The use of cement mortar is widely used for external and internal work. The standard color of this solution is gray. To give a decorative look, the cement surface can be painted in different colors or at the stage of preparing the solution, add a cement dye to it - this will give the solution a more saturated and uniform color.

Adding pigments to the solution extends the service life of the painted cement surface. If you paint gray concrete, then this decorative layer will last a long time.

Types of paints

All facade paints can be divided into two large groups - water-based coatings and facing materials based on organic solvents.

To work on concrete, it is customary to use water-based paint - emulsions of synthetic resins and water dispersions, in particular: acrylic, silicone, latex, acrylate and other coatings on the market. Organic solvents are used to produce paints containing polyurethane and alkyd compounds.

Facade paint not only performs an aesthetic function, giving the building an attractive appearance, but also protects the facade of the building from contamination by harmful chemicals, from sudden temperature changes, from precipitation, from exposure to ultraviolet rays, from mold and mildew.

Preparing concrete walls for painting

The process of preparing concrete walls for painting consists of several stages.

- Surface cleaning, which may include: removal of old oil paint, removal of mold and dirt. If the concrete is fresh, cement laitance forms on its surface, which must be sanded after the material has dried.

- Removing dust from the surface (you can use a vacuum cleaner).

- If there are cracks and potholes, they are filled with plaster, putty or polyurethane foam.

- After the mixture has dried, the surface is sanded manually or with a special grinding machine and then primed.

Now you can proceed to painting, having previously carried out tinting. To do this, use a white base paint and add pigment.

Which cement to choose for making colored concrete with your own hands?

When making colored concrete, any type of cement can be used. But it is still worth taking into account the following nuances:

- It is advisable to use high-quality cement;

- It is worth paying attention to the color of the cement, because the initial color affects the shade after it is painted;

- Remember that the gray color of cement has a muting effect on the tone, thereby making it dirty and reducing brightness;

- It is best to use white cement. When stained with this concrete, the color will be bright and crisp.

To avoid problems when painting, use the following recommendations:

- It is advisable to do preliminary mixing and filling;

- If a large amount of pigment is introduced into the cement mixture, cracking may increase in the future;

- In addition, cracking can occur due to the high absorption of water by the cement powder. Therefore, plasticizers and water-retaining additives should be added to the mixture.

Advantages of painting concrete at the preparation stage

The only drawback of the method is the high cost of materials. To obtain a rich and deep color, you will need to introduce a significant amount of a substance, the price of which is not small.

If the introduction of dyes is implied at the stage of mixing the solution, a number of advantages can be obtained:

- through coloring of the entire mass of material;

- when the top layer is abraded, the beauty and richness of color are not lost;

- in the manufacture of curbs, paving slabs and other reinforced concrete products, it is recommended to use this type of painting, since the finished structure does not require updating or touching up for many years;

- colored concrete obtained by this method can be used for monolithic pouring of retaining walls, platforms, and colored concrete paths.

After the material dries, the coloring matter does not dissolve in water, oil and other solvents, and is resistant to sun fading

We paint cement cheaply and efficiently

Paint for cement plaster ensures durability and reliability of the finish

Is there a universal, durable and at the same time inexpensive paint for cement floors? Yes, there are such coatings and there are many of them, but the most affordable of them is the solution that you will make yourself.

It is no secret that cement itself can demonstrate the best adhesion to a cement floor or wall plaster. So why not make your own paint based on this material!

Production of coloring composition

Carbon black is a dye used for construction purposes.

Cement paints are compositions based on Portland cement with pigments and integrated fillers - additives responsible for the intensity of hardening, hydrophobicity and strength of the coating.

It is not difficult to prepare a simple composition at home.

We do it this way:

- Pour distilled water into a plastic container (if distilled water is not available, you can use rainwater).

- Constantly stirring the water with a paint brush, add cement in small portions.

- After the solution has acquired the consistency of liquid sour cream, add a suitable color (the best option is a color for mixing into water-based paints).

- Next, mix the solution until it acquires a uniform color.

- If cement paint is made for future use, it is advisable to use a bucket and a drill with a special attachment for mixing. The dosage in this case is 2 kg of Portland cement per 10 liters of water.

Important: If the paint is stored in finished form for more than an hour, the cement base will precipitate. Therefore, before use, the composition must be thoroughly mixed again, and as it thickens, small portions of water can be added to the solution. The resource of the solution is small, as a rule, it is 3-4 hours, so you should prepare a composition that you will have time to use during this time.

Painting technology

Application of cement paints instead of traditional plasters

What to consider when preparing the solution

To prepare a dye for concrete with your own hands, you need to take into account the color of the concrete base. White concrete can be lightened by adding titanium dioxide to it in a proportion of 1-2%. And in the production of paving slabs, it is recommended to use mineral-based dyes in a proportion of 1-5%.

In order to prepare a pigment for concrete with your own hands, it is important to consider that the dyes must withstand the effects of alkalis, atmospheric conditions and direct solar radiation.

Before painting the cement mortar, it is necessary to study the range of shades that powder paint provides. The green tint comes from chromium oxide, red from iron oxide, and black from manganese peroxide. White pigments are obtained using limestone and chalk.

Recommendations from experts (2 videos)

Different types of pigments for cement (23 photos)

Useful tips

Despite the fact that there is nothing particularly difficult about painting concrete walls, there are some useful tips that will help you avoid serious mistakes and get the job done efficiently from start to finish:

- It is necessary to prime the wall. This will not only improve the quality of work, but also increase the service life of the paint;

- if holes or through openings are made in the wall, the exposed reinforcement needs additional processing;

- if there are areas on the wall that are covered with mold, you must first remove it and only then paint it;

- In no case should you apply paint without putty or plaster - after all, the wall must be leveled;

- You should make sure that there are no stains of grease, rust, etc. on the wall, otherwise they will show themselves, even despite several layers of paint.

Advantages and disadvantages of colored cement composition

Dyes are widely used for cement surfaces, since after hardening the product does not need to be touched up. As the outer layer wears out, the cement composition retains its original shade.

Let us note important operational characteristics:

- Safety of supplements for health.

- Economical in use. A small concentration of the substance allows you to obtain a rich color range.

- Wide possibility of achieving different color shades by changing the concentration of additives.

Despite many positive aspects, there are negative aspects. The composition, colored with the help of additives, loses its original color over time and acquires a yellowish tint. The costs of installing a colored concrete surface are quite significant.

Modern paint application technology

Plastered walls intended for painting must first be well dried, since paint does not adhere well to a damp surface and, due to dampness or temperature changes, it bubbles, peels and bounces, which is often observed with poor painting of new buildings.

Painting of cement plaster usually begins no earlier than the next year after the construction of the building. In this case, before painting, new plaster is coated with drying oil so that the oil penetrates as deeply as possible. In cold weather, it is useful to add 5-10% turpentine.

Coloring pigments

The principle of operation of the colors is that they color the mixing water , saturating the aluminates and silicates of cement with pigment. The proportional mass of the substance changes depending on the required color saturation. Pigment is a special additive, which is most often presented in the form of dry powder , emulsions, concentrated paste, microcapsules.

Classification

All additives are divided depending on their origin and type of receipt.

The main varieties are as follows:

- organic - artificial cinnabar, blue, yellow, burgundy, scarlet, pink, red, green, purple, green;

- mineral (inorganic), which are divided into: natural - obtained through mechanical processing of various materials. These are red lead (pigment for concrete) iron, kaolin, ocher, umber, manganese peroxide, lime, graphite, chalk;

- artificial - obtained from mineral raw materials that have undergone heat treatment - painter's glaze, lead, zinc, titanium white, chromium oxide, zinc greens and crowns, dry lithopone, burnt umber;

- metal – zinc dust, golden bronze, aluminum powder.

The range of modern chemicals is quite large, therefore, the main thing when purchasing is not to make a mistake with the choice. When selecting a material, you should take into account the properties and requirements for the characteristics of the painted product.

It should be borne in mind that when wet, the colors look more intense and brighter than after the concrete has hardened.

Specifications

The chemical composition of dyes determines its characteristics, such as heat resistance, corrosion resistance, chemical resistance, and color.

It is customary to identify the main parameters of the pigment composition:

- coloring ability - allows the mixture with white cement to obtain the required shade;

- dispersion - the indicator shows the fineness of grinding and affects all the properties of the pigment - the finer the particles, the higher the coloring ability;

- alkali resistance - determines the resistance of the tone to the effects of cement. Almost all pigments have excellent alkali resistance;

- Lightfastness - the ability of a shade to maintain its saturation under the influence of ultraviolet radiation. Natural pigments are more light-resistant; the majority of synthesized substances are prone to discoloration.

Paints for concrete and other mineral surfaces

Concrete surfaces, be it a monolithic facade, internal walls or floors, are rarely left without finishing. Yes, there are trends in the interior (high-tech, industrial style), where raw concrete is the accent of design. There are also architectural objects with minimalist, strict gray facades. But they are not so popular in Russia. Vertical concrete surfaces are usually plastered and painted. The floors are filled with cement-sand screed under the finishing coating or painted with special paints and varnishes (in technical rooms, warehouses, shops, etc.). The ceilings are plastered and subsequently painted, suspended PVC sheets are installed or sheathed with gypsum boards.

Interior painting plays a more decorative role. An exception is the installation of epoxy floors. External finishing of concrete and plaster surfaces acts not only as decoration, but also as protection. Why? The facade of the house and the basement are negatively affected by humidity. It is this, in combination with temperature changes, that is the main cause of destruction. Moisture, getting into the pores of the material and freezing there in winter, tears it apart from the inside.

The surface of concrete on the street is affected by:

- rainwater, especially in the case of slanting rains;

- water vapor that moves from inside to outside and at a certain stage (passing the dew point) turns into water. In a properly constructed structure, such transformations do not occur, and therefore there is no fear of damage to the structures. At risk are wet rooms where the waterproofing is not done properly;

- moisture that is sucked from the soil due to the absence or errors in waterproofing;

- construction moisture in new structures, which gradually evaporates;

- street dirt and dust, mold and mildew;

- acid gases in the air (hydrocarbon gas with a high concentration of hydrogen sulfide);

- CO2, which initiates corrosion processes that promote weathering of the top concrete layer.

External mineral coatings are usually coated with paintwork materials.

Types of paints for concrete and other mineral surfaces

Manufacturers offer the best paints that are suitable for finishing most mineral surfaces: concrete, brickwork, plaster, gas/foam block, etc. Paintwork materials are classified depending on the type of binder into acrylic, silicone, silicate, epoxy (for concrete floors).

Acrylic paints

for exterior work and interior decoration based on polymers of the same name, they have a mild odor. They are comfortable to use and, as a rule, do not require special application skills. They have good adhesion to all mineral substrates. The finished coating is quite resistant to weathering. What is important is that it is vapor permeable. Types of acrylic paints for concrete can be supplemented with acrylate and latex materials.

Water-based paints based on silicone resins

They also have excellent adhesion to concrete, plaster, etc. Silicone coatings are more inert to the environment. They have reduced dirt retention. The vapor permeability of silicone paints is higher than that of acrylic paints. The durability of the coating, if the work technology is followed, is measured in decades. Low consumption and high spreadability also make these paints stand out from other materials. They perform well even in harsh weather conditions.

Based on silicate paints and varnishes

Potassium liquid glass is coming. This paint has excellent adhesion to mineral substrates. The coating is durable and reliable, and in cases where the composition contains organosilicon resins, it acquires exceptional strength. Good vapor permeability and water resistance make this material attractive to buyers. Water, without being absorbed, flows down the wall, and through micropores, steam is separated from the walls and air circulates. Thus, the most optimal conditions for preserving the facade are maintained. But it also has its own characteristics. For example, before applying silicate paint, it is necessary to remove the old paint coating, since the material does not have good enough adhesion to acrylic and alkyd films. Silicate materials have high requirements for surface preparation. Unfortunately, they will not hide small cracks and irregularities, but will only emphasize them, since they have rather low elasticity. The silicate coating is quite difficult to remove. This is due to high adhesion to mineral substrates.

Dyes for brickwork

The masonry mortar can also be given the desired color, which is achieved by introducing pigments. There are many dyes for masonry on sale - Precolor, YIPIN, Perel, Fepren and others. Shades of the same color vary greatly from one manufacturer to another, so you should choose them according to your individual needs. It is extremely undesirable to use pigments of different brands on the same masonry - this can spoil the overall appearance of the building, because the color of the seams will not be the same.

Types of dyes for brickwork mortar

All described types of pigments, as well as dyes created on their basis - acrylic, acid and others, are suitable for this purpose. They color lime, cement, cement-lime mortars. The proportion of paint in the total mass should not exceed 8%, otherwise the strength of the brickwork will decrease.

Choice - what to look for

The most important indicator is the color of the pigment. With its help, you can highlight the seams or, on the contrary, make them invisible (if you use dye to match the brick). The pigment should strengthen the structure and make the solution more resistant to the sun, water, and temperature changes.

Also, when selecting dyes, their moisture retention rate is taken into account:

- low – 5-6% (for clinker bricks),

- average – 7-10% (for facing bricks),

- high – 10-15% (for sand-lime brick).

Taking into account such parameters, it is possible to reduce the risk of pigment discoloration and the appearance of efflorescence spots on the surface of the seams. Most often, shades of pigments such as brown, yellow, pink, beige, and white are used for brickwork. Although you can use any other color.

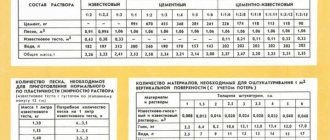

Preparation and use of the solution

To make lime mortar, mix 1 part fine lime, 2 parts sand and a sufficient amount of water. The cement-lime mortar includes cement and lime milk, as well as sand (1 part each of lime, cement and 4-6 parts of sand).

First, mix the dry ingredients, then pour in water so that the consistency is like soft butter (the amount of water can be determined by eye). Afterwards, pigment or liquid dye is added to the prepared masonry solution. It is better to use a concrete mixer for mixing. A small volume of components can be mixed manually, using a spatula, in a bucket or other container.

The classic color is white; it is obtained by adding slaked lime, zinc oxide or titanium oxide. The last option is the most expensive, but it ensures longevity of the shade for decades. To reduce costs, the entire masonry is often filled with ordinary, gray mortar, and colored mortar is placed only along the edges that will be visible.

Innovations in the use of colored masonry mortars

Manipulating the color of brickwork or individual walls or sections of the wall will help create unusual housing design options. A universal way to highlight masonry is to use contrasting shades. White seams will look especially bright in combination with any brick tone except yellow.

Also, colored solutions can mask masonry seams and completely hide the structure of the wall. To do this, pigments are added to give the solution an absolute similarity to the tone of the brick itself. When cleaning the seams, they are well aligned so that they follow the texture of the base material. You can, on the contrary, not give the wall a monolithic appearance, but make an extruded pattern. To do this, blocks of bricks are laid in a special way.

Experts also use the following new techniques to create spectacular brickwork:

- adding finely ground glass fluorescent powder to the solution to glow the seams against the background of dark brick,

- introduction of pigments that change color depending on the ambient temperature.

When choosing dyes, you need to ensure their suitability for the purpose of tinting the solution. Unscrupulous manufacturers replace non-ferrous metal salts with aniline dyes, which wash out and fade literally within a season. Only real pigments will provide a beautiful appearance to buildings and will serve for a long time - do not skimp on quality!

Construction of houses

White cement, compared to its traditional counterpart, has a number of advantages: both operational characteristics and its aesthetic properties.

Due to its beautiful color, it is widely used not only for construction work, but also for creating sculptures and other architectural forms. In this article we will look at the main characteristics of white cement and the areas in which it is used. Content:

What is white cement

The light shade of white cement is obtained due to the composition and special technology of its production.

It is produced on the basis of low-iron clinker, with an admixture of mineral additives, limestone, gypsum, and chlorine salts, which give it a whitish color. And firing with rapid cooling ensures strength.

This material is multifunctional. It is used for:

- construction;

- construction of self-leveling floors;

- can serve as a component in the production of dry finishing mixtures.

Composition and properties of white cement

Materials. The light color of cement is achieved by using raw materials where ferrous compounds are absent or present but in small quantities. White cement is produced on the basis of low-iron clinker, where the content of manganese and chromium is minimized. It also contains mineral additives, limestone, gypsum, and chlorine salts, which give it a whitish color.

Technology. Crushing of raw materials and grinding of clinker occurs in crushers/mills equipped with a special lining. Flint, basalt, and porcelain slabs are used here. At the same time, the specific surface area (grinding fineness) is significantly higher than that of conventional cement:

- grinding fineness of gray cement ̴ 3,500 cm²/g;

- white grinding fineness ̴ 4,500 cm²/g.

For firing the raw material mixture, liquid, gaseous or other fuel is used that does not produce soot or ash particles.

The strength and whiteness of cement is achieved by burning clinker at high temperatures and then cooling it in an oxygen-free environment (1200°C-200°C). Or sudden cooling with water is used (1500°C-500°C), after which the wet clinker is dried in a drying drum at a temperature of 300°C.

- Dry method. When the moisture content of the raw materials is low, most enterprises use this method. For this purpose, shaft furnaces are used, which combine the stages of fine grinding, thorough drying and mixing of all the necessary components. The resulting clinker is fired at a temperature of 800°C.

- Wet method. This scheme involves crushing hard components in a mill, and soft ones in a special device - a grinder using water. After this stage, the wet sludge is dried and then it is ground into finer quantities and mixed with the rest of the raw material, as with the dry method.

Cement is produced with two strength indices: M400 and M500.

Peculiarities. The grinding of such cement is finer, therefore, when sifting through mesh No. 008, the remainder should not be more than 12%.

The degree of whiteness determines its decorative properties; based on this indicator, cement is produced in 3 grades: 1 (highest), 2 and 3, where the reflection coefficient is 80%, 75%, 68%, respectively.

The material sets in 45 minutes, completely dries in 12 hours.

Colored cement is produced in a similar way with the addition of mineral dyes. Rare colors give:

- eskolaite – pistachio shade;

- cobalt – brown;

- manganese - from blue to deep black.

Advantages

- Maximum strength and accelerated hardening of the material. After 16 hours, the hardening of the solution is already 60%, thereby shortening and reducing the cost of the construction process;

- such a high technological indicator as dispersion prevents the material from deteriorating under the influence of aggressive solutions and atmospheric moisture;

- environmental friendliness of cement, thanks to the use of natural mineralogical components in production;

- finished buildings are durable and stable. They are resistant to cracking (chips). Such advantages of the material minimize the costs of repair or restoration work;

- the aesthetics of whiteness, color stability of cement and versatility allow it to be combined with other finishing decorative materials;

- multifunctionality: used as a building and decorative material; used in casting floor slabs and bricks; It is part of dry adhesive mixtures, colored concrete, grout, putty, and so on.

Application area

Nowadays, almost all buildings contain white cement; in some cases, its use is the best and only solution.

- It is used in the manufacture of a variety of building elements; white concrete looks especially impressive as a decoration for facades. Thanks to it, buildings and architectural fragments become more durable and expressive.

- High technical characteristics of cement prevent discolouration of concrete and allow it to be used both indoors and outdoors. It has increased resistance to various atmospheric conditions (sunlight, snow, rain), while maintaining whiteness for a long period.

- It provides manufacturers of cement products and concrete products, as well as architects, with an excellent basis for realizing a variety of ideas. Allows you to work with forms, fillers, color, as well as apply various technologies for concreting, finishing and processing of hardened surfaces.

In what cases is white cement used?

- An amazing resemblance to natural stone is achieved by mixing white Portland cement with expanded clay gravel, fine marble or granite crushed stone and the desired shade of dye. This kind of mixture is used in the manufacture of terrazite plaster for cladding the facade of a building, paving slabs or decorative bricks.

- It serves as the basis for cement-lime mortars, adhesives, grouts, self-leveling floors, and plaster mixtures.

- It is used in the manufacture of sculptures, columns, steps, borders, flower beds, small architectural forms, and decorative fragments.

- A high degree of wear resistance and reflective properties make it possible to use white cement both for marking airfields and road surfaces, and as a material for road surfaces.

Working with white cement. Useful tips

- The forms used (formwork, various types of containers) and tools must be clean: free of dust, dirt, grease, and rust. This rule also applies to the concrete mixer;

- only clean water is used to mix the solution and subsequently moisten it;

- if the structure uses steel reinforcement, then it should first be covered with a 30 mm layer of concrete. Otherwise, there is a high probability that over time rusty stains will appear on the white surface;

- Titanium dioxide can serve as a whitening additive, but its mass should not be more than 1% of the total weight;

- aggregate for concrete is selected only in white color and fine fraction (up to 2mm). It should not contain silt particles or fine earth. The content of sulfide class minerals in quartz sand should be excluded, the recommended fraction is 1.5 mm;

- plasticizers and retarding additives are also selected with a shade that will not affect the color of the solution. It is not recommended to use zinc-based white.

Manufacturers of white cement and its price

You can buy white cement at any hardware store. It is represented by a wide range of manufacturers.