For some types of construction work, cement-lime mortar is used. This building material is very plastic, in addition, it is very durable. Cement-lime is chosen very often also because it adheres well to surfaces.

Cement-lime mortar is very plastic and is used for high-strength adhesion of surfaces.

In order to make a high-quality solution, you first need to prepare a dry mixture, which is made from 1 part cement and 5 parts sand (you can take less sand, it all depends on how thick you need it). After such a mixture is obtained, you need to pour lime milk into it to achieve the desired thickness.

The preparation of lime milk is as follows: take one part of dry lime and dilute it in water until it is completely dissolved and a homogeneous liquid is obtained.

It is necessary to pay great attention to quality, since this determines how well the plastering work will be completed.

Such building material must be of the highest quality, because it largely determines how well the plastering work will be performed. In most cases, grade 400 cement is used to prepare cement-lime mortar. It is very important to take into account that before you start making cement-lime mortar, you should carefully check the material, it must be crumbly, there should not be any lumps in it, otherwise the entire construction the process may end badly. To prepare, you need to take a large container, and you will also need a sieve for sifting.

Specifications

The composition of such a solution must include cement, sand, slaked lime and water.

It is worth paying attention to the fact that it is slaked lime that needs to be added. Otherwise, the quenching reaction will begin in the solution itself when water is added, and bubbles, forming inside the solution, will lead to cracking of the plastered surface

This process of bubble formation will lead to deterioration in the quality of the solution and to brittleness after it dries.

Construction mixtures, their composition and properties are regulated by various GOSTs. This is necessary for standardization and regulation of norms in construction. GOST 28013-98 is the main legal act regulating the technical requirements for building mortars and materials included in the composition.

This standard also includes characteristics of quality indicators, acceptance rules and conditions for transportation of finished solutions. It contains the qualitative and quantitative characteristics of masonry mortars, materials for plastering and for interior work, used in various operating conditions.

Cement mortars

Cement is prepared from a mixture of ordinary cement and medium sand. The proportions can be different, they depend on the brand of cement used and can be: for one part of cement, take from three to six - sand.

Mix the dry mixture with the addition of water until a homogeneous mass is formed.

First, the dry mixture is mixed, then water is gradually added, then everything is mixed until a homogeneous, thick mass is obtained. But this option is not the best, since ordinary cement is inactive, even when using any brand it turns out to be too hard and too strong.

The cement-lime composition for bricklaying consists of lime and cement. The cooking process is as follows:

- Slaked lime, that is, lime dough, is diluted to the state of thick milk, and then filtered through a sieve.

- A dry mixture is prepared based on sand and cement, which is dissolved with lime milk, after which it is thoroughly mixed. Adding lime can increase the plasticity of the resulting mixture; this mixture is recommended for use for laying any type of brick.

Simple masonry mortar

The simplest solution is prepared from a binder (it can be ordinary cement or lime) and sand. In some cases, clay can also act as a binder, but this is very highly specialized work that is not performed very often.

The most common cement-sand mortar has the following proportions: one part of cement to three of medium-fraction sand. The resulting mixture is thoroughly mixed first in dry form, after which plain water is gradually added to it. Stirring is carried out until the resulting composition acquires the proper density and mobility.

Checking such characteristics is not so difficult: the container in which the solution is mixed must be tilted at an angle of forty degrees; if the mixture does not pour out, then you can begin the masonry process.

Complex installation solution

The solution should not spread or slide well off the surface.

A complex brick mix is a mixture of several components and a binder material that affects the physical characteristics. Among such complex mortars for brickwork, cement-lime-clay, cement-lime and others are used, thanks to which the masonry is simpler, but also reliable.

Clay, for example, is added to make the composition more plastic. It does not fall apart during operation and is installed very neatly and easily. The use of plasticizers makes the brick mixture indispensable when laying facade walls. This mixture is very economical, it provides uniform compaction, and when spread, it is conveniently leveled over the surface of the previous row. Therefore, many experts recommend spending a little more time preparing the solution, but then this will only help in the work.

How to make the mixture - preparation and application

Cement-lime mortar has found its application in modern construction; it is often used to treat external or internal walls. Each ball of applied material is distinguished by its individual characteristics and concentration of components, their quantity.

First ball

It should be applied exclusively to a surface that has been pre-treated to maximize filling of all pores. This allows you to increase the adhesion strength of the base (ceiling or wall) to the ball of plaster.

Therefore, the solution for the first ball should be liquid in consistency, with its thickness being 0.4 cm and 0.3 cm for the ceiling.

The solution for applying the first ball can be prepared without adding potassium oxide, but when carrying out exterior and interior decoration, in houses with a high concentration of moisture, it is still recommended to add GOST 9179 77 lime.

For the first ball, connect together:

- water - up to three hundred liters;

- hydrated lime - one hundred kg;

- crushed crushed stone - two hundred kg;

Second ball

Its thickness should not be less than 1.5 cm. This ball is applied after the first one has dried, but until it becomes completely hard. The consistency of the solution should resemble pie dough.

The surface is leveled with a special construction tool, however, for the ideal application of the third layer, it is advisable to leave the second one rough and slightly uneven.

For the second layer, mix:

- water - three hundred liters;

- crushed crushed stone – one hundred and forty kg;

- hydrated slaked lime - one hundred and twenty kg.

Third ball

It is recommended to prepare it from fine sand and potassium oxide. It is only advisable to add very little of the last component. In this case, the resulting mixture will become as plastic as possible.

The third layer is applied thinly and carefully leveled using construction rules.

Alignment by rule

For the third ball you will need to mix (proportions):

- water - three hundred liters;

- crushed crushed stone - one hundred kg;

- sand – one thousand six hundred kg;

- hydrated potassium oxide – one hundred eleven kg.

The builder loves to work with cement-lime mortar because it is considered the most flexible and easy-to-work material. Plaster is constantly crumbling.

Gypsum

Crushed crushed stone hardens quickly.

Crushed crushed stone

Clay is not easy to work with.

Clay

The building mixture discussed in the article is easy to apply, and its price is more than affordable. Of course, there are several walls that are recommended to be treated exclusively with gypsum-lime or clay-lime mortars.

But still, the combination of crushed crushed stone and potassium oxide will certainly provide a fairly diverse range of uses.

According to the actual and technical characteristics, plaster made from crushed crushed stone and potassium oxide is determined by its complex composition, which is rational to use both inside and outside the building, or in houses with a high concentration of moisture.

Crushed crushed stone makes the plaster as durable as possible and resistant to aggressive environmental factors; it provides antibacterial characteristics.

The solution can be supplemented with fine sand, which is specially cleaned and prepared. When water is added, it becomes as flexible as possible and adheres perfectly to the surface.

For more information about plastering walls with a cement-lime mixture, watch the video:

Mixture proportions

There is a classic version of the mixture, which is determined by the ratio 1:3 - 1 part cement and 3 parts sand. Both components are first mixed dry with each other, and then water is added to this mixture in portions. All this is thoroughly mixed until a solution is formed, the consistency of which is similar to thick sour cream. Be sure to give the finished mixture 15 minutes to thicken, after which it is mixed again.

By the way, the cement-sand mortar “lives” for no more than 1.5 hours. After which it begins to lose moisture and dries out. So a small batch is a justified decision.

To mix the components, it is recommended to use a construction mixer or a drill with a special attachment. If you need a large volume of material, for example, to pour a foundation, then we recommend carrying out the preparation process in a concrete mixer

Please note that the end result is a lump-free composition in the form of a homogeneous mass

Sand for masonry mortar

Main ingredients of the solution:

Cement is a binding component. It must be in paper bags. It is recommended to buy it before starting construction processes. That is, it must be “fresh”. After all, during long-term storage this material cakes, which means it loses its qualities. Sand is a filler. There is one point regarding quality here. There should be no foreign materials in the sand. This is especially true for clay. Therefore, it is recommended to purchase river sand

Pay attention to the fraction of the material. For example, fine material promotes the spreading of the mortar, so it is not used for masonry mixtures. But in screed mortars, such sand is an ideal choice

The coarse fraction is not used for preparing plaster, although it works great in foundation mortars. Water is the basis, so it must be clean. The main requirement for it is the absence of acid and oil impurities.

Features of choosing a brand of solution

Now you can move on to the proportions and understand such an indicator as the brand of solution:

- The masonry composition is grade M100. It is used in the construction of walls and barrier structures made of bricks or blocks based on different materials. To do this, you will need M400 cement and sand, which are mixed in a ratio of 1:4.

- To increase the strength of the masonry, you can use M200 grade mortar. To do this, you will have to reduce the amount of sand by 2 times.

- To level the floor bases, the M300 grade of mortar is used. To do this, you can use cement M400 or M500 with the addition of water and sand in a ratio of 1:3:0.5.

- To plaster the walls, use exactly the same solution as above, only with a slight increase in the amount of cement. For example, it could be 1.2-1.5. Plaster mortars are often made with the addition of lime milk. This reduces the strength of the material, but increases its ductility. In this case, the cement-sand-milk ratio will be 1:5:2.

Standard proportions

Making the solution in the correct ratio

There are certain technological standards that regulate the ratio of building mixture components. Here are three examples:

- To prepare the screed solution, use proportions of 1:2-1:6. In this case, the amount of water is not indicated, but only the cement-sand ratio is indicated.

- In low-rise construction, 1:3 or 1:4 solutions are most often used.

- For erected structures - from 1:3 to 1:6.

Why don't the standards specify water? The fact is that it is easy to make a mistake with the volume of water. After all, the sand may be wet, and it is impossible to determine the degree of humidity at home. At the factory, this indicator is strictly controlled. What can you offer to those who use handmade solutions? To do this, it is better to double the batch if the first one turns out to be liquid. Just add cement and sand to it according to the standard, but reduce the amount of water.

3be072818ab0367a28183b8064b824bf.pic

Today, facing tiles and stone are placed on ready-made adhesive mixtures, which greatly simplifies the process of preparing the composition. But since we are considering all cement-sand mortars, we should not ignore this masonry material. Let's just designate the proportions - 1:2.4:0.4. This is such a non-standard ratio.

Many people ask a question regarding determining the volume of one serving. What means and instruments can be used to measure the required amount of material? Construction stores sell special measuring buckets, with the help of which the building mixture is measured or weighed.

Requirements for masonry mixture

The requirements for masonry mortars are described in detail in GOST 28013-98. According to this document, the following requirements apply to mortar mixtures:

- the composition must have a high degree of adhesion to brick and other substrates;

- withstand large amounts of freezing and defrosting;

- to ensure that the masonry does not collapse under the influence of atmospheric influences and temperature changes, the masonry mixtures must have high water resistance;

- due to the plasticity of the mortar, during the laying process, it becomes possible to timely adjust the position of the masonry material, which significantly increases the quality and productivity of the work;

- water-retaining properties prevent decomposition of the mixture and precipitation of heavy fractions;

- the strength characteristics of the composition are decisive in the calculation of building structures. This parameter shows what maximum loads the material can withstand. The brand of the solution reflects its strength in kgf/cm2.

Failure to comply with these requirements leads to the formation of cracks in the brickwork, increased consumption of the mortar mixture, increased thickness of the joints and reduces work productivity.

Making sawdust concrete with your own hands

Independent production of lightweight concrete composite is carried out according to the following algorithm:

- The necessary materials are being prepared. There is no need to purchase components in advance. All components can be prepared immediately before production by visiting stores or building materials warehouses, as well as using waste from woodworking enterprises.

- The ingredients are mixed according to the proportions. Mixing of components can be carried out mechanically using a concrete mixer or manually using shovels. Automation of the technological process through the use of a concrete mixer increases productivity, improves mixing intensity, and has a positive effect on product quality.

- Molding is in progress. The group molding process is predominantly used, when the pre-mixed composition is poured into several dozen molds. Single and group forms of collapsible design are used, made of wood 2 cm thick and upholstered in metal or plastic. The use of polyethylene film makes it easier to remove finished products.

- The finished product is dried naturally. The molds are removed 4–5 days after pouring by loosening the wing nuts, removing the threaded rods and disassembling the molding box. The natural drying process lasts, depending on the type of wood, up to three months, during which the moisture concentration is significantly reduced and the product acquires operational strength.

Standard composition of concrete with sawdust: cement-sand mixture, wood shavings, lime (if necessary)

Why are plasticizers needed?

Plasticizer is a special compound added to the solution to increase its plasticity and elasticity.

Beneficial effect of using a plasticizer:

- Reducing the amount of water that impairs the hardening of the solution.

- Increasing the moisture resistance of the seam.

- Increased frost resistance.

Plasticizers have different purposes:

- Catalysts. Serve to speed up and increase the strength of the hardening of the solution.

- Modifiers. Allows you to obtain additional capabilities of seams - greater resistance to mechanical stress, moisture resistance, etc.

In addition, plasticizers make it possible to obtain a more elastic seam that compensates for thermal expansion of the cladding. This ability helps maintain the strength of connections with the load-bearing wall and prevents the appearance of cracks in the seams that can accumulate moisture.

Making your own solution

First you need to slak the lime for the plaster so that it is suitable for work. This requires a metal container, since the reaction is accompanied by a large release of heat and an increase in volume by 3 times. The lime packaging indicates the slaking speed: slow (25 minutes or less), fast (8 to 10 minutes), medium, 15 to 20 minutes. It is better to mix the mixture with a shovel or oar. Slaking is carried out for at least a day, however, ideally use lime that has been standing for a month.

The note! The sand also needs to be prepared before preparing the plaster: remove impurities, clean it by passing it through a sieve.

Instructions for creating a limestone-sand mortar:

- Sand is mixed with lime paste in the selected proportion. This is done dry and mixed thoroughly.

- After which water is gradually added to the container. There is no need to pour in the entire volume at once; it is poured in in a thin stream, and the solution is constantly stirred.

Now that the preparation is complete, you can begin plastering the surface.

How to prepare cement-lime mortar

In general terms, cement-lime plaster is prepared similarly to cement-sand plaster, but lime paste is added along with the mixing water.

Usual solution proportions:

- 1 volume part of cement;

- 4–5 parts sand;

- water until the required consistency is reached.

How to properly slak lime. Lime mortar preparation technology

Lime is used to make plaster. It is supplied in quicklime, powder, paste or granule form. Before preparing the solution, it must be extinguished.

Important!

Quicklime can irritate the skin, and when mixed with water, it produces caustic fumes, so the use of protective gloves and a respirator is necessary when slaking.

You can’t just pour water over fluffed lime: the reaction will go very violently, releasing heat.

Find a heat-resistant, non-plastic container, such as a metal bucket or trough. Pour water at the rate of 5–6 liters per 2 kg of quicklime. Gradually add lime, stirring thoroughly but gently. It is better to do the work together. To completely extinguish, it is necessary to let the solution stand for 1–2 hours, stirring occasionally so that the lime does not settle to the bottom. At the end of the process, you will get a white, opaque, milk-like solution. It is used instead of water to prepare cement-lime plaster.

The procedure for preparing plaster mortar

To mix the plaster mortar, use a concrete mixer or a construction mixer. Small portions of the solution can be mixed with a shovel or using a drill.

The mixing order may vary, but usually sand and cement are mixed first, then water or lime solution is gradually added.

It is necessary to mix the solution thoroughly so that it is homogeneous without lumps.

The consistency of the solution is like thick sour cream, although a thinner consistency is sometimes used for the first layer.

Important!

You can work with cement-lime mortar for 3–4 hours; this must be taken into account when mixing plaster.

Safety precautions

When working with cement-lime and cement plaster, wear long sleeves and rubber gloves to protect your hands. Safety glasses are also required, and a respirator when mixing the solution.

What is lime plaster

Adding lime to solutions can significantly increase the ductility and crack resistance of plaster. It becomes much easier to work with, it does not dry out as quickly, it even sticks easily to wood, and the surface is smoother and free of defects. It also provides excellent protection against mold and mildew. Another indisputable advantage is its environmental friendliness - unlike synthetic additives, lime is absolutely harmless.

Lime is widely used in construction as a plasticizer. However, when plastering facades, it should be taken into account that it can only be used in areas with a dry climate. Such solutions are not recommended for use in rooms with high (over 60%) humidity.

Lime plaster is considered warmer and more vapor-permeable, that is, “breathable,” and it is much easier to remove it from the walls in case of repairs than, for example, ordinary cement plaster. But excess lime can weaken the strength of the surface. That is why it should be added in moderation, strictly adhering to the proportions.

As you can see, lime plaster has many advantages. The disadvantages include not such high strength as that of cement compositions. It is also not recommended to use it in damp areas and

But such a solution does not require special strength. After all, the purpose of plastering is to level the surface and cover up small cracks. A more durable solution is required when laying. However, even in this case, according to SNiP, it is allowed to add a small amount of lime paste or clay to it to increase plasticity.

When slaking lime, you should be extremely careful - splashes of the hot mixture can cause burns. The smallest lime dust that can settle on the mucous membrane also has a harmful effect. Therefore, when working, you should use protective clothing, gloves and a respirator.

Applying plaster. Step-by-step instruction

Let's look at the stages of applying plaster.

Preparatory work before applying plaster

Before plastering the wall, it must be dust-free and thoroughly cleaned.

Then, using a level, the beacons are set and fixed with a quickly setting solution, for example, with the addition of gypsum.

Before proceeding directly to plastering, the wall should be moistened with water until saturated, then wait about half an hour. If this is not done, the dry wall will draw water from the plaster mortar, and as a result, the strength of the coating will decrease.

Sometimes, before coating, the surfaces are treated with a primer for better adhesion. The primer must dry completely.

Splash

Spraying is a necessary step before plastering. This procedure is very important because it helps the plaster adhere better to the surface. To do this, prepare a solution that is more liquid than the main one, apply it with a trowel, as thin as possible and do not level it. Once the plaster has dried slightly enough to support the base coat (usually after 2-3 hours), begin applying the base coat.

Base layer

For this layer, which can be up to 50 mm thick, a thicker solution is used. It is thrown onto the walls with a trowel or trowel, starting work from the top, and leveled with wide movements from bottom to top.

The excess is cut off as a rule.

Grinding

The finishing coat is necessary for surfaces to be painted and wallpaper.

Apply a layer of liquid plaster, as for spraying, and level it with special graters until a perfectly flat and smooth surface is obtained.

We take out the beacons

Sometimes beacons can be left, for example, if work is carried out in a room with low humidity. In other cases, the beacons are removed and the surface is leveled.

Preparation of masonry mortars

Since various types of mixtures can be used for masonry mortar, let us consider in more detail how to prepare mortar for bricklaying.

Cement mortar proportions

Sand-cement compositions are widely used in capital construction and other areas where increased demands are placed on the strength characteristics of brickwork.

When starting to prepare masonry mortar, you should remember that excess cement in the working mixture does not increase its strength, and in some cases, even worsens its characteristics. Only strict adherence to dosage will ensure optimal performance properties of the masonry mixture. The proportions of the most common cement-based compositions are given in SP 82-101-98, which clearly regulates the percentage of ingredients in various types of cement masonry mixtures.

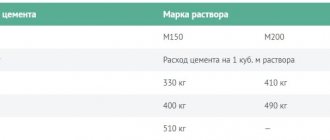

The table shows the percentage of ingredients in cement masonry mortar, depending on the brand of cement used.

| Brand of masonry mixture | Cement brand | Ratio cement/sand |

| M25 | M300 | 1/9,5 |

| M50 | M300 | 1/5,8 |

| M400 | 1/7,4 | |

| M 75 | M 300 | 1/4,2 |

| M 400 | 1/5,4 | |

| M 500 | 1/6,7 | |

| M 100 | M 300 | 1/3,4 |

| M 400 | 1/4,3 | |

| M 500 | 1/5,3 | |

| M 150 | M 300 | 1/2,6 |

| M 400 | 1,3,25 | |

| M 500 | 1/3,9 |

Scope of application of cement mortar depending on strength characteristics

Below is the scope of application of different brands of masonry mortars.

- M25.

Used for plastering and floor screeding. The composition does not contain any additional ingredients. - M 50.

Used for brick and stone masonry in the construction of low-rise buildings and structures. May contain plasticizers, dyes and other additives. - M 75.

Used for laying concrete slabs, installing reinforced concrete structures, erecting internal partitions and installing concrete floor screeds. - M 100.

Widely used in monolithic construction, masonry work and pouring light-loaded strip foundations. - M 150.

Used primarily for foundation work on loose soils.

Proportions of cement-lime mortar

The percentage ratio of cement, lime and sand in cement-lime mortar is given in the table.

| Cement/lime/sand ratio | |||||

| Cement brand | Masonry mixture M 50 | Masonry mixture M 75 | Masonry mixture M 100 | Masonry mixture M 150 | Masonry mixture M 200 |

| M 300 | 1/0,6/8 | 1/0,3/4 | 1/0,2/3,5 | 1/0,1/2,5 | |

| M 400 | 1/0,9/8 | 1/0,5/5,5 | 1/0,4/4,5 | 1/0,2/3 | 1/0,1/2,5 |

| M 500 | 1/0,8/7 | 1/0,5/5,5 | 1/0,3/4 | 1/0,2/3 |

The solution is prepared in the following sequence:

- Fluffed lime is diluted to the consistency of kefir, and then filtered.

- Separately prepare a dry sand-cement mixture.

- Strained lime is added to the cement-sand mixture and mixed thoroughly until a homogeneous mass is obtained.

Proportions of cement-clay mortar

The ratio of cement, clay and sand in a cement-clay masonry mixture is given in the table.

| Brand of masonry mixture | Cement M 500 | Cement M 400 | Cement M 300 |

| Cement/clay/sand ratio | |||

| M 300 | 1/0,15/2,1 | 1/0,07/1,8 | |

| M 200 | 1/0,2/3 | 1/0,1/2,5 | |

| M 150 | 1/0,3/4 | 1/0,2/3 | 1/0,1/2,5 |

| M 100 | 1/0,5/5,5 | 1/0,4/4,5 | 1/0,2/3,5 |

| M 75 | 1/0,8/7 | 1/0,5/5,5 | 1/0,3/4 |

| M 50 | 1/0,9/8 | 1/0,6/6 | |

| M 25 | 1/1,4/10,5 |

The addition of clay increases the ability of masonry mixtures to retain moisture.

The low strength of lime mortar prevents its widespread use in masonry work. Most often, lime mixtures are used for plastering work. The proportions of the working solution depend primarily on the fat content of the lime and can range from 1/2 to 1/5.

Application of lime-sand mortars

This type of solution involves mixing lime, water and sand into the mixture. The sand must be sifted and washed in advance; in addition, proportions must be taken into account. The optimal ratio of lime and sand is approximately 1:2 or 1:3. A solution with added sand is quite cheap, but very often, for better results, cement is added as an additional binder. Then it would be best to take from 3 to 6 parts of sand to one part of cement. Lime-sand and lime-sand-cement mortar are used for bricklaying and plastering work.

The spheres and areas of application of lime mortars are essentially limited only to the construction sector. But, as we all know, construction is a very complex industry with many different technological processes, and it is in them that it is necessary to use lime mortars. With their help it will be possible to build a reliable and durable house.

Concrete mortar and its composition.

Cement should only be stored in a closed, dry place! Per 1 bag of cement, the dosage of concrete mortar is as follows:

| Cement binder material | Dry construction sand filler | Water | Plasticizer Added to cement mortar for high plasticity |

| Purpose | Cement | Dry construction sand Fraction 0.5 mm Density 1.5 g/m3 | Water approximate amount | Plasticizer |

| Construction of walls from concrete blocks Example: blocks 20x20x50 cm by 7 m2 | 50 kg | 190 kg or 127 l | 25 l | |

| Construction of brick walls Example: brick 120x250x65 mm per 7 m2 | 50 kg | 190 kg or 127 l | 25 l | + |

| Concrete floor screed | 50 kg | 200 kg or 135 l | 25 l | |

| Traditional facade plaster for 20 m2 First layer 3-5 mm | 50 kg | 250 kg or 167 l | 25 l | |

| Cement-lime second layer Soil 15-20 mm | 50+50 kg | 250 kg 167 l | 25 l | + |

| Cement-lime third layer Covering 5-7 mm | 20 kg | 190 kg 127 l | 25 l | + |

| Grout for joints on a stone wall | 50 | 190 kg 127 l | 25 l | |

| Grout for joints on a brick wall | 25 kg | 95 kg or 63 l | 13 l | + |

This solution is used for various construction works (screed, foundation, floors, beams). Steel reinforcement is placed into concrete to increase strength, resulting in reinforced concrete. Bonding the reinforcement to the mortar makes it easier for the metal surface to oxidize.

| Cement binder material | Dry construction sand filler | Gravel filler | Water |

| Purpose | Type of fittings | Cement in bags of 50 kg | Dry construction sand Fraction 0.5 mm Density 1.5 g/m3 | Crushed stone for concrete Fraction 20-40 mm Density 1.6 g/m3 | Approximate amount of water |

| Concrete screed, garage floor, terrace | Welded reinforcement mesh | 8 | 1200 kg (90 kg/bag), or 800 l (60 l/bag) | 850 kg (176 kg/bag), or 530 l (110 l/bag) | 175 l |

| Foundation | Foundation mesh | 8 | 1200 kg (90 kg/bag), or 800 l (60 l/bag) | 850 kg (176 kg/bag), or 530 l (110 l/bag) | 175 kg |

| Beams, floors | Square reinforcing mesh, smooth or corrugated steel rod | 8 | 720 kg (90 kg/bag), or 490 l (60 l/bag) | 850 kg (130 kg/bag), or 530 l (81 l/bag) | 200 l |

Calculation of the required volume of concrete is calculated using the formula:

Volume of concrete = Length x Width x Height, for example: 10 x 5 x 0.1 m = 5 m3

When adding water to a solution or building mixture, the following proportions must be observed:

Volume of water = Weight of cement / 2, for example: 25 liters of water per bag of cement weighing 50 kg.

Preparation of simple plaster compositions

Cement mortar is the simplest and most common.

Simple plasters include those mortars based on a single binder. These include the following plaster solutions:

- Cement.

- Lime.

- Clay.

- Plaster.

Cement

This composition is the most common type of finishing: its consistency is very similar to brick laying mortar. However, the density in this case is different, and the use of various additives and plasticizers is widely practiced.

Although this may sound unexpected, what most closely requires personal control is the quality of the sand used. That is why, before use, it is carefully sifted through a special sieve to remove all impurities and debris.

After cleaning the sand, the mixing procedure begins: the main components must first be mixed dry. The proportions of cement mortar for plastering walls outside the room are taken in a ratio of 1:5 sand to M500 cement. As for the interior finishing, in this case cement is mixed with sand 1:4, where M400 cement is used for preparation. After the dry ingredients have acquired the required homogeneity, water is added to the composition and stirred until it becomes mushy. To carry out such a procedure, both a trough and a construction mixer can be used.

Lime

In lime mortar, lime acts as a binder.

This composition differs from the previous one in the absence of cement: in this case, lime is used as a binder: it must only be slaked and have excellent qualities. The first step is to thoroughly grind it so that the particles are as small as possible. Then water and sand are added to the vessel with lime powder, constantly mixing the entire material

It is very important that the resulting lime mortar for plaster does not contain lumps, with the density of the mixture resembling dough. Then another portion of purified sand is added to the resulting mass in a ratio of 3:1

After this, the final stirring of the plaster is carried out by adding water: the finished consistency of the solution should resemble thick sour cream.

Clay

This easy-to-prepare plaster mortar is the oldest known. With the development of construction technologies, its composition has undergone some changes, because clay in its pure form is quickly washed off by rain. To strengthen the finish, it is practiced to add cement, lime and gypsum, which helps to increase its durability and reliability: while maintaining the availability of preparation. In the process of preparing clay plaster, the main component must be thoroughly cleaned of all kinds of debris and impurities. Then clean and dry clay is soaked in water for 3-5 hours until it is completely soaked: the preparation of the solution is completed by adding sand to its composition, at the rate of 2-4 parts of sand to one part of the clay mixture. Typically, clay plaster is used to decorate interior spaces.

Gypsum plaster

Most often, final operations on leveling walls are carried out using gypsum plasters, with the possibility of application not only on concrete and brick, but also on wooden bases. The first recipe for preparing such a solution involves using 3 kg of chalk and 1 kg of gypsum, while the chalk is crushed to dust, and then mixed with gypsum. In this case, water is not used, since 5% wood glue is used as a solvent. The proportions of glue in this case vary, depending on the required thickness of the final solution. This type of solvent not only makes the mass of plaster homogeneous, but also allows you to somewhat slow down the hardening process. However, the drying speed of gypsum plaster is still quite high.

Working with gypsum plaster requires skill, as the mixture dries quickly

The second method of preparing a finishing mortar from gypsum is especially suitable in cases where it is necessary to plaster painted bases or chipboard partitions. In this case, you will need to take 2 kg of gypsum, 1 kg of drying oil and 100 g of drier: after thorough mixing, the composition must be immediately prepared. The reason for this is the lightning-fast drying of the drier: when working in this case, you will need appropriate construction skills.

Why is lime added to concrete?

Lime is a popular material for wall finishing that has disinfecting properties and is not susceptible to mold and mildew. Most often, this type of finishing is found in public places, where a coating that is resistant to abrasion and mechanical stress is needed.

General information about lime

Lime is a mixture of substances that are a product of calcination of limestone rocks. The most common types of lime found on store shelves are lump quicklime and slaked fluff. Lime destroys all microorganisms that come into contact with it, and therefore is the most hygienic type of finishing. In addition, it has a high level of moisture resistance and strength. When the lime coating dries completely, a film forms on it, which ensures such durability of lime whitewash. Another advantage of lime is its low price compared to other types of finishing materials.

There are also disadvantages to lime. If the craftsman performing the work does not know how to properly dilute the lime and makes the solution in the wrong proportion, then bubbles, streaks and streaks will appear on the treated surface. A solution that is too thin will not give the desired color on the wall, and a solution that is too thick will begin to bubble and fall off when dry. It’s easy to avoid this - dilute lime strictly following the instructions and in the right proportion.

Scope of application of lime

- In construction, lime is used as a plasticizer for cement mortars. It prevents cracking of the solution and binds it well. It is an indispensable ingredient in plaster mixtures. Helps the coating adhere to stone and wood surfaces. For this purpose, only slaked lime is used.

- In gardening it is used to treat trees and reduce acidity in the soil. To whitewash trees, lime is mixed with copper sulfate.

- In industry, animal skins are treated with lime, and water is softened and disinfected with it.

- In everyday life, lime is used for whitewashing various surfaces - walls, ceilings, stoves, etc.

- In medicine, bleach is used to disinfect premises, equipment and water.

Proportions of lime dilution and its consumption

The proportions of lime dilution depend on the type of material used. Quicklime and slaked fluff lime are displayed on store shelves. Read below on how to dilute the second type of lime. As for slaking lime and using chlorine solution, this information is located in a separate section of the same name.

Slaked lime is sold in two versions - powder or liquid dough. Both configurations are diluted in a ratio of 3:1, that is, 3 liters of water per 1 kg of powder or dough. The result is about 8 kg of whitewash, which is enough to treat 12 m2 of surface. Consumption will increase if you whitewash brickwork.

Another way to calculate how to dilute slaked lime correctly is to proceed from the total square footage of the surface being treated. To do this, for every 2.5 m2 take 500 g of lime and 750 ml of water.

Consumption depends not only on the type of surface to be coated, but also on the materials used for whitewashing - brushes, sprayers or others. Optimal materials for whitewashing will also be discussed in a separate section. As for the cost of work, lime is not an expensive material at all, which will make finishing activities inexpensive.

How to dilute slaked lime

On the one hand, the process of diluting lime looks quite simple, but, nevertheless, it has some important nuances:

- Lime is mixed in small portions; there is no need to immediately combine a large amount of powder or dough with water. The maximum permissible value of water poured at one time is 1 liter per 2 kg of lime.

- When water and lime mix, a chemical reaction begins, the product of which is heat. Therefore, it is best to pour the powder with cold water.

- The mixture is thoroughly stirred and another liter of water is added and stirred again. This continues until the entire required amount of moisture has been added.

- The diluted and thoroughly stirred mixture is left to settle for 24 hours.

- At this time, pour 2 kg of salt into 1 liter of water in another container and stir until the salt is completely dissolved. It is best to prepare this solution after the lime has settled for a period of time, otherwise the salt will settle within a day and will have to be stirred again.

- When the lime mortar is ready, salt water is poured into it and stirred. The mixture is diluted with a small amount of water to bring it to the desired thickness.

- The salt water and lime are mixed again and left for another 24 hours.

- Salt is added to lime so that it wears off less and remains on hands and clothes when touched after drying. Whitewashing can also be done without a saline solution; for this, the lime only needs to be diluted with water and allowed to sit for 24 hours.

How to slak lime

Quicklime is used as a binder for plasters and various cement mortars. It gives the material plasticity and makes its bond to the base stronger. But quicklime is not suitable for whitewashing surfaces. It is optimal for this purpose to purchase ready-made powder or fluff dough. If you bought quicklime for whitewashing, then it is not difficult to extinguish it.

Extinguishing lime with your own hands in a residential area is simple and not dangerous. In industrial enterprises, a special pit is often used for this process, into which powder and water are poured in the required proportion. The amount of water added depends on whether the resulting material should be thick or milky.

The lime slaking period is 24 hours, but it is optimal to keep it for 36 hours. To extinguish you will need the lime itself, water and any long object for stirring. It is necessary to work in goggles, a respirator and a canvas suit. Do not allow drops of the solution to get on the skin, as it will damage them.

Proportions of cement mortar for brickwork

For brickwork, as for plaster, cement-lime or cement mortars are created. However, it must be taken into account that in this case the grade of mortar should not be higher than the strength class of the bricks used for masonry. It is most convenient to work with plastic mortar: it is easy to apply, but does not drain from the masonry elements. In order to prepare a mixture with optimal consistency, you need to know the most successful ratio of all components of the solution.

Preparation of branded cement mortars

The brand of mortar depends on the ratio of cement and sand in the mortar. The more sand and less cement, the less durable the solution is and, accordingly, the lower its grade.

- 1 part cement: 5 parts sand - the proportion of preparation of the MZ grade solution;

- 1 part cement: 4 parts sand - the proportion of preparation of the M5 grade solution;

- 1 part cement: 3 parts sand - the proportion for preparing the M8 grade solution.

Recipe for plastic cement mortar M3 for brickwork

To create 1000 liters of M3 grade solution you need:

- water – 340 l.;

- sand – 2064 kg;

- cement – 268 kg.

To create 200 liters of M3 grade solution you need:

- water – 54 l.;

- sand – 206 l. (330 kg.);

- cement – 33 l. (43 kg.).

To create an M3 mortar from a 25-kilogram bag of cement, you need:

- water – 32 l.;

- sand – 120 l. (192 kg);

- cement – 25 kg.

Recipe for plastic cement mortar M5 for brickwork

To create 1000 liters of M5 grade solution you need:

- water – 350 l.;

- sand – 2000 kg;

- cement - 327 kg.

To create 200 liters of M5 grade solution you need:

- water – 56 l.;

- sand – 320 kg;

- cement - 52 kg.

To create an M5 mortar from a 25-kilogram bag of cement, you need:

- water – 27 l.;

- sand – 177 kg;

- cement - 25 kg.

Recipe for plastic cement mortar M8 for brickwork

To create 1000 liters of M8 grade solution you need:

- water – 360 l.;

- sand – 1904 kg;

- cement – 412 kg.

To create 200 liters of M8 grade solution you need:

- water – 58 l.;

- sand – 305 kg;

- cement – 66 kg.

To create an M8 mortar from a 25-kilogram bag of cement, you need:

- water – 22 l.;

- sand – 115 kg;

- cement – 25 kg.

Recipe for plastic cement-lime mortar M3 for brickwork

To create 1000 liters of M3 cement-lime mortar you need:

- water – 470 l.;

- sand – 1760 kg;

- cement – 191 kg;

- hydrated lime – 106 kg.

To create 200 liters of M3 cement-lime mortar you need:

- water – 75 l.;

- sand – 282 kg;

- cement – 30.5 kg;

- hydrated lime – 17 kg.

To create a plastic cement-lime mortar of grade M3 from a 25-kilogram bag of cement, you need:

- water – 61 l.;

- sand – 230 kg;

- cement – 25 kg;

- hydrated lime – 14 kg..

Application for plastering walls

Cement-lime mixture is considered a versatile finishing material that firmly grips the surface of wood, brick or concrete.

Application to brick

Such a solution has one drawback, which is so insignificant that it cannot resist the advantages. It is unstable to any type of deformation.

But from a practical point of view, even if a nail is driven into the surface, it does not form depressions on the surface or chips.

Among the advantages of the building mixture in question:

- antifungal characteristics - traces of fungus or mold will never appear on the surface treated with the composition. The material creates the required level of air permeability and an ideal microclimate in the room;

- If you compare cement and lime plaster with its sand counterpart, the first composition is much stronger. It is used to process the plane between the wall and the window itself, cornices or even basement rooms. Even if the mixture hardens, it will not lose its original characteristics.

Cement-lime mortar is used to create the most even facade and to process complex geometric shapes. Thanks to the plasticity of the composition, it evenly covers any wall.