wax paper and wood fibers. The thickness of 1.2 cm does not reduce the usable area of the room. Sticks to the wall, sound absorption is up to 23 dB.

Photo: Kraft cardboard with wax paper

Pros:

- frameless installation;

- high strength material;

- light weight;

- environmentally friendly;

- inexpensive.

Minuses:

- cannot be used in wet areas;

- susceptible to attack by insects and rats;

- flammable

Liquid sound insulation

This type of insulation is suitable for filling cavities that other materials cannot reach. Liquid sound insulation of walls in an apartment is carried out using polyurethane foam, which is sprayed onto the walls, into holes and cracks. As a result, a special monolithic layer is created, through which sounds do not penetrate. When the foam cools, it does not put pressure on the walls, since polyurethane foam does not have much of its own mass.

Liquid thin insulation is used to “close” the entrance to the premises to rodents, insects, and ants.

The advantages of using liquid sound insulation include:

- There is no need to carry out preliminary preparation of the walls.

- No frame required.

- Virtually no dirt or dust.

- Long service life of 50 years.

- High adhesion to various types of walls.

- Helps make the room warmer.

- The apartment becomes closed from drafts.

- The rooms are completely sealed.

In order to use liquid sound insulation, you need to stock up on special tools. This type comes in different types and structures. The material also differs in price. The main types of polyurethane foam used for insulation include:

- Synthesia, country of origin: Spain.

- Ecotermix, country of origin: China.

- Demilec, country of origin: USA.

- Bayer, country of origin: Germany.

Using liquid thin sound insulation is the best way to get rid of sounds, noise, and rodents. At the same time, you can get the warmest room possible, which will be protected from drafts and the outflow of heat energy.

Texound

The Texaund membrane is made of pure aragonite with a complex of necessary polymers.

Photo: Texound membrane

Pros:

- high level of sound absorption;

- elasticity is maintained at temperatures down to -20 ° C;

- small thickness;

- resistance to moisture and biological damage;

- environmentally friendly material;

- low-flammability and self-extinguishing;

- universal;

- durable.

Minuses:

- the wall needs to be leveled and primed;

- significant weight;

- high price;

- sheet length – 5 m.

How to make acoustic insulation of a ceiling: instructions

For this purpose, mainly plasterboard and soundproofing materials are used, which are laid between rigid sheets. These can be the following types of insulation:

- Basalt or mineral wool.

- Coir.

- Cork.

- Polyurethane foam mats.

Before making the main soundproofing of the ceiling, it is necessary to carry out preparatory work. This involves installing a special auxiliary ceiling system:

- Hemmed. They are mounted on a metal frame and then covered with plasterboard.

- Hanging. First, the frame is installed, and then slabs designed for sound insulation are placed on them.

- Tension. They are attached to the ceiling on brackets on which film or fabric for such work is stretched.

The cracks and distances between the plates must be sealed with foam or other materials, which will increase the sound insulation of the ceiling covering several times.

Quite often, mineral wool slabs or panels are used to create acoustic ceilings, which absorb almost 90% of noise from neighbors and muffle sounds coming from the apartment. The installation instructions for mineral wool slabs look like this:

- Install the frame on the ceiling.

- Mineral or basalt wool is placed in it.

- The structure is sheathed with plasterboard boards.

- Puttying is being carried out.

- Wallpaper or paint.

The design is effective, but has a thickness of 15 to 17 cm. Because of this, the ceiling is lowered and the height of the room is reduced.

To soundproof the ceiling, you can use the following methods:

- Install a suspended acoustic ceiling, which is made of a perforated structure.

- Cork slabs or panels.

- Combined systems that use membranes and sound-absorbing boards.

Article on the topic: Soundproofing membranes for walls

Isoplat

Soft fiberboards are made from softwood, which is rich in lignin. Due to this they have high compressive strength.

Photo: Izoplat

Pros:

- simple installation;

- can be cut;

- environmentally friendly;

- hypoallergenic;

- gives strength and rigidity to the structure;

- long service life.

Minuses:

- high price;

- exposed to moisture;

- difficult to find in stores.

Soundproofing walls: step-by-step instructions

- You must first find cracks and cracks in the walls in order to accurately determine the sources of possible noise.

- Carry out thorough puttying, which will allow the walls to absorb sound.

- Before soundproofing, the electrical outlets are disconnected. To do this, you need to unscrew the plugs or press the special toggle switch on the dashboard.

- The socket is disassembled and taken out to treat the hole with mineral wool, fiberglass, and then seal it with a mortar or plaster.

- Soundproof and seal the heating system, especially in those places where they touch the walls. An elastic sealant is used as sound insulation.

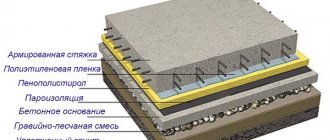

After the preparatory work, the stage of soundproofing the walls begins. First you need to assemble a plasterboard structure, which consists of wooden slats, hardware for attaching the profile to the floor, ceiling and walls, a layer that absorbs sounds, self-tapping screws, and plasterboard boards.

The profile is attached to the wall at a distance of 2 cm. A cork or rubber should be placed in this space. Then glass wool or mineral wool is placed under it. Sometimes they are replaced with slabs that are made of the same material. Plasterboard boards are attached to the profile using self-tapping screws. At the last stage of work, you need to glue the joints with mesh, putty them, glue wallpaper or paint the wall.

Another method of sound insulation is the use of decorative panels, which are attached to the sheathing with liquid nails. Next, the structure is assembled using the tongue-and-groove method. You can choose a variety of panels by design, fabric and shape.

The least simple and inexpensive way to carry out sound insulation is roll sound insulation. It is sold in rolls and glued to the wall using special glue. The noise level when using rolled sound insulation is reduced by only 50%.

Isolite

Non-combustible slabs consist of basalt fibers coated with polymer compounds.

Photo: Isolite

Pros:

- high sound insulation properties;

- excellent vapor permeability;

- low thermal conductivity;

- versatility;

- tear resistance;

- light weight;

- resistance to mold and mildew;

- fire safety;

- environmental friendliness;

- durability.

Minuses:

- vulnerability to prolonged exposure to moisture;

- a vapor barrier layer is required.

Soundproofing walls under wallpaper

The main materials used for preparing wall coverings for wallpaper are polyethylene and polyethylene foam boards. Their thickness does not exceed 5 mm.

- Before use, the material is cut into pieces of the required size.

- Then the old plaster and wallpaper are removed from the walls. If there are cracks, they must be sealed with a special solution or liquid soundproofing material.

- When everything is dry, glue is applied to the wall and the backing, and the backing is glued to the wall as wallpaper. When it dries, the joints are sealed with paper tape, after which you can glue the wallpaper.

Mats or slabs are also used as a soundproofing substrate under wallpaper. Their thickness is 40 mm. They are mounted to the walls with screws, and sheets of drywall are glued to them.

Modern materials include a soundproofing membrane, characterized by its small thickness, excellent structure and sound-absorbing properties. The membrane is used with other soundproofing materials, which allows you to get almost 100% noise protection.

Summarize

In this article, we examined the rating of soundproofing materials for an apartment, as well as the main technical characteristics of each of the participants in this rating.

What would I like to say as a conclusion?

Here, of course, not all are presented, but the most popular soundproofing materials on our market. They have different thicknesses, different structures, different purposes and different sound insulation indexes. Therefore, you need to choose the material that will be optimal for your specific purpose. For example, to combat impact noise penetrating through a floor or ceiling, you need a material specifically designed for this purpose.

To soundproof walls, the choice can be made in favor of a multilayer structure using materials suitable for these purposes.

But it is important to understand that you should not expect that you can achieve complete silence in your apartment. Even if you use imported, expensive material.

In reality, you can only achieve noise reduction to an acceptable level. Otherwise, you will have to build a soundproofing system half a meter thick.

And yet, you should not believe that 5 mm thick soundproofing material can completely solve your problem with your neighbors. It can only improve the situation when the noise is no longer loud and annoying, but becomes muffled.

Therefore, initially set the right goals for yourself in the struggle for a comfortable life, so as not to later experience disappointment from the work done and money spent.

Best regards, Alexander Tkachenko.

Criteria for choosing material for soundproofing an apartment

All materials intended to protect premises from external and internal noise are divided into two groups:

- Sound-absorbing. Convert sound energy into heat, reducing noise intensity.

- Soundproof. They are used to create a barrier to noise penetration or spread throughout the living space.

When choosing a sound-proofing surface, pay attention to its thickness, density, structure and sound-conducting qualities. Materials with high density and mass are suitable for sound insulation, and materials consisting of soft and porous coatings are suitable for absorbing sound waves.

Take into account the features of the wall - whether it has cracks, how many sockets are installed in it, whether there are joints between the walls and pipes, what type of coating it is, what material it is made of. For the external wall you will need one material, and for the interior flooring - one with different characteristics.

Mineral wool

Mineral wool has been used for soundproofing walls since it was proven that the porous structure of the material effectively blocks sound waves.

Photo: mineral wool

Pros:

- weighs little;

- reduces noise level by 5-10 dB;

- is an excellent thermal insulation material;

- universal material for all surfaces;

- does not accumulate dust;

- does not burn.

Minuses:

- first of all, cotton wool is a heat-insulating material, and secondly, a sound-proofing material;

- a multilayer frame structure will take up at least 5 centimeters of room area;

- afraid of moisture.

Sound absorption

The main purpose of sound absorption is that it should not allow sound to be reflected from the wall surface. The material absorbs noise without allowing it to reach surfaces. The value is measured by the noise absorption coefficient, which can vary from 0 to 1.0. when the noise absorption coefficient is equal to zero, then there is full sound reflection from the surface. When sound is completely absorbed, the coefficient will be equal to unity.

@ProAntiShum

Different building materials have their own specific absorption coefficients, and when choosing sound insulation it is important to take these parameters into account. Sound-absorbing materials can be considered those with an absorption coefficient higher than 0.4.

Sound-absorbing building materials can be divided into groups:

- Layered construction;

- Volumetric;

- Porous;

- Resonant.

If the sound absorption coefficient is high, then the noise-absorbing qualities of the product are good.

Video description

Frameless sound insulation (sound insulation) of walls and ceilings in the apartment.

Fastening ZIPS panels

Soundproofing multi-layer wall material is easy to install. During the procedure you will need self-tapping screws and dowels. Work begins from the lower left corner, gradually moving up and to the right. After installing the first layer, the bottom is cut along the long or short side, adjusting to the geometry of the room.

Holes are drilled in ZIPS soundproofing panels using a hammer drill. The depth of the holes is up to 6 cm; fasteners are inserted into them and carefully driven into the wall with a hammer. When installing, the joint is kept within 2.5 cm. After fixing the last part, the seams are sanded, empty cavities are filled with sealant.

Overview of wall soundproofing panels

Today, Russian manufacturers supply two types of panels to the market: isotex and Haltex. Each option has its own qualities and features. When selecting a material, it is necessary to take into account all its design features and characteristics. Modern technologies are improving every day, which contributes to the development of construction and finishing materials. Today, many people are making design changes using innovative materials, because such products have many more advantages than other finishing options.

@PaneliZvukoizolyatsii

Sound-absorbing structures

Soundproofing boards can have a fibrous or porous base; the choice depends on the area of application and the characteristics of the canvas itself. It is worth noting that such products are used in the arrangement of cinemas, recording studios or concert halls. In addition, due to the environmental friendliness of the products, it is possible to soundproof residential premises, schools and kindergartens. The noise insulation coefficient of the materials on the wall will provide the necessary level of protection.

If you need to increase the degree of noise absorption, you can increase the number of plates used, which in turn will make the material even thicker. The right approach to solving the issue is guaranteed to make your home or premises comfortable and cozy. When choosing a suitable material, it is important to look at indicators such as the thickness of the slab and its soundproofing properties. To set the optimal parameters for a room, you need to choose the right sound insulation.

@ProAntiShum

Sound absorption structures have a perforated screen made of painted metal sheet, which repels sounds well without penetrating into the middle of the room. If we consider the design as a whole, then a breathable layer of canvas should be installed between the screen sheet and the fiber, which will retain small particles. Such designs can be used for any type of sound at different frequencies. Noise insulation using sound-absorbing structures will be maximum. Quite often such screens are used in decoration as anti-vandal.

Sound absorption coefficient

When a sound wave passes through a material, the reflection value is its sound insulation coefficient. The maximum level of absorption is considered to be one. In this case, the sound is completely absorbed and is not reflected from the surface. As a rule, such indicators can show the complex composition of the insulation layers. If the indicator is zero, then the insulation does not absorb sound waves and, therefore, does not guarantee protection. Sound-absorbing building materials can be considered products with a coefficient of 0.4. When choosing insulating materials, this parameter should be given primary importance, since comfort inside the building depends on it.

Thermosound insulation

Roll material with a three-layer structure. Inside there is a pierced fiberglass fabric, on the outside there is a shell made of a polypropylene base. Provides good sound and heat insulation.

Photo: Termozvukoizol

Pros:

- excellent noise insulation and vibration insulation characteristics;

- low thermal conductivity;

- elasticity;

- environmental friendliness;

- good hygroscopicity;

- non-flammability;

- can be laid on the wiring.

Minuses:

- high price;

- heavy weight.

The nature of sound absorption

The fibrous structure of sound insulation is widely used in modern construction. Such slabs perfectly protect against airborne noise, providing comfortable conditions. Few people think about how sound absorption occurs, but everything is quite simple and easy to explain.

@ProAntiShum

It is worth understanding that when air with sound enters an insulating structure, the average sound absorption coefficient is that it rubs against the fibers of the product. Each fiber, due to friction and vibration, distributes sound, absorbing it. Depending on the noise level, the coefficient and the design index of the slab are selected. With proper calculation and installation, it is possible to provide the required level of protection with minimal material losses.

Schumanet

Soundproofing boards or rolls based on basalt wool or staple fiberglass. Panels from 1.2 m long, from 0.6 m wide; thickness 50 mm, 4 pieces per pack. Rolls 10-15 m long, 1 m wide; thickness – 3-5 m.

Photo: Schumanet

Pros:

- light weight;

- high sound and waterproofing properties;

- environmental friendliness;

- does not shrink;

- affordable price;

- durable.

Minuses:

- dusty;

- storage conditions must be observed.