The bakelite varnish composition includes a liquid compound consisting of a formaldehyde-type resole resin.

Ethyl alcohol acts as a solvent. Ammonia is also included in the structure of the varnish; it is an accelerator of the chemical process. Because of the ammonia, the varnish has a special smell.

Composition LBS-1 is used for:

- adhesion, finishing and impregnation of objects;

- protecting devices involved in the heat exchange process from the adverse effects of technical fluid at elevated temperatures;

- protection of many devices from the influence of solutions of acids and salts of moderate strength;

- painting gas tanks and oil tanks;

- production of connecting links used in the manufacture of laminated plastics, the structure of which contains mineral organic additives;

- production of abrasive materials, chemical jutes;

- protection of pipelines and air-drying devices from negative atmospheric influences;

- varnishing of protective surfaces;

- processing concrete objects and wood products for the purpose of protection;

- in the chemical apparatus industry.

Area of use

This composition perfectly protects all kinds of devices from the influence of hot liquids, weak acids, and is used when painting containers in which gasoline is stored, as well as during the manufacture of binding components of layered types of plastic.

Nowadays, bakelite varnish is used everywhere; this solution is used in the production of various substances, as well as in the construction industry. The characteristics of this material allow it to be used for the following purposes:

- covering all kinds of surfaces, impregnating them and joining them;

- effective protection of heat exchange equipment, which is adversely affected by heated technical fluid;

- reliable protection of various elements of equipment and parts from the effects of salts and acids with a moderate impact indicator;

- processing containers of any volume in which petroleum products and gasoline will be stored;

- creating binding components used during the production of plastic parts, especially during the production of laminates to which organic fillers are added;

- production of chemical fibers;

- production of metal devices and various abrasive parts and devices;

- creating an anti-corrosion layer on pipeline systems, air ducts, air purifying filters and structures;

- coatings of concrete and wood surfaces, for which bakelite-based varnish provides reliable protection and extends their service life;

- often used for various purposes in chemical engineering.

Short description

LBS1 varnish is a mixture of phenol-formaldehyde resole resin dissolved in ethyl alcohol. This substance is produced according to the criteria of GOST 901-78.

The alcohol solution is widely used: for joining, gluing, impregnating surfaces made of a wide variety of materials (these are the main areas of application of varnish). It is also worth noting that alcohol varnish LBS1 perfectly copes with the protective function of various devices from the negative effects of hot liquids and weakly diluted acids, and is also used for painting gasoline containers and the production of connecting elements of laminated plastic.

Specifications

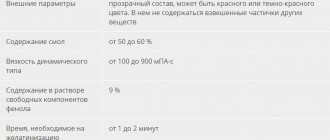

Externally, bakelite varnish looks like a translucent liquid; it has a burgundy or red color. There are no inclusions, foreign particles or impurities in this solution. Many varieties of this bakelite mixture, for example LBS-1 varnish, contain 50-60% bakelite resin. The dynamic viscosity index can be different, in the range of 100-900 mPa-s.

This solution contains approximately 10% water and 9% free phenolic elements. In about one to two minutes, this mixture undergoes gelatinization. Technical characteristics of bakelite varnish may vary, depending on the specific brand of solution. The varnish consumption is about 120 grams per square meter if LBS-1 varnish is applied with a brush. When applied from a spray bottle, the consumption will be less.

Types of insulating varnishes

Depending on the purpose of varnishes there are:

Integumentary

Covering materials, mainly intended to protect electrical insulating materials, as well as products made from them, from moisture penetration. These varnishes are closest in composition and methods of application to conventional anti-corrosion varnishes. Coating varnishes, in accordance with their intended purpose, should provide a dense, moisture-proof coating, capable in some cases of withstanding prolonged heating up to 100-120° and having good dielectric properties. In some cases, these varnishes are subject to a number of additional requirements: ozone resistance, oil resistance, etc.

Impregnating varnishes

Impregnating varnishes intended for impregnation of the windings of electrical machines, during which process the goals are pursued:

- a) reducing the hygroscopicity of insulation,

- b) increasing the electrical strength of insulation,

- c) increasing its mechanical strength,

- d) increasing its thermal conductivity, etc.

Impregnating varnishes are usually subject to the following requirements: good dielectric properties, good impregnation ability, non-hygroscopicity, chemical neutrality, etc.

Adhesive varnishes

Adhesive varnishes are intended for gluing various insulating materials. One of the main desirable properties of adhesive varnishes is good adhesion to a particular material, for example, to mica for varnishes used for the production of micanites, to paper for varnishes used for the production of paper-resin insulation (getinax). In many cases, very serious requirements are also placed on the electrical properties of adhesive varnishes, since in this case the varnish layer may be in an electric field of high intensity (for example, varnish used for the manufacture of varnish-mica insulation of high-voltage generator rods). In most cases, the varnish layer is also required to be able to soften when heated to allow hot pressing of the bonded insulation. If we also take into account that in many cases moisture and ozone resistance are required from adhesive varnishes, then it should be recognized that adhesive varnishes are perhaps the most “difficult” varnishes.

Special varnishes

Special varnishes, which include varnishes for the production of varnished fabrics and varnished papers. Essentially, these varnishes are close to cover varnishes, but differ from them in a number of significant indicators. Thus, they are required to have very high electrical properties at both normal and elevated temperatures. Further, these varnishes must be very durable and elastic, cover the fabric with an even layer and withstand the effects of elevated temperatures for a long time. Finally, the varnish should not be destructive to the fabric or paper it covers. Special varnishes may include varnish for enameling wires, then semi-leading varnish for leveling the electric field, etc.

The classification of varnish into one category or another is often done very arbitrarily in view of the possibility of using varnish of the same formulation for different purposes. The technology of insulating varnishes does not differ significantly from the technology of conventional coating varnishes.

Basic Rules

Before using bakelite paint and varnish composition, you must familiarize yourself with the following important rules that must be followed:

- the surface on which the varnish is applied must be free of dust, dirt, rust, grease, oil, and it must also be dry;

- Before application, bakelite varnish LBS-1 must be thoroughly mixed and shaken;

- During application, a film appears on the base, which needs to be baked; for this, heat treatment is carried out, during which the temperature gradually increases and should reach 160 degrees. This procedure produces a cross-linked polymer. When heated to a temperature of 150 degrees, the gelatinization process takes place in about 2 minutes, usually in 70-80 seconds;

- Bakelite-based varnish should be stored in a dark room, the air temperature should not exceed 20 degrees.

Details

Basic rules of application

Before using bakelite paint and varnish composition, you should first familiarize yourself with the following important rules that you should adhere to:

- The surface on which the varnish composition will be applied must be cleaned of dirt, dust, grease, rust, oil, and must also be well dried.

- In addition, before application, bakelite varnish should be thoroughly mixed or even shaken if possible.

- When applying the composition to the base, a film will appear that should be baked, and for this it is worth carrying out a heat treatment, during which the temperature will gradually increase and reach +160 degrees. Thanks to such a procedure, a network polymer will be obtained, and when heated to a temperature of +150 degrees, the gelatinization process will take place in a couple of minutes, more often even in 1 minute 10 seconds.

- Bakelite-based varnish should be stored in a dark room, and the overall air temperature should not be more than +20 degrees.

Preparation of the surface and varnish composition

In order for the protective coating to be of the highest quality and reliability, you should first prepare the base. To do this, you will need to remove grease stains, dirt, rust, scale, and old paint and finishing materials from it. The best cleaning is achieved by using shot blasting and sandblasting units. You can also use sandpaper or an electric sanding tool. At the second stage of preparation, you will need to work on bakelite-based varnish, that is, LBS-1. Before applying it to the surface, you should shake everything well so that it becomes homogeneous, and if the composition contains 40% kaolin or even graphite, then this composition can be used as an excellent priming solution. It can be applied to metal bases for reliable protection against rust and corrosion.

Varnishing process

The technical characteristics of bakelite varnish LBS-1 or solutions similar in composition make it possible to apply it using a spray bottle and a brush. The primer mixture, which is based on varnish, can be applied 3 hours after painting, and the primer solution can also be applied with a paint sprayer.

The first applied layer of varnish must dry for about 5 hours, and then it will be time for polymerization. After this, the treated surface must be covered with a layer of primer, then a second layer of varnish is applied, in which the filler must contain no less than ¼ of the total composition. When the second coating is applied, then, as in the first case, polymerization will be required. All further layers of coating should be applied without filler. It is important to remember that the thickness of all layers of varnish as a whole should not be more than 0.5 mm. Ideally, bakelite-based varnish should be applied with a brush or, better yet, with a spray bottle. The spraying method is used when it is necessary to cover a large area, and when applying it is necessary to ensure that the layer is spread evenly, there are no cracks, thin areas, drips, sagging or a very thick layer.

Please note that in order to obtain a coating with the maximum degree of strength, a primer mixture should be applied to the base and 2 or even 3 layers of cotton fabric, which will be soaked in advance in bakelite paint and varnish material.

Bonding cotton fabric

The gluing process will include the following steps:

- The material should be cleaned of dust and dirt, starch should be removed, the fabric should be thoroughly washed, dried and cut into small strips.

- Prepared pieces of cotton fabric should be soaked in a varnish solution, for example, in the same LBS-1, and it should be 25%.

- After 5 minutes, remove the pieces of fabric from the container where the varnish solution is poured and squeeze everything out. The spinning process should be carried out only with rubber gloves to avoid burns and irritation on the skin.

- The cotton fabric will take several hours to dry to allow the solvent to evaporate.

- After partial drying, stick the sticky pieces of fabric onto the ground surface of the metal.

When carrying out such a procedure, you should be sure to ensure that the fabric does not begin to stretch, because if this happens, it can tear when drying, as it will begin to shrink. At the last stage, the cotton material should be painted using a brush, which will be dipped in the varnish composition.

Coating of chemical equipment

Bakelite varnish, which has no alternative, is used to protect various chemical equipment, for example, mixers, coils and everything else. To do this, you should prepare cotton fabric, which you will cut into strips, and then tightly wrap them around the protected surface, and during processing you will need to make fabric overlaps of 3 cm. You can wrap any number of fabric layers, it all depends on your needs. After winding the layers, they will be covered with a layer of bakelite-based varnish mixture, and after that the coating should be treated with a thermal method, during which the composition will begin to harden.

At the end of the heat treatment, the coating should be cooled for approximately 7 hours, and the air temperature should be +25 degrees. If all the rules are followed, the surface that will be varnished will be smooth and shiny, and also have a red-brown tint. You can easily check the quality of the surface being treated, and to do this you will need to take a rag, moisten it in ethyl alcohol, and then rub it over the varnished surface several times. If there are brown or even yellow spots on it, this will indicate that the heat treatment was carried out incorrectly. If the rag remains clean, then the varnish composition has polymerized correctly and there is nothing to worry about.

Share the post “Characteristics of bakelite varnish + application features” by copying the link: https://kaksdelatsvoimirukami.ru/xarakteristika-bakelitovogo-laka-osobennosti-primeneniya/

Surface and varnish preparation

In order for the protective coating to be as reliable and high-quality as possible, you first need to prepare the base. It removes greasy stains, dirt, dust, scale, rust, old finishing and paint materials. The best cleaning is achieved using shot blasting and sandblasting. You can also use sandpaper or an electric sander.

At the next stage, bakelite varnish LBS-1 is prepared. Before applying it to the surface, you need to shake it so that it becomes homogeneous. If the composition contains 40% kaolin or graphite, then such a bakelite composition can be used as an excellent primer solution. It can be applied to metal substrates to reliably protect them from corrosion and rust.

Using bakelite varnish

Typically, LBS-1 must be used to protect chemical devices and their parts from corrosion that occurs under the influence of atmospheric factors.

Preparatory stage

Before finishing, it is recommended that the protective coating be carefully processed to further form a Bakelite surface of excellent quality.

Using a sandblasting or shot blasting device, you need to remove all dirt, rusty traces, soot, dust particles and traces of fat until a gray tint with a matte tint is formed. Then the compound itself is prepared.

Shake the container with varnish and stir the varnish.

If it contains about forty percent of additives, for example graphite, diabase powder or kaolin, the varnish material can be used for priming purposes.

The treatment should be carried out with a paint brush, with little force, rubbing the liquid into the metal surface, but this should be done before three hours have passed after application.

In this case, the likelihood of rust forming on the metal will be eliminated.

Varnishing

The characteristics of bakelite varnish LBS-1 or a solution similar in composition allow it to be applied using a brush and a spray bottle. A primer mixture based on bakelite varnish can be applied 3 hours after painting. The primer can also be applied with a paint sprayer.

The applied first layer of varnish must dry for four to five hours, then polymerization is performed. After this, the treated surface is covered with a layer of primer, then a second layer of varnish is applied, which should contain 25% filler. When the second coating is applied, just as in the first case, it is necessary to carry out polymerization. All subsequent coatings must be applied without filler. It is important to remember that the total thickness of all layers of varnish should not be more than 0.5 millimeters.

It is best to apply bakelite-based varnish using a spray bottle or brush. The spraying method is used when it is necessary to cover a large area; during application it is necessary to ensure that the layer is applied evenly, there are no thin areas, cracks, sagging, drips or too thick a layer.

To obtain a coating of maximum strength, a primer and 2-3 layers of cotton fabric are applied to the base, which is pre-soaked in Bakelite paint and varnish material.

Rules for applying bakelite varnish

Applying the first layer should not cause any problems to any average person who has at least once encountered some kind of basic repair. When the first layer of varnish material is applied, you should patiently wait for it to dry naturally.

Typically this takes about four hours.

- The first coat should contain varnish diluted with 40 percent filler.

- The second layer of filler will require only 25 percent. This is done so that the layers do not adhere too tightly to each other and a favorable microclimate is maintained in the areas of the coating.

- The third and fourth layers are applied without filler at all. The total thickness of the varnish surface should not exceed half a millimeter.

Each layer should be subjected to a polymerization procedure for better fixation and adhesion to the surface.

Bonding cotton fabric

The gluing process includes the following steps:

- The material is cleaned of dirt and dust, starch is removed, the fabric is washed well, dried and cut into small strips.

- Prepared pieces of cotton fabric are soaked in a 25% solution, for example, LBS-1 varnish is used.

- After 5 minutes, the pieces of fabric are removed from the container with varnish and wrung out. The spinning process must be performed strictly with rubber gloves to avoid irritation and burns on the skin.

- The cotton fabric dries for several hours to allow the solvent to evaporate.

- After partial drying, the sticky pieces are glued to a primed metal surface.

During this procedure, it is necessary to ensure that the fabric does not stretch, because if it stretches, it may tear during drying, as it will shrink. At the last stage, the cotton material is painted using a brush dipped in LBS-1 varnish.

Types of varnishes for fireplaces

You should choose a heat-resistant varnish for stoves based on the technical characteristics and design features. The modern construction market is filled with various types of paints and varnishes, but only a few of them have become popular among those who want to decorate and protect a stove or fireplace. Among the most effective products are the compositions KO 85 and KO 815.

KO-85

This petroleum-based product is used not only as an external finish for stoves and fireplaces in private homes. This composition is widely used in the industrial sector. It is applied to steam and heat pipelines, oil pipelines. It is used to cover engine parts and metal structures exposed to high temperatures.

Varnish KO-85 became popular due to its composition. The product is based on silicone resins and solvent. This is reflected in its characteristics:

- High resistance to high temperature influences. The dissolved resin does not lose its characteristics even at 300 degrees.

- The product can withstand sudden and large temperature changes.

- The surface does not delaminate even after prolonged use.

- The structure of the varnish is homogeneous - the resins adhere well to any surface and adhere well to metal stoves even at sub-zero temperatures.

- This varnish is applied very well - you can use rollers, brushes, and spray guns.

KO-815

This varnish for metal, brick, stone and other materials can withstand temperatures even higher than the KO-85 composition. It can withstand open fire, so it is used not only outside, but also inside heating equipment.

The varnish has the following characteristics:

- Does not lose properties at low temperatures down to -60 degrees and at high temperatures - over 300 degrees. The material can be applied at any air temperature.

- If the coating thickness is from 20 to 40 microns, then the consumption is about 110 g/m2.

- Curing processes are carried out hot using infrared rays.

- Fire hazard – class 3.

To get the maximum effect from a heat-resistant material, experts recommend applying it in several layers. Each layer must dry for at least 60 minutes. The final polymerization processes of the coating will take place within 72 hours.

Alternative materials

The above-described coatings can be replaced with the product Siltek-1. It also withstands high temperatures well. Before using this product on metal or stone, you do not need to prime the surface first. The material for the brick kiln is applied in three layers. Consumption is 300 g/m2. Subsequent layers are applied after 30 minutes.

Coating of chemical equipment

This varnish composition is used to protect various chemical equipment, for example, coils, mixers, and others. To do this, prepare cotton fabric, which is cut into strips, the protected surface is tightly wrapped with them, and during wrapping it is necessary to overlap the fabric, approximately 3-4 centimeters.

You can wind any number of fabric layers, depending on your needs. After winding all the layers, they are covered with a layer of bakelite varnish mixture, then the coating is treated thermally, during which the composition hardens.

Upon completion of the heat treatment, the coating must be cooled for 7 hours at an air temperature of 25 degrees. If these rules are followed, the varnished surface will be shiny and smooth, red-brown in color.

You can easily check the quality of the treated surface; to do this, you need to take a rag, moisten it with ethyl alcohol, and rub it several times over the varnished part. If yellow or brown spots appear on the rag, this will indicate improper heat treatment. And if the rag remains clean, then the varnish composition has polymerized correctly.

Equipment protection

One of the most useful and practical functions of this varnish composition requires detailed consideration. We are, of course, talking about protecting equipment from chemical exposure.

As already mentioned, the composition and structure of bakelite varnish ideally allows it to be used as a reagent and protective agent.

- It is necessary to apply several layers of varnish to the working surface of the equipment that needs protection.

- The number of layers directly depends on the degree of chemical activity into which the processed object enters.

- After this, the treated equipment should be subjected to heat treatment.

It should be noted that when processing in an environment of high temperatures, the change in this very temperature should be carried out gradually.

If you sharply lower or increase the temperature parameters in the workroom, the varnish may not withstand it and the structure will be destroyed.

This will ultimately lead to complete failure of not only the varnish layer, but also the entire equipment. You need to alternate and maintain balance. After processing in an environment of elevated temperatures, all equipment must be cooled.

How to choose and apply autovarnish

After painting the car, it becomes necessary to varnish it. In this case, the question arises about which car polish to choose. Experts have different opinions. Some recommend expensive brands, others believe that you can purchase cheaper options.

Aerosol car spray is divided into 2 types:

- soft (HS);

- solid (MS).

Type HS must be applied twice. The first layer should be very thin, and the second more solid. This type of aerosol does not leave streaks. It is quite thick and has low viscosity.

Type MS is applied three times to the surface of the car

It has a fluid structure, so it is important to monitor the thickness of the layers to avoid smudges. The period between applications is on average 15 minutes, but this also depends on its composition

Exact recommendations can be read in the instructions.

Types and brands

There are several types of material, depending on the technology used by the manufacturer:

- FBS. Products of the highest quality. Distinctive properties appear due to the fact that the veneer is completely immersed in bakelite. This method ensures that all layers of plywood are impregnated with alcohol-soluble resin. The result is a moisture-resistant product that can withstand constant contact even with sea water. The material is expensive.

- FBS-1. For gluing, a composition similar to the previous one is used, but the layers being joined do not undergo impregnation. The bakelite mixture is applied only to the outer areas of the veneer.

- FBS A. The inner and outer layers of plywood are coated with an alcohol-soluble composition. The resulting sheets retain their basic properties, but are inferior to the previous options in terms of stability.

- FBS-1 A. The solution is used to treat the outer and inner layers, except for two layers, which are placed across and adjacent to the core on both sides.

- FBV. It is made on the basis of water-soluble resin, which retains all the qualities, but deprives the material of its resistance to moisture. External areas are impregnated, internal areas are coated.

- FBV-1. Similar to the previous version of plywood, the mixture is applied only to the veneer layers.

Bakelite sheets can have both a dark and natural wood color, which significantly expands the scope of their application.

The difference between FBS and FBV is that for the first option, alcohol-soluble glue is used, and for the second, water-based.

Comparison of varnishes by chemical composition

The key point is the composition of the varnish coating. It depends on what loads the coating is designed for, how many years your floors will last and where you can lay the treated parquet.

Primer varnishes

They are applied before the final work as a layer between the wood and the finishing coat. Even shade, smooth surface, isolation of oils when using natural materials - these are the reasons why 95% of people use primer. In addition, they dry in no more than 3 hours.

If you buy professional products, then there is no need to apply a primer: special components are already included in the coating. Preparation is only necessary when using conventional means.

Water-soluble parquet varnishes

Due to the water base, these solutions dry in a special way: first, all moisture must evaporate naturally, and only after that the binding and hardening of the main components begins.

In stores, solutions are available in three versions: completely without solvents, weakly concentrated with no more than 5% solvents in the composition, and moderately concentrated, containing from 5 to 15% of active substances.

Pros:

Due to the water base, they do not smell as strong as other types.

This is the only option to make beautiful floors in a room where safety regulations prohibit the use of solvents. The high percentage of water in the composition makes it non-flammable, so in the event of an accidental fire, the floor will not support the fire.

Accidentally getting water during drying will not ruin the repair, because the solution already contains a large percentage of moisture.

Minuses:

- Demanding requirements for coating technology. Each jar requires a specific type of roller; sponges and spatulas with brushes are immediately excluded.

- It can flow into the cracks on the parquet, which will lead to an unpleasant squeak during mechanical stress (for example, walking).

- Not suitable for all parquet options. For beech, pine and hornbeam you need to look for a different varnish.

- Primer is required.

In addition, water-soluble compositions are characterized by low strength. Of course, you can buy special additives to extend the life of the varnish, but such a mixture will not lie smoothly if the humidity in the room is below 50%. Creating the necessary conditions is a very troublesome task.

Waterless polyurethane varnishes for parquet

This is the “heavy artillery” in the family of varnishes. Dancing, dirt, pets - a protective varnish coating will withstand everything, so this type is often applied in the hallway, kitchen and hallway.

Dries quickly due to the waterless base. Preparation with priming is not necessary, it is enough just to protect the floor from water while drying.

The varnished surface withstands high temperatures and sunlight and lasts for many years.

One of the disadvantages is the fact that waterless polyurethane varnish strongly glues the lamellas. If water spills on the floor during repairs, the coating will bubble.

Alkyd varnishes

The main component is oil resins. Wood and linen elements are similar in composition to parquet, so they combine well. Like all natural materials, alkyd coating is very capricious, so it is best to choose it for furniture rather than parquet.

Advantages:

- Due to its composition, varnish penetrates wood more strongly than other types.

- The coating enhances and emphasizes the structure of the floor, so it is perfect for parquet made from natural materials.

- Easily copes with changes in temperature or humidity.

- Prevents parquet from fading under the influence of sunlight.

Flaws:

- During drying, keep the temperature low.

- One extra layer will ruin the whole job.

- It takes a long time to dry.

Wear resistance deserves 3 out of 10 points.

Formaldehyde varnishes

Made from resin. There is an opinion that formaldehyde is deadly to people. However, during the repair process, all harmful chemical elements evaporate, so the finished coating is absolutely safe.

Pros:

- They will last for many years. If you want to deal with the floor once and for all, then choose this coating.

- No priming preparation required.

- Applies well with any sponges and rollers.

- Does not require a certain temperature level in the room.

- Slightly brightens the parquet.

- Does not respond to changes in temperature and humidity.

There are also disadvantages. For example, a very big disadvantage of acid-curing varnishes is a strong unpleasant odor that will disappear only after three days. Before starting repairs, open all windows and stock up on a mask.

The solution strongly glues the sides of the lamellas, so a new floor will have to be made from scratch, and the existing one will be irreparable.

When choosing a varnish, think in advance where you will apply it. For rooms with high traffic, polyurethane or formaldehyde are suitable, for the bedroom - water-soluble, and a composition with oil resins will improve the living room.