Issues discussed in the material:

- Preparing for the brick laying process

- Basic principles of working with different types of brick walls

- Calculation of the thickness of types of brickwork

- Nuances of calculating wall thickness for various types of brickwork

- Brick house: types of masonry

- Types of lightweight brick walls

- Types of brickwork reinforcement

- Types of brickwork corners

- Types of facing brick masonry

- Types of jointing of brickwork

- Types of cracks in brickwork

- Typical mistakes when working with different types of brick walls for the home

- Dirty brickwork and poorly filled joints

Different types of brickwork, no matter what purpose they are intended for, have their own rules that must be followed. This is not only a laying algorithm (drawing), but also compliance with the thickness of the masonry, level and taking into account operating conditions.

During construction, different methods of laying bricks are used, each of which has its own characteristics. You will learn from our article about what is needed to start this type of work and in what order to carry it out.

Preparing for the brick laying process

A brick house is durable and reliable; it will last for several decades. But if you are new to construction, you should understand what types of brickwork there are. You will also need to study what dressings are and how they differ from each other. It is quite difficult to build a cottage with your own hands from this material, but if you adhere to the technology, the structure will be durable and you will not have to contact a specialist mason.

If you are going to build a brick building, in addition to the building material itself, you will also need the following tools:

- corner;

- measuring tape;

- level (rule or plumb line);

- jointing;

- trowel;

- fines;

- a concrete mixer with which you prepare the building mixture;

- containers;

- shovel-scoop.

In order to mix the solution, you will need cement and sand. With its help, the bricks are connected to each other. To prepare the solution, the following components are required:

- cement suitable for the brand;

- sand;

- water.

The technology for preparing the solution is as follows: mix sand and cement in certain proportions, and then add liquid to the resulting mixture.

If you want to lay brickwork quickly, you need to properly equip the work area. It is located at a distance of 3.5 m from the facility under construction.

Scaffolding, necessary equipment and building materials are placed at the workplace. Since the walls and corners of the house must be positioned vertically and evenly, boundaries are set along the perimeter of the base; this will require a cord. It is necessary to ensure that the intersection of the cord lines occurs at an angle of 90°.

If you are new to construction, then you should lay out the first row of bricks without using mortar. The blocks are placed on the base, this is necessary to see where the inserts will be needed: a quarter of a brick, a half or three quarters.

Tools

Proper laying of facing bricks is impossible without the necessary set of tools. You will need:

- A trowel (popularly called a trowel) is a steel spatula with a handle used for applying mortar, removing excess, and leveling bricks.

- Construction level - so that the rows come out even. It is better to stock up on two levels: a long one (at least a meter) to determine the evenness of the row and a short one (30-40 cm) to determine the position of an individual brick.

- A construction cord, like a level, will help determine the evenness of the rows.

- Grinder and discs for it with diamond coating - used for cutting facing material.

- Hammer (possibly with a pickaxe) - used to accurately split bricks. Professional installers sometimes use a weighted trowel for this purpose.

- A metal rod with a square section of 10*10 mm will help make the seams between the rows neat.

- A metal rod with a round cross-section with a diameter of 10 mm is used for jointing.

- Anchor bolts and tying wire will be needed to connect the load-bearing wall and cladding.

Please note: cutting brick with a grinder or splitting it with a pick/trowel is often used for cladding. However, experts try to avoid violating the integrity of the brick during facade work, as this can damage the aesthetics. In addition, now the choice of cladding on the market is such that there is no need to resort to cutting or splitting.

Basic principles of working with different types of brick walls

In order for a building built of brick to be durable and last for many years, it is important to follow the cutting rules.

Let's look at three cutting rules that are used most often:

- beds of bricks are located at an angle of 90° to the force that acts on the masonry. In this case, the stones are laid in horizontal rows. Thanks to this approach, the pressure acting on the masonry is distributed evenly over the contacting planes of the faces. Otherwise, if the load is bending, the stones will crack;

- vertical joints are necessary to separate the stones from each other, so it is important that they are at a 90° angle to the beds. Elements are placed in rows so as to prevent them from shifting. If the bricks are laid at an angle or the geometry of the side surfaces is not respected, the wall may crack over time;

- seams in horizontal rows (longitudinal and transverse) must be covered with bricks from the following rows. To do this, you need to shift the length of the element located below by half or a quarter. That is, from the top brick there will be a load on two stones from the bottom row. Otherwise, due to vertical load, cracks will form on the wall in the future.

Note!

All types of brickwork joints must be made of high-quality sand-cement mixture. When preparing the solution, it is necessary to observe the proportions; you can also purchase a ready-made composition at a hardware store. This is the only way to ensure the reliability of the erected walls and to prevent the formation of efflorescence on the outside.

Calculation of the thickness of types of brickwork

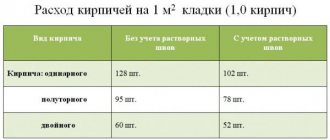

People have been using different types of brickwork in the construction of buildings for many centuries. Bricks of any type are produced with dimensions of 25 by 12 by 65 cm. Therefore, in order to calculate how thick the wall will be, it is necessary to take into account these standard dimensions.

Since a strong load-bearing wall is the foundation of the house, it is unacceptable to destroy or move it, since in this case the structure will become fragile and can easily crumble. Such a wall can withstand maximum loads: in addition to its weight, it serves as a support for the roof, ceilings, and partitions.

Load-bearing walls must be thick enough - at least 250 mm (one brick). In this case, the structure will be durable and the thermal insulation will be quite effective.

If the brickwork is made in compliance with the technology, the structure will last for several centuries. When constructing low-rise buildings, solid bricks are most often used (in this case, the walls will need to be insulated) or perforated.

This material can be used to lay out both internal and external walls. In the first case, the permissible thickness is at least 120 mm (0.5 bricks). In this case, the cross-section of the pillars and piers should be 25 by 38 cm or more. Internal partitions can be quite thin - 65 mm. This type of brickwork is called “on edge”. In this case, the wall is reinforced with a metal frame across 2 rows. Reinforced walls will be strong and reliable, and will withstand heavy loads.

In this masonry, the stones are not placed side by side, otherwise the wall will be weak. The thickness of a brick wall can be one and a half, two or two and a half bricks, it all depends on the load that the building will experience.

It is permissible to erect an internal partition, which will perform all the necessary functions, in 0.5 bricks, in this case the wall thickness will be 120 mm.

At the same time, a wall with such thickness remains sound-permeable. To ensure silence in the house, you will have to install additional sound insulation or make the walls thicker.

The type of brickwork “on edge” is used to create small internal partitions quite rarely. In this case, the stones are laid “on edge”, and the walls are 7 cm thick. Thanks to this approach, you can save building materials and expand the rooms, but the heat and sound insulation characteristics will be noticeably worse.

What you shouldn't forget

In conclusion, I would like to mention a few nuances that should not be forgotten when laying facing bricks:

- Joining the slopes can be done immediately. Firstly, there is not too much load on the seam. And secondly, it will save time on rearranging scaffolding.

- Every 3-4 rows of bricks, check along the entire length with a level. This way you can minimize distortions.

- If the cladding is done indoors or even during a completed renovation, then the same technology is followed only with exceptional care.

- Make sure that no construction debris gets into the gap between the load-bearing wall and the facing wall. It should be left empty for better ventilation and thermal insulation.

- Try to get rid of dirt on the front surface of the bricks as quickly as possible. Wipe them with a sponge or rag immediately - later it will be very difficult to get rid of these marks.

Nuances of calculating wall thickness for various types of brickwork

For any structure, the thickness of the walls is calculated taking into account heat loss and the required strength. The resulting values do not always coincide. To keep the house warm, especially if you live in a region with a cold climate, the walls should be laid out thick enough (according to thermal requirements).

But if we take into account strength calculations, it is possible to build external walls of 1–1.5 bricks. Many people cannot figure out what to do in this case, since walls built taking into account thermal requirements will be excessively thick in terms of strength.

The way out of this situation is as follows: solid brickwork made from solid bricks is used exclusively for the construction of first floors in multi-story buildings. In this case, the strength of the structure is just necessary and there is no question of redundancy. This allows you to significantly reduce the cost of building materials.

What type of masonry should be used for the construction of low-rise buildings and for the construction of the upper floors of multi-story buildings? In this case, a lightweight type of masonry is used for external walls made of hollow or light stone.

However, this solution will not work if the building is damp, for example during the construction of saunas. Laundries and bathhouses are built from solid bricks, and a layer of vapor barrier is installed on the inside of the wall.

The walls can be laid out in half a brick, one, one and a half, and so on (half a brick is equal to 12 cm). The thickness can be calculated using the formula:

B = 130 * n - 10, where

- B – wall thickness (in mm);

- 130 – dimensions of half a brick, taking into account a vertical seam of 1 cm;

- n is the number of half-brick pieces in the masonry.

Masonry dimensions of bricks with a 5 mm laying seam

| Standard brick size | Wall area, m2 | Purpose | Brick consumption, pieces | Solution consumption, m3 | Type of masonry |

| 1/4 | 2.0x2.5=5.0 | Partition, toilet | 142 | 0.027 | Chain single row |

| 1/2 | 2.0x2.5=5.0 | Partition, bathroom | 283 | 0,054 | Spoon |

| 1 | 2x6=12 | Carrier, garage | 1372 | 0,326 | Cross |

| 1.5 | 3.2x10=32 | Load-bearing, one-story house | 5466 | 1,404 | Cross |

| 2 | 6.5x10=65 | Load-bearing, two-story house | 14859 | 4.178 | Chain |

| 2.5 | 10x10=100 | Load-bearing, multi-storey building | 28510 | Multi-row | |

| 3 | Z.2x10=32 | Special wall of increased reliability | 10932 | 2,808 | Multi-row |

Brick house: types of masonry

Types of brickwork, photos of which you might have seen on the Internet, are used in the construction of all kinds of buildings and houses. The differences between them lie in the orientation of the bricks themselves, design features and decorative elements. There are also different types of brickwork dressings. They help create a stronger wall. Let's consider the types of masonry that are most often used in the construction of residential buildings.

- Spoon masonry

Of all, the most popular for cladding due to its simplicity is the laying of 0.5 bricks, while the ligation of spoon rows of stones is carried out as follows: they are mixed by one-fourth or half the length. It is worth noting that this masonry is not often used for the construction of walls.

- Chain masonry

This method is the optimal solution to increase the reliability of the structure if the walls are built in one brick. How is this type of masonry performed? The first row is bonded, the next is spooned (parallel laying of two bricks), with the seams being spaced.

Note! The splice and spoon rows should not be allowed to coincide.

If the walls are built with 1.5 stones, what type of brickwork should be chosen? In this case, the element will be made in the form of one spoon brick, as well as two interlocking bricks, the seams will be mixed in each subsequent row.

- Multi-row dressing

When building brick houses, craftsmen almost never make every second row interlocking. This technology is not practical. Most often, one tyke row alternates with three, four, five or six spoon rows. The building erected in this way is quite strong and reliable.

This dressing is performed with certain features. The following should be laid out with a poke:

- first and last rows;

- areas located under the beam;

- building elements that protrude greatly, such as cornices.

Is it necessary to insulate?

Many people ask the question of whether it is necessary to insulate brick houses and, undoubtedly, our answer is yes. The absence of insulation is possible only with a large masonry thickness acceptable for your climatic region. Insufficient thickness leads to the effect of a cold house, since the brick itself conducts heat quite well.

This was not the case in old houses; they used very thick walls of 700mm or more. Of course, no one makes such walls now because they are very expensive: it is easier and cheaper to add insulation.

Also in favor of insulation is the possibility of cracks appearing in the brick and the formation of cold bridges, which has a detrimental effect on the heat resistance of the structure. An indisputable argument is also the reduction in the total weight of the structure and lightening the load on the foundation, which in turn saves the budget and construction time.

Types of lightweight brick walls

What are the types and purposes of lightweight brickwork? It is most often used in the construction of low-rise buildings. The main difference between lightweight masonry is that the wall has voids. They are filled with heat insulator. Such lightweight structures look like two walls connected by brick ties. Metal connections can also be used.

Each type of lightweight brickwork has its own design features:

- brickwork with 3-row dressings. In this case, after five rows of masonry with a void inside, there are three continuous rows of dressings;

- anchor brick and concrete masonry. Its main feature is that the bonded rows are laid in the internal cavity. They act as anchors. Then foam concrete is placed into the hollow walls;

- well masonry. If you cut it open and look at it from the inside, it will look like a chain of wells. That's why it's called that. If you use this type of masonry, you should make vertical dressings.

Decorative design of facades

The finished house is usually decorated with architectural details and covered in a designer way so that the house stands out from the rest and pleases the owner's eye. A house that stands out with its bright decor or flight of fancy among its neighbors will not go unnoticed and will receive its own name, for example, “Lily House.”

Types of facing brick laying:

- Openwork masonry is an unusually interesting solution for finishing work. The block is laid alternating with gaps between adjacent pokes. The seams are neatly finished. The same method is used to make openwork decorative fences, laying out various patterns.

Beautiful colored facade decoration Source www.zsm-altair.ru

- Relief masonry - the stone is laid out with a protruding relief according to a pre-prepared pattern.

- Dutch version - the first row is laid with a poke, and in the second row pokes and spoons alternate.

- Silesian - several colors are used in design, resulting in incredible combinations of patterns.

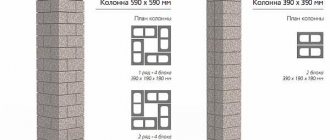

Types of brickwork reinforcement

Thanks to reinforcement, it becomes possible to make a brick house more durable and increase its service life.

In what cases is it necessary to choose the type of brickwork with reinforcement:

- the land on which a residential building is built may sag;

- if a multi-story building is being built, in this case the walls experience increased loads, taking the weight of floors, stairs, and roofing;

- if the main building material is not enough and you have to use budget building mixtures, leftover bricks. Reinforcement makes the structure more durable and reliable;

- during the construction of columns, pillars with a small cross-sectional diameter;

- if a residential building is being erected in a place where there is a high risk of earthquakes;

- when it is necessary to make an extension to an already finished building. In this case, reinforcement must be performed where two structures are joined;

- reinforcement helps strengthen masonry areas above window and door openings, since increased strength is needed in these areas;

- if a type of brickwork without dressing is used, reinforcement can be used to make the walls more rigid.

TOP 5 articles on construction:

- Is it possible to build a second house on the site: we understand the legislation

- Location of the house on the site: taking into account cardinal directions, distance to neighbors and regulations

- What is the best material to build a house from: a review of popular materials

- House for 2 families with different entrances: layout and advantages

- Maternity capital for building a house: how to get and spend

There is a special provision that determines how the reinforcement should be performed. You can find it in SNiP 3.03.01-87 “Load-bearing and enclosing structures”. What is stated in this document:

- If reinforcement is used for external walls or columns, it is necessary to make a seam not exceeding 16 mm. It must be at least 0.4 cm greater than the sum of the diameters of the reinforcement (at intersection). If the installation is transverse (walls and piers), the mesh must be made across the width of two or more rods. It is necessary that it extends beyond the outer edge of the wall by 0.2-0.3 cm.

- It is possible not to reinforce the partitions if they are not secured with temporary fastenings, and also if their height is 150 cm and thickness is 90 mm. If the thickness is 120 mm, the permissible height is no more than 180 cm.

- If the masonry is longitudinal, the steel reinforcement bars must be welded. In the case when welding is not used, there should be hooks at the ends of the rods, which must be tied with wire. The rods should be overlapped, with the ends being equal to or longer than the sum of twenty diameters.

- To determine how often horizontal reinforcement mesh should be laid, construction requirements must be taken into account. When determining the frequency, you should take into account the load experienced by the wall, as well as its location relative to the axes, and the height of the masonry. Most often, reinforcement is laid through 2–5 rows of bricks. If the material is thick, the mesh must be laid every four rows.

- The reinforcement can be laid in a zigzag pattern in pairs in adjacent rows, so the grids will be at right angles to each other.

- The gap between the reinforcing mesh should not exceed 0.45 m. Otherwise, this method of strengthening the walls will be ineffective. If the reinforcement is laid with an overlap, the ends should protrude by 15 cm or more. In this case, the rods should protrude onto the façade by at least 2 mm. This reinforcement technology makes it possible to optimally lay the mesh so that the connection of the external finish is as reliable as possible.

Types of brickwork corners

Full-size bricks are used to bandage the seams of vertical restraints, as well as areas where walls, piers or pillars intersect or adjoin. For example, quarters, halves and three-quarters bricks. The master makes them during the construction of the building. To prepare quarters, three-quarters, and halves, you will need stones that have broken corners or other defects. In this case, stones of incomplete size, for example, quarters, must be laid with the whole side outward, and the broken side inward.

Most often, when laying corners, multi-row or single-row, that is, chain ligation is used. In the first case, it will greatly facilitate the work of the master.

Experts advise laying out the corner at a height of three to four orders of magnitude, and it is important to monitor how the vertical seam is bandaged. Only after you understand how each stage of laying corners and walls is carried out should you begin building a residential building.

- In one brick

This type of brickwork is the simplest; it is used in the construction of partitions 25 cm thick, which are not load-bearing. To lay out the stone evenly and vertically, a plumb line and a level are used.

The laying begins with two quarters, they are placed with the spoon side out. With the help of quarters, the gaps between the butt blocks and three-quarters are eliminated. In the next row, the mile should be done using the spoon technology, and the backfill should be done using the butt technology. After this, it is necessary to bandage the vertical seam using a spoon row. By doing this, you can build a corner.

This construction technology is recommended to be used if you do not need to build a load-bearing wall.

- One and a half bricks

The construction technology is such that you need to lay out the corners three to four rows before you start forming the wall orders. Thanks to this approach, it is possible to maintain the straightness, verticality and horizontality of the masonry when creating the walls of a future brick house.

Laying a corner of 1.5 bricks is not as easy as the method described above. The fact is that you will have to use block elements of various shapes: 0.5 bricks, three-quarters, quarter. Only if the corners are optimally set will the structure be strong and reliable. It is important that the inner corner is reinforced with a plaster corner.

This construction technology is used during ligation of vertical seams.

- Laying in two bricks

This type of brickwork is the most difficult to implement; it is used during the construction of load-bearing structures. It is necessary to correctly lay the blocks both in the very corner of the wall and two adjacent bricks from it. This is the only way to build a strong structure that will last for many years.

Follow these guidelines to lay 2 bricks:

- The 1st row is laid out using the butting technology, but in one place the spoon technology is used;

- The 2nd row is laid out in the same way as the main wall. In the area where it is necessary to create a corner, it is important to connect the elements correctly;

- in the 3rd row, spoon masonry technology is used (move clockwise). It is important to check the vertical and horizontal of the masonry;

- The 4th row is laid out in the same way as the 2nd, and the 5th row is laid out like the 1st.

This type of brickwork is used for the construction of load-bearing walls, since it is quite difficult to implement this technology in practice.

After the four corners have been laid out, you should begin to build load-bearing walls, as well as internal partitions. You must adhere to the bricklaying method that you have chosen. This is the only way to build a strong building. Such a brick house will remain in its original form several decades later. At the same time, you will not have to spend huge sums on its repair.

Why is it important to make the right choice?

The strength characteristics and service life of brick walls are influenced by a number of indicators:

- type of building structure,

- brand of masonry material,

- consumption of laying solution and dressing scheme.

All this data must be determined by calculation and attached to the design documentation of the house. If a master, even a very experienced one, starts building walls without a design, such an object will be unviable.

The most vulnerable area is the vertical/horizontal joints in the brickwork, which can collapse much earlier than the blocks themselves. Their strength mainly depends on the optimal choice of plasticity of the laying mortar and the adopted arrangement order, regulated by cutting rules.

The strength of the wall structure and its ability to resist delamination, both vertically and horizontally, mainly depend on their compliance.

Types of facing brick masonry

In practice, many types of brickwork are used, as well as several ways to design a pattern using stone for cladding. In some cases, 2-3 shades of bricks can be used at once.

The types of brick cladding are determined by the pattern, as well as the laying technology.

- Path . The main feature is that all layers are laid exclusively with the long outer part of the brick, while the layers are shifted by 0.5 of the length of the stone.

- Block . In this case, rows with the long side of the brick and the short side facing outwards alternate. The joints are installed vertically.

- Gothic . In exactly the same way as in the previous version, there is an alternation of rows with long and also short outer sides. The difference is that every 2nd row with a long or short side is shifted.

- Brandenburg . In the 1st row, two long sides of the stone and one short side are laid. The second row is designed in exactly the same way, the difference is that the joints of the long sides are located in the central part of the short stone from the previous row.

- Lipetskaya . The bricks in the first 3 rows go with the long side outward, the joints coincide. In the 3rd row, the short sides are positioned so that there is no displacement of the joints.

- Krestovaya . This type of brickwork alternates rows of stones with a long face in the first row and a short face in the second. The joint will be located in the middle of the stone from the previous row. And it doesn’t matter whether it has the short side or the long side.

- Dutch . The 1st row is performed using stones that are positioned with the short outer part facing out. In the 2nd row, elements with long and short outer sides alternate. It is important that the joints do not coincide; they must be located strictly on half of the bottom stone, it does not matter whether it is long or short.

- Tychkovaya . The stones are placed with the short front side outward, and the joints are shifted by 0.5 bricks in relation to the previous row.

- Spoon . With this type of brickwork, the stones are placed with the long side outward; it is necessary to offset one-fourth of the element from the previous row. There is also a type of spoon masonry, when the stones are shifted by 0.5 the length of the element from the previous row. If the direction of the shift is in one direction, for example to the right, it will be oblique. Also, the shift can occur in different directions in turn: first to the left, and in the next row to the right.

- Chaotic . Its main feature is that the long and short outer parts of the stones are arranged in a chaotic manner. However, the joints should be offset by one-fourth the length of the short or long part.

- Silesian . In the 1st row, the bricks are placed in turn. First two long parts, then one short. The 2nd row is performed in exactly the same way, only the joints are shifted one-fourth of the length to the right side. In the 3rd row, the shift occurs to the left.

- Flemish masonry . The 1st row is done like this: stones with a long and short part are laid in turn, the 2nd row looks exactly the same, only the short part is located in the center of the long side of the brick from the first row.

Many people prefer to clad their house with brick because the finish is visually attractive, durable and will last for many years. But if you have chosen the type of offset brickwork, you need to understand that you will need quite a lot of building material. The fact is that 0.5 stones will be laid in rows on an entire side.

Openwork

Another type of decorative design with brick. In this case, non-continuous masonry with possible gaps is used. The openwork is erected using ordinary spoon masonry, but at the same time a gap is left between the pokes of adjacent stones. This perforation creates a certain openwork effect.

At the same time, the masonry can have no gaps at all. Look at this photo - it's also openwork!

Types of jointing of brickwork

All existing types of jointing of brickwork are necessary to ensure that the mortar in the joints is compacted, while the building looks attractive from the outside. So, for example, masonry can be done with cutting the mortar.

What a brickwork seam might look like after jointing:

- in the shape of a triangle;

- concave;

- convex;

- in the shape of a rectangle;

- rounded.

For example, to make a seam convex, jointing with a concave shape is used.

In order not to disrupt construction technology and reduce labor costs, jointing of brickwork is done before the mortar dries. The algorithm of actions includes several steps:

- Using a brush or cloth, remove any drops of mortar that have stuck to the stones from the wall.

- After this, the vertical seams are sewn; it will be enough to make three or four spoons or six to eight pokes.

- Next, the horizontal seams are sewn.

If you are going to apply plaster to the surface, the laying of stones should be done “in a wasteland”. This means that the cement-sand mixture should not reach 1–1.5 cm to the wall surface. Thanks to this technology, the plaster will reliably adhere to the brickwork.

Preparation of solutions

Skinny. They have little binding property. This composition has low ductility and strength. In the future, cracking of the building may occur. The advantage of this mixture is its low cost.

Fatty. A large amount of binder material is added to this solution composition. It has good ductility and therefore high strength is guaranteed, but during curing there may be a risk of shrinkage.

Preparation of normal cement mortar, in which compliance with the proportions will retain all the advantages during masonry.

Types of cracks in brickwork

Many owners of brick houses are faced with the fact that cracks form on the surface of the walls. This happens for many reasons: they can be both external and internal. In the second case, the walls crack due to the influence of force, which arises from the physical and mechanical properties of the brickwork, as well as from the harmful effects of the environment.

How deep the crack will be and where it is directed will differ in each case. If central compression occurs, cracks appear in the overload area, located vertically and parallel to the force acting on the wall. In this case, cracking occurs to its full depth. If the compression is eccentric, small cracks appear horizontally, and the wall bulges.

Let's consider what happens to the wall if distribution elements, for example, a reinforced layer of mortar or a reinforced concrete pad, are not laid under a steel or reinforced concrete beam. In such a situation, shallow cracks located vertically appear in the support area. This indicates that the compressive stress in the wall is too high.

If the building has reinforced concrete floors that work together with the walls, cracking occurs mainly due to the difference in the thermal expansion rates of these two materials.

What could be the external reasons for the formation of cracks? First of all, this is the settlement of the foundation of the house, which occurs unevenly. If the building does not have a basement, the house will settle unevenly due to the fact that a trench is dug for water supply and sewerage, and it is located below the base of the house. Also, the cause of cracking may be a pit dug for another house, which is located next to a brick building.

Ground vibration can lead to cracking of brickwork if piles are driven in near a building under construction. However, most often cracks form because the foundation of the house gives uneven settlement due to waterlogging of the soil. This happens because the water supply or sewer pipes are leaking.

Popular styles

Red brick allows you to decorate houses in a wide variety of styles.

- The classic never goes out of style. Here you will not find a combination of time-tested brick with modern materials. A house with a representative red color in the right proportions will indicate the homeowners' commitment to traditional values.

- English-style houses with large square or rectangular windows, a high roof topped with a stone chimney, and decorated red tiles remain interesting.

- A castle-style house with round turrets, a slightly chipped brick facade and thick walls will help you stand out from other buildings.

- Red brick goes well with Gothic motifs - majestic vaults, towers and large windows. A house in this style will be appreciated by romantic natures.

Typical mistakes when working with different types of brick walls for the home

What is the most common brickwork error? Deviation in vertical or horizontal level. This happens because the master is inexperienced or does not work carefully enough. If one row of brickwork is uneven, the result will be that the entire wall will be crooked, convex and with other defects.

To prevent this situation, you should monitor during the construction of walls whether you are laying out the stones evenly. To do this, you can pull the cord or use a plumb line or level. By working in this way, you can save on plastering the building, because you will need a thin layer of plaster to eliminate minor imperfections and make the surface perfectly smooth. If the wall is crooked, even after plastering the defects will not be eliminated.

Brick bonding can also be done incorrectly. Most often, the master applies the dressing with insufficient force or does not follow the work technology. When performing the dressing layer, it is necessary to ensure that the vertical seams do not coincide with those adjacent in height. Otherwise, the dressing will be of poor quality, resulting in the structure being unreliable and not strong enough. The fact is that in this case the wall will not be solid and strong; over time it may collapse.

Cracking of walls usually also occurs due to poor quality of dressing. At the same time, the size of the cracks increases over the years. You will notice that the bandaging was done incorrectly after some time, when the foundation of the house shrinks. Therefore, it is important to bandage the seams of the brickwork in compliance with construction technology. If everything is done correctly, the seams will be perfectly straight.