The outer part of the corner is cut at an angle of 45°. In order to properly glue the products onto the window slopes, an adhesive is applied to the inside of the product, maintaining an interval of 1 - 1.5 cm.

Applying glue to the corner The products should be fastened by pressing them firmly to the corners of the window slopes. To achieve strong adhesion, the products should be secured with masking tape . When working with liquid PVA, the strength of the connection is ensured after 1 minute.

It is recommended to fix the corner after gluing with masking tape.

Dimensions

Dimensions are selected based on the type of work to be done - indoors or outdoors . The condition of the corner is also assessed for the presence and nature of defects and damage.

To finish external slopes use wide corners

When installing corners on slopes, it will be enough to use elements measuring 10 x 10 mm or 20 x 20 mm. Wider elements are used for exterior window decoration.

Main characteristics

Among other characteristics, such as fastening method, material of manufacture, manufacturer, color and weight, special attention should be paid to the dimensions of the fittings. Corners for slopes come in the following sizes :

- 10x10;

- 20x20;

- 25x25;

- 30x30;

- 40x40;

- 50x50.

All dimensions are indicated in mm, so it’s easy to figure out which length is best to choose for your window. The smallest ones are suitable in those places where you just need to strengthen a corner, and those that have dimensions of 50x50 mm will already allow you to hide serious imperfections in the finishing.

Manufacturers also produce corners with dimensions of 60x60 mm. The entire size range is available in both plastic, aluminum and wooden models. Wider elements are often used for exterior decoration.

Important! The Russian market has corners of local production and foreign production. They are supplied in 2700mm lengths and can also be sold to order.

Glue selection

When choosing an adhesive composition, it is necessary to give preference to such products that can be used for PVC products.

It is common to use silicone sealants for gluing a product, but it is important to consider that they are washed off with water and lose their qualities over time. As a result, the product may become loose .

Installation of slopes on plastic windows and their finishing has recently been increasingly carried out using “liquid plastic” technology.

Liquid plastic is used to glue slopes using new technology

For this purpose, glue of the same name is used, which is a liquid plastic. This material has many positive qualities:

It is not recommended to use silicone sealant for gluing slopes

You can use it to glue the starting profile. Liquid plastic is used as window sill adhesive. This modern material is also used for installing plastic trim on windows.

Peculiarities

These elements have become widespread in various fields due to their positive qualities.

- used to mask corner joints of various materials; right angles are formed at the finishing site;

- These are durable elements, the service life of which is estimated at tens of years; they are easy to install and process;

- the presence of several types of materials from which these products are made allows them to be used in different conditions and for different jobs; a wide range of colors and textures for the appearance of fittings; they are affordable;

- like the PVC profile for slopes, the fittings are highly moisture resistant;

- despite the fact that plastic slopes are susceptible to the formation of condensation on their surface, neither they nor the corners rot or become moldy;

- installation of plastic elements on slopes made of plaster allows you to form perfectly even corners;

- during repair work, metal perforated products are used to strengthen joints and corners;

- PVC profiles and corners are safe for the environment and people;

- due to the low weight of the PVC profile and corner, the structure is not loaded;

- they are resistant to mechanical stress and are not subject to deformation under the influence of the sun.

Preparation and installation

To learn how to glue plastic corners, you can familiarize yourself with the sequence of work.

First you need to make sure that the corners do not have obvious protruding elements. Before gluing the product, it must be degreased.

How to glue plastic corners to slopes efficiently and reliably is described below.

It is recommended to fix the corner after gluing with masking tape.

Source

Variety of plastic corners for windows

For the beauty and aesthetics of internal and external slopes in window openings, it is best to install plastic corners on the windows.

From our article you will learn how practical such a design as corners for plastic windows is. We will introduce you to different types of corners, name the sizes of plastic corners and indicate their prices.

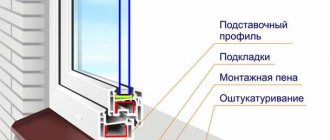

Plastering slopes.

Slopes on windows, doors and other openings are especially important places, since a person looking there automatically compares them with a window or door. That is, with straight lines. This means that no deviations are allowed - deviations from the lines of the window or door. As for matching the level, the windows can easily be slightly blocked.

Therefore, slopes are plastered mainly according to level. It is recommended to use a corner for plastering slopes. And, again, as a plaster beacon. If the slopes were mounted from gypsum fiber board or gypsum board, and not of very high quality, then a perforated corner will help eliminate all the shortcomings.

By the way, before installing gypsum plasterboard or sandwich panels on slopes, the basic brick slope, according to technology, must be covered with plaster. The perforated corner installed at the same time will help to correctly align the sheet of drywall.

Comparing types and sizes

Framing always begins with choosing the type and size of the plastic element. The table shows data about plastic corners, their sizes and types for slopes:

| 20*20 – 50*50 mm, standard length, attached to give strength. | |

| Not equilateral: | 5*17 and 20*25 mm, lining of arch openings, usually installed on curved compositions. |

| T-shape: | 12*10, 18*10, 20*10, 22*10 mm, installation is necessary to hide the seams. |

| Removable (with latch): | Standard, the shelf bends for dismantling. Easy to install, no need to stick. |

Important! The colored plastic corner for internal slopes is available in lengths of 2.6 m, 2.7 m, 2.8 m, 3.0 m.

How to glue plastic corners onto slopes (video)

Plastic corner

Plastic corner

BI PLAST IS THE FIRST COMPANY TO PRODUCE PLASTIC CORNERS.

The production company offers to buy a plastic corner for various needs. Our range is represented by products that are designed for finishing various joints, door and window openings, as well as installing PVC panels and corners. The catalog also includes self-adhesive strips of various shapes and colors.

Bee-Plast

We started producing plastic corners in 2002. Bi Plast became the first company to produce corners with protective film, which are widely used by window companies on slopes.

Flexible PVC corner is installed on window slopes, used to protect wall corners, and installed on wallpaper. “Plastic corners for slopes” are used in conjunction with sandwich panels.

The decorative plastic corner is presented in a full range. Wood-look PVC corner, colored, plain, white. Available in any sizes, arched corner.

The plastic corner is made from soft or hard PVC and can be covered with mounting film to protect against contamination during work. After gluing to the corners of the walls, the film is removed.

Decorative plastic corner is widely used in any repair. To cover any joints. To protect wallpaper from abrasion and premature wear when installing window slopes.

You can buy a decorative corner from us wholesale and retail. Ask our managers for wholesale prices.

Detailed description of the corners:

Plastic corners with Bee-Plast protective film

Plastic corner with Bee-Plast protective film is designed for finishing internal and external corners.

The product is used to bridge the gap between two planes, for example, window and door blocks. It protects the surface from premature wear due to its strength and resistance to negative environmental influences. A plastic corner with a protective film Bee-Plast is a high-quality finishing material, the production of which is carried out using modern technology. Each product has a right angle of 90°, however, due to the elasticity of the material, it can be given any desired degree.

Due to its flexibility, the plastic protective corner does not lose its shape and does not break during installation and operation. Installation is carried out using special adhesives, which makes this product universal.

The protective film is easily removed from the surface of the plastic corner without leaving any marks on it.

White PVC corners without film

PVC corner without film is made by extrusion and due to this has less elasticity.

The product is also designed to protect window slopes and corner joints of walls from wear. Easy to clean and has a long service life. Installation of PVC corners is also carried out using glue. We offer products whose length is 2.7 m.

Colored PVC corners

The colored PVC corner has all the same properties as its white counterpart.

Suitable for use on internal and external corners. This product is convenient because it can be matched to the color of the walls, and it will not stand out against the general background. We offer PVC corners of various shades and textures, so you can easily choose the right option.

Plastic corners for plastic panels, window slopes and lining

This plastic corner is designed for the convenience of connecting corners when decorating walls with plastic panels and lining, as well as installing window slopes.

We offer products of various widths and shapes, which are very convenient to work with. We are suppliers of any plastic corners to large wholesale companies throughout Russia due to the low price and quality of our products. We also have the opportunity to sell our products to construction teams and retail customers.

The F-profile is used for external and internal finishing of window slopes.

Self-adhesive plastic protective corners (coverings)

A self-adhesive plastic protective corner, or flap in other words, allows you to hide any gaps that arise during the finishing process.

The edges of the product are equipped with a soft strip, which ensures a tight connection. These PVC corners are easy to attach because double-sided tape is glued to the back. Most often used when installing plastic windows.

We offer to purchase the material both in rolls and in sections.

What will you need?

When starting work with the formation of a ceiling from PVC panels, you should first of all use a starting type of plank. This is the name of the P-shaped molding that locks the panel from the end. Similar strips are also used when panels are placed on walls. But there they are already needed for another task - a more elegant design of door and window openings.

A profile in the shape of the letter F must be placed at the ends; it is needed to make corners and joints between PVC and other materials more beautiful. This profile is also used in the design of recesses for doors and windows. The joining is done using a molding like the letter H. It is used when it is necessary to connect the short edges of the panels due to the fact that one of them is not long enough to cover the ceiling space.

The outer and inner corners are needed respectively to mask the joints in different corners. Using a universal decorative corner, you can cover the outer intersections of the canvases, converging at an angle of 90 degrees.

Ceiling skirting boards can intersect:

- on ledges;

- next to the beams;

- near the columns.

In all three cases, outer corners of a special type (they are called that for ceiling plinths) turn out to be very valuable. Such products should not be confused with similar-named designs directly for panels.

Internal corners for baseboards help seal intersection points in areas farthest from the entrance. Sometimes the skirting boards are not long enough, and then a special connecting element helps solve the design problem

An important component of the fittings for plastic ceilings are slats (guides), from which the lathing is formed

Glue selection

When choosing an adhesive composition, it is necessary to give preference to such products that can be used for PVC products.

It is common to use silicone sealants for gluing a product, but it is important to consider that they are washed off with water and lose their qualities over time. As a result, the product may become loose .

Installation of slopes on plastic windows and their finishing has recently been increasingly carried out using “liquid plastic” technology.

Liquid plastic is used to glue slopes using new technology

For this purpose, glue of the same name is used, which is a liquid plastic. This material has many positive qualities:

It is not recommended to use silicone sealant for gluing slopes

You can use it to glue the starting profile. Liquid plastic is used as window sill adhesive. This modern material is also used for installing plastic trim on windows.

Advantages

As already mentioned, plastic corners for slopes have a number of advantages, which will be listed below:

- Ease. Indeed, this material is light in weight.

- Price. Plastic ones are cheaper than other materials that are used for the same purposes.

- Cutting. During the installation process, excess parts will need to be cut off, and this is done very easily, since plastic profiles are easy to cut.

- Fastening. They can be secured with self-tapping screws, glue or putty. In any case, the fastening will be of high quality.

- Color. It has a large number of colors, so the consumer can choose a profile of one color or another at his discretion.

- Durability. The service life of plastic materials is just over 100 years.

- Finishing. Plastic corners do not require subsequent finishing, and this in turn saves money spent on repair and finishing work.

- View. Window slopes, seams, arches finished with this material will have a neat and finished look.

- Protection. As already mentioned, the material will perfectly protect the corners from mechanical damage and help ensure that the wallpaper does not peel off.

Blitz tips

Tip 1 . When buying a flexible corner, pay attention to its shape - if the product does not hold the given configuration, then it is better to refrain from purchasing.

Tip 2 . In the case of small volumes of work (up to 10 meters) on plastic surfaces, it is more advisable to use a “second” adhesive gel - it does not spread, otherwise it is better to use a more professional product - Cosmofen CA-12.

Tip 3 . It is necessary to buy decorative elements after the angular size of the slopes is clear. For a clear 90°, a rigid profile is suitable; for deviations to a greater extent, it is more convenient to use a flexible folding product.

Tip 4. When using compositions from the “liquid nails” series, you need to pay attention to the initial setting force - it should not be less than 40–50 kg/m².

Fixing elements for plastic

The method of installing PVC panels, that is, attaching them to walls and ceilings, depends on the characteristics of the room - humidity level, curvature of working surfaces, the presence of communications and temperature bridges. In each individual case, certain fastening elements are used, which will be discussed.

There are three different methods of fixation.

The most inexpensive and simplest means of fastening plastic is silicone glue or “liquid nails.” You need to choose a special heat-resistant type of product. Silicone dries quickly, has high strength, allows the panels to be assembled in a short time, however, it can be used with a perfectly flat wall surface, and during repairs, this method does not allow replacing a damaged PVC lamella.

Clippers are universal parts; unlike nails, they do not damage the joints and locks of panels, fit tightly to the surface and ensure high quality assembly. Despite the strength of the fastening with brackets, minimal distortions remain, allowing the walls to settle while the panels are intact.

Application of plastic corners

The finishing perforated profile is used at the beginning of finishing work when plastering and finishing with plasterboard. Placing it under the wallpaper helps to secure the top layer of putty and level out the outer corners.

Note: Finishing profiles do not require gluing; they are pressed into the plaster.

Of course, the use of these corners cannot solve all corner problems, so a plastic one is installed as an additional option to the perforated profile. This will help to achieve full protection of the corners, hide irregularities and crevices, and also improve the appearance of the corner itself. Also, don’t limit yourself to just finishing the outer corners. The internal ones are also closed, for example, to disguise the transition between different types of finishes.

Wall corners, depending on the material of manufacture, are:

For wooden or tiled walls, you will need corners made of the same materials, since plastic will not look good here. For all other finishes, PVC corners occupy a leading place.

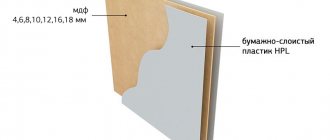

An exception may be corners made of metal and MDF. They are used to cover the street side of a window opening.

Peculiarities

The popularity of PVC profiles is justified by the following features:

For tiles

Aluminum profiles are used. They are processed using chemical and thermal methods, polished, varnished or laminated. On one side of the corner, the perforated strip has cuts; it is laid on the surface of the wall or step. And the second is decorative, having a small protrusion on the inside into which the side end is inserted when laying the corner. The tiled corner also plays a leveling role during finishing.

Arched corners made of plastic

They differ from others in that they have different side sizes and are very flexible.

They come in color and decorative solutions. They are produced up to 3m long. Arched corners help hide the line between the drywall and the slope. This method of constructing arched openings is the simplest and most inexpensive. However, you need to have an idea of how a plastic corner is bent correctly, and simple corners will not work here.

Sticking a simple corner to drywall can lead to peeling and breaking of the profile. Therefore, it is better to immediately use a special arched profile.

As a rule, profiles with a length of 25 to 30 millimeters with a reduced side flange are used for arches. Due to the fact that the side shelf is slightly smaller, the profiles can bend well, which prevents them from moving away from the edges when gluing.

Important: When gluing a corner to an arch, you should first mark the places of their contact for applying glue. If this is not taken into account and done by eye, then a large amount of glue will be wasted.

If the arch has a small radius, then the corner will have to be bent quite strongly that even a special corner may not withstand it and will warp. In such situations, the hot bending method is used. At the same time, fix the corner at one end and heat it to 60-70C, while simultaneously pressing it against the drywall. While the material is cooling, roll it along the profile with a paint roller.

Window openings and doors

Replacing old windows with double-glazed windows entails re-plastering the slopes and the need to select material to cover the outer corner.

Traditional plasterboard slopes and perforated metal corners on the outer corner contribute to ideal surface leveling. However, even this is not an ideal solution, since the window is in private use and damage to the edge cannot be avoided. Therefore, a plastic corner is simply needed here. The dimensions of the plastic corners depend on the dimensions of the window opening.

For example, for the plasterboard-wallpaper corner, profiles of 20*20 mm are suitable, and for the transition from an MDF board to wallpaper, profiles of 25*25 mm in size are taken. You will also need corners to close the gaps between the window and the slope and between the window sill and the wall. Here you will need T-shaped corners. Many people believe that it is not necessary to close the line between the slope and the window sill. However, a plastic window sill has the ability to spring back even from small loads, so after some time the material sealing the corner joints may crumble. Maybe it would be more humane to close this gap with a profile.