Tightening requirements for heat and energy conservation of building structures requires at least a twofold increase in the thickness of walls and ceilings. For brick and concrete walls this figure is 90 and 110 mm, respectively. The problem is solved by using perfect facade and foundation thermal insulation. So how much brick does Penoplex replace, and why is this material considered optimal for insulating almost any building structure?

The current price list in our ]Penoplex[/anchor] offers several types of insulation made from extruded polystyrene foam, the thermal conductivity coefficient of which will pleasantly surprise you.

The material is difficult to counterfeit, so the risk of purchasing a low-quality counterfeit is reduced to zero.

Heat insulator brand Comfort properties and characteristics

Penoplex "Comfort" is a modified and improved "Penoplex 31C" with universal characteristics.

The material is actively used for insulating country houses, country houses and cottages. The high speed of installation and minimal labor costs popularize the insulation among private homeowners - it is used to insulate the subfloor, foundation and basement of a house, basement and roof, walls and partitions from the inside and outside of the building. Penoplex "Comfort" has high levels of moisture resistance and thermal conductivity. In the penoplex series line, the Comfort brand is recognized as universal. Penoplex protects the soil from heaving when it freezes - when the soil is insulated with this material, the freezing point of the soil will rise. This series is optimal for insulating road and railway surfaces, runways and technical areas of airfields. Comfort slabs retain their unique characteristics throughout the entire period of operation. Characteristics of the “Comfort” penoplex insulation brand are in the table below:

It is a misconception to think that penoplex and foam plastic are brother materials. Some properties of penoplex can be equated to the parameters of polystyrene foam, but not flammability and water absorption.

Manufacturers have long mastered the production of both non-flammable polystyrene foam and high-burning polystyrene foam. But the truth is that penoplex cannot spontaneously ignite, and in an open fire zone it will only melt, releasing carbon monoxide (CO) and carbon dioxide (CO 2) gases. If the fire is extinguished, the penoplex will not even smolder.

When choosing the thickness of expanded polystyrene sheets that will be used to insulate a building, it is important to take into account the climatic characteristics of the region where it is located, the dimensions of the building and the material from which it is built. There are two operational and technological characteristics that directly affect the quality of insulation of polystyrene foam - thickness and density

There are two operational and technological characteristics that directly affect the quality of insulation of polystyrene foam - thickness and density.

In general, sheets with a thickness of 50 mm and a density of 25 kg/m3 are considered optimal. This is the type of material that is usually recommended to developers or repairmen who do not know what thickness of polystyrene foam to insulate a house. However, the specified thickness and density are not an inviolable standard and may vary depending on the specific conditions indicated above.

Sheet sizes

All penoplex used in construction has standard dimensions. Thanks to this, it is very convenient to use it for cladding enclosing structures and make preliminary calculations of its required quantity.

The dimensions of 50 mm penoplex supplied to the modern market, in most cases, are 60x120 mm. These sheets are the most common and in demand among private developers.

Many owners of country houses who have decided to insulate their enclosing structures are also interested in how many pieces of 50-mm penoplex the manufacturers put into the packaging. Depending on the variety, such slabs can be sold at a time in 7-8 pieces. Sheathing using material from one package can thus cover 4.85 or 5.55 square meters of insulated surfaces.

Such sheets are widely used in both private and industrial construction. In the latter case, 50 mm foam boards measuring 60x240 mm can sometimes also be used. It is, of course, more convenient to cover the walls and foundations of high-rise buildings with such sheets.

This material is sold in absolutely all construction supermarkets. It is relatively inexpensive. The price for a package of 50 mm penoplex is about 1,500 rubles.

Penoplex Roofing properties and characteristics

Penoplex insulation of the “Roofing” series is a renamed material “Penoplex 35”, which is recommended for use in insulating pitched and flat roofs of any design. The use of the “Roof” series makes the further operation of the roof as simplified as possible, since the reliability and long service life of the insulation minimize the possibility of repairing the roof surface. The popularity of this innovative insulating material is also due to the fact that greenhouses and summer gardens can be built on such a surface - such trends are now in fashion. Penoplex can withstand such high loads that it doesn’t care about soil loads of up to several tons. Characteristics of the foam insulation brand “Roof” are in the table below:

Application area

Thermal insulation boards "Penoplex" 30 mm are used for thermal insulation of walls, roofs, foundations, plinths and floors in private properties. The extrusion product has also found wide application in insulating balconies and loggias in city high-rise buildings.

Penoplex 30 mm is used to insulate enclosing structures, garages and other types of outbuildings.

When laying slabs between the working surface of the insulating material and the facing surface, “cold bridges” do not form, thereby creating an optimal microclimate inside the living space. The ambient temperature is always pleasant for a person to be in under any weather conditions.

Due to its high strength, Penoplex 30 mm can withstand high loads in both horizontal and vertical positions.

In any condition, it does not deform during facing work. Boards of extruded material do not absorb moisture, so the products are successfully used for cladding baths and saunas, wine cellars, swimming pools and other rooms where the humidity level is constantly high. If you need to insulate an apartment, make repairs in a country house, or waterproof the foundation, you don’t need to overpay by buying Penoplex of more expensive series.

For interior work, 30 mm Penoplex extrusion is quite sufficient. The cost of packaging this product will be significantly lower compared to the same “Penoplex” 100 mm, in addition, the smaller thickness will not “eat up” the usable area of the home.

A Penoplex insulation board with a thickness of 30 will be useful when arranging:

- "warm floor" systems;

- waterproofing the base and foundation;

- any type of roof and ceiling;

- partitions or “well” masonry walls;

- garden paths.

What to choose

If we compare these two insulation materials, then Technoplex is more technologically advanced and has better qualities, but the difference between it and Penoplex is so insignificant that it is impossible to say for sure which one should be chosen.

By choosing polystyrene foam insulation, regardless of whether it is Technoplex or Penoplex, you can get not only thermal insulation, but also sound and vapor barrier.

Please note: the service life of extruded polystyrene foam boards is more than 50 years, which is a long time. . However, it is worth remembering that polystyrene foam is still a chemical insulation, not a natural one.

Therefore, when burned, it releases very corrosive substances

However, it is worth remembering that polystyrene foam is still a chemical insulation, not a natural one. Therefore, when burned, it releases very caustic substances.

Table of thermal conductivity of materials

This factor is significant, especially in the case of insulating a residential building, since many materials emit formaldehyde, which affects the growth of cancerous tumors. Therefore, it is necessary to make a choice towards non-toxic and biologically neutral materials. From an environmental point of view, stone wool is considered the best thermal insulation material.

The material must be non-flammable and safe. Any material can burn, the difference is at what temperature it ignites. It is important that the insulation is self-extinguishing.

Those materials that are waterproof have an advantage, since moisture absorption leads to the fact that the effectiveness of the material becomes low and the useful characteristics of the insulation after a year of use are reduced by 50% or more.

On average, the service life of insulating materials ranges from 5 to 10-15 years. Thermal insulation materials containing cotton wool significantly reduce their effectiveness in the first years of service. But polyurethane foam has a service life of over 50 years .

How many bricks does Penoplex replace?

Tightening requirements for heat and energy conservation of building structures requires at least a twofold increase in the thickness of walls and ceilings. For brick and concrete walls this figure is 90 and 110 mm, respectively. The problem is solved by using perfect facade and foundation thermal insulation. So how much brick does Penoplex replace, and why is this material considered optimal for insulating almost any building structure?

The material is difficult to counterfeit, so the risk of purchasing a low-quality counterfeit is reduced to zero.

What properties of Penoplex determine the high level of consumer demand?

When choosing a material, its unique low thermal conductivity, light weight, simple installation and long service life are taken into account.

- New generation extruded polystyrene foam thermal insulation differs from polystyrene foam in its perfectly homogeneous structure, resistance to compression loads and other adverse external influences.

- For all its advantages, mineral wool has strict weight restrictions. Therefore, to insulate devices that do not have a sufficient safety margin, lightweight materials based on polystyrene foam are used.

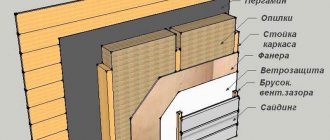

The disadvantages of Penoplex Facade, which you can buy from our company at any time of the year - zero vapor permeability and fairly low heat resistance, are partially or fully compensated by the use of façade systems with slot ventilation and the installation of heat-resistant protective and decorative coatings.

As for the insulation of underground structures, including foundation ones, in this case moisture- and frost-resistant polystyrene foam does not have a worthy alternative.

The strength of the foundation lining is sufficient to protect the waterproofing from damage by seasonal movements of heaving soils. The range of polystyrene foam insulation includes panels of different sizes: from 30 to 100 mm thick. In most central regions, panels with a thickness of 50-60 mm are in high demand. You can buy Penoplex 50 mm in Moscow with significant discounts at promotional and seasonal sales of building materials.

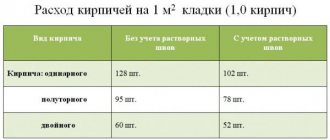

How much brickwork does Penoplex take?

For those who plan to order Penoplex, the ratio of thermal insulation material to brick plays an important role. We will tell you about the most popular thickness of thermal insulation boards and their correspondence to the thickness of the brickwork.

- Penoplex 20 mm replaces a brick wall with a thickness of 370 mm - this is almost 40 cm, that is, 2 times the thickness of the insulation itself. If you wanted to purchase reliable thermal insulation, but you were only stopped by ignorance of how much brick a 2 cm thickness of Penoplex replaces, today you learned an additional plus in the piggy bank of this material!

- How much does Penoplex 30 mm replace brickwork? Based on the data on the correspondence of 2 cm of insulation to a brick wall, it turns out that Penoplex 30 mm replaces as much as 555 mm of brickwork in terms of energy efficiency. Here is your answer to how many bricks 30 mm thick Penoplex replaces!

- What brick thickness does Penoplex 50 mm replace? A pleasant surprise awaits you! The technical characteristics of Penoplex 50 mm in comparison with brick will conquer not only the homeowner, but also the experienced developer. Brickwork 925 mm thick can be compared with 50 mm Penoplex - that’s how many bricks this insulation replaces!

Now that you have found out what wall thickness Penoplex replaces, there is no reason to put off the purchase of thermal insulation material - call us and order insulation at a favorable price today!

Expanded polystyrene insulation in country and cottage-type houses

Many developers use the material for external insulation of facades and ceiling structures of country houses, which are being converted for year-round living. The main range of applications for polystyrene foam insulation is finishing foundations, blind areas, and insulating cement screeds under floor tiles.

Unlike mineral wool, expanded polystyrene does not require film or mastic waterproofing, so it can be mounted directly on a flat ground surface.

The more than moderate cost of polystyrene foam materials is complemented by the possibility of do-it-yourself installation, which allows you to reduce the cost of thermal insulation work by 35-40%.

Buy high-quality Penoplex insulation from our company right now at a competitive price!

Are there any negative reviews about penoplex 50 mm

Consumers consider that some of the disadvantages of this material are mainly its rather high cost. The price of this type of insulation is higher than that of mineral wool. Also, the disadvantages of penoplex include its low degree of vapor permeability. This material can be used mainly only for cladding enclosing structures on the street side.

Consumers consider another disadvantage of penoplex to be that, like foam plastic, mouse passages and nests are often built in it. In houses with rodents, this material for covering walls, floors and ceilings, respectively, usually has to be used only in combination with a metal mesh with a small mesh size. Many owners of such private buildings also advise using mineral wool rather than penoplex for their insulation.

Below is a list of frequently asked questions and answers related to PENOPLEX ® thermal insulation:

Using PENOPLEX indoors?

The molecules of polystyrene used in the production of PENOPLEX ® thermal insulation consist only of hydrogen and carbon atoms, so the material is completely environmentally friendly and safe for humans. Polystyrene, from which PENOPLEX ® thermal insulation is made, is also used for the manufacture of children's toys, disposable tableware, food packaging, medical products, etc. Items made of polystyrene surround us every day in everyday life: refrigerator parts, cocktail straws, egg packaging, yogurt jars and much, much more.

PENOPLEX ® is an environmentally friendly insulation material and does not contain small fibers, dust, phenol-formaldehyde resins, soot and slag. This material can be used as thermal insulation for internal and external insulation of building envelopes of residential, public, agricultural and industrial buildings and structures, as well as for external insulation during the construction of household water supply and sewerage facilities.

According to the results of the sanitary and epidemiological examination, the products of POLYSTYRENE FOAM EXTRUSION PENOPLEX, manufactured according to TU 5767-006-56925804-2007 and TU 5767-006-54349294-2014, meet the established requirements.

What to buy

The building materials market offers a huge selection of polystyrene foam boards. The high thermal conductivity of insulation boards depends on their type. For example: a sheet of polystyrene foam PSB-S 15 has a density of up to 15 kg/m3 and is 2 cm thick. For a sheet from 2 to 50 cm, the density is no more than 35 kg/m3. When comparing polystyrene foam with other similar materials, you can easily trace the dependence of the thermal conductivity of polystyrene foam boards on its thickness.

In order to apply one of the insulation methods, it is necessary to select the correct dimensions of the material. The following algorithm can be used to calculate:

- It is necessary to clarify the overall thermal resistance. This value depends on the region in which the calculation needs to be performed, namely on its climate.

- To calculate the thermal resistance of a wall, you can use the formula R=p/k, where its thickness is equal to the p value, and k is the thermal conductivity coefficient of the foam.

- From constant indicators we can conclude what resistance the insulation should have.

- The required value can be calculated using the formula p=R*k; the value of R can be found based on the previous step and the thermal conductivity coefficient.

Manufacturing technology

The equipment used is an extruder. Its name, arbitrary from the name of the head with dies located at the exit of the alloy from the unit, is extrusion.

The main component of the technological process is polystyrene granules. It is divided into several stages:

First

Second

Making the slab - staying in the holding chamber for 24 hours. All air is pumped out of the unit using a vacuum pump, and the material is left inside. It stabilizes, the pressure inside the granules filled with air is balanced.

Third

Blocks are formed in a closed type matrix. Steam is supplied inside the container under pressure. Residual moisture is lost. The aging stage ends for a day, with each new heating cycle increasing the density of the structure.

A moderately dried block is cut on a conveyor belt. Violation of technology leads to uneven edges. The cutting tool is a red-hot refractory steel string. The production uses equipment with an electronic program that controls the level of metal heating.

Source

Thickness calculation

The heat transfer resistance R is tied to the thickness of the building structure, and its minimum value established by regulatory documents varies depending on the climatic conditions in the region. For example, in the southern regions of the Russian Federation, the walls of residential buildings must have a heat transfer resistance of at least 2.1 m 2 °C/W. It is proposed to take this value as a basis and calculate how much brick and Penoplex will be needed to comply with it. The minimum indicator is calculated using the formula:

δ=Rxλ, where:

- δ—thickness value of the wall structure, m;

- λ is the thermal conductivity of the material from which the wall is built, W/m 2 °C.

- R is the heat transfer resistance, in the example it is 2.1 m 2 °C/W.

If we take the thermal conductivity coefficient of ordinary brickwork λ = 0.7 W/m 2 °C, then in the southern regions of the Russian Federation the thickness of walls made of ceramic products should be: δ = 2.1x0.7 = 1.47 m.

The same wall, but made of Penoplex with a density of 30 kg/m 3, will have a thickness: δ = 2.1x0.037 = 0.077 m, or 77 mm.

The difference between the materials will be 1.47/0.077=19. The brickwork must be so many times thicker than the expanded polystyrene layer in order to achieve the same thermal insulation value of the building. The full picture, showing a comparison of different types of brick walls and polymer insulation, is reflected in the table:

Now the table clearly shows how much worse the thermal conductivity of a brick wall differs from extruded polystyrene foam.

//www.youtube.com/watch?v=Fiv2o06iaQs

Brick lacks thermal insulation properties, and Penoplex lacks load-bearing capacity. Together they will give an excellent result: it is enough to insulate a masonry of 1.5 hollow pieces with 50 mm expanded polystyrene sheets, and the total cross-section of the fence will be only 0.43 m.

Due to the fact that the range of insulation materials presented on the building materials market is very large, each consumer can choose the type of insulation that is suitable for him.

One of these insulation materials is penoplex.

This is a synthetic insulating material for internal and external insulation.

What is the total area of Penoplex slabs in one package?

Knowing the basic parameters of the material and the number of sheets in a pack, it will not be difficult for you to calculate on your own how much area it will be enough for. But we have simplified your task and have already calculated how many squares (m2) there are in a package of penoplex of various thicknesses:

- 20 mm – 12.5 sq.m.;

- 30 mm – 8.3 sq.m.;

- 40 mm – 6.2 sq.m.;

- 50 mm – 4.9 sq.m.;

- 60 mm – 4.9 sq.m.;

- 80 mm – 3.5 sq.m.;

- 100 mm – 2.8 sq.m.;

- 120 mm – 2.1 sq.m.;

- 150 mm – 1.4 sq.m.

Comparison by main parameters

Mineral wool has a coefficient of 0.032-0.046, while penoplex has a coefficient of 0.03-0.032. The lower the indicator, the better, because there is less heat loss and the temperature inside the room is better maintained.

Penoplex is a fairly hard material that does not rot, dry out or crumble. The insulation has a long service life under the correct storage conditions, when it is reliably protected from prolonged sunlight and excessive heat. Mineral wool also does not dry out. Without exposure to high physical stress, it can last for a long time, is not afraid of high or low temperatures and long exposure to sunlight on the surface.

It is not at risk of mold and other harmful organisms, and it is also not susceptible to destruction by rodents. But mineral wool can crumble and settle on the wall. In general, both materials have an enormous service life, lasting at least 50 years.

Environmentally friendly.

Both materials are manufactured without the use of any hazardous components that could be harmful to human health, but still require absolute containment to protect the respiratory tract.

When insulating a perfectly smooth surface, work using penoplex is carried out much faster. It is lightweight, easy to cut and sand, and with an L-shaped edge, it eliminates the formation of cold bridges. When using it, there is no need to cover it with a vapor barrier. If there is no tongue-and-groove edge, then it is tedious to seal the seams or lay them in two overlapping layers, which will lead to unnecessary costs.

Mineral wool has a little more weight, but it is much more efficient and simplifies installation in existing heavy, disproportionate areas and structures. But when working with it, you must purchase special clothing in advance, along with a respirator and safety glasses.

If used to insulate the facade of a house, if the penoplex has a thickness of 50 mm, then the mineral wool should have a thickness of 60 mm to have a similar effect. The difference is not entirely dramatic. Depending on the situation, each of them is good in its own way, because cotton wool is capable of allowing air to pass through, unlike penoplex, which has an absolutely airtight structure.

Mineral wool absorbs water much more strongly, subsequently losing some of its thermal insulation characteristics. In this case, penoplex is significantly better, because even with intense and frequent rains, its mass will practically not change.

Mineral wool has the best performance in this parameter, because it is almost inflammable. Its melting point should be more than 1000°. Cotton wool contains an adhesive base that can ignite, but it occupies a very tiny part of the total volume of the material and does not pose a significant danger.

Penoplex is completely opposite in its qualities. It can melt and burn in open fire, releasing toxins that are very harmful to the human body. To ensure a high level of protection of buildings from fire, penoplex is categorically unsuitable for use. For these purposes, the best and unconditional option is mineral wool.

The price of materials is practically no different. There may be a slight difference only depending on the choice of the manufacturer.

Why is thermal insulation needed?

The relevance of thermal insulation is as follows:

Heat loss through the walls of a typical multi-storey residential building is 30-40% . To reduce heat loss, special thermal insulation materials are needed. The use of electric heaters in winter contributes to additional energy costs. It is more profitable to compensate for these costs by using high-quality thermal insulation material, which ensures heat retention in winter and coolness in the summer heat. At the same time, the cost of cooling the room with air conditioning will also be minimized.

In the case of industrial buildings using a metal frame, insulation helps protect the metal surface from corrosion, which is the most detrimental defect for this type of structure. And the service life of a brick building is determined by the number of freeze/thaw cycles. The impact of these cycles is perceived by the insulation, because the dew point is located in the thermal insulation material, and not in the wall material.

Such insulation allows you to increase the service life of the building many times.

Protection against increasing noise levels is achieved by using such noise-absorbing materials (thick mattresses, sound-reflecting wall panels).

The use of a thermal insulation system makes it possible to reduce the thickness of external walls, while increasing the internal area of the building.

Answers from experts

Engineer:

Both brick and foam are different.

Formally, the thermal conductivity of red brick is 10 times greater than that of highly porous foam. (0.56 and 0.05 W/m*deg - respectively)

That is, feel free to multiply the thickness of the foam by 11 and get the thickness of the brick wall.

Kirill Gribkov:

none

Bolt-gnawer:

Extruded polystyrene foam "Extraplex" with a thickness of 20 mm is equivalent in its heat and sound insulating properties to a brick wall with a thickness of 370 mm

Samson Altunyan:

Hello, the best!

You forgot to mention the conditions (parameters) of the assessment...

1) If you mean thermal conductivity? . The engineer answered you.

2) If we are talking about mechanical strength? . Polystyrene foam is NOT a replacement for brick. Especially in earthquake-prone regions.

3) Durability? The brick will last longer.

4) Resistance to environmental influences (temperature changes, humidity, etc.)? Foam plastic, in this case, is not even a building material...

5) Safety (physiological, chemical, environmental)?..Again, the comparison will be in favor of fired clay (brick)...

And generally speaking.. . That's not what they teach you... ;-( Foam plastic is NOT a good choice of material for construction or interior decoration. And in this ODIN is absolutely right...

Good luck to you!

Nurgaliev Marat:

5 cm of penoplex is half a meter of brick!!! And don't listen to the reindeer herders!

kukuzya:

I read the answers and I'm confused. What kind of tusk do you need to be in order to answer the question about the equivalence of brick and foam plastic and compare their load-bearing abilities... Of course, they compare thermal conductivity...

ST:

10cm of foam replaces 50cm of brick

Lulechka:

thickness is the same. in terms of strength, thermal insulation and other qualities - this is for builders!!!

Igor Chekalin:

Considering the beginning of winter, I suspect that we are talking about thermal conductivity?

Is the brick hollow or solid, silicate, ceramic, silica or even slag? The difference between different types is almost two times, and with silica it is 5 times.

For the worst case - solid sand-lime brick - the thickness ratio is approximately 20 times. That is, in terms of thermal conductivity, a 250mm wall (ordinary one-brick masonry) corresponds to only 13mm of polystyrene foam. For hollow bricks the ratio is ~10 times. That is, in our case - ~25mm foam. However, brickwork is almost airtight, and when insulated with foam plastic, there are gaps at the joints, loose edges, etc., so it’s not entirely correct to take such a formal and mathematical approach.

Well, more accurate numbers - google for “thermal conductivity table of building materials”

Alexander Kulikov:

The thickness of your knowledge of the Russian language...

Albert Belkov:

In fact: 1 cm of foam plastic in terms of thermal conductivity can be estimated as half a brick inside the masonry or backfill.

ST:

10cm of foam replaces 50cm of brick

Operational and technical properties of penoplex, advantages and disadvantages

- Thermal conductivity – 0.03 Wm·0 C, the indicator does not decrease even with strong humidification;

- Water resistance – 0.4-0.6% when immersed in water for 24 hours and for a month;

- The vapor permeability of the material can be compared with the same indicators of roofing felt with a layer thickness of 20 mm;

- Chemical passivity: penoplex does not react to contact with building mortars and most aggressive substances. Substances with which penoplex contact is contraindicated: kerosene, acetone, formaldehyde, benzene, xylene, toluene, formaldehyde, methyl ethyl ketone, ether, diesel fuel, gasoline, tar, paints and epoxy resins;

- High mechanical resistance to stretching, compression, tensile forces and multi-vector pressure. The compressive strength of penoplex is 0.2-0.5 MPa;

- Biological neutrality - penoplex does not develop mold, does not decompose and does not rot;

- Wide range of operating temperatures - from -50 to +75 0 C. The temperature range for each brand is indicated on the packaging;

- Flammability groups for different brands are different, from G1 to G4, depending on operating conditions;

- Environmentally friendly material without the use of phenols and freons in the production;

- Guaranteed service life ≥55 years without noticeable loss in properties.

Advantages of penoplex:

- Thermal conductivity properties make it possible to use penoplex even in the Far North - multiple freezing/thawing cycles of the material do not affect its characteristics;

- Light weight makes transportation, warehousing, storage and insulation of the object easier, allows you to lighten the foundation and not strengthen the ceilings;

- Simple installation without the help of specialists and special tools - penoplex can be easily cut with a regular hacksaw or cutter;

- Safety and environmental friendliness - you can work with the material without personal protective equipment;

- Low cost of all brands of insulation. Even with a large consumption of heat insulator, the costs of its purchase and installation pay off in 2-3 seasons.

Disadvantages of penoplex:

- Low fire safety - material of any flammability group, even with fire retardant additives, can catch fire and release caustic toxic smoke;

- Low coefficient of vapor permeability, and under certain weather conditions - negative. Therefore, it is not recommended to use penoplex for internal insulation of house walls. To maintain optimal operating conditions for the insulation, it is necessary to provide forced-air ventilation in the house and ventilation of channels in walls insulated with penoplex;

- Destruction of the material when exposed to ultraviolet radiation - sunlight. It is necessary to protect the insulation layer with plaster or other methods;

- Due to the smooth surface, the adhesion of penoplex to mortars is quite low, so the insulation should only be attached to dowels or special expensive glue, but not to mortars.

How do they do it?

This material is produced at enterprises from polystyrene granules using various kinds of additives, which ultimately improve its performance qualities. In the production of penoplex, the initial raw materials are previously exposed to high temperatures under high pressure. Next, a special catalyst for foaming is added to the mass. Then substances are added to the penoplex that increase its fire-resistant properties, ability to resist ultraviolet radiation, etc.

How much Penoplex will replace a brick wall?

How much does Penoplex brick replace? The latter is not the name of the building material. This is what one of the most popular brands producing polymer thermal insulation boards sounds like. Here we mean extruded polystyrene foam, one of the best insulation materials that currently exists. It is worth understanding in what respect it can be compared with brick.

Clarification of terms

First of all, you need to understand to what extent expanded polystyrene can replace brickwork. These are completely different building materials.

Considering that both materials take part in the construction of external walls of buildings, only one comparison is appropriate between them - in terms of thermal conductivity. It is this characteristic that is meant when posing the question, but it needs to be reformulated correctly: what thickness of Penoplex and brick will create the same thermal resistance. In terms of other characteristics, the comparison is not in favor of the polymer.

Thermal conductivity indicators

The ability to resist the passage of thermal energy flow is characterized by the thermal conductivity coefficient λ, expressed in units of W/m 2 °C. As a rule, sellers of various insulation materials provide the value of this coefficient for products in a dry state. At the same time, regulatory documents require calculations to be made based on real operational indicators, the values of which are not so impressive.

The materials in question are available in several varieties. Brick is made from different materials and using different technologies. Brands of extruded polystyrene foam differ in density, which affects its thermal conductivity. Operating thermal indicators for products of different types look like this:

The list shows values for finished brickwork built with cement-sand mortar. For other types of solutions, the indicators will be slightly different. The characteristics of extruded polystyrene foam of different densities are strikingly different:

- Penoplex density 30 kg/m 3, λ=0.037 W/m 2 °C,

- the same, density 50 kg/m 3, λ=0.038 W/m 2 °C.

It is noticeable how much less the thermal conductivity of polymer insulation is than that of a brick wall. But these numbers are abstract and therefore difficult to understand for the average person. To understand the situation, we need to bring all the indicators to one concept - thickness. To do this, it is necessary to determine one more characteristic - heat transfer resistance R, expressed in units of m 2 °C/W.

Thickness calculation

The heat transfer resistance R is tied to the thickness of the building structure, and its minimum value established by regulatory documents varies depending on the climatic conditions in the region. For example, in the southern regions of the Russian Federation, the walls of residential buildings must have a heat transfer resistance of at least 2.1 m 2 °C/W. It is proposed to take this value as a basis and calculate how much brick and Penoplex will be needed to comply with it. The minimum indicator is calculated using the formula:

- δ—thickness value of the wall structure, m,

- λ is the thermal conductivity of the material from which the wall is built, W/m 2 °C.

- R is the heat transfer resistance, in the example it is 2.1 m 2 °C/W.

If we take the thermal conductivity coefficient of ordinary brickwork λ = 0.7 W/m 2 °C, then in the southern regions of the Russian Federation the thickness of walls made of ceramic products should be: δ = 2.1x0.7 = 1.47 m.

The same wall, but made of Penoplex with a density of 30 kg/m 3, will have a thickness: δ = 2.1x0.037 = 0.077 m, or 77 mm.

The difference between the materials will be 1.47/0.077=19. The brickwork must be so many times thicker than the expanded polystyrene layer in order to achieve the same thermal insulation value of the building. The full picture, showing a comparison of different types of brick walls and polymer insulation, is reflected in the table:

Thermal conductivity and density of penoplex, comparison with polystyrene foam PSB

A comparative table of the values of the thermal conductivity coefficient, density of penoplex and polystyrene polystyrene PSB of various brands in a dry state at a temperature of 20...30°C is presented.

Their operating temperature range is also indicated. Penoplex thermal insulation, in contrast to non-pressed polystyrene foam PSB, is produced at elevated temperatures and pressures with the addition of a foaming agent and extruded through an extruder. This production technology provides penoplex with a closed microporous structure.

Penoplex, compared to polystyrene foam PSB, has a lower thermal conductivity coefficient λ , which is 0.03...0.036 W/(m deg) . The thermal conductivity of penoplex is approximately 30% lower than that of such traditional insulation as mineral wool. It should be noted that the thermal conductivity coefficient of polystyrene foam PSB, depending on the brand, is in the range of 0.037...0.043 W/(m deg).

The maximum temperature for using Penoplex expanded polystyrene is 75°C. For PSB foam it is slightly higher and can reach 80°C. When heated above 75°C, penoplex does not melt, but its strength characteristics deteriorate. The manufacturer does not report how much the thermal conductivity coefficient of this thermal insulation material increases under such conditions.

Thermal conductivity and density of penoplex and expanded polystyrene PSB

| Brand of expanded polystyrene | λ, W/(m K) | ρ, kg/m 3 | trab, °С |

| Penoplex | |||

| Penoplex comfort slabs | 0,03 | 25…35 | -100…+75 |

| Penoplex Foundation | 0,03 | 29…33 | -100…+75 |

| Penoplex Roofing | 0,03 | 26…34 | -100…+75 |

| Penoplex segments grade 35 | 0,03 | 33…38 | -60…+75 |

| Penoplex segments grade 45 | 0,03 | 38…45 | -60…+75 |

| Penoplex Block | 0,036 | from 25 | -100…+75 |

| Penoplex 45 | 0,03 | 40…47 | -100…+75 |

| Penoplex Slope | 0,03 | from 22 | -100…+75 |

| Penoplex Facade | 0,03 | 25…33 | -100…+75 |

| Penoplex Wall | 0,03 | 25…32 | -70…+75 |

| Penoplex Geo | 0,03 | 28…36 | -100…+75 |

| Penoplex Base | 0,03 | from 22 | -100…+75 |

| Expanded polystyrene PSB (foam plastic) | |||

| PSB-15 | 0,042…0,043 | up to 15 | up to 80 |

| PSB-25 | 0,039…0,041 | 15…25 | up to 80 |

| PSB-35 | 0,037…0,038 | 25…35 | up to 80 |

| PSB-50 | 0,04…0,041 | 35…50 | up to 80 |

It should be noted that Penoplex thermal insulation, due to its closed microporous structure, practically does not absorb moisture, is not affected by mold, fungi and other microorganisms, and is an environmentally friendly and safe insulation for humans.

In addition, extruded polystyrene foam Penoplex has fairly high chemical resistance to many materials used in construction. However, some organic substances and solvents listed in the table below can cause insulation boards to soften, shrink, and even dissolve.

Source