Andrey

14549 0 4

Andrey June 12, 2017 Specialization: facade finishing, interior finishing, construction of dachas, garages. Experience of an amateur gardener and gardener. We also have experience in repairing cars and motorcycles. Hobbies: playing the guitar and many other things that I don’t have time for :)

What is polyester putty with fiberglass, what properties and characteristics does it have? Since I often have to work with this material, I will answer these questions. In addition, I will tell you for what purposes this material can be used.

Polyester putty is a widely used material for leveling metal surfaces.

general information

Like any other putty, this building material has a paste-like appearance and is a polyester product mixed with fiberglass. Its production is based on modified unsaturated polyesters. Since these resins are very hard in their natural state, styrene is additionally added to them in order to give them plasticity and consistency suitable for use. It is not difficult to guess that the addition of fiberglass in putties serves to impart reinforcing properties to the material. The strength of the putty increases, and some other characteristics also improve. It is necessary to pay special attention to safety rules when working with this material. The solvent contained in polyester compounds is unsafe for human health. Therefore, when working with such putty in a closed area, you should use protective equipment, namely, use a respirator and ventilate the room from time to time. Polyester based putties are sold with two components. Before using it, it must be mixed with the hardener from the package.

Conclusion

Now you know what glass fiber reinforced polyester putty is, what properties and characteristics it has, and for what purposes it can be used. Additionally, watch the video in this article. If you have any questions regarding this putty, you can contact me in the comments.

Did you like the article? Subscribe to our Yandex.Zen channel

June 12, 2022

Construction Chemicals, Plaster and Wall Putty

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

Properties

Fiberglass putty, like any building material, has both advantages and disadvantages.

Advantages

- The product can form a thick layer. The thickness of one coating can be made from 5 to 8 mm.

- Polyester putty, unlike acrylic putty, does not shrink after drying, even with a thick layer.

- The fiberglass contained in the putty prevents the coating from cracking during operation.

- Strength, thanks to which this building material can be used not only to eliminate dents and cracks, but also through holes.

- Resistance to fluctuations and vibrations. Thanks to this quality, this building material is popular among motorists. It is often used to repair cars.

- Fast hardening. The time at which the putty hardens is approximately 20 to 30 minutes. You can begin the grinding process within 15 minutes. after covering.

- Resistance to atmospheric agents. This product is not afraid of moisture, temperature changes, or ultraviolet rays.

Which putty is better to choose?

Polyester leveling paste is recognized as the highest quality and most convenient to use. This is a two-component composition. Before use, the mixture is prepared by adding a small amount of hardener (catalyst) to the base material (resin).

The advantages of this variety, compared to one-component nitrocellulose and acrylic materials, are as follows:

- low shrinkage;

- high polymerization rate.

Epoxy putties are becoming increasingly popular. They protect the metal from corrosion.

Disadvantages: long drying time and difficulty in grinding due to high hardness.

Acrylic pastes are used to eliminate the smallest defects.

Leveling deep unevenness is carried out using 2 types of compounds:

- filler (roughing);

- finishing (finishing).

For final finishing of large areas, it is recommended to choose a liquid spray product.

Flaws

- The product is toxic. As mentioned earlier, the solvent in the composition of polyester putty has a negative effect on the human body.

- Fast hardening. The composition must be used within 4-8 minutes. after its preparation. Consequently, the work must be done very quickly, which, as a rule, beginners have some problems associated with this.

Putty with green fiberglass from the Novol Fiber brand leaves a good impression.

Scope of application

The most common use of putty with fiberglass is for leveling metal surfaces, which is why motorists often use it. The polyester mixture is also widely used for the restoration of wooden objects. It has excellent contact with surfaces made of various materials, for example, concrete, wood, products with paint and varnish coating, natural stone, etc. Putties of this type should absolutely not be used as a coating for acid-curing soil, and they should not be used to putty objects made of thermoplastic or viscoelastic material.

The best manufacturers of automotive putties

The products of the following companies are highly rated:

- Carfit. One of the most common is Soft brand paste with a lightweight structure. Hollow glass or plastic balls are used as filler.

- Novol. The assortment includes fiberglass composition of the Fiber brand.

- CAR Fit. For example, the liquid composition Spray is popular.

- Roberlo. The popular composition A80 fills microcracks well and forms a smooth surface.

- DuPont. Of the line offered by this manufacturer, the most popular is finishing putty 791R.

- ICR. The liquid composition Sprint 2K HS Spray was highly rated by users. The putty does not spread even on vertical surfaces, but at the same time it is elastic and sands well.

- Chamaleon. The company produces a wide range of coatings, incl. lightened.

Each manufacturer produces several products designed to repair surfaces with varying degrees of damage. For example, Chamaleon 503 green fiberglass paste is well suited for filling large irregularities.

Prices

The cost depends on the weight of the building material and the manufacturer. Below are approximate prices for individual putty mixtures with fiberglass based on polyester compounds that have won the appreciation of the buyer. The REOFLEX GLASS FIBER brand weighing 2 kg costs 620 rubles, Body Fiber weighing 240 g costs 340 rubles, Mobihel weighing 0.5 kg costs 280 rubles. Rules for using putty with fiberglass Regardless of the surface that will have to be restored, this process includes several stages:

- surface preparation for work;

- padding;

- puttying;

- grinding.

Instructions for implementation

First you need to prepare the following materials:

- degreaser;

- abrasive paper grades P80 and P120;

- primer mixture (it should be selected depending on the type of surface being treated).

Preparing the site for coating is carried out in stages in the following sequence:

- If there is old paint or varnish on the surface, as well as crumbling or peeling coating, all this must be cleaned off.

- If the metal surface is affected by rust, it must be removed. This is done using abrasive sandpaper.

- If narrow gaps or cracks are to be sealed, they should first be widened. This is done so that the putty fills them thoroughly.

- Degreasing the surface. Wipe the treated areas with a cloth moistened with a special-purpose product.

Criterias of choice

The composition is selected taking into account the following circumstances:

- The nature of the damage is through or blind.

- Heights of unevenness.

The choice also depends on what surface you plan to repair. Purchase a paste with good adhesion to this material.

Pay attention to the following parameters of the repair composition:

- Curing time.

- Minimum application temperature.

- Issue date and expiration date.

- Storage conditions.

- Porosity, grindability.

- Price.

Expensive compounds are easy to use and provide a durable, smooth coating.

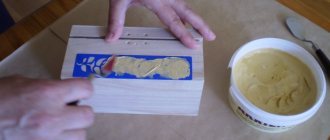

Puttying

Before using the putty, as mentioned above, it must be mixed with the hardener in the proportion specified by the manufacturer: 2-3 g per 100 g. Then mix thoroughly. How to prepare the mixture for use is described in detail in the instructions on the package. Since the solution is usable for only 4-8 minutes, it should be diluted in small quantities. The mixture is applied with a spatula and immediately leveled. We must strive to ensure that the surface is immediately as smooth as possible. The thickness of the coating, however, should not exceed the maximum value specified by the manufacturer. Now you need to wait until the putty applied to the surface dries and hardens. If necessary, puttying can be done with another layer.

Polyester putty

If anyone in their life has ever had to deal with serious repair work, then they are definitely familiar with many construction and finishing materials, including putty. Putty is an indispensable finishing material that allows you to qualitatively prepare the surface for further application of any finishing layer (wallpapering, painting, etc.). Since its inception, this finishing material has had a gypsum or cement base for a long time. Some time later, putties based on polyester resins began to be produced. The development of the chemical industry contributes to the emergence of new materials. And today the so-called polyester putty is very popular.

It is named polyester due to the fact that its composition is based on a mixture of two components - polyester mass and filler. Thus, two-component polyester putty is a white plastic material to which a hardener is added. Depending on the work for which the mixture is being prepared, it is necessary to obtain a certain structure, for which substances such as fiberglass, aluminum powder, and glass micro-granules are added to the putty.

In this regard, polyester putties are classified as follows:

- Universal polyester putty. It contains two main elements, as well as specialized minerals and silicone- and asbestos-free fillers as additional additives. It is distinguished by its ability to dry in a fairly short period of time. This putty is perfect for leveling surfaces made of metal, wood, concrete, aluminum, zinc, and polyester. Thanks to its unique properties, which include plasticity, strength, and minimal shrinkage, it is easily applied to the surface and perfectly hides various irregularities.

- Facing putty. It has a fine-grained structure. Just like the previous type, it takes little time to dry. Mainly used to eliminate minor irregularities, scratches, and pores. This type of finishing materials can act as a finishing layer for painting or a primer mixture. It fits well on surfaces, the main material for which is concrete, metal, wood, polyester or zinc. It is characterized by great flexibility and fillability, thanks to which the work proceeds quite easily and quickly.

- Fiberglass putty. It is based on fiberglass filler. This material is used to level out damage of varying volumes, as well as small through holes and areas damaged by rust. Shows resistance to various mechanical damage.

In addition, all putties have another classification depending on the fraction:

- Rough. They are heavy putties designed to smooth out all the main irregularities, fill unnecessary spaces and depressions (for example, seams between sheets of drywall), and also hide gross defects. Another advantage of this type of putty is that it imparts additional strength to the surface to which it is applied. It has a coarse fraction and forms a layer with visible roughness, which is not yet ready to be covered with paint, varnish or wallpaper.

- Finishers. Apply over rough putties. Used for final leveling of the surface and making it smooth. They have a very fine fraction and are called finishing due to the fact that after drying they form a layer on which there are no roughnesses and on which paint can be applied and wallpaper can be glued.

In addition to the characteristics and classifications of putties listed above, when choosing it, you should also take into account the material on which you plan to apply it. After all, each putty will exhibit its properties differently, reacting with a particular surface. Therefore, it is impossible to cover, for example, plasterboard walls indoors and a car body with the same type of finishing material. By the way, the latter has its own special type, which is called automotive polyester putty.

Automotive polyester putty is a powder or paste finishing material that has certain properties. Puttying a car body is a very important and painstaking process that requires skill, patience, time, as well as the availability of high-quality material and tools for the job. After all, if you treat this process irresponsibly and do everything in a hurry, you can end up with a poorly finished body. This will cause the fact that when priming the body, all irregularities, depressions, as well as transitions from putty to metal will be visible. Moreover, even the smallest flaws and scratches will be clearly visible. Accordingly, it will also be impossible to hide them when painting, as a result of which the surface of the car will not have the desired evenness and glossy surface. Therefore, you need to take a serious approach to both the choice of automotive putty and the process of applying it.

It is worth saying that each type of putty has its own nuances of preparation for work. You cannot prepare putty for both concrete and metal using the same recipe. This is due to the presence (or absence) of certain components in the composition of these finishing materials. For example, putties intended for application to metal surfaces contain components such as a catalyst and a hardener, due to which they are distinguished by their high degree of adhesion to the surface, as well as the speed of drying.

Automotive putties also contain metal powder, which allows you to properly mask various cracks and scratches, thereby making the surface perfectly smooth and glossy, and also giving it greater resistance to vibration. However, such putties cannot be used on painted or plastic surfaces. Before applying them, you should carefully prepare the surface by removing all traces of paint, rust, and also degreasing the surface.

Some rules for applying polyester putty:

- The putty should be applied in a thin layer by hand. This will give you a nice, even surface.

- It is necessary to mix the putty components just before using it, carefully studying in what proportions to add the hardener. Otherwise, the material will quickly thicken and become unsuitable for work.

- As a rule, the hardener has a red color, which should disappear with thorough mixing. Therefore, the answer to the question of whether the putty is ready for application is simple - the mixture is ready for use when the red color has disappeared. It is also worth paying attention to the fact that the amount of finishing material must be prepared in such a way that you can use it at a time. The finished mixture cannot be stored; it hardens and becomes unusable. Thus, the hardener and the putty itself should be mixed in portions, and not the entire amount at once.

- Manufacturers take about 5-10 minutes to apply the mixture, after which it begins to quickly thicken, making it impossible to use;

- The putty should be applied only to a well-prepared surface;

- After finishing work, all tools must be washed and dried.

In addition, it is worth noting that the components of the putty mixture should be mixed strictly according to the instructions and in the proportions specified by the manufacturer. If there is less hardener than needed, then the applied mixture will take much longer to harden or it will not harden at all. In another situation, when there is more hardener than required, the mixture will not harden faster either. However, after drying, a strong hardener will remain in the material, which will lead to stains after painting the car.

Thus, for an ideal surface, you should choose high-quality finishing materials, and also take a meaningful approach to the filling process itself. There is a golden rule - the better the putty is applied to the surface, the less time it takes to polish it.