It’s not for nothing that people came up with the idea of calling repairs a second “fire.” In reality, this is quite a troublesome task and takes a lot of time and financial costs. Professional repair teams have a considerable amount of special tools for carrying out repair work. And if there is not enough finance, to hire a whole team.

Knives for cutting drywall.

About repairs

Most often, young couples decide to do this difficult work on their own. In fact, this strengthens the union of young people and makes their relationship or marriage stronger.

And one more funny phrase about renovation - if you want to quarrel with your wife, hang wallpaper together with her. But enough about jokes and let's move on to the serious topic of today's conversation - a drywall knife.

Many will throw up their hands and say – what’s not to like about a stationery knife? Yes, this is a pretty good option, and it will also be discussed. But from the point of view of a professional builder, there must be specific equipment for specific purposes.

Cutting drywall can be done with a regular table knife, but when the volume is slightly larger than just one or two corners, a special knife will be required.

Scissors for cutting drywall profiles

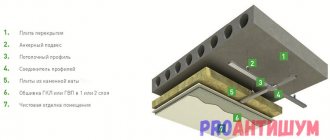

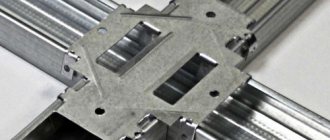

Drywall profiles are used as the main frame element of many structures. In particular, plasterboard partitions, suspended ceilings, and it is also used for wall cladding.

Scissors are one of the most popular, practical and frequently used devices for cutting drywall profiles. There are many types of metal scissors, so it’s worth deciding which ones are needed in which case.

It is important to note that you should not save money and buy old-style monolithic scissors. Working with them every day means not feeling sorry for yourself. Progress does not stand still, so many different scissors for metal have appeared, which will be lighter and require much less effort to work with.

There are several common types of scissors:

- Combined;

- Longitudinal cut;

- Curly;

- Right cut;

- Left cut.

Combination scissors are suitable for daily work. They are universal. With their help you can make both straight and curved cuts. The name of the longitudinal cut scissors speaks for itself. Their purpose is to cut metal lengthwise, that is, along.

Curly metal scissors are necessary for curved cuts. They are distinguished from universal ones by a short cutting head, with which it is much easier to turn the cut to the side. Curved scissors are also excellent for curved cutting; they are divided into “right” and “left”, depending on the location of the upper blade in relation to the lower one.

Basic requirements for the tool

Plasterboard structures are very popular today. It is the most common material for leveling surfaces. Or, conversely, to create structures of very complex shapes.

For these purposes, a special knife was invented, which is designed to make working with sheets of drywall easier. It also saves time, the cut is perfectly smooth and accurate.

The special tool contains a thin and durable blade, otherwise it will bend and move to the side when cutting. A special knife for plasterboard includes all these functions, and this is its main purpose.

Best models

The rating is based on customer reviews.

STANLEY FatMax Exo

Country of origin: USA. Model of a mounting knife with a trapezoidal retractable blade. Its maximum length is 6.3 cm. Blade thickness is 0.65 mm. The cutting edge is located on both sides. The back of the handle has a compartment for storing accessories.

The shape of the knife has a slight bend. It has comfortable handle ergonomics. There are rubber pads on the top and bottom of the handle. The front part of the handle has a thickening. It strengthens the structure and prevents the blade from breaking under strong lateral pressure.

- increased strength;

- light weight;

- comfortable handle;

- versatility.

- No deficiencies identified.

"Bison" 09225

Country of origin: Russia. The model has a retractable design with a mechanical lock. The width of the canvas is 18.7 mm. The knife can be used to cut drywall, plastic, linoleum and roofing materials. The blade has a two-edged sharpening. The body of the product is metal. It has clips for attaching to a belt.

- robust construction;

- comfortable handle;

- versatility;

- double sharpening at the end of the cutter;

- increased blade strength.

- No deficiencies identified.

Olfa Ol – RTY – 1/G

Country of origin: Japan. The model belongs to special cutting knives and has a round blade. The blade material is tungsten. Blade thickness – 28 mm. The knife is designed for cutting drywall, fleecy materials, leather, wallpaper and other materials.

The model has a comfortable handle. It is adapted for left and right hands. The design has a hole for installing a device for cutting parts according to a template.

- increased strength;

- comfortable handle;

- sharp cutter.

- No deficiencies identified.

BRAUBERG "Professional"

Country of origin: China. The universal knife model is a professional tool. The product has a metal body, an ergonomic handle with anti-slip rubber inserts.

The case has a hole for installing a mount for hanging the tool on a belt. The knife set includes 5 blades of varying thicknesses, which can be easily replaced if necessary.

- versatility;

- convenient design;

- stylish design;

- robust design.

- No deficiencies identified.

Gross 78882

Country of origin: Germany. The model has a retractable trapezoidal blade. It has double-sided sharpening. Working blade length – 60 mm. The handle is equipped with anti-slip pads. The Gross 78882 knife is considered one of the safest.

- ease of blade replacement;

- reliable fixation;

- anti-slip handle.

- No deficiencies identified.

Kinds

In fact, the choice is not that great. The only difference between them is the thickness and width of the blades. There are also some design features. But all of them can cope with the assigned tasks, in terms of gypsum boards. I propose to consider each type in more detail.

Painting (wallpaper)

Outwardly, it is not much different from an ordinary stationery knife. But it is clearly larger in size. It’s quite simple to explain: the blade width of such knives starts from 18 mm.

Wallpaper knife.

Let's consider several options:

- It’s better to warn you right away that a knife with an 18 mm blade, usually with a plastic handle, is not very reliable. If you plan to work with a small volume of plasterboard, then this option may be suitable. You should not protrude the blade more than 10 mm; it may break from the applied pressure, otherwise it simply will not cut through the paper on the drywall. And over time, the blade begins to cut through the surface of the plastic, where it rests on the knife, and it becomes unusable;

- There are also reinforced options; they include a metal guide along the blade. The body will no longer push through, and most importantly, it will give rigidity. And the blade itself can already reach a width of 25 mm;

- professional options, this is the lot of real masters, they have a metal body with rubberized inserts. The blade width is only 25 mm, and the thickness already reaches 0.6 mm. But their price category is already different. Accordingly, reliability is at its best.

Determine for yourself how much volume you are going to work with. And based on this, make a purchasing decision. Since the three types described above have a fairly wide price range.

Special purpose

Special-purpose knives are exactly the tools that professionals prefer. It is also called a trapezoidal knife. It is initially adapted for working with drywall:

- has a comfortable handle, all models are rubberized;

- knife blade of high strength and rigidity;

- the handle may have a niche for replaceable blades;

- the handle is anatomically comfortable.

Special knife for drywall.

This drywall knife will not let you down when cutting curved lines. And some manufacturers provide them with a built-in tape measure, which also makes work easier and increases productivity.

And these knives also include folding models that are convenient to carry. It looks like a wide fold.

With disc blade

Quite an interesting design, but if you take a closer look and listen to the professionals, you can conclude that this is one of the most durable knives. Which, in turn, can make cuts of absolutely any shape.

There are no geometric obstacles for him. And if they need to make straight cuts, they can do it all day long, like a robot. Not afraid of big efforts. He doesn't mind high loads.

Knife with a disc blade for drywall.

Hacksaw

This tool is not used very often, but it is simply necessary in some situations. For example, when the gypsum board sheets are already mounted in place and it becomes necessary to cut a small hole.

The downside is that the edges of the cut become frayed. The cutter itself is coated with a special coating, which allows it to make cuts smoothly and not get stuck in the slots.

Hacksaw for drywall.

Disc cutter

This device has the main advantage that it can make even strips up to 12 cm. It is used for special tasks, for example, for multi-level ceilings, where long and perfectly even strips are needed.

Ensuring high-quality cutting of drywall is provided by two small disks, which are located strictly opposite each other. The paper layer is cut at the same time, which gives a perfect evenness to the cut.

Using it is quite simple: you need to set the guide to the desired width and install the device on the end of the sheet. Then smoothly move it from beginning to end of the plasterboard. The result will be a long piece of a given width.

Disc cutter for drywall.

Power tools

In reality, many craftsmen, if urgently needed, can resort to the help of any power tool at hand. If you need a straight strip or a curved one, you can use a jigsaw to mark the sheet.

You just need to install a saw with the shortest tooth distance. Holes for sockets and built-in lights can be easily made using a drill and a special “crown” attached to it.

In general, any sawing and cutting power tool is suitable for working with plasterboard. But it is better to do this if there is an urgent need, and ideally, use the tool that is intended for this.

Jigsaw for drywall.

Blade runner

This is an innovation in the world of drywall cutting. Its operating principle is very similar to that of a rotary cutter. But only that tool has restrictions on the width of the resulting strip, and the blade runner has no such barriers. It is absolutely safe to use, since the working blades are hidden in the body of the structure itself.

The sheet is also marked and then the device is installed, as if digging into the gypsum board, then we match the guide with the markings. And we begin to move the device along the marking line. The cut is smooth and even due to two cutting blades on different sides. The time savings are obvious.

Blade runner for drywall.

Disc blade knife

This type of tool has also become widespread in the processing of drywall, for the following reasons:

- The circular knife is ideal for high-precision cutting of straight, broken and curved lines of large radius, as it moves rigidly along the guides, and the constantly rotating blade cuts through the material without gaps.

- The cutting blade can withstand high loads and high forces, resulting in a long service life.

Recommendations for selection

The recommendations are quite simple. Decide for what purpose you are purchasing the knife and how much volume you are going to process, but in general:

- pay attention to the thickness of the blade, the thinner it is, the more ideal the cut, but the likelihood of a break is high;

- the quality of the metal from which the blades are made;

- the case itself is metal or plastic, plus in favor of metal;

- availability and availability of spare materials.

If you are purchasing a cutter for small jobs, then there is no point in overpaying for professional equipment. Well, if you are already an experienced master, then you know exactly what you need.

Conclusion

There are a lot of options for knives for gypsum boards, choose a specific solution based on the amount of work, because you have to do everything with your own hands, and if you choose the wrong thing, then you will have to suffer. The video in this article will tell you in more detail about some of the options discussed above; if you have questions on the topic, write them under the review.

Did you like the article? Subscribe to our Yandex.Zen channel

October 22, 2016

Plasterboard systems, Tools and materials

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

How to cut gypsum board?

If you need to cut something off, then one hundred percent - you need to try it on seven times. This old truth, although paraphrased, has a deep and meaningful meaning. Therefore, you need to approach the work responsibly, otherwise you will run to the store for gypsum boards, or assemble a wall or ceiling from pieces.

One of the ways to cut gypsum boards.

Let's try to compose instructions:

- We measure the required segments.

- We transfer all the contours to a sheet of drywall and make all the necessary marks for cutting.

- Once again we measure and check the cutting lines on the gypsum board.

- For straight cuts we use it as a ruler, level or profile.

- When cutting, we do everything carefully, without jerking, and without lifting your hand.

- Having laid the sheet on a flat surface with the cut side down, we make a small bend towards ourselves; the drywall will crunch and break along the entire cut.

- Then we turn it over and cut through the wrong side.

That's it, the piece is cut off. If you need to make curved cuts, read above about the tools designed for this. With a little experience and some skill, you will soon be able to do all these steps in a matter of minutes. Good luck with the renovation!

Previous

Kitchen knivesKnife for filleting fish: which one to choose, rating

Next

Making knivesHow to make a knife with your own hands

Blade Runner

At the moment, it is not the most common tool option among professionals and home craftsmen. The main feature of the device is that it doubles the speed of cutting plasterboard sheets. The knife has the following features and advantages:

- The cutting part consists of two parts, held by magnetic clamps. The blades are in special blocks, so they can be easily removed and inserted.

- A set of rollers is enough to cut 600 plasterboard sheets. Each such video costs 100 rubles, which is quite profitable and economical.

- The special belt bag with which the tool is sold makes it easier to use a tool of considerable size. It becomes easy to carry around.

- The device can cut curly and straight lines, even cut corners by pressing the top button and turning the tool.

The tool also has disadvantages. The blades can be damaged when cutting sheets 0.9 cm thick, since the halves collapse when leaving the gypsum board. Blade Runner is ideal for cutting large curves. With small ones, it is difficult to ensure accurate hits on the applied markings.

Specifications

The physical parameters of the gypsum cutting knife are as follows:

- Fabric strength: 350-500 MPa.

- Canvas length: from 8-18 cm.

- The thickness of the canvas is from 0.35 to 0.55 mm.

- The handle material is metal, covered with rubber on top.

The hollow handle is made of light metals and their alloys, but there are also versions made of durable plastic. The top is covered with multi-component rubber. But the blades are made of high carbon steel. There are options made of stainless steel or even titanium. Spare blades included.

cutting