Drywall is a rather fragile material that is used to level the surface of walls and ceilings, as well as to create niches. To install this material, special fasteners are required - dowels. Since there are several types of these fasteners, which dowels are best suited for drywall becomes a rather pressing question.

Driva

Made from zinc alloy, nylon or polyethylene, the latter option is used much more often due to its low cost.

The installation principle is that a dowel is inserted into a pre-created hole, the diameter of which is about 6 millimeters. This product is cut into a sheet of drywall with a cross bit, after which a screw or self-tapping screw is screwed into the gap (has the shape of a cross) in the dowel.

When choosing a self-tapping screw, you must take into account that its length for plastic dowels should be 23 millimeters, and for metal products – from 33 to 44 millimeters.

Options for fastenings in GVL

Next, we’ll look at the most popular options and what can be screwed into a plasterboard sheet to securely attach various decorative elements.

The easiest option is to find the guide profile using a magnet and screw a steel screw into it with a screwdriver. If this cannot be done, then it is necessary to resort to the help of special fasteners in a sheet of drywall.

The most common type used in drywall projects is the butterfly . In appearance it has the appearance of a butterfly with spread wings. The main material for fasteners is polypropylene. Metal products are also on sale.

Photo of the most common dowel for plasterboard “Butterfly”

Butterfly action for drywall

Initially, a drill is used to make a hole of the required size. You need to insert the plastic part of the dowel there. To do this, the side elements are pressed to the center, the dowel is driven in with a hammer. This should be done carefully. After which a screw is screwed into this part. At the moment of mounting the self-tapping screw, the polypropylene part opens from the back side of the plasterboard surface (as if the wings are spreading to the sides). They rest against the gypsum board, thereby rigidly fixing and distributing the suspended weight over the surface, there is no point load.

The butterfly dowel has a distinctive property - it is possible to dismantle fasteners from a plasterboard surface.

The butterfly has different sizes. Their selection depends on the weight of the item:

- Size 8/28. We will use this dowel to fix a lightweight structure. Self-tapping screws for the butterfly must be purchased separately. For this size, a 3.5/35mm screw is most suitable. The coating on the screw is completely unimportant. The hole for the dowel is made with an 8 mm drill. The inserted fastener has a lock that will prevent the butterfly from completely “falling” inside.

- Size 10/50. Inside the wings of this dowel there are 2 strips that provide additional strength when fixed to the base from the back. This butterfly can withstand a weight of 24 kg. For a butterfly size of 10*50, you should purchase 3.5/55mm self-tapping screws. The hole for this butterfly will need a diameter of 10mm. Installation of butterfly dowels

Molly screw fastenings (MOLLY)

The MOLLY drywall dowel is used when it is necessary to fix a heavy object on the surface. It is perhaps the most reliable mount.

In its structure, Molly differs from plastic dowels in that it has a completely metal frame. The material is galvanized or stainless steel. The dowel consists of a sleeve and a screw. The second part is sometimes selected independently, depending on the assigned functions - it can have an ending in the form of a head, a ring, or a hook.

Molly dowel has teeth for strong fixation on the surface

The sleeve has slots through the entire element, this creates a spacer. In the center of the sleeve there is a thread for a screw. When purchasing a separate screw, you should pay attention to this.

The screw included in the kit has a support washer, which is a kind of limiter - without it, the fastener rotates in the spacer part.

Molly mount

To install the molly dowel, you will need a special expanding device.

- It is required to make a hole in the plane with a size selected for the dowel dimensions from 8 to 13 mm.

- Next, a sleeve (collet) is inserted into the hole. It is driven in until the teeth on it rest against the surface.

- After this, the screw is screwed in.

- Use special pliers to pull the screw out. With this action, the end of the collet is attracted to the surface from the back side, the spacer part is activated and fixed.

Molly Attachment Diagram

Depending on the size of the Molly, there are different weight categories. Basically, rolling goes from 25 to 75 kg. You can hang up to 30 kg on a plasterboard surface using this dowel. weight.

The dowel is shown in more detail in the photo

It is possible to purchase a sleeve with a hook for the Molly dowel

Video:

DRIVA dowel with drill

The dowel is made from 2 types of materials: plastic and metal.

Plastic dowels are slightly cheaper than metal ones. For their production, polyethylene or nylon Mark TT 22 is used. This fastener can withstand up to 25 kg. weight.

Driva metal dowel

The metal wood is made from duralumin. It is not as popular as nylon products for one reason - pricing. This dowel carries 35 kg. weight.

The dowel (both types) has a locking device, as well as a screw thread with an acute-angled profile.

Fastening the Driva dowel

To fix the fasteners, you need to make a 6mm hole. but, if the thickness of the plasterboard sheet is 12.5 or less, then a hole is not needed. The dowel is screwed in there using a screwdriver until it reaches the locking head. A self-tapping screw should be screwed into this dowel.

The length of the nylon dowel is 23mm, the metal one is 44mm.

Video:

KNAUF fastenings Hartmut

This dowel has 4 components:

- the anchor strip is a kind of U-shaped galvanized plate;

- there are 2 guide antennae made of plastic;

- plastic locking insert;

- screw M5-60.

Knauf Harmut has a complex design due to which it can withstand up to 50 kg.

KNAUF Hartmut is able to withstand a weight of 55kg. In most cases, this anchor is designed for heavy objects on a plasterboard wall. This is a large-screen TV, a shelf with dishes in the kitchen, and a cabinet for bath accessories in the bathroom.

To install the dowel, a corresponding hole is made in the gypsum plasterboard wall. The plate is inserted into this gap using antennae. When the U-shaped part goes into the hole, the antennae break off. A screw is screwed inside.

Video:

Universal Fischer dowel

This dowel consists of a plastic cylinder and contains a sleeve. There are blades on the side, as well as a powerful end switch. Inside the dowel there is a thread for a screw. Dowel dimensions: length – 27mm, diameter 12.5mm.

The Fisher dowel has a plastic cylinder and sleeve

To install Fischer in drywall, a hole is made that matches the sleeve with a diameter of 12 mm. Fischer is inserted into the hole made and secured with a 6*50 corkscrew screw. When the screw is screwed in almost to the end, pressure begins on the conical part of the sleeve. Ultimately, under the applied pressure on the screw, the sleeve opens in different directions with blades that are pressed against the back side of the gypsum board sheet.

For small and medium loads, the UX universal dowel is suitable. This unique shape allows it to be used for fastening into drywall and other building materials.

Fischer dowel is sold as a set with self-tapping screws

When attached to a standard 12.5mm gypsum board sheet. For example, a board 8mm thick is attached. in this case, the screw from the back side of the drywall came out to a length of 27mm. this shows that there should be a 30mm empty space under the gypsum board.

Video:

The weight supported by the dowel is 16 kg.

Dowel with spring for ceiling mounting

This type of fastener is designed to be lightweight. It consists of several components:

- base – screw with hook;

- spacer component – 2 strips;

- spring strip retainer.

A hole needs to be made. Insert a dowel with pressure blades into it. As soon as the planks go beyond the boundaries of the plasterboard structure, the spring is activated and the planks are straightened, thereby being fixed on the other side of the plasterboard.

Types of folding dowels with spring

This dowel is mainly intended for hanging decorative elements and chandeliers.

If you need to hang a heavier object, we recommend using a special metal anchor and attaching it directly to the concrete.

Nail

The dowel-nail is used for installation of plasterboard products that are light in weight and size. To install a dowel, insert it into the hole, then use a hammer to hammer it in.

A significant advantage of this fastening option is the small amount of time spent on its installation.

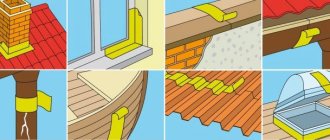

Types of dowels for drywall profiles

Dowels for profiles are fasteners used in the installation of guide profiles and hangers for the frame under gypsum boards.

There are:

- dowel nail;

- dowel-wedge (anchor);

- butterfly;

- wood;

- Knauf-Hartmut;

- Fischer Pd";

- umbrella;

- chemical anchors.

The main types of dowels used when installing a frame base

To understand which dowel should be used in a certain situation, all options are discussed below.

Dowel-nail for drywall profile

The most common fastener for mounting the gypsum board frame. According to the method of fastening, there are two types: manual driving and using a mounting gun.

The first type consists of a fastening base and a nail. The base is made of polypropylene (for warm rooms) and nylon (withstands low temperatures). Used when fastening structures with low weight. Familiarize yourself with the process of installing heavy and light structures on a plasterboard wall using the link.

The second type is a fastening element consisting of a nail and a washer. Used for installation of heavy massive structures to a concrete base.

This type of fastening element is not applicable for working with gypsum plasterboards

I mark products by size. Dimensional characteristics indicate the diameter of the base and the length of the nail. When working with a profile for drywall, the optimal option is 6/40, 6/60 mm, where 6 is the diameter, 40 and 60 are the length. They are used to fix guide profiles to the rough base, and also fix direct hangers.

Butterfly

Butterfly dowel for drywall is a standard type of fastener. Installation is simple; a dowel is initially installed in a pre-created hole, and then a self-tapping screw.

The product was called a “butterfly” due to the fact that during twisting it opens in the free area and rests on the inside with “wings”.

To use this fastening option, you will need special cuffs that will prevent the scrolling process. The most common sizes of this type of dowels for drywall are 9*13 and 10*50 millimeters.

Technical characteristics and dimensions of dowels

To choose a self-tapping dowel for moisture-resistant and ordinary drywall, you need to take into account the size of its legs (length) and the diameter of the head. In addition, the choice of the required fasteners depends on the type of wall material.

| Diameter, mm | Length, mm | Diameter | Leg length | Drill | Depth, mm |

| 3 | 12, 16, 20, 25, 30, 35, 40 | 5 | 12, 16, 20, 25, 30, 35, 40 | 5 | 16, 20, 25, 30, 35, 40, 45 |

| 3, 3,5 | 12, 16, 20, 25, 30, 35, 40, 45, 50 | 6 | 12, 16, 20, 25, 30, 35, 40, 45, 50 | 6 | 16, 20, 25, 30, 35, 40, 45, 50, 55 |

| 4 | 12, 16, 20, 25, 30, 35, 40, 45, 50, 60, 70 | 5, 6 | 12, 16, 20, 25, 30, 35, 40, 45, 50, 60, 70 | 5, 6 | 16, 20, 25, 30, 35, 40, 45, 50, 55, 65, 75 |

| 4,5 | 16, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80 | 6, 8 | 16, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80 | 6, 8 | 20, 25, 30, 35, 40, 45, 50, 55, 65, 75, 85 |

| 5 | 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | 6, 8 | 16, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | 6, 8 | 20, 25, 30, 35, 40, 45, 50, 55, 65, 75, 85, 95, 105 |

| 6 | 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | 8, 10 | 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | 8, 10 | 45, 50, 55, 65, 75, 85, 95, 105, 130, 150, 170, 190, 220 |

| 8 | 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | 10, 12, 14 | 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200 | 10, 12, 14 | 45, 50, 55, 65, 75, 85, 95, 105, 130, 150, 170, 190, 220 |

| 10 | 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200, 220, 240, 260 | 12, 14 | 40, 45, 50, 60, 70, 80, 90, 100, 120, 140, 160, 180, 200, 220, 240, 260 | 12, 14 | 45, 50, 55, 65, 75, 85, 95, 105, 130, 150, 170, 190, 220, 230, 260, 280 |

You can buy fastening elements at any hardware store or market. The price of drywall dowels also depends on the size and materials of the fasteners. Hollow dowels will cost a few rubles apiece, while butterflies can cost more – up to 5.

Video: operating principle of the molly dowel

Molly

In appearance, the fastener is similar to an umbrella and has an almost similar operating principle. These products are equipped with rings and hooks for fasteners.

In the empty space located behind the sheet of drywall, the dowel opens, thereby ensuring a uniform load over large areas. To facilitate the installation process, it is recommended to use special pliers.

You can see all the types of drywall dowels presented in the photo.

What dowels to use to attach the profile to the wall?

Experts recommend using a dowel-nail. By type of fastening there are:

- spacer;

- universal.

Universal – size 6x37 mm. If you need to increase the reliability of fastening, use anchors. Self-tapping screws are suitable for installation on wooden bases.

Fasteners are used for fastening to a wall made of concrete or brick

Dowel with drill

This is a version of a self-tapping screw that is designed to be screwed into a material. This fastener is recommended for use with single- or double-ply drywall with insulation or decorative coating on the inside of the drywall. Under no circumstances should such dowels extend beyond the other side of the partition.

Lanyard for rigging workCrab system for profile pipes: features of the selection and use of fastening systems and connecting elements

What is a rigging shackle? Size standards, modern types, rules and features of choice

Installation

The use of dowels for gypsum boards is not difficult. The classic screwdriver (Hilti, HLD, TNF, etc.) is mounted into the wall using a suitable drill. Preliminary (depending on the type) surface preparation may be necessary. It is cleaned of nicks and debris and drilled with a drill of the required diameter, which can be selected according to the table above.

If you use dowels that do not require drilling, then you just need to mark the location of their installation and install the parts into profile guides or sheets. Afterwards they are necessarily puttied and reinforced to create a perfectly flat surface for further processing.

16 June 2015 Author: Vladimir Bakaev

Screw

This is a type of dowel-nail, which consists of a nail with a screw thread and an expansion dowel. Used during installation of ceilings with a hollow structure.

Such products must be screwed in with high quality, but you should avoid twisting them, so you need to pay special attention to the size and complexity of the work.

Driva

The dowel called Driva consists of a hollow conical rod with a flat head based on a screw thread for a profile with an acute angle. Externally, the head is similar to the shape of a cap, like self-tapping screws or self-tapping screws, which is expressed by the presence of Phillips slots for working with a screwdriver.

The rod part has a diameter of about 15 mm. In the internal cavity, a blind version of a through-type hole is formed, intended for an easier process of screwing in a screw.

The design is proposed on the basis of a drill, similar to a trident or the shape of a perk and with its absence. Available in a metal version made from zinc alloy or a plastic version made from propylene.

Usually used if it is not possible to use other types of fastening due to lack of internal space.

What are its advantages:

- It has its own drill, which eliminates the need to first create a nest for it;

- Can be used if the distance from the drywall to the main wall is too small;

- There is a possibility of dismantling.

Dowel selection

The selection of fasteners for drywall requires taking into account many factors:

- planned load;

- possibility of dismantling;

- product price.

The process of selecting a dowel is quite individual, since each specific situation may require completely different fasteners.

But still, the most reliable option would be to mount it into load-bearing profiles, since in this case, the area on which the load is created is almost hundreds of times higher.

How long will a drywall screw last?

Quick response

A simple self-tapping screw in drywall will hold a maximum of 21 kg, after which it will destroy the hole and fly out.

I think you've asked yourself this question, why use special dowels when almost every home has regular screws? Such as in the photo below:

Self-tapping screw for drywall

I immediately want to say a few words about simple self-tapping screws and not return to them again.

Regular drywall screws cannot be used for hanging objects. Use only special dowels!

Such a self-tapping screw presses the gypsum board well against a metal profile or a wooden guide, but by itself, in drywall alone, it sits quite weakly, there is simply nothing for it to catch on. With any slight load on the self-tapping screw, be it shearing or tearing it out, the plaster is easily destroyed.

Watch the video, here Andrey, using a canter, shows the weight of the maximum load on simple self-tapping screws screwed into drywall. The self-tapping screw flies out of the gypsum board already at 21 kg. Please note that this is the maximum weight, and the working permissible weight, taking into account constant dynamic loads and vibration, will be 2 or even 3 times less.

Expert

Video author: Stroyhak

Stroyhak is a channel about construction and repair on YouTube with more than 1 million subscribers! The author of the channel, Andrey, shares useful tips, tricks, life hacks, tool reviews and other useful things for improving your apartments.

Construction hack on social networks:

I hope I have convinced you that you shouldn’t hang even 5 kilograms on a simple self-tapping screw and it will only be suitable for a photo frame or a small painting. What to do then? Use fasteners with increased load-bearing capacity - special dowels for drywall (for items up to 30 kg), or double sheathing (for items up to 50 kg), or embedded structure (for items over 50 kg).

When can you not do without a Molly dowel?

All-metal fasteners are suitable not only for fastening into drywall, but also into hollow walls or sheet materials. The opening mechanism on the back side of the hardware provides better fastening strength. The load-bearing load is determined not only by the parameters of the dowel itself, but also by the characteristics of the base material. The Molly dowel is perfect for sheets up to 26mm thick. If the wall is insulated and you used insulating material when installing it, difficulties may arise when installing the dowel.

Molly dowels, the elements of which are made exclusively of durable steel, are indispensable for installation in fire hazardous areas. Once installed, you can dismantle and even reuse the hardware. Galvanized dowels are intended for rooms without exposure to moisture, precipitation, or temporary connections. Stainless steel products are considered the most resistant to external factors.

Installation of the door frame

The frame for the opening is made in two versions:

- In a regular PS rack profile, reinforced with a wooden beam, which is placed in the middle of the profile.

- Using a special UP profile, the metal thickness of which is 2 mm.

Doorway frame

Usually the first option is used by amateurs. In this case, the PS profile is attached to the floor and ceiling to conventional PN profiles with an opening 20 mm wider than the door frame. A wooden block 50 mm x 50 mm is inserted into it. The beam is also inserted into the upper lintel, which is also 20 mm higher than the doorway. The door frame is attached to the frame with ordinary wood screws through a metal profile into a wooden beam.

In the second and technologically correct option, special profiles with a metal thickness of 2 mm are used. This is a reinforced profile and is designed to withstand the loads of doors. They are also mounted in the opening under the door frame with a gap of 20 mm in width and height. But they are fastened to the floor and ceiling using special connecting metal corners 2 mm thick.

Fastening the corner to the floor and ceiling using the usual dowel-nail pattern. The profile should be fastened to the corner only with special bolts with nuts and washers, which are included in the kit. The transverse jumper can be made from a regular PS profile. It is necessary to insert a wooden beam into it to secure the door frame, but it would be more correct to install it from the UP profile.