One of the most important quality criteria for mineral wool is its environmental safety. the determining factors for the safety of the material:

- Length and diameter of mineral fibers;

- Quality and chemical composition of the binder;

- Availability of environmental certificates from the manufacturer.

The best mineral wool manufacturers

Only brands with a proven reputation deserve consumer trust. Among them, it is worth paying attention to the brands:

- Rockwool

- Paroc

- Isover

- Knauf

- Ursa

- IZOVOL

- Beltep

7 leaders of narrow and broad specialization are fighting for buyers by advertising their products. In contrast, “ExpertTsen” will try to give an impartial assessment of the thermal insulation material and rank the types of mineral wool based on their safety, construction merits, taking into account the average price tag and reviews of real customers.

Rockwool - stone wool without disadvantages

Photo: zorenko.ucoz.ua

Despite its Danish roots, Rockwool has many factories in Russia, which allows the company to offer a range of European quality, but without unnecessary price markups. The high quality of this mineral wool is confirmed by builders who consistently choose products from the Danish brand when carrying out work.

Rockwool mineral wool has enhanced characteristics:

- fire safety - Rockwool fibers can withstand up to 1000 degrees with standard data of 600 degrees Celsius;

- absorption of sound and vibration, which is why the material is chosen to create noise barriers and to increase the acoustic comfort of rooms;

- environmental friendliness - Rockwool has an EcoMaterial Green certificate, although it has long been known that many people do not like mineral wool, attributing to it properties that are dangerous to the environment, life and human health;

- durability without deformation and destruction;

- thermal insulation.

We are, of course, talking about real Rockwool; purchasing from unreliable suppliers does not guarantee the above-mentioned quality.

Our rating : 10 points out of 10

Reviews : “Rockwool light butts mineral wool is the best - it holds its dimensions perfectly and does not fray.”

“The house was saved in a fire only thanks to the presence of Rockwool slabs in the ceiling - it does not burn, does not shrink, and does not form dangerous voids at high temperatures.”

Production Features

It is worth noting that wool in the Russian Federation is produced from various raw materials - diabase, dolomite, basalt, slag. Externally, mineral wool from different manufacturing companies may not differ, but technologically it does. Formulas are calculated in specialized laboratories, the results of the research are a trade secret.

In general, the recipe looks like this:

- Stage 1. Melting of raw materials to a certain state. The prepared mixture is loaded into a specialized oven. The temperature reaches one and a half thousand degrees Celsius. The length and thickness of the fibers and their technical characteristics are determined from the degree of viscosity of the mass.

- Stage 2. The mass is placed in a centrifuge. Inside, rotating shafts roll the composition until discrete fibers are formed. A binding element is also poured here - a synthetic composition that holds the raw melt together. Next, a powerful air stream transfers the resulting mass into the cooling chamber.

- Stage 3. The lamella apparatus forms fibers of the required volume and length. Then treatment is applied in a heat chamber. When exposed to high temperatures, the mass polymerizes and reaches its final volume, size and shape. Strength indicators are formed at the final stage, where it is extremely important to maintain the correct temperature conditions.

- Stage 4. The final stage of production is the molding and packaging of the resulting mass into blocks of the required dimensions. The cotton wool is packed in shrink film. It allows you to preserve the properties of cotton wool during storage and transportation.

Paroc mineral wool - excellent quality, but high price

Photo: www.budowazagrosz.pl

Having opened any construction forum, in the topic “thermal insulation” you immediately come across the brand name Parok. Its basalt mineral wool firmly occupies a leading place in the user ratings, and there are many reasons for this. After all, Paroc means the same quality of products regardless of the location of the plant, and the best characteristics for all the main indicators of mineral wool.

Paroc's main focus is on energy efficiency. Basalt wool Parok allows:

- save energy, including heat;

- do not have a negative impact on the environment;

- protect from noise and dust;

- ensure fire safety.

This manufacturer has realized all the advantages of stone wool, there are practically no fakes, but there is still a drawback

Rating : 9.9 points out of 10

Reviews : “I like Paroc mineral wool the most! This is what I’m planning for the roof of my house.”

Main characteristics

- Density is a characteristic that shows how many kilograms of stone fiber are contained in 1 cube of mineral wool. The denser the material, the better its insulating properties and the higher the price.

- Thermal conductivity is the ability of a material to conduct heat. The lower the coefficient, the more effective the insulation.

- Flammability is the ability to burn independently.

Environmental friendliness depends on the origin of the binder. Artificial resins are toxic, natural substances are harmless.

Isover - high quality mineral wool to choose from

Photo: atlaccapital.ru

The manufacturer offers two solutions: glass wool and stone wool. This is a big plus when choosing thermal insulation, since both of these materials are usually in demand in the construction of a particular facility. Izover has an excellent reputation in Russia and offers thermal insulation only with environmental quality certificates. The constant introduction of modern technologies makes it possible to improve the characteristics of manufactured products and reduce costs. The latest “new product” from Isover is the release of mineral wool with high strength and elasticity, without dust and with a minimum of “prickliness”. In terms of quality, products under this brand are unlikely to compare with more expensive competitors, but in terms of price/quality ratio, Isover mineral wool is one of the best.

Rating : 9.9 points out of 10

Reviews from builders : “Isover mineral wool is cheaper and better than many other insulation materials, so I use it for large volumes.”

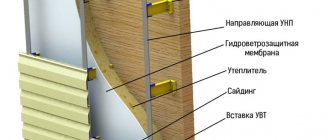

Rules for installing mineral wool slabs

Preparation for installing mineral wool slabs or rolls includes a number of procedures, among which the following should be highlighted:

- Cleaning surfaces from traces of mold using a construction spatula, if necessary, treating the surface with an antiseptic.

- Sealing of holes and cracks, carried out using cement mortar, sealing of deep voids with the help of polyurethane foam and tow.

- Treatment with antiseptic agents and primer, it is important to maintain the recommended time between applying different layers so that each of them has time to dry.

- At the last stage of preparation, the flatness of the surface is ensured, which is necessary for a tight fit of frameless insulation to it.

- After completion of preparation, an adhesive solution for fastening rolls applied in a spot manner ensures the creation of an air gap.

- Starting from the top of the wall in a horizontal direction, using a furniture stapler or double-sided tape, install the vapor barrier film to the frame.

- After this, the joints are glued using construction tape or mounting tape.

- Then the sheathing is carried out using slats having a width of about 1.5–2.5 cm, which is necessary to create a ventilation gap between the inner lining and the vapor barrier layer.

- At the next stage, the required length of the rigid mineral wool , taking into account a tolerance of 10 cm, and its installation on the surface of the facade by pressing the brackets on the frame with the bent ears, ensuring reliable fixation of the insulation in a vertical position.

- At the last stage of installation, the final finishing is carried out, for example, profiles are installed and sheets are installed, made of plasterboard or plaster is applied.

Note! Builders consider it more preferable than using material in rolls to use rigid mineral wool slabs for finishing vertical surfaces. This is due to the lack of rolling of the insulation, however, before installing it, it is recommended to first install the strips in a horizontal direction to reduce their weight.

Knauf produces everything!

Photo: www.dostavkasmesi.ru

Knauf is a manufacturer that has proven more than once that it can provide the construction market with the best offers. Thermal insulation is no exception. Knauf offers good quality mineral wool based on basalt fiber, as well as glass fiber composition. The first option is widely used for technical insulation, in construction and in the production of complex equipment. Fiberglass insulation is produced for specialized purposes (TEPLOKnauf), as evidenced by its names:

- HEATWALL;

- HEAT stove;

- WARM roofing;

- Acoustic partition;

- HEATROLL.

Most of the mineral wool sold by the manufacturer belongs to the Knauf Insulation series. There are no toxic phenol-formaldehyde resins used in the production of this product. The Knauf Insulation and TEPLOKnauf thermal insulation lines are intended for the construction of residential buildings by individuals and construction organizations.

Disadvantage : high price

Rating : 9.9 points out of 10

Reviews : “You rarely hear a bad word about Knauf. This means that the material is truly excellent.”

Comparison table of the presented models

The rating presented above included insulating compounds from different manufacturers, configurations and characteristics. In order to simplify the choice among the entire variety, we will place the information in a comparative table:

| Model | Material | Thermal conductivity, W/(m°K) | Density, kg/m2 |

| Ecoroll Mini | glass | 0.04 | 0.624 |

| Ursa Terra Pro 2095810 | slag | 0.034 | 1.02 |

| Knauf Insulation TeploKnauf 545572 | fiberglass | 0.037 | 0.775 |

| TechnoNIKOL Rocklight | basalt | 0.03 | 1.75 |

| Rockwool Acoustic Butts | basalt | 0.035 | 2.25 |

| Knauf Insulation TeploKnauf 545566 | glass | 0.037 | 1.55 |

| Rockwool Rock façade | fiberglass | 0.029 | 5.41 |

Ursa - a new generation of mineral wool

Photo: alkiv.kiev.ua

For a long time, the Ursa brand was known for its fiberglass products. But technology does not stand still, and today the company offers the market PureOne - a new generation of mineral wool made from natural and naturally renewable components, interconnected with an acrylic-containing binder.

The effectiveness of PureOne in terms of heat and sound insulation is very high, there are almost no complaints about other characteristics. The material has a bright white color, does not chip, does not crumble, and does not deform.

In addition to PureOne, Ursa also offers a standard range of glass wool, with all their disadvantages and advantages. The cost of products does not differ from analogues of other companies.

Rating : 9.8 points out of 10

Reviews from builders : “PureOne is the best mineral wool; its elasticity and rigidity are 1.5 times higher than traditional fiberglass insulators.”

“A friend who has been working on the construction of dachas for many years said: take Ursa insulation, you won’t regret it - it keeps you warm, it’s easy to work with, and it doesn’t burn. I insulated the attic at the dacha, then I itched for a week, but the house is now warm.”

What it is

Mineral wool is a thermal insulation material that, due to its structure, reduces heat exchange between the internal and external environment. The substance does not heat or emit heat, it only effectively retains it inside the insulated room.

The product consists of fibers that are tightly woven together. The samples are strongly compacted and compacted to the required thickness. The resulting raw material is flexible, bendable, unbreakable and very strong.

Air in the cells of the porous structure reliably retains heat

The porous structure is filled with air, which, as is known, does not allow heat to escape outside. By the way, this is how most thermoses work, between the internal and external vessels of which there is an air gap. It is this that prevents the temperature inside the sealed container from contacting the environment, and therefore cooling.

Depending on the raw material from which the material is made, the color, degree of fiber, wool density, as well as some physical properties vary.

Let's consider the physical characteristics of mineral wool:

- It is environmentally friendly and safe. The product is made from natural ingredients: rocks, sand, slag

- It is fire resistant. Try setting the above materials on fire. Mineral wool does not burn, but at temperatures above 200°C it begins to melt

- Provides reliable sound and heat insulation

- Light weight and elastic structure

- Absorbs and allows water to pass through well

In rooms with high levels of humidity, it is necessary to take care of high-quality vapor barrier. Better yet, buy foil-coated mineral wool.

IZOVOL mineral wool is the best choice for walls and roofs

Photo: stroimaterialytorg.ru

Izovol is another type of basalt wool that is in high demand and is used for thermal insulation of walls, roofs and ventilated facades. It has excellent physical, mechanical and operational characteristics. It is non-flammable, has standard density indicators for the material, so it can crumble during operation, causing some discomfort.

It does not have a high price; all thermal insulation is available for sale and is in demand by construction organizations. The most popular line of materials is recommended for insulating pitched roofs and attic spaces.

Rating : 9.5 points out of 10

Reviews about Izovol mineral wool : “The material showed its best side. Very easy to work with, non-allergenic, fireproof. It doesn’t cut well in terms of thickness—perhaps the only drawback.”

Manufacturers from different countries, offers from companies in Russia and beyond

At the preliminary stage of construction or renovation, many owners of private houses, summer cottages, baths, saunas and other premises, as well as performers of the work, are wondering - which brand of basalt insulation is better ? Given the diversity that exists on the building materials market, choosing the optimal option can become a serious problem for an inexperienced consumer in the relevant field .

TechnoNIKOL stone wool for flooring 8 slabs 1200x600x30 mm. Photo by Leroy Merlin

Information about production features is not always available, so you have to rely on widely available information , the appearance of the insulation and reviews. But there is an alternative solution; it is necessary to compare basalt wool from different manufacturers. Customers are provided with a wide selection of products , but there are not many large enterprises with a good reputation that produce high-quality insulation materials. Some brands and manufacturers that are of increased interest to Internet users are presented below.

Isover

The Isover trademark belongs to the international industrial group of companies Saint-Gobain , whose headquarters are located in Paris. The Group of Companies has representative offices in many countries. Saint-Gobain specializes in the development, production and sale of high-quality materials and effective solutions for creating comfortable living spaces. Successfully operates in three sectors:

- innovative materials;

- construction products manufactured under several brands, in particular insulation materials are produced under the brands Isover, Isoroc, Isotec;

- distribution of building materials.

The company produces mineral wool insulation based on quartz and basalt . Stone wool is produced in factories in Germany, Spain, France, the Czech Republic, Poland, and Romania. In 2011, the company acquired a plant for the production of basalt insulation in Chelyabinsk. And just two years later, Isover stone wool appeared on the Russian market, meeting all modern requirements and quality standards . This was preceded by hard work aimed at modernizing production facilities, attracting qualified foreign and Russian colleagues, interacting with research laboratories and carrying out work based on customer feedback.

Isover stone wool is a reliable material that provides a high level of thermal protection for at least 50 years. The special fiber structure provides floor and wall insulation with excellent acoustic characteristics, which significantly reduces the noise level in the room. Insulation materials meet all basic requirements, they are durable and safe for humans and the environment. These properties have been confirmed by Russian research institutes. Thermal insulation materials are produced in accordance with the European standard EN 13162 and the international standard ISO 9011 .

Under the Isover brand, a wide range of heat and sound insulation materials are sold for all types of buildings and structures. Basalt materials cover all structures requiring insulation and insulation. It is possible to opt for a universal option or purchase products designed specifically for each individual design. The range includes solutions for private and professional construction .

Products for apartments and houses are intended for insulation of the entire house, frame walls, roofs, partitions, ceilings, floors, balconies, facades, siding. The slabs vary in thickness (from 25 to 1150 mm) and heat retention class. Professionals are provided with materials for insulating roofs, frame walls, partitions and ceilings, facades and floors. It is possible to include stone wool for sound insulation labeled “Acoustic” into a separate category.

The manufacturer's Russian-language website makes it easy to choose the best option for basalt wool by correctly selecting the required purpose, scope of application, shape, type of material, load on the insulation, heat retention class and thickness of the products.

IZOVOL

The production of IZOVOL brand products was carried out by the Belgorod Stone Wool Plant . In 2022, TECHNONICOL acquired 100% of the shares of the joint stock company ZNOiM, part of the IZOVOL group of companies. A year later, the integration of the Belgorod plant into the structure of the TECHNONICOL corporation was completed. Modernization and automation of production and logical processes made it possible to increase labor productivity by 17%. In 2019, the product range included materials for shipbuilding and new types of professional insulation for construction needs. Products are supplied to various regions of the country and abroad .

The production of high-quality basalt wool is carried out using a unique melting device , which completely eliminates the formation of slag and ensures maximum melt quality. As a result, the brand’s products are distinguished by high physical, mechanical and consumer characteristics, optimal thermal conductivity, durability, reliability and safety for humans and the environment.

The manufacturer also notes the resistance of the insulation to the effects of bending and rodents. The company's product range includes several lines of stone wool:

- IZOVOL ST , products vary in density, indicators range from 50 to 90 kg/cub.m., used for floors, partitions and sloping roofs.

- IZOVOL B , designed for insulation of ventilated facades, has a protective layer that prevents stone wool from being blown out.

- IZOVOL F , designed for thermal insulation of plaster facades, has high density and strength, water absorption does not exceed 1%.

- IZOVOL K , used for insulating flat roofs, is produced in sheets with an almost square shape, which allows you to quickly insulate large areas.

- IZOVOL KV , used for insulation of single- and two-layer roofing systems, is characterized by increased rigidity and moisture resistance.

- IZOVOL L and IZOBEL L , more universal products, are used for partitions, floors, attic spaces, attic floors.

- IZOVOL LIGHT IZOBEL LIGHT is used as a non-load-bearing heat and sound insulation layer in pitched roofs, ceilings and partitions, floors, attics and attics.

KNAUF

The top lines in the ratings of the best manufacturers of mineral wool insulation are occupied by KNAUF products. The company was founded by the Knauf brothers in 1932 . Initially, the company specialized in the production of plaster mixtures from gypsum, and later construction gypsum mixtures. In 1958, plasterboard production opened. Since the 1970s, ready-made structural parts and construction chemicals have appeared in the assortment. The subsequent stages of development included the production of high-quality insulation from glass and basalt fiber, foamed polystyrene. The company came to Russia in 1993.

Insulation TeploKnauf Wall 50 mm, 6 sq.m. Photo by Leroy Merlin

Now the transnational company includes more than 200 factories located in Asia, Europe, North and South America. For potential clients, it is important to note that the Russian market mainly presents fiberglass-based products. Stone wool is quite difficult to find; you need to contact either the manufacturer directly or the official partners of the German company.

KNAUF insulation products are highly resistant to evaporation, have a low thermal conductivity coefficient, effectively absorb sound, and are produced without the use of dyes or bleaches. Available in slabs and rolls . There are two categories of products:

- Knauf heat is a series of basalt and fiberglass materials used in private construction to insulate various building elements: walls, ceilings, roofs. There is an option TeploKNAUF Bath based on fiberglass.

- Knauf Insulation - materials intended for professional insulation are divided into several types for use on various structures.

Paroc

Paroc was founded in 1930 in Sweden . In 1950, the production of stone wool was opened in Finland, and in Sweden the production of technical insulation and cylinders was launched. Since 1970, packaging has acquired the familiar white color with red stripes . In 1980, sandwich panels appeared in the product range, and products began to be produced under the Paroc brand. 1990-2000s the company actively expands to European and Baltic countries . Today, the enterprise has production facilities in Finland, Sweden, Poland, and Lithuania. The head office is located in the Finnish city of Vanta.

The company produces and sells energy-efficient thermal insulation solutions made from stone wool. The highest quality of basalt fiber provides a unique combination of advantages of finished products : mechanical strength, fire safety, moisture resistance, processability, sound insulation, chemical resistance, environmental properties, elasticity, dynamic elasticity. Customers are provided with insulation in the form of plates, rolls, cylinders, bends, lamellas and lamella mats .

The entire list of materials can be divided into products for construction and technical insulation. The first category includes several groups of products: general building thermal insulation and thermal insulation for walls, plaster facades, sandwich panels, flat roofs, foundations and floors on the ground, insulation and fire protection of ceilings and floors, fire-resistant building insulation, soundproof building insulation. The second group includes technical bends and segments, cylinders, lamella, piercing and OBK mats, mats for OBK and industry, plates, HVAC and OEM plates. Each line has individual characteristics and is designed to implement specific tasks.

ROCKWOOL: Sauna Butts 1000x600x100 mm. and other offers

ROCKWOOL Group (ROCKWOOL) is an international group of companies, the structure of which includes several divisions : ROCKWOOL; Rockfon; Grodan; Lapinus; Rockpanel; Rockdelta; BuildDesk. The division of the same name is a manufacturer of a wide range of solutions based on basalt wool. The company was founded in 1909 in Denmark , the central office is located in the city of Hedehusen. The production of thermal insulation was launched in 1937.

The next four decades saw the expansion of production in Europe and North America . The 1990s were marked by active expansion in the East, the company acquired and modernized factories in Eastern and Central Europe, and increased its zones of influence in Asia. In 1999, the first Russian plant , located in Balashikha, began production. Between 2006 and 2012, three more factories opened . Thus, today the number of production sites located on different continents exceeds 40.

ROCKWOOL is a manufacturer and supplier of comprehensive solutions for heat and sound insulation, fire protection of all types of buildings and structures, in shipbuilding and for industrial equipment. It's that simple. In more detail, clients are provided with materials for:

- fire protection;

- marine and industrial insulation;

- private housing construction, with the help of which it is possible to heat and sound insulate baths and saunas, fireplaces, attics and attics, ceilings, walls, in particular frame walls, the insulation of which can be carried out from the street or indoors, floors;

Reference. Of particular interest is cotton wool Sauna Butts 1000x600x100 mm, designed for insulation of baths and saunas, specially designed for walls and ceilings of steam rooms. Provides heat and vapor barrier (aluminum foil is located on one side of the sheets). They retain heat, which allows you to save on wood and electricity.

- soundproofing;

- roofs;

- facades.

The company offers basalt insulation with middle density indicators; the most chaotic arrangement of fibers ensures high strength. The service life is at least 50 years, during which the wool does not lose its characteristics. The manufacturer notes the following advantages of the product:

- Non-flammability. Insulation materials do not burn, prevent the spread of fire, withstand temperatures up to 1000 degrees, and do not emit heat or smoke in the event of a fire.

- Thermal insulation. Insulation materials allow you to achieve optimal temperature in a room, increase its energy efficiency, and reduce utility costs.

- Soundproofing. Many insulation options absorb, some are more effective, since they are designed specifically for sound insulation.

- Water resistance. Prevents water penetration.

- Environmentally friendly. The materials are easily dismantled and recycled. Basalt wool can be converted into a similar material again and again.

URSA

Despite the interest of Internet users in URSA stone wool, the company does not offer these products, but sells the following categories of thermal insulation materials:

- URSA GEO - fiberglass-based insulation, produced taking into account high environmental requirements;

- URSA TERRA - non-flammable mineral insulation, intended for private housing construction, meets professional standards;

- URSA PUREONE - new generation non-flammable mineral insulation;

- URSA XPS - high quality extruded polystyrene foam materials;

- URSA SECO - modern high-quality membranes and films for vapor and waterproofing, wind protection of walls, ceilings and roofs.

Beltep

The production of thermal insulation of the Beltep brand is carried out by OJSC Gomelstroymaterialy (Republic of Belarus) . The company is one of the largest manufacturers of a wide range of building materials. The main goal of the enterprise is to produce only high-quality products . Beltep stone wool guarantees environmental friendliness, fire safety, energy efficiency, acoustic comfort, manufacturability, and the best price-quality ratio.

The main advantages of stone wool are vapor permeability, non-hygroscopicity, resistance to deformation, low shrinkage, different densities, and affordable price. Using Beltep stone wool, it is possible to effectively insulate various elements of buildings and structures:

- walls, ceilings, floors and partitions;

- frame buildings;

- ventilated and plaster facades;

- flat and pitched roofs.

The range also includes universal materials designed for insulating various structural elements. The products are produced in slabs, the density of which varies from 35 to 190 kg/cub.m., and thickness from 30 to 200 mm.

Euroizol

Basalt insulation of the Euroizol brand is produced in Ulyanovsk . The production of products is carried out by a company of the same name, created on the basis of the Ulyanovsk plant of thermal insulation products, known on the market since 1957. A new milestone in the history of the enterprise began in 2004. Then, together with specialists from the TERMO plant (Slovenia), the automated Heraclith line was launched . Equipping its facilities with innovative equipment allowed the company to become a major manufacturer and supplier of thermal insulation materials with a wide range of applications.

Euroizol products are distinguished by consistently high quality, low water absorption, non-flammability, resistance to deformation, good sound insulation, chemical and biological resistance. The use of unique AeroDraive technologies makes it possible to improve the basic properties of materials.

Euroizol stone wool is used for insulation in private housing construction and in the construction of civil and industrial facilities . It is used for insulation of pitched and flat roofs, floors along joists and under screed, ventilated and plaster facades, partitions, as a filler for sandwich panels, for sound insulation. Available in slabs of various thicknesses (30-200 mm) and densities (25-200 kg/cub.m.).

IZBA

The production of mineral thermal insulation is carried out by the Bogdanovichi Mineral Wool Plates Plant (BZMP). The enterprise is equipped with modern high-tech Italian equipment . The manufacturer notes the following advantages of IZBA slabs: non-flammability, non-hygroscopicity, resistance to mechanical stress, high heat and sound insulation, long service life.

Insulation Izba Light Super 50 mm., 4.8 sq.m. Photo by Leroy Merlin

Products are manufactured on the basis of gabbro-basalt rocks with the addition of a synthetic binder. This composition provides several more important characteristics : low water absorption, biostability, and environmental friendliness.

IZBA slabs are intended for use as a heat and/or sound insulating layer in three-layer and frame walls, partitions, interfloor, basement and attic floors, plaster and ventilated facades, soft flat, pitched and flat roofs with a polymer membrane. The company offers several product lines:

- IZBA Super Light;

- IZBA Light;

- IZBA Standard;

- HUT Venti;

- IZBA Facade;

- IZBA Roof;

- IZBA Roof Top;

- IZBA Roof Bottom;

- IZBA Sandwich;

- Minslab, GOST-9573-2012, four varieties : soft slabs marked “PM”, semi-rigid - “PP”, hard - “PZh” and increased rigidity - “PPZh”.

ISOROC

ISOROC (ISOROC) is a trademark under which mineral wool thermal insulation is produced, owned by CJSC ISOROC, created in 2000, a Russian company with 100 percent foreign capital . In 2016, the company became part of the Saint-Gobain concern. Integration into the structure of a global industry leader opened up new markets for the company and the opportunity to expand its product line. Today the company produces materials of European quality that are in demand in the domestic market.

ISOROC stone wool Super Warm. Teplostroy Photos

The products have low thermal conductivity, high fire resistance, deformation and tear strength, hydrophobicity, sound insulation ability, good vapor permeability, and environmental friendliness. The consumer has several options for building insulation to choose from:

- heat-resistant boards marked “Thermal Protection” for insulating stoves, fireplaces and surfaces near this equipment;

- “Super” slabs - a line of products in slabs and rolls;

- rulers marked “P” and “PP” are intended for three-layer wall structures, frame structures, partitions and pitched roofs;

- “Izolight” and “Ultralight” - lines of materials for a wide range of tasks;

- "Isophas" - a line of products for walls under plaster;

- "Izoruf" - a series of insulating materials in slabs for interfloor ceilings and roofing of buildings;

- "Isovent" - slabs for three-layer and frame walls, ventilated facades, interfloor ceilings, pitched roofs.

Nazarovo

Nazarovo Plant of Thermal Insulation Products and Structures (Nazarovo Plant TIiK) specializes in the production of one of the most effective materials for heat and sound insulation - products based on stone wool. The production process is highly technological, as it is carried out in accordance with the project (Sweden) . This ensures high quality and compliance with stringent international requirements , which are significantly higher than Russian state standards. As a result, the finished products surpass in their characteristics not only domestic analogues, but also materials from global enterprises.

The products of the Nazarovsky plant are divided into four categories:

1) Thermal insulation boards. Used to insulate a wide range of building structures. They are made from basalt energy wool with the addition of synthetic binders with water-repellent additives.

2) Two types of mats: thermal insulation and basalt pierced energy mats with one-, two- or all-sided lining. Refers to the type of non-combustible materials. Used for insulating power equipment.

3) Two types of cords: thermal insulation and basalt energy . Designed for insulation of equipment and pipelines with surface temperatures from -120 to +700 degrees.

4) Heat-insulating energy cylinders . They are used for insulating pipelines with surface temperatures from -120 to +400 degrees. They have a longitudinal through cut, which makes installation and dismantling easier, and they can be reused.

Thermolife

The production of basalt wool under the Thermolife brand was carried out by a company of the same name from Ukraine. Based on publicly available information, it can be concluded that the company is no longer operating. However, it is possible to find Thermolife materials on sale.

Thermolife stone wool has thermal insulation, fire protection and hydrophobic properties, chemical resistance, environmental friendliness, and provides high quality installation and sound insulation.

Used for thermal insulation of internal structures: Light, EcoLight and Cavity; for facade thermal insulation: Facade, VentFasad, VentFasad V and VentFasad N; for roofing thermal insulation: Roofing; Roof B; Roof S and Roof H; for thermal insulation of floors: Pol and Pol-S; for sandwich panels: Sandwich C and Sandwich K; for technical thermal insulation: Techizol 50, 75, Techizol 100, 125 and Techizol 150.

TECHNONICOL: Rocklight and others

TECHNONICOL Corporation was founded in 1992 and is a leading manufacturer of effective and reliable solutions for construction. The structure of the enterprise includes a significant number of production sites equipped with modern equipment from leading European enterprises from Denmark, Germany, Italy, Slovenia, etc. A wide range of products . The corporation's research centers are conducting activities to develop new products . The corporation's representative offices ensure effective cooperation with clients from different countries. The corporation offers consumers a wide range of insulation materials, which can be divided into three classes:

Insulation TechnoNIKOL GreenGuard Universal 50 mm 8 plates 600x1200 mm. Photo by Leroy Merlin

TECHNONICOL - non-flammable materials based on basalt rocks, intended for heat and sound insulation of various structural elements: plaster and ventilated facades, pitched and flat roofs, walls, ceilings, floors. In demand in private and industrial construction. Of particular interest is Rocklight wool , which is intended for use as an insulating layer in pitched roofs. Available in slabs.

BAZALIT - hydrophobized, non-flammable basalt materials for heat and sound insulation of facades, roofs, partitions and ceilings, attics, attics, pipelines of various types, heating networks, as well as for use in sandwich panels. Available in slabs and mats.

GreenGuard. The development of this product has become a qualitative leap in the company’s activities. The revolutionary material is produced using GEOlife technology, which is based on the use of exclusively natural raw materials and natural binders. As a result, the main advantages are: service life is 100 years, odorless, recommended for use in kindergartens and schools, medical institutions, and residential buildings.

Beltep is a good and inexpensive mineral insulation

Photo: hypermir.by

Basalt mineral wool from this manufacturer is available in two packages: rolls or slabs and is considered a good solution for creating multi-layer thermal insulation systems. The high rating of Beltep basalt wool is confirmed by reviews from construction forums and from individuals.

Among the advantages of Beltep mineral wool insulation:

- fire safety;

- environmental friendliness;

- vapor permeability;

- resistance to deformation;

- acoustic comfort;

- large selection of materials by density;

- low hygroscopicity;

- affordable price.

In addition, the material has high rigidity, is shape-resistant, and is easy to cut and install. When compared with European manufacturers, BelTep is inferior to them in some respects, but when there is a choice between it and many Russian brands, they often buy mineral wool from a Belarusian company. So we can say that BelTep basalt wool is the best competitor to many similar proposals.

Rating : 9.5 points out of 10

Reviews from builders : “I tried Beltep mineral wool in my work. The density is good, it doesn’t sag, it stands clearly between the rafters without falling out.”

Differences from other insulating materials

Foil insulation

The main advantage of mineral wool specimens is their environmental friendliness. But besides them, other insulation materials are used in construction. They are often used to insulate external facades, roofs, garages, balconies and loggias.

Let's look at the differences and features of popular analogues.

Expanded polystyrene

Expanded polystyrene

Expanded polystyrene A type of plastic with a foam structure. When a gaseous substance solidifies, it forms cells containing air. Its thermal conductivity is better than that of mineral wool and polystyrene foam.

The product is almost not afraid of moisture. Absorbs noise well. Service life exceeds 30 years.

Styrofoam

Styrofoam

Foam plastic Its thermal conductivity is lower than that of mineral wool. The material costs almost twice as much. It is lightweight, does not load the supporting structures of the building, and promotes sound insulation.

But it is a little more difficult to install, since it is less flexible and crumbles easily. This is not a problem if the product is driven into vertical hollow spaces. But laying it evenly on the floor is much more difficult.

Penoplex

Penoplex

Penoplex This is also a type of plastic, the most popular in the construction industry. It has the longest service life - more than 40 years. It transfers heat worst of all, which means it retains it best of all.

It costs a little more than mineral wool. Inflexible, sold in sheets.

Which mineral wool is better?

Often, a comprehensive analysis of any product at the end allows us to say: “This brand is the best. We recommend it for purchase!” It is impossible to draw such a conclusion with mineral wool. Assessments of the quality of manufactured products are too subjective; diametrically opposed reviews can be found about the same product. Therefore, “Expert Price” does not take the liberty of naming the best manufacturer of mineral wool, but makes the following recommendations :

- The 7 brands mentioned are truly the best on the Russian market and the most in demand in the construction of residential buildings and utility rooms, so it is best to purchase something from the announced list.

- To choose the optimal thermal insulation material after reading the article, it is best to carry out your own subjective assessment in a building materials store: look, touch, test for breaks - in a word, understand which thermal insulator is convenient for your work.

The combination of these two simple tips will allow you to choose what is truly best for insulating and insulating your home from external adverse factors. Happy shopping and have a comfortable winter!

Let's put the definitions in order!

In order to have a truly meaningful conversation with the reader, it is necessary to clarify the further use of terminology. And judging by the title in the title, it is very far from correct.

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

I wonder what answer you would find, for example, if you were asked the following question: “what is better – a car or a passenger car?” Or, let’s take an even more paradoxical one: “Which do you like better – trees or birches?” Surely you will look at the person who asked such a question with some wariness and, perhaps, “twist your finger at your temple.”

Meanwhile, these formulations of the question are no more absurd than the one in the title of the article! Don’t believe me, do you think that the author just decided to “get smart”? Well, let's turn to the source and go through the chain of definitions to the points that interest us.

In this case, the primary source will be GOST 31913-2011 .

A document that brings order to definitions in the field of use of thermal insulation materials. By the way, please note that the standard is not just state, but even interstate.

The standard has interstate status, or more precisely, it can be considered a Russian-language version of the European standard EN ISO 9229:2007 . And for the basic terms used in it, even in the Russian edition, the accepted international name (in English) is indicated.

So, let's look:

Clause 2.1.13 - it combines all types of fiber insulation.

“Thermal insulating material consisting of natural or artificially obtained fibers.” In the English version – “fibrous insulation”.

It is clear that natural fibers (cotton, linen, cellulose, etc.) are not of interest to us in this case. But mineral ones - they are negotiated separately.

Clause 2.1.15 – under the collective image of mineral fiber (English – “mineral fibre”) all fibers of inorganic nature are hidden, with the exception of metallic ones.

It also includes subclause 2.1.15.1 - about artificial mineral fiber (English: “man-made mineral fiber”, which includes what is obtained in industrial conditions from glass melts, rocks, slag, clay, metal oxides, etc.). P.

But now we come close, that is, literally verbatim, to our problem.

Clause 2.1.16 directly talks about the concept of “mineral wool” (English: “mineral wool” or abbreviation MW). This term refers to fibrous thermal insulation materials obtained from molten glass, rocks or slag. And then there are three subparagraphs that completely reveal the whole picture:

2.1.16.1 - glass wool (English: “glass wool”) - obtained mainly from melts of broken glass or natural quartz sand.

2.1.16.2 - rock wool (English: “rock wool” or “stone wool”) - from rock melts of volcanic origin.

2.1.16.3 - slag wool (English: “slag wool”) - obtained from blast furnace slag melts.

Here we can put an end to the dispute - so which is better, mineral or stone (basalt)? Are there still any ambiguities about the incorrectness of the question?

And if we carry out a “showdown”, then rather in this vein - which of the mineral wools is better to use for home insulation: stone wool, glass wool, or slag wool?

But here, it must be said, the “leadership” of one of the listed insulation materials is clearly visible. This can be displayed with this kind of rating.