One of the key disadvantages of all multi-story buildings is noise, which is everywhere and everywhere. Once in the home, it can serve as the main cause of irritation and interfere with concentrated work or sleep. You can, of course, be original and buy earplugs, but this will not radically improve the situation.

The most effective way is to make high-quality sound insulation. Since sounds often pass through interfloor ceilings, in addition to the walls, much attention should be paid to the floor. Moreover, normal soundproofing of the floor in an apartment is a very feasible task.

Types of noise

The noise that can be heard in the apartment is:

- Indoors - noise from the elevator, slamming doors, voices of neighbors on the landing.

- Indoor – noise from doors opening or closing, the actions of people in different rooms can be heard.

- Indoor noise - this noise depends on the habit of speaking loudly or quietly, or listening to TV.

- Externally - the noise of the city: kids on the playground in the yard, cars, barking dogs on the street.

Good soundproofing of the floor in the apartment will allow you to partially get rid of indoor and intra-apartment noise.

Attention! It is the plank floor that needs sound insulation most of all. The noise of even small children's footsteps is easily transmitted through any wooden structure of the house.

A carpet spread on top of a plank floor will help practically get rid of the noise of footsteps and creaking floorboards. The thickness of such a coating is directly proportional to the degree of sound absorption. In addition, linoleum and cork tiles will help with sound insulation.

Approximate calculation of suitable sound insulation

To select a material, first take into account the approximate noise level in the apartment (depending on the material of the house’s construction). You can perform calculations either manually or using a calculator. For example, in a standard reinforced concrete building, the thickness of the floor is 22 cm, and there is no additional sound insulation or is represented by a linoleum backing. Thus, the guaranteed sound absorption index will be 0.1-0.2. If the neighbors on the lower floor are noisy, you will need an index from 0.45 to 1. To these indicators add a screed over a layer of mineral wool, having a thickness of 50 to 100 mm. This way you can easily calculate the index value and the approximate level of required sound insulation.

Nuances worth knowing

- Soundproofing a wooden floor is a much more expensive option than insulating a concrete floor.

- Pipes and cables located under the floor should be insulated with special elastic material.

- Skirting boards must be attached only to the wall, or only to the floor. If you attach it to both the floor and the wall, it will become a bridge for noise.

- When choosing building materials for floor soundproofing, never save money and always look for official certificates for the materials. This will give you the opportunity to avoid any unwanted effects of low-quality building materials on your health for decades.

Texound

Recently, a new soundproofing material called Texaund appeared on our domestic market.

With a thickness of 3.7 mm, it is considered one of the highest quality sound absorbers. This material is made on a special mineral basis. It is ideal for flooring in a wide variety of living spaces.

Texaund has the following advantages over other soundproofing materials:

- It is elastic and flexible, and also stretches well.

- Its installation is clear and simple.

- Texaund does not react to sudden changes in temperature.

- It is not hygroscopic, not susceptible to rotting and mold formation.

- It belongs to the category of self-extinguishing and low-flammable materials.

- Ideal and easy to install on a variety of surfaces.

- Has an unlimited period of use.

- The material has a high absorption coefficient of sound waves.

The only drawback of Texound is that it must be used in combination with very thin insulation or other material.

Important! That is, in order to achieve maximum effect, it cannot be laid directly on a concrete slab without a special substrate.

Texound installation

How to make sound insulation? When doing soundproofing, you want to achieve the optimal effect. To achieve this, you should act according to the recommendations and instructions given by the manufacturer of the selected material.

Texaund must be laid on a special prepared base. So, any roll or sheet insulation is perfect for it. It can be thin foamed polyethylene - plasterboard, plastic, polyethylene foam or plywood.

If the ceilings are high, and it is also possible to make a thick layer of noise insulation, then mineral wool can be used for one of the components.

- The concrete slab is cleaned with a vacuum cleaner.

- Then the base is laid on it. If it is some kind of elastic material, then it is better to secure it with glue.

Polyethylene foam will only raise the floor by 3-5 mm. The best option is still drywall. This is due to the fact that it will make the floors perfectly smooth and will also cover all the flaws in the slab. This will protect the texaund material from damage. In addition, he himself is a good sound insulator.

Polyethylene foam

After the base is completely ready, coat it on top with special glue, wait 15 minutes, and then carefully lay the texaund, extending 12 cm onto the walls.

When all the material has been laid, you need to use hot air or glue to connect the joints between the sheets. The sheets must create a completely airtight coating, otherwise the soundproofing effect will be reduced.

Then the texaund is covered on top with an additional layer of plasterboard or 10 mm plywood. Without decorative covering, the floors in the room will rise by 23 mm.

Almost any floor covering can be laid on drywall - laminate, carpet or linoleum. It will also create good additional sound insulation. If you increase the number of layers and use modern materials with very different densities for them, the sound insulation of the floor in an apartment under a screed will improve significantly.

Cork sound insulation

Cork is an excellent decorative sound insulator; it is laid using laminate technology. It is used to make a substrate - a flooring for any floor covering. Cork perfectly absorbs noise and reflects extraneous sounds from the outside. For example, a 2 cm thick cork material protects against loud sounds in the same way as a 10 cm thick concrete wall.

Cork is sold in the form of slabs, rolls, and panels. It can be used with or without a cork backing. The material has a lot of advantages:

- keeps the room warm;

- environmentally friendly;

- "breathes";

- easy to install;

- eliminates noise at low thickness.

Cons: ignites quickly, is affected by pests, has a high price.

1 sq. m of cork insulation with a layer of 1 cm costs approximately 650 rubles. The price of laying the coating starts from 100 rubles. per square.

Mineral wool

For insulation and sound insulation, three types of mineral wool are used: stone wool, slag wool, and glass wool. They all have different thicknesses and are produced in slabs or rolls.

Mineral wool can be of very different densities, on which thermal conductivity will completely depend, as well as its ability to withstand various external loads. In addition, this material varies in moisture and heat resistance.

Stone wool

Stone wool is a heat-resistant material that can easily withstand high temperatures up to 550 degrees. This sound insulator is made from fibers obtained from the melting of rocks.

MaxForte EKOplita floor (https://maxforte.ru/maksforte-ekoplita) - high-quality acoustic slabs made of 100% basalt, completely safe PVA glue is used as a binder, that is, the composition does not contain harmful phenol-formaldehyde resins. The slabs are designed specifically for floor soundproofing and provide a high sound insulation index for impact and airborne noise.

The optimal type of stone wool is basalt. This is an environmentally friendly sound insulator and excellent insulation. Another key advantage is that it does not contain binders, namely formaldehyde resin.

Basalt wool, produced in rolls and slabs, can be used for soundproofing work without installing lathing, since the material has a very high density.

Glass wool

This is the most affordable type of mineral wool. True, it is more difficult to install due to the very scratchy fiberglass. Installation should be done with gloves and a special mask on the face, since the hard thin fibers of the material dig into the skin and can get into the respiratory tract and eyes.

Glass wool has a lower density than stone wool and must be laid in the sheathing. This type of material is usually used for non-residential premises, for example, workshops, or for external sound insulation or insulation.

Slag

This type of mineral wool is made from a variety of blast furnace slags. It cannot be used in rooms with high humidity.

In addition, it cannot be used for external work.

The material is hygroscopic and perfectly absorbs moisture, which rapidly reduces its quality. In principle, it can be used for sound insulation by laying it between the lags of the sheathing, but it is not advisable to use it in any residential premises.

Attention! From the characteristics presented above, we can easily conclude that of the three types of mineral wool, only basalt stone wool is ideal for soundproofing the floor of an apartment.

Installation

Installing mineral wool on floors for sound insulation is very simple. It can be made in two ways: using a sheathing made of timber, or without it.

Sound insulation using wooden lathing:

- The very first thing to do when installing soundproofing is to prepare the surface of the base. All debris must be removed from it using a vacuum cleaner.

- After this, if there are cracks in the concrete floor, they should be widened and sealed with cement mortar and these areas should be allowed to harden.

- Next, a thin heat and sound insulator, namely foamed polyethylene, should be laid on the concrete slab.

- If you decide to lay logs, then you need to correctly calculate the step of their installation. It must fully correspond to the width of the mineral wool slabs, so that they fit tightly enough between all the bars.

- The bars are selected to be of the same thickness as the thickness of the soundproofing material. Immediately after marking the floor, special logs are attached to it. They should not be located close to the wall, but at a distance equal to the thickness of the insulation.

- Strips are then cut from basalt mineral wool slabs. The latter are installed around the perimeter of the room, between the sheathing bars and the wall.

- The next stage is laying the slabs between the bars.

- When all the building material has been laid, sheets of plywood are laid on it and secured to the sheathing bars using self-tapping screws.

- If gaps have formed between the plywood sheets, they should be sealed with a special wood putty.

- After the putty has dried, linoleum, laminate or carpet can be laid on the plywood.

- If you want to enhance sound absorption, you can lay a cork covering on top of the plywood, which also has good sound-absorbing qualities.

Do-it-yourself soundproofing without using wooden sheathing:

- A special polyethylene foam is also placed on a well-cleaned floor, which should be secured together with adhesive tape. This material must be applied to the walls to the thickness of the entire soundproofing layer.

- Along the walls of the entire perimeter of the room, strips cut from mineral wool slabs are placed. Their height is about 15 cm.

- Plywood sheets or durable plasterboard are laid on the substrate, almost close to the soundproofing installed on the walls.

- The slab sound insulators are laid close to each other. It is pressed tightly against strips of material that are installed along the wall.

- An additional layer of plywood is laid on top of the mineral wool slabs and is well secured to the floor.

- The protruding part of the sound insulator, which is laid around the perimeter of the room, is cut off flush with the laid sheets of plywood.

- If gaps have formed between the sheets of plywood, they must also be sealed with putty.

- After the putty has dried, you can immediately proceed to installing the decorative floor covering under the laminate.

Floating floor

The method of installing a floating floor has nothing to do with water. The set of words, “floor” and “floating”, is formed from the understanding that the decorative layer on the surface is without connection.

If parquet or floor boards are laid on joists, then today's floor installation techniques do not consider the use of nails, screws, or adhesive bases. In this regard, a floating floor creates excellent sound insulation.

Surface preparation

The base for such sound insulation must be level, dry and clean. In this regard, the preparation stage should be taken with great seriousness. The old coating is removed.

The base is checked for height differences. If they are significant, then the base must be leveled. Self-leveling mixtures or a regular cement-sand screed are suitable for this.

Formwork

To prevent the occurrence of acoustic bridges that reduce the effectiveness of sound insulation, the flooring should be insulated from partitions and walls. To do this, temporary formwork made of plywood, plasterboard, or thin boards is installed around the perimeter of the entire room. Its height must necessarily be greater than the floating floor.

Immediately after the screed hardens, all formwork is removed. The resulting gap is filled with polyurethane foam or the remains of soundproofing materials.

Soundproofing material

Sound insulation is laid evenly on the prepared base without cracks or gaps. To minimize waste, installation usually starts from the corner of the room. If necessary, the joints are glued.

MaxForte ShumoIzol (https://maxforte.ru/maksforte-shumoizol) is a thin soundproofing substrate, available in the form of a roll 10 m long, 1 m wide, thickness 4-5 mm. Darnit non-woven fabric is used as a soundproofing layer, providing protection against impact noise up to 27 dB. Also, due to the high-quality bitumen layer, which does not tear or crack during installation, it has high waterproofing properties and is suitable for class “A” houses (luxury housing).

MaxForte SoundPRO (https://maxforte.ru/materialy-dlya-shumoizolyacii-kvartiry/maksforte-soundpro) is the latest material, available in the form of a 1.4 x 5 m roll. Capable of providing a high level of protection against impact and airborne noise, with only 12 mm thick. High performance is achieved due to aluminosilicate fiber laid in a special way. The sound insulation is completely non-flammable, which is confirmed by a certificate.

You can watch the installation video on the YouTube channel Soundproofing MAXFORTE.

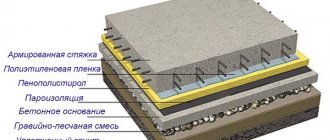

Sand-cement screed

Before installing a full-fledged cement-sand screed, it is advisable to lay an oilcloth on the substrate for sound insulation, the edges of which are folded upward, and then glued with tape to the formwork. Beacons 15 mm high are installed on the oilcloth, and a strong reinforcing mesh is installed on top of them.

After this, you need to lay the guides level. These could be, for example, metal profiles. A sand-cement mixture is laid on top, the surface is leveled and rubbed.

Dry screed

To avoid “wet” procedures, it is quite possible to make a dry screed. For this, different sheet materials are used: gypsum fiber sheets, plasterboard, plywood and OSB. These sheets are laid in two layers, securely fastened together with glue.

To avoid the appearance of acoustic bridges, all joints are shifted. If necessary, the surfaces are puttied and covered with a special waterproofing mastic. After this, the floor covering is laid: tiles, parquet boards, laminate, linoleum, carpet.

Other materials

Less popular sound insulators are soundproofing, expanded polystyrene, shumoplast, shumane.

- Sound insulation is a product made from two-layer bitumen-polymer raw materials, sold in rolls. Easy to install, has excellent hydro- and sound-proofing properties, and can be laid under all types of floor coverings. Minus – high price: 1 sq. m costs 570 rubles.

- Expanded polystyrene is resistant to moisture, weighs little, is cheap, and easy to install. Disadvantages - fragile, quickly flares up from fire. 1 sq. m of extruded polystyrene foam 5 cm thick costs 260 rubles.

- Shumoplast - polymer granules for soundproofing concrete floors. Based on rubber, polystyrene foam, acrylic compounds. For complete sound insulation, a layer of 2 cm is enough. Cons: long wait for complete polymerization - about 2 days, more suitable for floors with floating screed.

- Schumanet is a mineral acoustic slab. It has high density and thermal conductivity, is non-flammable, and is used in damp rooms. Price per 1 sq. m — 260 rub.