Wood products look impressive after additional impregnation with viscous, quick-drying compounds. After polymerization, NC varnish extends the life of furniture, parquet, decorative panels and wood coverings. After covering it with furniture nitro varnish, a table or chair made with your own hands from natural wood will look like a real masterpiece or an antique product. Varieties of paints and varnishes have their own characteristics, which are important to know about.

Features of nitro varnish

Varnishes are a large group of paints and varnishes based on natural or synthetic resins. They differ in functional use (wood, metal). These include NC - nitro varnish for wood, which is included in the list of products for impregnating wood.

Before use, the thick substance is diluted with quickly volatile liquids (white spirit, acetone), acids or specialized solvents. They have different markings, differ in smell, consistency, shade, hardening time and light reflectance (matte nitro varnish or glossy).

Basic classification of paints and varnishes by type of solvent:

- Turpentine;

- Oily;

- Water soluble;

- Alcohol.

NC varnish is made from nitrocellulose, previously treated with a chemical composition based on organic compounds. By adding various components to these raw materials, a wide variety of substances with specific properties are obtained.

NC varnish is made from nitrocellulose, previously treated with a chemical composition based on organic compounds.

Varnish composition

The basis, as already noted, is a polymer - high quality wood or cotton cellulose. This substance is diluted with a special organic mixture to obtain varnish colloxylins. The composition also includes additives:

- alkyd resins, shellac,

- amino formaldehyde resins,

- cyclohexanone-formaldehyde resins,

- Winsol,

- rosin.

The amount of such additives can be in different proportions with colloxylin (up to 1:1). To give the solution the desired consistency, the composition contains a mixture of solvents - propyl acetate, ethyl acetate, acetic acid esters, xylene, toluene, and various alcohols. The material may contain nitroparaffins, and there must be plasticizers (casterol, chlorinated paraffin, phosphates and others). As you can see, the composition of NC varnish is very complex and multi-component.

Compound

Thanks to its special composition, nitrocellulose varnish is used in various fields - from the protective coating of parquet to the decoration of expensive yachts. A layer of varnish extends the life of the product. This is important when making furniture and decorative coverings from elite types of wood that are sensitive to changes in temperature and humidity.

The effective coating with protective properties is explained by the content of wax-like substances in dissolved form and the accompanying fillers of nitro varnishes for wood. Improved surface properties are ensured by the impregnation composition:

- Natural resins;

- Synthetic plasticizers;

- Organic solvents;

- Dryers (film formation accelerators);

- Alkyd oligoesters;

- Acetylacetonates;

- Pigments similar to shades of natural wood.

The use of substances that are included in “nitro” wood varnish solves several problems, including improving the aesthetics of products and protecting them from rotting.

A layer of varnish extends the life of the product.

Properties of NC varnish

Nitrovarnishes are used for metal and wood. Some come in bottles and are applied to the surface with broad brush strokes, while others come in aerosol cans for ease of use.

The thick mass has such a consistency that the varnish spreads well over the treated area and dries quickly, forming a hard, uniform film. Sometimes the finished mixture has to be diluted by 5-10% with a solvent - when processing a large surface area, the paintwork polymerizes before the work is completed.

Based on the degree of gloss, NC varnish mixtures are distinguished:

- High gloss (almost mirror);

- Glossy (high gloss factor);

- Semi-gloss (medium degree of light reflection);

- Matte (no shine);

- Semi-matte (low degree of reflection).

After polymerization, a glossy or matte surface is obtained. Matting nitrocellulose varnish deeply saturates the wood without leaving marks, but slightly levels out the wood texture. To enhance the aesthetic properties of the product, before varnishing it is treated with stain of the desired shade.

After impregnation with NC varnish, the product looks more attractive. But more important is protection from the negative effects of chemical reagents and various damages, in accordance with GOST standards.

The thick mass has such a consistency that the varnish spreads well over the treated area and dries quickly, forming a hard, uniform film.

Varnish UR-231: more details

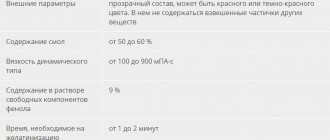

Compound

Varnish UR-231 is produced in the form of two-component solutions based on a hardener (70% DGU urethane in cyclohexanone) and semi-finished varnishes (alkyd-epoxy resin made from linseed and tung oil).

Purpose

Coating of metal materials and printed circuit components in the temperature range from –60C to 120C.

Application

UR-231 is applied to the surface of the material by pneumatic spraying, brushing, pouring, dipping and dipping with further centrifugation. If necessary, UR-231 is diluted with xylene and butyl acetate in a ratio of 4:1

Price and packaging unit UR-231 in the Epsilon online store

1 kg is sold for 590 rubles; 10 kg is sold at a price of 4293 rubles.

Production

The production of oil varnishes based on natural resins was established in Britain, which kept their recipe secret for the sake of a monopoly. Later, chemists from other European countries developed a similar formulation, and the import of colorless oil-based varnishes was officially permitted. By the middle of the 19th century, there were factories in Europe and America, and in 1874 - in Moscow.

There is information that the German monk Theophilus was the first to come up with something similar to nitro varnish for wood back in the 12th century. The mixture was used in the construction of the temple. The secret composition has not been deciphered, but descriptions of the technical characteristics of the transparent viscous liquid remain.

The modern construction market offers clear and tinted varnishes:

- Copper;

- Bronze;

- Gold;

- Silver;

- Canadian walnut;

- Red tree;

- Mahogany;

- Rosewood;

- Ebony, etc.

A factory for the industrial production of varnish opened in Europe in 1803. Chenet, a chemist of French origin, worked to improve the formulation of alcohol-based resins. Today, the production of high-quality nitrocellulose varnishes has been established in different countries, including Turkey, Kazakhstan, Poland, Finland, Ukraine and the Russian Federation. The products of White house, Tikkurila and Parade are in stable consumer demand.

Today, the production of high-quality nitrocellulose varnishes has been established in different countries.

Advantages

By studying the technical characteristics of varnish NTs 222 and similar compositions from different manufacturers, it is easy to evaluate their positive properties:

- Nitrovarnishes provide high-quality protection and a noble appearance of the treated surface;

- When applying paintwork materials, it is often recommended to use a primer, but nitro varnish combines the properties of both substances;

- Experts note the ease of use if all stages of pre-treatment of wood are followed;

- The varnish deeply impregnates the wood, the surface can be sanded;

- Long period of operation of products opened with varnish;

- The smooth surface is resistant to fluctuations in temperature and humidity, the product is additionally protected from mold and mildew;

- Good quality tinted, matte and varnished surfaces at an affordable price.

The wide variety of nitrocellulose-based offerings ensures the choice of a specialized composition that meets all operational requirements. For example, you can select adapted compositions for parquet, laminate, terrace or deck boards.

Nitrovarnishes provide high-quality protection and a noble appearance of the treated surface.

Features of the material

Nitrocellulose varnish (NC) is made on the basis of nitrocellulose - a chemical compound, cellulose nitrate ester. The resulting organic product has valuable properties - it helps protect wood from damage, creates a beautiful coating on it, which improves the aesthetic appearance of the product. The resulting varnish film is transparent, without color, or colored, and is quite durable.

An important feature of varnishes is that there is no special need for priming the surface, although sometimes primer is still applied. The product can be used even in hot or cold weather, but to obtain a high-quality coating it is recommended to add a solvent - up to 5%. This will help prevent the material from drying out.

Flaws

Most often, nitrocellulose-based varnish is used in furniture production, where there are large workshops with good ventilation. Abroad, many subspecies are not used in everyday life and in production, due to the pungent odor of phenols and polyesters.

NC varnish, like any other product, has not only positive characteristics, but also a number of disadvantages that are important to know about:

- Fire hazardous mixtures have a pungent odor;

- They take a long time to dry (some subspecies remain sticky for several days after application);

- Resinous polymers in liquid form are sensitive to moisture;

- Volatile substances make them unstable in terms of polymerization time at different temperatures;

- The smell of NC varnish in the room;

- Low service life (up to 3 years).

The wood processing process has several stages, and if the technology is violated, the coating can form sagging and wrinkle. Nitrovarnish NTs 62 colorless is used as additional protection for wood and metal products. The pungent odor confuses potential buyers of this type of varnish, for example, when they are looking for a composition for homemade furniture.

NC varnishes take a long time to dry (some subtypes remain sticky for several days after application).

Nitrocellulose varnishes

This type of varnish is made from nitrocellulose, which is pre-diluted in a special mixture consisting of organic matter. Next, to obtain a variety of nitro varnishes, alkyd or amino-formaldehyde resins are added. Subsequently, using nitro varnishes, you can obtain transparent colorless films that will serve as protection for the wooden surface. Due to the durability of the coating, varnish can sometimes be applied without priming the surface. Please note the following: if you apply nitro varnish in hot or humid weather, we also recommend adding a 5% solvent to prevent premature drying of the material.

Among the advantages of nitro varnishes, the following parameters can be distinguished:

- ease of use,

- high drying speed,

- long viability,

- excellent grindability,

- small price.

But, like any material, nitrocellulose varnishes also have their disadvantages:

- they are sensitive to moisture,

- they have low physicochemical resistance,

- increased fire hazard.

The main use of nitrocellulose varnishes is in the treatment of wood and plywood furniture during production.

This process consists of several stages, and often nitro varnishes in it play not only the main role, but also as additional protection. This happens especially often when varnishing parquet.

Brands and specifications

Studying the technical characteristics of varnish NTs 62 and substances close to it, the composition of which has remained unchanged since the times of the USSR, it is easy to notice a lot of positive properties. But due to toxicity and rapid flammability, they have been officially discontinued in some European countries.

NC varnishes are classified as mixtures of cold and hot application. There are alcohol-soluble and acid-curing nitro varnishes. These are mixtures of NTs-241 (transparent varnish), NTs-241M and NTs-2101 (matting compositions). Glossy coatings do not fade, reflecting UV rays, preserving the structure of the wood.

In terms of the “price – quality – functionality” ratio, nitro varnishes remain the most popular in their niche. But the uniqueness of these coatings is in their highly specialized diversity. Each variety has its own specifics.

Glossy coatings do not fade, reflecting UV rays, preserving the structure of the wood.

NTs-62

This category of paintwork materials cannot be underestimated - NC 62 varnish is considered universal. It is produced in different colors, replacing varnish and paint - red, blue, green, brown.

Nitrovarnishes such as NTs-62 and NTs-132P are used for coating metal, glass, thick cardboard and ceramics. This eliminates the need to purchase different compositions - with one nitro varnish you can open diode lamps, garlands, stained glass windows, and art installations.

Glossy coatings do not fade, reflecting UV rays, preserving the structure of the wood.

NTs-134

A quick-drying exterior compound suitable for wood and metal. After 40-60 minutes a smooth film (gloss) is formed.

Among the technical characteristics of the NTs-134 varnish, experts note the viscosity coefficient (according to the VZ-246 viscometer) - within 28–60 s, the proportion of heavy substances - up to 17% (high density), acid coefficient - no more than 0.5 KOH / g.

A quick-drying exterior compound suitable for wood and metal.

NTs-218

Waterproof furniture varnish NTs 218 costs a little more than other offers, although it has the same characteristics as other paints and varnishes. It is used without primers, although the quality of the coating is not inferior to compositions that are more complex in application technology.

The furniture coating looks better when nitrovarnish NTs 218 is applied in a thick layer. On top of it you can apply other types of varnish, for example, pitch or with a mirror effect.

It is used without primers, although the quality of the coating is not inferior to compositions that are more complex in application technology.

NTs-223

This variety (previously labeled NTs-315-M) has many specific properties. Furniture, parquet and other surfaces can be coated indoors.

Furniture nitro varnish NTs-223 is known for its high hardness of the coating; it can be polished. The hot drying method is allowed.

Furniture nitro varnish NTs-223 is known for its high hardness of the coating; it can be polished.

NTs-224

The chemical composition of NC-224 differs from other nitro varnishes. Thanks to colloxylin and other components, the viscous substance does not require dilution before application to the surface to be treated.

The beautiful smooth film after polymerization is easy to sand. The previous marking of the varnish was designated as “T3”. Today it is a modified (improved) paint and varnish mixture.

The beautiful smooth film after polymerization is easy to sand.

NTs-225

The varnish, previously known as “TK-N”, is today produced under the label “NTs-225”. Forms a hard, durable, sandable and polishable coating.

Typically, the composition NTs-225 with zinc stearate is recommended for painting interior doors and decorative panels. Hot drying and application after heating to +75°C is possible, which gives a thinner coating (saving composition).

Typically, the composition NTs-225 with zinc stearate is recommended for painting interior doors and decorative panels.

NTs-241

Transparent concentrate NTs-241 is often confused with matting varnishes like NTs-2101. They both belong to acid-curing nitro-varnishes with the addition of urea resins - for moisture resistance, frost resistance and protection against chemical reagents.

The high strength of finished coatings is an invaluable property for wood products that can withstand changes in temperature and humidity. This varnish can be used to process carved parts of wooden log houses, openwork porches and decorative facades.

The high strength of finished coatings is an invaluable property for wood products that can withstand changes in temperature and humidity.

NTs-243

The use of nitrovarnish NTs 243 will give a “long life” to any product due to its hardness and resistance to mechanical damage. The varnish mattifies and hides minor defects. Drying time is 45-60 minutes, after which the wood product receives a noble pinkish or yellowish tint, depending on the type of wood.

The use of nitrovarnish NTs 243 will give a “long life” to any product due to its hardness and resistance to mechanical damage.

NTs-551

This representative of the nitro varnish series is distinguished by its high quality coating. Varnish NTs-551 is a specific product that is used in conditions where other compositions cannot cope with the task.

Transparent viscous liquid without foreign impurities and suspension. Experts note the high viscosity of the substance (according to a viscometer, this is a coefficient of 130–160 s). It can be applied in 3-4 layers without worrying about the quality of the varnished surface and shrinkage of the layers (0.6%).

This representative of the nitro varnish series is distinguished by its high quality coating.

The process of applying nitro varnishes

Nitrovarnishes can be sprayed in a magnetic field or processed wood in the traditional way.

It is better to dip small carved parts, door handles, and façade moldings briefly into a container of varnish, allow the excess to drain off, and hang to dry.

Recommendations for applying NC to a wooden surface:

- Complete the wood sanding process, remove any remaining dust and shavings;

- Open with stain of the desired shade (alcohol or organic based);

- Apply nitro varnish to a dry surface;

- After drying (1-2 hours), apply 2 layers of nitro varnish;

- After 6-8 hours you can proceed to grinding.

If you work with a brush, each layer of nitro varnish is applied perpendicular to the previous layer. Drying of the primary coating can be accelerated with an industrial hair dryer.

If you work with a brush, each layer of nitro varnish is applied perpendicular to the previous layer.

Nitrovarnishes for wood

Nitrovarnishes are still leaders in terms of the ratio of such parameters as price/functionality, as for Russia, the former USSR, in which people relied on their own strength.

In Europe today, nitro varnishes have been discontinued from official production. Such measures were taken because these substances are not environmentally friendly: they are flammable and toxic.

If we divide nitro varnishes into categories, we get the following data:

- transparent (hot and cold application);

- matting;

- acid-curing nitrovarnishes - transparent (NTs-241); matting (NTs-241M, NTs-2101).

The peculiarity of transparent nitro varnishes is the formation of shiny coatings on a wooden surface, which have the ability to retain the original color, as well as the natural pattern of any type of wood.

Service life and storage of NC varnish

Experts note that nitro varnishes have good technical characteristics. Therefore, they are in demand by consumers engaged in the manufacture of budget wood products. They are available, dry quickly under favorable conditions (low air humidity and temperature +18-20°C).

Guaranteed shelf life is about 6 months (see production date).

Viscous liquids are produced in containers of different volumes - from 0.2 to 2.5 kg/l. Nitrovarnishes are stored in closed containers in warehouses protected from UV rays at temperatures up to +40°C.

Guaranteed shelf life is about 6 months.

Varnish production

The production process of this paint and varnish material is quite complex. It is based on the following steps:

- dissolving resins and colloxylin in organic solvents;

- connection with plasticizers and other additives;

- measuring the indicators of the received material;

- cleaning, filtration;

- spilling into containers.

To obtain black varnish and its other shades, the necessary pigments are added at a certain stage of production. In their absence, the result is a colorless varnish. Each component is administered in a regulated quantity, and the rate of the rest changes based on the volume of colloxylin.

Attention! The preparation of colloxylin is carried out under special conditions due to its explosiveness and flammability. This substance is stored only in sealed containers under special conditions.

When producing a material, you can change its density - if it is too liquid, add colloxylin, if it is thick, add solvents. Homogeneity is achieved by introducing high-quality and purified components, as well as subsequent purification in centrifuges.

Precautionary measures

When working with wood, craftsmen take into account that quick-drying varnish hardens within 1-2 hours, but completely polymerizes in 1-2 days. Nitrovarnish looks dry after application, but looks like glue. At this time, the finished product cannot be used, otherwise defects, scratches and sagging may occur.

The thickness of the varnish coating and drying time for the listed compositions vary, so it is important to read the instructions carefully. The technical characteristics of NC 218 varnish will differ from the composition of NC 2144 or NC 134. This depends on how quickly the volatile part of the substances evaporates. When thinning and varnishing, it is not advisable to lean over the container so as not to breathe in the fumes.

The thickness of the varnish coating and drying time for the listed compositions vary, so it is important to read the instructions carefully.

Nitrovarnishes are a popular niche in paint and varnish products. They have a specific smell, so it is necessary to work with it in compliance with all safety precautions. Because of this, not everyone decides to purchase these compounds. However, today special components are added to furniture varnishes that optimize evaporation, which is typical for paints and varnishes with a long polymerization period.