One of the best options for exterior finishing is clapboard cladding on the outside of the house. Thanks to this material, your home will begin a new life, in a new appearance. Although it differs from the interior, such finishing will not only give the building a beautiful appearance, but will also improve sound and thermal insulation. But to carry out the work correctly, you need to know how to choose the right lining, and how the outer cladding is performed with lining.

Types of lining

First you need to study the varieties of this material. First of all, there are two types:

- Plastic. Helps create a high-quality coating that will last for many years because it does not corrode. It is also worth noting its high level of moisture resistance and low requirements for attention, i.e. no need for additional care.

- Wooden. It has quite a beautiful appearance. Good sound insulation qualities and low thermal conductivity are also noted.

Looking at wooden samples in more detail, we can distinguish two subtypes: regular and eurolining. This division is caused by the large abundance of imported material, provided that it differs significantly in quality and the types of wood used in production.

It should also be noted that foreign-made material is of higher quality and has a certain variety of geometric solutions.

Nuances to consider

When purchasing wooden panels, attention should be paid to the following points:

- Storage conditions (how to store lining correctly?).

- The quality of the wood, the panels themselves, grooves, ridges, decorative sides.

- Humidity, drying method.

- Recommended mounting method.

- The shelf life, which is stamped on the panel packaging label.

- Availability of information describing the qualities, features, and technical characteristics of the cladding.

- Acceptable paints and varnishes or other protective materials in accordance with the type of wood, profile shape, and other characteristics of the material.

Attention Even with the most accurate calculations of the amount of material, you need to purchase at least 10-15% of the stock. This is done to replace damaged, cracked, or damaged panels during transportation, due to the impossibility of accurately calculating the area to be covered due to the tongue-and-groove method of fastening.

How to choose a lining

Speaking about the choice of material for clapboard cladding, you should pay attention to some factors that determine the quality of the product:

- First of all, when choosing wooden lining, it is humidity. This figure should not exceed 15%; if it is higher, then under the influence of the environment after some time a drying process will occur, this in turn will have a great impact on the appearance (cracks will form, deformation will occur and the exterior finish will be damaged).

- The next factor is the integrity of the material. Under no circumstances should you accept products with defects or any damage.

- Also, for wooden products, you need to pay attention to knots; their number should be minimal.

Important! It is recommended to use coniferous wood, since deciduous trees are not intended for use as exterior decoration for a house.

Benefits of coverage

Lining is actively used in suburban construction due to its multiple positive characteristics:

- has a long service life and does not change its original qualities;

- resistant to temperature changes and used in any climate zones;

- simultaneously provides additional thermal insulation of the premises;

- has an attractive appearance and makes it possible to use all kinds of design options;

- finishing does not require specialized and expensive tools;

- easy to install.

Exterior decoration of a house using lining helps transform the structure and hide technological shortcomings.

Exterior cladding of a house

The clapboard cladding process itself is divided into seven main stages, each of which is quite important, so the following can be distinguished:

- preparation of materials;

- vapor barrier device;

- preparation and installation of the frame;

- heat and waterproofing of the surface;

- installation of an additional frame;

- covering material.

Each of the points must be treated as responsibly as possible; any neglect can negatively affect the final result. But let’s move on directly to the work and consider each of the stages separately.

Mounting options

Installation of eurolining can be done in several ways.

Self-tapping screws

In this option, the screws should be screwed on the side on which the tenon is located.

- The size of the screws for fastening the lining should be 10 to 15 mm.

- When the screws are already screwed in, they are closed using a dowel.

- After completing the covering, all protruding elements must be cut off, and the surface must be sanded.

To prevent the panels from splitting while tightening the screws, it is necessary to make holes in advance using a thin drill.

Hidden fasteners

This method involves fastening with staples (kleimer). The first panel is cut to the required size and fixed in the right corner using these same staples. These fasteners perfectly fix the panel to the sheathing.

The only negative factor when attaching to brackets is their considerable cost. And when working with the necessary tool, the user needs appropriate experience.

Nails

This option for fixing panels is similar to fastening with staples. Only in this case, thin galvanized nails are used instead. To ensure that the hammered nails do not interfere with the installation of the subsequent panel, they must be driven in so that the heads do not stick out.

Preparation of materials

The first thing to start with is preparing materials for the work. Here is the minimum list of materials that will be needed:

- Vapor barrier. For its arrangement, foil, polyethylene or roofing material can be used.

- Wooden slats and boards. Will be needed for arranging the frame and fastening insulating materials.

- Mineral wool boards are most often used as thermal insulation.

- Waterproofing film.

- And lining for cladding.

The quantity of each material is calculated individually depending on the surface area of which the finishing will be carried out.

Where to apply

Clapboard finishing is often used in steam rooms and other bathhouses. In this case, choose panels made of linden and alder (for steam rooms) and coniferous wood (for other places). These types of wood are endowed with healing properties, thanks to substances that are released when heated. Boards with knots cannot be used in steam rooms, as the corresponding areas become hotter. For a good aroma, it is recommended to install several pine boards in the area of the stove. The lining treated with protective compounds is suitable for cladding facades; the type of wood in this regard is not particularly important. Interior decoration is a complex task; panels in a uniform color scheme are required. Mahogany lining is used for cladding walls in expensive mansions. The panels are also used to make partitions to divide space: both in apartments and in open areas.

Vapor barrier device

Moving directly to the process, the vapor barrier device begins. As already mentioned, foil, polyethylene or roofing felt can serve as it.

The main tasks for which it is equipped include ventilation of the facade.

The device is carried out as follows:

- Wooden slats are provided, which are fixed vertically.

- The vapor barrier is directly attached to them.

- After fastening, ventilation holes are installed at the top and bottom of the covering.

Scope of application

If we talk about wooden lining, it is most often used as wall cladding inside a log house. In the interior, lining is used as decorative decoration for rooms. A design with wooden lining can be a bright accent of terraces and balconies.

Craftsmen who provide wall covering services claim that the most difficult thing is to attach wide panels. And designers advise diversifying the appearance of the cladding by combining wide and narrow lining panels.

There can be two options for cladding with wooden lining:

- Horizontal. Sheathing is done from the corner.

- Vertical. Fastening is carried out from floor to ceiling.

There are several types of plastic lining. For example, the most economical option is vinyl lining. It is only suitable for interior finishing. PVC lining for exterior work is suitable for exterior decoration of a dacha. It is resistant to frost, as it contains special components.

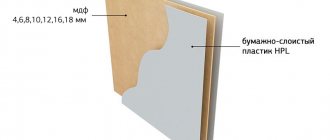

The scope of application of MDF lining is interior cladding. This is a frequently used material for finishing the hallway in an apartment. MDF panels coated with varnish are a common option for finishing a bathroom. This material is not afraid of moisture and steam, as are other negative factors.

These panels feature numerous installation options.

In addition to vertical and horizontal placement, the following methods are known:

- herringbone styling;

- combined styling.

Aluminum lining is used for finishing inside and outside. They can be used on the ceiling provided the wiring is carefully insulated. Aluminum is a good conductor of electricity, so even a small exposed section of cable will cause a lot of damage.

Aluminum lining can also be used as wall decoration. The work procedure also implies complete insulation of the electrical wiring.

If all requirements are met, the use of aluminum lining entails the following benefits:

- efficiency;

- aesthetics;

- durability;

- easy care.

Heat and waterproofing device

The next stage is the installation of insulating materials.

The first thing to do is attach the thermal insulation. For its arrangement, mineral wool slabs 5 centimeters thick are used. The insulation is laid in 2 layers so that there are no gaps between them. In this case, each layer must be equipped taking into account the displacement of the joints, i.e. Each slab of the second layer should lie centered on the joint of the first. Additional fastening is usually not required, since the material is sufficiently elastic and is able to adhere independently between the frame boards.

After this, the waterproofing material is attached. It uses a special film; it does not have the ability to hold back steam, but at the same time it does not allow moisture to pass through. Its fastening is carried out using a construction stapler. In this case, each piece of film is overlapped with the previous one by at least 5 centimeters and is additionally glued with tape.

Important! The structure of the film is double-sided, with one side being smooth and the other being rough. For the most efficient use, it is necessary to lay the smooth part towards the insulation, while the rough part will be turned towards the lining.

Soviet board versus eurolining

The concept of lining for external cladding is quite general.

Is it generally correct to call these boards clapboard? Where did this name come from?

Initially, wagons were lined with wood to protect the cargo from the sun and rain. Wood was the most affordable solution. Cheaper than metal. And wood protected better from the greenhouse effect.

At first these were ordinary boards secured with boards. To simplify installation and also eliminate gaps, tongue-and-groove locks appeared. As a result, the products successfully migrated from carriages to cladding work.

Abroad, finishing is carried out simply with profiled boards according to the DIN 68126/86 standard. They hardly know about the word lining. This European standard is stricter than the domestic GOST. Because of this, material manufactured according to the DIN standard is called Euro lining.

External lining according to GOST has a number of disadvantages. These are weak characteristics, questionable ease of installation, and humidity at 20-25%. Such products are often deformed. Plus, many external defects do not allow achieving the desired visual effect.

Eurolining wins in all respects. And this is a more than objective assessment.

Nowadays plastic lining is also available. Although these panels cannot be fully classified as this type of material. In the traditional sense, lining is products made from natural wood.

Exterior clapboard finishing

The time has come for the most significant and labor-intensive stage of work, and this is directly covering the house with clapboard on the outside. It is carried out as follows:

- The material is prepared and the boards are cut to the required size.

- The cladding process itself begins from the bottom, the first board is laid with the groove up. If there is no need for leveling, the material is fixed to the frame.

- Next, the next board is laid and driven into the groove with a hammer, after which additional fastening of the lining is also carried out.

- Further consolidation is carried out in the same way.

- When the fixing is completed, it is necessary to paint the surface, or cover it with a special solution.

This kind of impregnation will give the surface a more aesthetic appearance and make it resistant to external influences.

Important! If painting, the surface must be sanded first.

For some types of paint, for example, oil paint, it is necessary to pre-treat the surface; this is done by applying drying oil, preferably in 2 layers, and you will need to wait until it dries completely, and then continue working.

What work should be done beforehand?

Before carrying out construction work, each board and timber must be thoroughly treated with an antiseptic.

Processing of lining

Please note that many antiseptics contain a coloring pigment that will affect the decorative function of the lining. If you want to preserve the natural color of the wood, it is recommended to treat only the inner part of the material, and varnish the outer part after installation. If the facade is being prepared for painting, this does not matter and both sides can be treated with an antiseptic.

Let the lining dry thoroughly so as not to deteriorate its technical characteristics.

Photos in the interior of the rooms

Wooden slats are used both in country houses and in apartments.

Kitchen interior with clapboard

In this room, the design can be different: complete interior decoration of the walls, partial, zoning. No matter how you plan to use the wood, coat it with a protective varnish before installation - this will protect it from moisture and make cleaning easier.

When covering the walls from floor to ceiling, protect the apron separately - in this area it is better to use more suitable materials (tiles, panels). In a Provence-style kitchen, a combination of boards with wallpaper would be appropriate, for a loft - with brick, Scandi - with painted walls.

If you have a studio or kitchen-living room in a large house, use wooden lining to divide the functional zones. For example, only add wood trim around the dining table or sofa.

When using decorative panels above or next to a kitchen unit, choose the facades correctly: they should be laconic. Upper cabinets can be replaced with shelves.

Living room covered with clapboard

There are many ideas of what a living room can look like. First, decide - will you use the planks on the walls or ceiling?

The warm shade of the wood above the room will envelop it in coziness, and it’s easy to place several lighting sources in the ceiling slats.

The walls are sheathed completely, 1-2 or accent walls. It is logical to place the latter either behind the sofa or opposite it. Zoning is suitable for multifunctional rooms - for example, to separate a work or storage area.

The color scheme depends on your preferences: white lining and bright interior details or colored boards and neutral design.

The photo shows an example of the symbiosis of white with natural wood

Photo of lining in the bathroom

Despite the reduced moisture resistance of wood, it can be used in wet areas. The main thing is to cover the wall with a protective compound.

Be that as it may, walls covered with eurolining should not be located above the bathtub or in the shower. Let them be located in remote areas - near the toilet or sink, then the repair will serve you for many years. Another exception is the ceiling; it is better to paint or stretch it.

Lining in the interior of the hallway and corridor

Often, in panel houses, the corridors are narrow and uncomfortable; horizontal lining of short walls will expand the space and make it more pleasant. On long walls, attach slats vertically or diagonally. The panels look interesting - for example, you can create the outlines of mountain peaks or a city landscape from boards.

An added bonus in your entryway is that you won't need any special equipment to hang an extra hook or shelf.

Lining in the bedroom

The most spectacular placement of the lining on the wall in the bedroom is behind the bed. Accentuate a wall or correct the geometry of a room with the correct placement of stripes.

An interior with natural shade slats in a bedroom with white furniture looks fresh and will remain relevant for many years.

The photo shows the design of a relaxation room in country style

Lining in the children's room

For children, the use of environmentally friendly materials is especially important, so wooden panels come first here. In addition, its variability and ease of processing allows you to create fancy designs on the walls and ceiling, which is a bonus when decorating a nursery.

Examples of finishing a balcony with clapboard

To save on repairing a balcony or loggia, but get a high-quality result, attach the boards to the walls and ceiling. You don’t have to level the surfaces or prepare them in any way - just prime them to prevent mold and mildew, make a sheathing and install slats.

What can you combine with?

Combining lining with other finishing materials is a popular solution that allows you to use wood trim in any room of the house.

Wallpaper. This tandem is used in the living room, bedroom, nursery, kitchen and even bathroom. Typically, panels occupy ⅓, ⅔ or half the height of the wall from the bottom. Improve the transition between them with molding or wooden plank. To achieve visual harmony, paint the lining in one of the shades that is present on the wallpaper.

Ceramic tile. A wonderful duet for the bathroom, toilet and kitchen. Paint the wood the same tone as the tiles for a small room, or use contrast for a large one. A bathroom made of natural-colored clapboard and white tiles looks ultra-modern and fresh.

The photo shows a dark set with bright accents

Stone. On the one hand, the union may seem unusual, but nature itself dictates it. Smooth slabs with wood are used in wet rooms, textured ones in the living room or kitchen.

Brick. A white brick-wood wall will appeal to fans of Scandinavian design, while dark patinated wood with red brick is perfect for a loft.

Video description

In the video, the master talks about how he assembled the interior of the bathhouse from lining and stone:

To decorate living rooms with windows facing south, designers recommend choosing lining in dark shades of brown.

To make it look good, it is important to have good artificial lighting; experts advise simply whitewashing and painting the ceilings. If you leave one of the walls in the room painted and cover the remaining three with wood, the design will only benefit from this

On the contrary, you can cover only one accent wall with clapboard, and wallpaper the other three. It will also look very good.

An interesting option for a combined design Source 1povagonke.ruIf you need to use lining to decorate a bedroom or kitchen, it is better to use light-colored lining for painting. If you paint it on top with white or light gray translucent enamel, you will get a cozy space. Light textiles with spot bright accents (tablecloths, bedspreads) go well with it.

In the bedroom, designers recommend finishing the wall with clapboard, next to which the head of the bed will then be placed. For this purpose, lining of any shape, any color is suitable. The main thing is that it is then linked to the overall range of interior content and decor.