What are PVC plastic panels

Before moving directly to the issue of installing PVC boards, you need to figure out what kind of material it is. PVC panels are two-sheet plastic products that are separated by stiffening ribs. Along the edges of such slabs there are structural parts that allow them to be fastened together. The thickness of the material ranges from 8 to 12 millimeters.

The PVC material itself stands for polyvinyl chloride. It was discovered in 1985 by the German chemist Regnald and has become widespread in interior decoration and window manufacturing, as well as other industries.

PVC panels are two-sheet plastic products that are separated by stiffening ribs.

Main types of PVC plastic panels

PVC boards can have different characteristics. This universal material has the following parameters:

- Size – there are square and rectangular elongated slabs. So-called PVC slats up to 15 centimeters wide are also produced. There are also slabs whose width reaches 2 meters;

- Surface – can be glossy, half-glossy or completely matte;

- Framing type – suture and seamless. With a seamless type, the joints between the panels are practically invisible. Thanks to this, the surface becomes continuous. With the suture type, the joints, on the contrary, show through well. These types of framing are used depending on the design of the room;

- Also, PVC panels have a huge range of colors, textures and images. Therefore, every apartment owner will find something to suit their taste and preferences.

PVC panels have a huge range of colors, textures and images.

Advantages and disadvantages of PVC panels

Why did plastic panels become so popular? It's all about their huge list of advantages:

- In terms of their moisture resistance, they are at the top among all finishing materials. The plates are able to repel water molecules in both liquid and gaseous states. Such material can even replace ceramic tiles and waterproof paint coating;

- This material is hygienic. It is easy to care for. In addition, fungi and other pathogenic microorganisms do not develop on plastic boards;

- Fastening plastic wall panels is a simple process that even an inexperienced novice craftsman can handle;

- In construction stores you can always choose the shade and texture of this material. You can buy such panels with any design and even put photographs on them;

- PVC boards always please customers with their price. It depends on the size of the slabs and starts from 50 rubles for 1 product.

The plates are able to repel water molecules in both liquid and gaseous states.

Like other wall cladding materials, PVC panels also have disadvantages:

- Plastic boards are very easy to deform or break. One sudden movement, albeit not so strong, and a crack or hole appears in the slab. Moreover, the strength does not depend on whether the panel was mounted on a frame or simply attached to the wall;

- This material is subject to combustion. In addition, it emits toxic smoke when ignited, which has a negative effect on human health;

- Poor quality products can emit harmful substances even if they do not burn. This is affected by high temperature, as well as direct sunlight;

- At first, PVC boards have an ideal surface. But over time, it gets scratched and expands due to temperature changes. Therefore, this material is very short-lived.

Before purchasing such material, you must carefully study its manufacturer. Otherwise, the purchased product will be unsafe. The country of manufacture, as well as the smell emitted by the product, can serve as a guide.

Plastic boards are very easy to deform or break.

Soft sheathing

Double-sided foam tape

Installing plastic panels over a soft sheathing seems flimsy, but in fact it is precisely these sheathings, which came out of the hands of the greenest but neatest beginners, that last for 10-15 years without signs of damage. Why? The soft sheathing is made of double-sided foam tape, see fig. In terms of thermal deformation properties, it exactly matches PVC, and its adhesive layer is very viscous and elastic: it stretches behind the board and then returns it to its place.

For soft sheathing to be truly reliable, three conditions must be met:

- Clear the wall of wallpaper, paint and level it with a rough, durable putty (Hercules, Prospector, etc.) to within half the thickness of the tape, 2-4 mm. Sharp small protrusions and depressions are acceptable, so puttying, which is already not difficult, is even easier.

- Stock up on a high-quality finishing profile; without it, sheathing over soft sheathing cannot be done. However, see the penultimate section.

- Reduce the contact time of the adhesive layer of adhesive tape with air as much as possible, up to an instant. This is something we need to talk about in more detail.

Installation of sheathing

The lathing scheme is the same as for the others. It is better to take the width of the adhesive tape from 25 mm, and best of all – from 60 mm. Technology:

- From the initial end of the tape in the roll, 300-350 mm of the upper (outer) protective tape is removed, and the tape with the bottom tape is cut off, as shown in the figure;

Trimming tape for soft sheathing - The master (it’s him!) presses the initial end against the wall, and the assistant pulls the final strip;

- The master peels off the lower (adjacent to the wall) end of the protective tape and carefully pulls it out from under the tape, immediately pressing the tape against the wall;

- At the final end, a tail of the upper protective tape of 100-120 mm is left;

- The remaining strips of tape are applied in the same way.

Installing profiles

The principle is the same - the shortest possible contact of the “bare” tape with the air:

- The long tails of the protective tape are pulled back and the strips are stuck to the “back” with ordinary, narrow and cheap stationery tape;

- Apply the upper installation profile (horizontal), carefully pull out the protective tape from under it by the tail, immediately attach the profile with pressure, and an assistant supports it;

- The lower installation profile is also glued;

- The starting profile (vertical) is applied, the assistant holds it, and the master one by one pulls out the protective tape from under the profile, immediately pressing the profile to the tape, the operation proceeds from the bottom up so that the profile does not hang on the tape even for a short time;

- The finishing profile is also installed.

Panel installation

The panels are mounted similarly to profiles, but with some subtleties:

- You need to cut to size very cleanly and precisely to avoid jamming.

- The next panel is brought into place by hand using two ends in agreement; You cannot use a mallet and rule.

- After installing each board, the tails of the protective film are re-glued, and those that are too long so as not to interfere with work are cut off.

Necessary tools and materials for attaching PVC plastic panels to the wall

Of course, before directly attaching PVC plastic panels to the wall, each master prepares in advance all the necessary tools for himself. Typically this is:

- Screwdriver.

- Hacksaw and scissors for cutting metal.

- Convenient staircase.

- Self-tapping screws.

- Water level, tape measure and pencil for measurements.

- Construction stapler.

- Electric drill.

In addition to the PVC boards themselves, other materials will be needed for their installation:

- Inner and outer corners.

- Starting and docking profiles.

- F-profiles.

- Ceiling and floor plinths.

All this can be bought in the same place where plastic profiles are sold.

Before attaching PVC plastic panels to the wall, each master prepares in advance all the necessary tools for himself.

Lathing

Lathing based on a metal profile

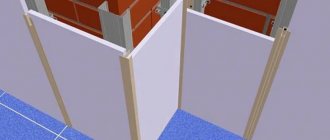

The sheathing is made of wooden slats or metal C-profiles, see fig. Insulating mats can be placed in the cells. They are attached to the wall with self-tapping screws in dowels, through or with clamps or mustaches. The latter is more troublesome, but cheaper: all the work can be done using flea screws. Level with a plumb line and a 2 m bubble level, also see figure; Rubber or plywood scraps will be used for gaskets.

Lathing for plastic panels

The battens are quite simple linear, without intersecting joists, with a pitch of 300-500 mm. But an important condition: the perimeters of both the wall and the openings in it must be completely framed, see the sheathing diagram. There should be no hanging ends of the joists, the exception being the protrusion of the window sill; a recess will have to be cut for it in the panel adjacent to it.

Lathing scheme for plastic panels

Preparatory work before attaching PVC plastic panels to the wall

The nature of the preparatory actions before fastening the products is related to the base and the degree of its evenness:

- If the master has chosen fastening by means of lathing, there is no need to level the base in advance;

- But if the slabs will be mounted directly on the wall, you should first check the base for evenness and carry out leveling work, if necessary.

Before any installation of PVC panels, the surface of the walls must be pre-treated with an antiseptic. This will protect them from mold and dampness. Next, the surface is primed. The primer must be applied in 2 layers. It is not recommended to apply a second coat until the first has dried.

Also, before installation, you need to prepare all the fittings and additional elements. In addition, you should immediately prepare the sheathing if the master decides to attach the slabs to it.

The primer must be applied in 2 layers.

Preparation

This is a simple operation and consists in the fact that the entire area that will be hidden under the plane of the new coating must be treated with a primer or impregnation with a bactericidal effect. This treatment is carried out so that mold does not appear under the future coating or fungus does not develop. Before this, all traces of the old finish and flaking fragments of plaster or putty are removed using available tools, such as a spatula.

The process of attaching PVC plastic panels to the wall

After completing all the preparatory work, you can begin directly attaching the plastic boards. Below are step-by-step instructions for installing wall panels using lathing:

- The first step is to install the frame. It is made with slats made of metal or wood. The distance between the blocks should be no more than 40 centimeters. The slats are mounted to the wall perpendicular to the plastic plates themselves.

- Then all available fittings are installed - internal and external corners, the final part of the panel. If the final part reaches the very ceiling, you need to install a ceiling plinth on the top beam.

- Then you can insert the remaining plates into the mount with the thin side. They are closed on the wide side with staples or regular nails.

- Now you need to check whether the very first panel is inserted evenly. If so, then you can insert the next slab into the groove of the outer panel with the narrow end first. The slabs must be mounted tightly.

- The last plastic plate will need to be inserted between the final one and the penultimate one. To do this you need to make an effort. When the panel does not give in at all, it is cut off a little lengthwise with a construction knife.

The first step is to install the frame.

Fastening method without lathing

PVC boards are attached directly to the wall without a frame if the room is dry and the surface of the walls does not have any differences. A special glue is used for this. It is applied to the very surface of the panels and the slab is immediately applied to the wall.

How to glue PVC panels to a wall with liquid nails? If liquid nails act as glue, they are also applied to the slabs, but wait 3-5 minutes for the nails to acquire a certain rigidity. Only then can you apply the slab to the wall.

Self-tapping screws can also serve as fasteners. However, in this case you will need to make a lot of holes. And the fasteners will be conspicuous.

PVC boards are attached directly to the wall without a frame if the room is dry and the surface of the walls does not have any differences.

Installation of plastic

In general, wall cladding with PVC panels is carried out in the following order:

- Arrange the sheathing;

- Install starting, finishing and guide profiles;

- The first board is inserted into the lower installation profile, and then, bent in an arc, into the upper one, the small fastening shelf should be facing the starting profile;

- With a mallet, as a rule, the board is brought into the starting profile to the place;

- Attach the board to the sheathing through a large fastening shelf in one way or another;

- The remaining boards are mounted in the same way, including the penultimate one;

- The last board is cut from the side of the LARGE mounting shelf to the width; you need to allow for thermal expansion, see the example above;

- Having bent the shelf of the finishing profile (if it is non-separable) with a spatula, insert the lower end of the last board into the groove of the installation profile and into the finishing profile; this work requires a skilled assistant, or better yet, two;

- Alternately bending sections of the narrow flange of the finishing profile with spatulas, insert the board into it to the upper corner;

- In the upper corner, the shelves of the finishing and mounting profiles are simultaneously bent with two spatulas, and the board is finally installed;

- Also, alternately bending the shelf of the finishing profile, attach the board together with the profile to the sheathing;

- install skirting boards.

Notes:

- When using a special finishing profile, all the difficulties of operations 8-11 are reduced to applying and snapping its flange.

- A cheap profile from all these manipulations sometimes remains bent or cracks along the edge of the corner. You can correct the defect simply - warm up the damaged area with a household hairdryer and immediately iron it with pressure with a COLD iron with a Teflon sole.

- For the sake of beauty, the profiles are cut exactly to size along the wall, and then their ends are cut at 45 degrees in a miter box. An option is to fill the cracks with PVC putty or a homemade compound. For this, plastic sawdust is kneaded in dichloroethane until the dough becomes thick. Prepare in small portions as needed; the mixture is not stored.

- If the sheathing was aligned carelessly, the last board will immediately show this - its edge will bend outward. The result was a “finish”.

The nuances of attaching PVC plastic panels in different rooms

How are PVC panels attached to the wall in different rooms? After all, installation has its own nuances depending on the room.

Bathroom and toilet

There is high humidity in rooms such as the bathroom and toilet. Therefore, the slabs should only be attached to the sheathing.

In the bathroom, slabs should only be attached to the sheathing.

Kitchen

There is always a lot of fumes in the kitchen. Therefore, it is better to install this finishing material using a pre-prepared frame.

It is better to mount this finishing material using a pre-prepared frame.

Balcony

If the balcony is sufficiently insulated and the humidity in it is minimal, you can take a chance and install the products without lathing.

If the balcony is sufficiently insulated, you can take a chance and install the products without lathing.

Other possible rooms where they can be used

In other rooms, you can also install PVC slabs without using lathing. Of course, it is better to use liquid nails or special glue as fastening. Self-tapping screws can spoil the visual characteristics of the interior.

It is better to use liquid nails or special glue as fastening.

The nuances of attaching PVC plastic panels to different types of walls

Depending on the type of surface on which the panels are attached, the fasteners will be different.

Concrete

For example, concrete surfaces are faced using dowel-nails or dowels and self-tapping screws.

Concrete surfaces are faced using dowel-nails or dowels and self-tapping screws.

Brick

Brick walls are finished according to the same rules as concrete ones.

Brick walls are finished according to the same rules as concrete ones.

Other possible options

For a wooden surface and a plasterboard base, it will be enough to use ordinary self-tapping screws as fastening.

For a wooden surface and a plasterboard base, it will be enough to use ordinary self-tapping screws as fastening.

What tools will you need?

It is worth preparing to work with PVC panels. First of all, you will need to find a special tool:

- Circular Saw. If you can’t find it, you can use a jigsaw. The file or disk must have fine teeth (“clean cut”). It is preferable to use a saw. The jigsaw file is highly flexible, so the cut can turn out wavy.

- Jigsaw cutter with angles of 45 and 90 degrees.

- Construction stapler for cladding on wooden sheathing.

- Rubber mallet with a hook rule. The same tool is used for installing laminate flooring. Needed to “rip out” jammed panels. Doing this with your hands can easily damage the panel or sheathing.

- A plaster spatula used to bend the finishing profile when installing the last plank. Spatula length 80-120 cm.

Also when performing work you will need:

- pencil and tape measure;

- building level;

- square;

- fastening elements (self-tapping screws, dowel-nails, clamps);

- screwdriver;

- perforator;

- sealant;

- antiseptic.

Tips and tricks for fixing PVC panels

Below are useful tips that will help you carry out installation quickly and safely:

- When cutting slabs, it is better to turn them face up;

- It is recommended to wear safety glasses when working;

- If there is glue left on the front side of the product, it can only be cleaned with soap and water;

- It is better to apply glue in the form of an even mesh;

- When screwing in screws or driving in nails, you need to be extremely careful so as not to accidentally break the slab.

When cutting slabs, it is better to turn them face up.

If you follow all the recommendations and follow the attached instructions, the installation of PVC panels will not take much time and will be done efficiently.