Of all the renovation work, the most interesting stage is the finishing. After all, this process is associated with decorating the room, implementing creative ideas and transforming the room. Knowing how important finishing is for a comfortable stay in a room, manufacturers produce a wide variety of cladding materials to satisfy everyone’s needs.

One material that will always remain popular is wood. However, not everyone can afford to use natural wood. There is an alternative - fiberboard panels. Although they cannot fully replace wood in decoration, the owner still receives a high-quality imitation for a lower cost.

Moisture-resistant wall panels for tiles - features of the material and work with it

( 1 , 3.00 out of 5) Loading...

As they say, the wall in the bathroom is not covered with a single tile. And the technology of laying tiles itself requires certain skills and knowledge. Even a master will lay it for several days, what can we say about an ordinary home craftsman. Until recently, there was no complete replacement of tiles and there are several reasons for this, the main one being high humidity, which is poorly tolerated by many materials.

Currently, there are several types of products that can not only compete with tiles, but even imitate their texture. These are moisture-resistant wall panels under tiles, and today’s material is about them.

Externally very similar to tiles

Panels may contain a drawing.

Speaking about wall panels, it should be noted that the base of the slab is a material very similar to ordinary fiberboard (fibreboard) with various additives and an outer layer that imitates not only tiles, but also many natural materials.

These panels are available in three types:

- The first rack type, which is painfully familiar to us, or, to put it simply, is ordinary lining, the installation technology of which involves guides and special fastening brackets;

Rack and pinion option

- The second type is tiled. These are squares, the main purpose of which is to decorate the ceiling, or lay unusual patterns on the walls (used in combinations of color and texture solutions);

Tiled panels

- And finally, the third type is leafy. A more interesting solution, as it quickly allows you to build a wall in any room. The wall panel for fiberboard tiles has standard dimensions of 1220x2440x3 mm, which determines the speed of covering the wall.

Sheet ones have faster installation, which is what we love

Fibreboard is produced under high pressure, but the wood fibers have a large fraction. As a result, fiberboards tend to swell when exposed to moisture. To eliminate this significant disadvantage, the material is impregnated with moisture-resistant compounds. Hardboard - fiberboard impregnated with bitumen - is considered the best option for bathrooms. To make it, the board is laminated with a film and a protective coating is applied on top. Be sure to check it for integrity, because this is additional protection from moisture and without it the material may swell.

About the advantages of panels

A wall panel for fiberboard tiles has a number of advantages that allow it to somewhat displace wall tiles in its niche.

What is meant:

- Naturally, the price of the panels will be less than tiles;

- The plastic coating does not rot, is not affected by fungus and mold;

- Unlike tiles for the bathroom, the fiberboard wall panel under the tile is much easier to install and dismantle;

- The tile requires a flat wall, a fiberboard wall panel under the tile is itself a screen that successfully hides unevenness;

- Hanging a shelf or mounting a lamp in such a panel is much easier than in tiles; special cutting tools are not required as when working with tiles;

The color is not decisive.

- Moisture-resistant tile-like wall panels are easy to clean with ordinary detergents and have a fairly presentable appearance;

- Wall panels under tiles withstand mechanical stress (shocks and bends are not scary);

- Plastic panels for tiles, or rather the outer covering of these panels, have a fairly wide range of ready-made color solutions, which significantly increases the range of potential buyers.

Preparing for installation

The wall must be clean and dry.

At this stage, two types of work are performed:

- The first is collecting tools;

- The second is preparing the wall itself.

In addition to the panels itself, we will need the following materials and tools:

- Jigsaw with thin files for laminate;

- Measuring tools and spatulas (regular and serrated);

- Gun for silicone sealant and liquid nails with appropriate materials;

- Deep penetration primer for walls;

- Panel adhesive;

- Fittings in the form of joining strips, internal and external corners, and other elements.

Let's take care of the walls:

- The wall is cleaned of the previous coating and primed;

- A few days before the actual installation, the material is brought into the bathroom, where it is “adapted” to specific conditions.

Don’t forget to “introduce” the material to the bathtub area.

Advice! Plastic panels for tiles (as we have already mentioned, a plastic covering with a pattern) are quite easy to adjust to the required size. Try to cut in such a way that whole parts of the tile are on top, and the trimmed fragments are closer to the floor. And it is better to make side adjustments in the far corners, for which start laying from the door and in places that are clearly visible, install a solid-tile pattern.

In the corners, one part of the panel should contain entire tiles.

Direct installation

Applying glue.

These activities are not complicated, but require the sequential implementation of the following actions:

- The cut fragment is applied and adjusted “on a dry” wall;

- A layer of glue 5-7 mm thick is applied to the back side of the panel with a spatula;

- The panel is installed on the wall and pressed lightly for a few seconds. In this case, the glue that has gone beyond the slab is removed with a spatula;

- There remains a small gap of 1-1.5 mm between the products, and between the ceiling and the panel (floor and panel) the gap will be 3 mm;

- After drying (approximately 12 hours), the seams are treated with a colorless bathroom sealant.

Wall panels will completely replace tiles.

Please note! Laying moldings (joining elements) also requires sealing the joints. This is achieved by placing sealant directly into the joint grooves. Sealing is mandatory, since otherwise you risk introducing moisture onto the wall.

This will lead to the development of fungus, mold and may damage the structure.

And one more tip! An attempt to use ordinary nails does not end well; when fixing with them, the protective moisture-resistant layer is destroyed.

Bathroom wall panels. Choosing wall panels: pvc, mdf, fiberboard, wood

There are many ways to decorate bathroom walls. Traditional methods are painting and laying tiles. Recently, new modern materials have appeared that allow finishing to be done quickly and inexpensively. Such materials primarily include wall panels for the bathroom: they are durable, moisture-resistant, resistant to fungus and easy to install.

What types of bathroom wall panels are there? Their features and advantages

Bathroom wall panels differ primarily in the material from which they are made. The materials for wall panels are: MDF, PVC (eraser), wood and artificial stone.

MDF wall panels

What are MDF wall panels made of? MDF is a tracing paper from the English abbreviation MDF, Medium Density Fiberboard. Essentially a close relative of MDF panels (wood fiber panels), MDF wall panels are made without the use of harmful resins and formaldehydes by high-temperature pressing of fine wood chips. Not only wall panels are made from MDF, but also furniture, doors, etc.

A big advantage of MDF wall panels is their resistance to temperature changes: they do not expand or deform when the temperature rises. However, you should pay special attention to the moisture resistance of such panels: MDF wall panels of mediocre quality may not withstand high humidity. It is not advisable to wash such panels with water and powders, as this can lead to damage to the waterproof coating; it is better to use a soap solution.

Moisture-resistant fiberboard wall panels are reliably impregnated with oils and resins and can be used in bathroom decoration. As a rule, this applies to rough finishing: another finishing material is fixed to the fiberboard panel. However, there are also decorative fiberboard wall panels, under the top acrylic layer of which one or another pattern is applied.

PVC/plastic wall panels

One of the most economical and simple types of finishing is finishing the bathroom with plastic panels. For many years now, widespread plastic bathroom panels have been made from PVC - polyvinyl chloride. This is a practical and lightweight material that is easy to install and easy to clean. If you choose PVC panels for your bathroom, you will be offered a wide range of sizes, colors and textures.

It is better to choose plastic panels for the bathroom in light colors with a glossy surface: this will visually increase the volume of your bathroom. In general, according to the surface type of PVC wall panels, there are glossy, semi-gloss and matte. Often in bathrooms the ceiling is made of plastic panels: you can even choose mirror panels for this.

As a rule, plastic panels are produced in the form of stacked-slat panels with tongue-and-groove fastening, which facilitates their installation.

Wooden wall panels

The use of wood wall panels in the bathroom has significant restrictions on where they can be placed. Natural, eco-friendly materials are always valued in home decoration: they are beautiful, durable, and repairable. If wooden panels are reliably treated with a moisture-resistant compound, they can be used in the bathroom in places that do not have direct contact with water. However, when it comes to solid wood panels, installing them in damp areas is always risky. And considering that the wall panels themselves are made of wood - an expensive pleasure, it is better to choose a different material for the bathroom.

Stone effect wall panels

An alternative to traditional finishing materials is the use of stone-look wall panels. They are much cheaper than bathroom tiles, but can reproduce almost any texture of various materials: stone, brick, wood and even the same tile.

In terms of strength and moisture resistance, stone panels are not inferior to tiles: the surface is treated with a special waterproof compound. The sizes of the panels are as varied as the sizes of the tiles; they are also similar in thickness to tiles (3-7 mm). Installation is carried out using construction adhesive (liquid nails).

For stone-look wall panels made on the basis of MDF with a melamine coating, everything that is written above about MDF wall panels is true.

3d wall panels

Wall panels with a three-dimensional effect are a good alternative to photo wallpaper. This is a relatively new type of finishing, it can create a unique design solution. They are lightweight, durable, non-flammable, waterproof, easy to install, but their supply is limited and the price is high. The materials from which 3d wall panels are made are usually polymer; the panel itself may consist of several layers of different materials. Therefore, to determine the properties of such wall panels for a bathroom, it will be the material that predominates in their composition.

Choosing wall panels for the bathroom. Which ones are better and more practical?

Let's briefly look at the pros and cons of different types of wall panels for the bathroom. For clarity, let’s evaluate the properties of bathroom wall panels in the table.

| Table. Comparative analysis of the properties of wall panels for the bathroom. | |||||

| Type of wall panel | Water resistance | Easy surface care | Durability (in wet conditions) | Ease of installation | Price |

| MDF panels | Fine | Great | Fine | Great | 2440x1220x3.2 mm From 900 RUR/piece. |

| PVC panels | Great | Great | Great | Great | 2700x250x8 mm From 120 RUR/piece. |

| Wood panels | Badly | Fine | Badly | Fine | From 1600 RUR/m2 |

| Stone panels | Fine | Fine | Fine | Great | 2440x1220x7 mm From 1300 RUR/piece. for MDF based panels |

The table shows that the champion in practicality is PVC wall panels. This is not surprising: the minimal porosity of the material, smooth texture, and complete waterproofness make this material ideal for bathrooms. Plastic wall panels are stain-resistant (do not accumulate dirt) and are easy to clean - this increases the “rating” of PVC panels in terms of sanitation, which is important for a bathroom. Of course, for those who want to save money, the deciding factor is the price, and PVC panels for walls have the lowest price.

MDF panels are not much different in their properties from PVC panels, and they are not much more expensive. As a rule, MDF wall panels are produced in wide sheets (sheet panels), which reduces the number of seams during installation. For a bathroom, this aspect is important, since if the tightness of the seams is broken, water will penetrate into the joints of the panels, which over time can lead to swelling of the MDF board.

Wooden wall panels are generally not suitable for the complete finishing of bathrooms (if we are talking about solid wood panels and the like). If we are talking about MDF-based panels with a pattern that imitates wood, then everything said about MDF panels for walls applies to them.

Moisture-resistant wall panels under tiles

Today, there are several basic ways to decorate bathroom walls, most often used during renovations.

These methods include finishing walls with tiles, painting walls, and repairing walls with plastic panels.

Somewhat less often, for repairs they choose to cover walls with moisture-resistant wallpaper.

But there is another way to make beautiful bathroom walls. To do this, you can use PVC panels or tile panels.

We'll talk about tile panels in this article. Let's see what they are and figure out what their pros and cons are.

Advantages and disadvantages of laminated panels

Tile is rightfully considered the most hygienic and durable material for finishing bathroom walls. But in order to lay tiles on the walls, you need some experience, which is not always available if you decide to do the repairs yourself. And laying tiles is not cheap. Therefore, cheaper laminated fiberboard panels are often chosen as an alternative. Such panels are made from eucalyptus wood fibers impregnated with special moisture-resistant compounds and are high-density panels (850 kg/m3) with PVC coating.

The most famous manufacturers of laminated waterproof fiberboard panels on the world market today are Georgia Pacific (USA), CANFOR (Canada), Eucatex (Brazil), PLY GEM (Brazil).

The main advantages of laminated panels made to look like tiles include the following characteristics:

- high hygiene. Walls decorated with such panels are not afraid of detergents.

- tile-like tiles are not afraid of temperature changes in the bathroom;

- the panels are highly resistant to mechanical damage;

- do not absorb moisture;

- do not support the spread of fungus and mold;

- aesthetic. Walls decorated with tile panels look very beautiful;

- The panels are fade resistant and quite durable.

In addition, installing panels is incomparably less labor-intensive than laying tiles. Thanks to the large sheet area, wall repairs are carried out very quickly.

The disadvantages of such panels include a slightly lower resistance to mechanical stress than that of tiles.

Such panels look simply excellent in the bathroom interior:

Coloring of fiberboard panels to match tiles

Today, the industry produces panels in a wide variety of color shades. In addition, the pattern can imitate various materials - tiles, marble, granite.

What such panels look like is shown in the figure below:

The panels have a size of 1220x2440x3.2mm and allow you to cover a fairly large area of the wall at once. You can choose panels to match any plumbing fixtures, furniture and bathroom door.

Installation of panels under tiles

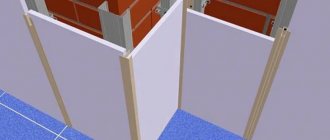

The panels are very easy to install. Previously, we already looked at how to make repairs with plastic panels. As you remember, the panels are mounted on a sheathing made of wooden blocks or galvanized metal profiles.

Panels under the tiles can be attached without installing the sheathing, that is, directly on the glue. But before you start installing the panels, you need to level the bathroom walls so that after finishing the panels are positioned strictly vertically.

Natural wood products

Ecological material treated with special impregnations against fungus and rot. Perfect for interior decoration and masking various defects and communications.

If you are trying to decorate a backsplash, then wooden panels in the kitchen are not a very good idea. Even impregnations that create a waterproof protective layer will not be able to protect the wood from swelling and deformation .

Near a gas stove, it is necessary to take into account the safe distance from the wall to the hob. Do not forget that wood does not like sudden changes in humidity and temperature, frequent cleaning and sharp objects.

What types of panels are there for use in the bathroom and what are the advantages over tiles?

A couple of decades ago, ceramic tiles were considered the most popular finishing material. Now there is an excellent alternative to choosing tile cladding - tile-like bathroom panels. They are not only not inferior to tiles, but in many ways superior to them.

What types of panels are there for use in the bathroom?

The panels are made from chipboard, PVC, MDF and fiberboard. Lath typesetting plates have been developed and offered for sale, which are suitable for cladding rooms with a small area.

Tile sets combine tiles and panels in the bathroom. But the most common are sheet wall panels. They can be made from different materials.

PVC sheets

Plastic panels for bathroom tiles quickly gained popularity in the market of facing materials. They are used in almost any room, including bathrooms, showers and toilets. The main substance from which the coating is made is polyvinyl chloride.

Bathroom cladding based on this synthetic material does not allow moisture to pass through, is not susceptible to high temperatures, is hygienic and has a long service life.

PVC sheets can be a good solution when choosing wall cladding in the bathroom.

MDF

Lightweight and durable, MDF is created by dry pressing small wood chips at high temperature and pressure. When exposed to high temperatures, wood releases lignin, which serves as a natural adhesive.

The material can withstand heavy loads. Wall cabinets and shelves are mounted on the coating. It is resistant to high humidity, has good heat and sound insulation. Some manufacturers of building materials produce sheets with increased fire-resistant protection. Therefore, when renovating a bathroom, you should pay attention to MDF panels.

From fiberboard

The material is made by hot pressing wood chips using plant fibers. Wall panels made from fiberboard sabot tiles are susceptible to moisture and high temperatures, but they should not be used in the bathroom.

Building materials made from fibreboard (fibreboard) can become wet over time, which will lead to a violation of the integrity of the structure and its gradual destruction.

Based on chipboard

Chipboard is made by hot pressing of shavings and sawdust. Similar to fiberboard, the material is of little use for finishing walls in rooms with high humidity.

Bathroom walls in the bathroom can be finished with chipboard sheets only if they are pre-treated with moisture-repellent and antifungal solutions.

What is the advantage over tiles?

A fixed panel in a bathroom with imitation tiles has a number of advantages compared to simple ceramic tiles. The relatively low cost of such materials is attractive.

In addition, installing MDF or PVC sheets is much cheaper than laying tiles. The installation process itself is simpler, cleaner and less time consuming.

Durability

In terms of service life, coatings made of polyvinyl chloride or other types of plastic are not inferior to cladding made of ceramics or natural stone. If you cover a bathroom with chipboard or fiberboard panels, their service life will be significantly shorter due to high humidity.

The service life can be extended if the sheets are periodically treated with sealants and water-repellent agents.

Moisture and mold resistance

Manufacturers of PVC and MDF panels have long been producing cladding that is practically not exposed to the negative effects of water.

The specially treated surface of finishing materials creates an environment unsuitable for the development of mold and mildew. This coating can be safely used in the bathroom instead of tiles.

Simplicity and ease of installation

Unlike tiles, installation of wall panels can be carried out on uneven walls. In addition, various defects and irregularities can be hidden behind such cladding.

To install the sheets, you will need liquid nails or mounting strips and sealant. There is no need to prepare an adhesive solution and wait several days for it to harden.

The installation process itself will take approximately 8-10 hours. Using wall panels instead of tiles in the bathroom will help save time and money during installation.

Ease of cleaning

The plastic surface is easy to clean from any dirt. In tile cladding, dirt accumulates in the seams between the tiles, but when covering the walls with MDF panels, you don’t have to worry about such a problem. Plastic plates fit tightly together. The coating is not exposed to household chemicals, which is a definite plus.

Variety of colors and designs

Manufacturers of building materials offer many shapes and color options for PVC sheets. Photo printing is possible.

In a hardware store you can order cladding with any image or picture. They create beautiful and colorful compositions or limit themselves to restrained monotonous patterns. In any case, wall slabs can become an accent in the bathroom interior.

Installation of wall panels

To install the facing material, you will need a jigsaw, spatulas (notched and plain), a gun for liquid nails and sealant, glue and a primer for walls. Before gluing plastic panels, the walls must be prepared by cleaning them from the previous coating and priming them.

The dimensions of the PVC plate must be adjusted in height and width. To do this, use a jigsaw with laminate files. Glue 5-7 mm thick is applied to the back side of the slab. Finishing the bathroom with plastic panels starts from the corner of the room.

The sheet is placed on the wall and pressed lightly against it for a couple of seconds. Excess glue is immediately removed, since the mixture hardens quite quickly. After gluing all the panels (after 10-12 hours), begin to seal the gaps between them. This is done using a transparent sealant for rooms with high humidity.

Source: https://oplitke.com/vybor/paneli-dlya-vannoj-komnaty

Application of glass structures

Ikea wall panels are made of tempered glass - skinali. They are waterproof, thickness from 4 mm provides high impact strength. Insensitive to moderate temperature and chemical influences. Sudden temperature changes, such as cold water coming into contact with a heated sheet, should be avoided. Glossy options require more effort to clean than matte ones.

The pattern on the IKEA apron is applied on the inside using the ultraviolet printing method. Thanks to this, the background has rich shades. Fastening is carried out on a flat surface using decorative fasteners or special guides.

Each material for the production of false panels has its own advantages and disadvantages, but when choosing, you should not neglect safety parameters.

Originally posted 2018-03-03 07:08:49.