6159 0 0

Michel December 7, 2016Specialization: plumber with 10 years of experience, computer repair specialist, powerlifting coach. I have extensive experience in construction, interior decoration, and making homemade furniture. Hobbies: sports

Greetings, comrades! Today we are going to find out what finishing putty is and what it is used for. We will find out what varieties of this finishing material can be found on sale, how to properly prepare putty from a dry mixture and how to putty it on the ceiling and walls.

Puttying walls for painting.

First meeting

- How does finishing putty differ from regular putty??

Smaller aggregate fraction size. For starting putties it is usually 0.2 - 0.3 mm, for finishing and universal putties it is no more than 0.15 mm.

The smaller the filler fraction, the smoother the surface can be obtained when filling.

The quality of the surface is determined by the grain size of the aggregate.

- What is superfinish putty and why do you need it?

It differs from the finishing one in the same way that the finishing one differs from the starting one - an even smaller grain size of the filler. For superfinish putty it does not exceed 0.08 mm, which allows you to get an even smoother surface. Superfinish finishing is used only for painting; putting it on walls under wallpaper makes no sense.

Shitrock Superfinish from Knauf.

Puttying for painting has one subtlety. Glossy paint is much more sensitive to the quality of the surface than matte: it emphasizes the slightest irregularities in the base. That is why superfinish putties are used mainly for gloss; For matte paint, pre-finishing is done with a regular finishing or universal finish.

Gloss is extremely demanding on surface quality.

Surface preparation

Preparatory activities can be divided into three main stages:

- Preparing the premises. Puttying walls for painting with your own hands is accompanied by the appearance of dirt, so before starting renovation it is recommended to empty the room as much as possible of furniture and things. Those items that cannot be removed are moved to the middle and covered with film. If the floor has already been laid, it is also covered with film or cardboard.

- Cleaning the base. This is the most important stage in wall preparation: it determines how tightly the putty layer will hold. All old finishing must be removed from the base surface (a strong scraper will be useful for this). In cases where the plaster does not hold, it is also removed. The easiest thing in this case is with concrete walls - you just need to clean everything from them down to the concrete. A more difficult situation is brick or block partitions covered with plaster. Having removed the top finish (old wallpaper, putty), you need to carefully examine the plaster layer: it is better to beat off all bulging and doubtful fragments with a pick .

- Applying a primer layer. The cleaned base must be impregnated with a deep penetration primer: acrylic compounds have proven themselves well in this regard. This will ensure good adhesion for subsequent finishing. In cases where traces of mold and other biological activity were found on the surface during cleaning, a special anti-mold liquid is applied before priming. It has been noted that such treatment is an excellent way to combat ants.

Varieties

Astringent

- What types of binders are used to prepare finishing putties??

When finishing mineral bases the following are used:

- Dry mixtures based on gypsum and cement binders;

- Ready-made acrylic putty.

Acrylic resins are used as a binder.

Less popular are adhesive, latex, epoxy, polyvinyl acetate and polyurethane finishing materials.

Putty on an oil-adhesive basis.

- Which binder is more suitable for facades and wet rooms?

Cement. Facade acrylic putties also serve well in high humidity, but the relatively high price (from 50 rubles per kilogram) forces them to be used mainly for minor repairs.

The external slopes of the window are finished with acrylic putty.

A caveat is worth making here. Gypsum binder mixtures cannot be used for exterior decoration of houses, but they are often used when renovating bathrooms, kitchens and toilets.

Their use in rooms with high humidity has only a couple of limitations:

- For trouble-free operation of the finish, the room must be ventilated. Constant dampness is detrimental to any mineral-based finishing materials - simply because mineral filler is a tasty food for fungus;

The hood in the ventilation duct can provide effective ventilation of the room.

- The final finish must be waterproof. It can be used, for example, tiles with epoxy or silicone grout, thick vinyl wallpaper or waterproofing paint.

Rubber waterproofing paint made in Sevastopol.

- Which putty to choose for finishing walls and ceilings in living rooms?

Unconditionally plaster. It is extremely easy to apply and sand, inexpensive (about 300 rubles for a 25-kilogram bag) and compatible with any mineral bases.

Dry gypsum mixture from Knauf.

Color

- How practical is white finishing putty?

In my opinion, this is an excellent solution that allows you to significantly reduce the time and money spent on finishing. White color allows you to get by with one or two layers of paint, while a dark base often shows through even after 3-4 layers. White acrylic putty is very convenient for repairing minor cosmetic defects in flows and whitewashed walls.

White color will make painting much easier.

Shrinkage

- What are the benefits of non-shrink finishing putty?

The fact that when it dries it does not crack, regardless of the thickness of the layer. In addition, the seams between finishing elements (for example, when leveling walls with plasterboard) can be filled in one pass.

Conventional gypsum mixtures require at least double filling: during the first pass, the joint cavity is filled, and during the second, the reinforcing material (sickle or fiberglass) is covered.

Non-shrinking gypsum mixture.

Rating of the best putties

| Nomination | place | Name of product | rating |

| The best starting putties | 1 | Volma Standard | 4.9 |

| 2 | Founds Ekonsilk | 4.8 | |

| 3 | Bolars façade | 4.7 | |

| The best finishing putties | 1 | Sheetrock SuperFinish | 4.9 |

| 2 | Weber vetonit LR+ | 4.8 | |

| 3 | Knauf Rotband Pasta | 4.8 | |

| 4 | Ceresit CT 225 | 4.7 | |

| The best universal putties | 1 | KNAUF-Fugen | 4.9 |

| 2 | VGT acrylic universal | 4.8 | |

| 3 | Weber vetonit JS | 4.7 | |

| 4 | UNIS BLIK | 4.6 | |

| The best putty for wet rooms | 1 | Weber vetonit VH | 4.9 |

Regulatory Requirements

- Is there a GOST for the production of putty??

Cement (as well as other building mixtures with a cement binder) are produced in accordance with GOST 31357-2007, gypsum putty mixtures are produced in accordance with GOST 31387-2008. For the convenience of the reader, I will present here the key requirements of the standards.

Cement mixtures

Any cement building mixtures must comply with GOST 31357-2007.

The document regulates:

- Humidity of the mixture. It should not exceed 0.3% for putties on a combined binder with an amount of cement not exceeding 80% of the total amount of binder, and 0.2% for mixtures with a large amount of Portland cement;

- The amount of aggregate with a fraction size higher than the maximum. It should not be more than half a percent. Estimating the amount of coarse aggregate is carried out extremely simply - by sifting through a sieve with the appropriate mesh size;

A simple aggregate size test.

- Water absorption after the finishing material reaches full strength. It should not be more than 15% for mixtures using a combined binder with less than 80% cement and more than 8% for mixtures with a large amount of cement;

- Adhesion to the base. The minimum permissible values are 0.4 MPa for exterior finishing and 0.25 for interior finishing;

- Packing method. Mixtures can be supplied in polyethylene bags, in multi-layer packaging made of kraft paper and in paper bags with polyethylene liners.

Typical packaging of cement mixtures.

Gypsum mixtures

Here are the standard requirements for gypsum mixtures:

- Humidity should not exceed 0.3% by weight;

- The maximum permissible aggregate fraction size is 0.2 mm, while the aggregate content of larger fractions should not exceed 0.3%;

- The beginning of setting should occur no earlier than 60 minutes from the moment the mixture is mixed;

In practice, long before setting begins, the mixture thickens and becomes unsuitable for application. The practical ceiling of its viability does not exceed 30-45 minutes.

That is why gypsum putty is prepared in small portions.

- After the putty has hardened, the tensile strength during bending should not be less than 1 MPa, and the compressive strength - less than 2 MPa;

- The adhesion strength of the hardened putty to the base must be equal to or exceed 0.3 MPa;

- The same types of bags can be used as packaging as for cement mixtures - polyethylene, made from multi-layer kraft paper and paper with polyethylene liners;

- The weight of one package should not exceed:

| Type of packaging | Maximum permissible weight |

| Plastic bag | 8 kg |

| Bag | 50 kg |

In practice, gypsum mixtures are sold packaged in 25-30 kg packages.

All about putty

Page navigation

Putty is a special building material for leveling walls for subsequent finishing - painting or wallpaper. All putties, regardless of type, contain glue with mineral fillers.

In fact, this is a more modern type of plaster, which has a fine fraction, which allows you to achieve a smooth surface. Also, the putty has a light color, not showing through even through thin layers of paint, which allows you to achieve the most aesthetic result.

Putty and putty are the same thing. Both of these names are correct and can be used when writing.

Calculation

- How much finishing putty is needed for 1 m2 of wall or ceiling surface?

With a finishing layer thickness of 1 millimeter, the consumption per 1 m2 is 1 - 1.2 kg of dry mixture. Accordingly, a 3-mm layer will give a consumption of about 3-3.6 kg, and a 30-kg bag will be enough for 8-10 square meters of finishing.

The thickness of the putty layer usually does not exceed 2-3 millimeters.

Wall sanding tools to help with large areas

Special grinding machines have been developed for grinding large areas. In this case, for walls, surface grinders are used, which have a large working surface, and for ceilings, machines with special attachments are used that create a vacuum and thereby stick, which greatly facilitates physical labor.

Based on the principle of operation, they are distinguished:

- tape;

- vibration;

- eccentric;

- orbital.

When choosing a model, you need to pay attention to the fact that orbital ones cannot be processed in corners, and tape ones are better suited for removing thick layers.

It is not recommended for non-professionals to use grinders, since when finishing leveling the main thing is not to remove excess.

Preparation

- How to dilute cement putty?

It’s extremely simple: add the amount of water specified by the manufacturer to the dry mixture and mix. For mixing, it is advisable to use a construction mixer, drill or hammer drill with a whisk. It is not advisable to mix the putty manually with a spatula: in this case, it is difficult to obtain a uniform consistency of the mixture.

When adding water, strictly follow the manufacturer's recommended recipe. A mixture that is too thick will not spread onto the base; a mixture that is too thin will flow down it.

Mixing cement putty.

- Mixing gypsum putty is done in the same way.?

No, in this case the procedure must be strictly defined:

- Fill a clean and wide container (basin or paint bucket) with about a liter of water;

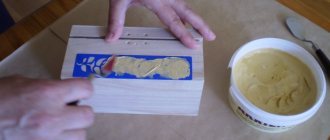

- Pour the dry gypsum mixture into the container, distributing it as evenly as possible over the surface of the water surface. And in this case, it is advisable to adhere to the proportion recommended by the manufacturer: how to dilute the putty is always written on its packaging. So, only 7 liters of water are added to a 25-kilogram bag of Knauf Fugen dry gypsum mixture;

Gypsum is poured into a container with water. If you pour water into a dry mixture, insoluble lumps will form at the bottom of the container.

- Wait about five minutes and thoroughly mix the swollen mixture with a mixer or whisk. After mixing, you need to wait another 3-5 minutes, and only then the putty will be ready for use.

Before preparing a new batch, always thoroughly wash both the container in which you prepare the putty and all tools. If this is not done, lumps of set gypsum from the old portion of putty will begin to leave untidy furrows trailing behind the spatula.

Where to buy quality putty?

In the Remonstr online store you will find a wide selection of putties for wallpaper, painting and other finishing at the lowest prices in Samara. Our assortment includes putties from Russian and foreign manufacturers, the quality of their products is always high: Berg, Forman, Makroflex, Knauf, NOVBYTHIM, Isover, Henkel, Quelyd EK Dry Construction Mixes, Dufa, Belcolor, Ursa, Prestige ", Penosil, "Rogneda", Tikkurila, etc.

Our qualified and friendly staff will always help you choose the right putty for painting or wallpaper, and calculate how much it will be needed for work in your home. If you wish, you can perform this calculation yourself using the convenient calculator on our website.

Finishing

- What tools are used to apply finishing putty before painting?

Use a wide (30-35 cm) spatula - regular or rectangular. The putty is applied to it with another spatula of smaller width (10-12 cm). Application is carried out with sliding movements and spreading.

Container and tools for filling with gypsum mixtures.

If you are puttingtying the base in several layers, alternate horizontal and vertical movements of the spatula. This will leave fewer grooves on the surface.

Puttying the wall with gypsum mixture.

- Do I need to prime the base for putty??

The answer depends on what binder is included in the mixture and on what basis it is intended to putty. In general, it is pre-primed with strengthening primer for mineral bases; however, cement plaster under cement putty can simply be moistened with water.

Penetrating acrylic primer.

- Is it possible to apply putty over the finishing putty to eliminate surface defects that you missed earlier?

If they are on the same type of binder, it’s possible. Gypsum works well over plaster and cement mixtures work well over cement finishes. Acrylic putty can be used on any surface.

If you come up with the strange fantasy of applying starting cement putty over the finishing gypsum putty, this is also possible, but the base will have to be pre-primed with concrete contact (adhesive primer with quartz sand), which will make the wall rough and improve the adhesion of the finish to the base.

Concrete contact is an adhesive soil with the addition of quartz sand.

- Is it acceptable to apply putty over paint?

In general, no, all old coatings must be cleaned off before filling. The exception is acrylic putty over acrylic water-dispersion paint. It firmly adheres to the base, does not lag and does not bubble.

Before puttying, old coatings are removed.

- How long does it take to dry cement, gypsum and acrylic putty?

With a layer thickness of 2-3 mm - no more than a day for a cement mixture and 3-5 hours for gypsum and acrylic. However, drying does not mean the completion of hydration processes:

- Like most Portland cement-based mixtures, cement putty gains full strength only a month after application;

- Gypsum finishing can be painted with water-dispersion paints only two weeks after puttying. If you rush, you can end up with dark spots and streaks in areas where the plaster is at its thickest (for example, at the seams between sheets of drywall).

There should be at least two weeks between puttying with gypsum-based mixtures and painting.

- How to finally prepare a surface for painting after puttying?

After filling with plaster or acrylic, the walls are sanded with a hand float with a sanding mesh or a sander. My choice is an orbital sander and #80 mesh for the first pass and #120 for the second. You need to sand in bright, oblique lighting, which will highlight the slightest irregularities in the base with shadows.

After sanding, be sure to inspect the surface under the prevailing lighting in the room (natural or artificial). The appearance of a ceiling or wall can change noticeably depending on the angle of light.

Sanding the finish with a hand float.

Cement putty is not sanded, but rubbed with a hand float (wooden or polyurethane). Grouting is done on a hardened but not dried finish.

The next stage of preparation for painting is dust removal. You can get rid of dust using a vacuum cleaner or an ordinary broom.

The last stage is priming with penetrating primer. It will increase the strength of the finish, improve the adhesion of the paint to it, and at the same time reduce its consumption, reducing the absorbency of the surface.

Ceiling primer for painting.

How to putty drywall

Puttying the main area of drywall is carried out in the same way as we described above. The difference lies in the surface preparation. If you have seen walls covered with plasterboard, you should know about the existence of seams and open screw heads that must first be hidden.

For this, a special putty is used. One of the affordable and high-quality materials with the necessary properties is Knauf Fugen.

Knauf Fugen

Step 1 – gluing the seams with serpyanka. We glue all seams on the surface with fiberglass mesh. Perforated corners are installed on the outer corners, which can be reinforced with the same putty, self-tapping screws or staples through a stapler.

Step 1 – gluing the seams with serpyanka

Step 2 – sealing the seams. The diluted putty is driven into the seams directly through the serpentine with perpendicular movements, after which the excess is removed with a wide spatula. The task is to achieve the closure of the grid and not go beyond the plane.

After the first layer has dried, a second one is made, which aligns the seams in the same plane with the drywall.

Step 2 - sealing the seams

Important! Embroidered end seams will protrude beyond the plane of the drywall due to the lack of a cavity, so it is important to make the least noticeable transitions in these places.

Step 3 – sealing the screws on the drywall. The screw heads are sealed with the same putty. Everything here is simple and extremely clear.

Next, the walls are cleaned, after which the main layers of putty can be applied. The procedure will be similar, so we will not repeat it.

Step 3 – sealing screws on drywall