Practical and high-quality acrylic varnish is used at many stages of construction, in repair work or in the manufacture of decorative products. Having studied the useful recommendations of specialists on the use and selection of this paint and varnish material, it is easy to solve many interior problems in an apartment and in a suburban area.

What is acrylic varnish?

This material consists of crushed plastic particles dissolved in a liquid polymer. Acrylic varnish on an acrylic base forms a durable, non-yellowing and crack-resistant layer. As the water emulsion dries on the treated surface, it loses moisture, and at the same time polymerization of the decorative coating occurs.

What does acrylic varnish look like?

The chemical solution described here does not require special preparation and can be applied immediately. The working emulsion is supplied to the retail chain in a sealed container, representing a homogeneous mass of predominantly light milky color. Acrylic colorless varnish becomes completely transparent after stirring; colored solutions are obtained by adding appropriate pigments to the base.

Composition of acrylic varnish

The properties of any paint and varnish material depend on its constituent components. Inventing the best acrylic varnish with optimal qualities, its creators used the following substances:

- Emulsion of mineral oils - to minimize foaming.

- Organic solvent coalescent – up to 7-8% to improve the formation of a protective film.

- Polyurethane thickener - about 3.5% to obtain optimal thickness.

- Preservatives – prevent the development of harmful organisms.

- Additives and plasticizers help to obtain the smoothest possible surface.

- Transparent acrylic varnish is the basis for obtaining color compositions using pigments.

- Acrylic dispersion - acts as a binder.

What is acrylic varnish used for?

Thanks to its excellent characteristics, this material immediately found application in many areas. Let's consider options for using acrylic varnishes:

- Finishing work – processing of plaster, glass wallpaper, fiberboard, plasterboard structures, facade materials.

- Acrylic varnish is recommended for wood: processing parquet, solid boards, solid floors, furniture.

- For decorating decorative elements and utensils.

Characteristics of acrylic varnish

Many people are interested in what perfect qualities this composition has gained enormous popularity in the construction industry. Let's take a closer look at the physical and chemical characteristics of this paint and varnish material:

- The water-soluble composition is initially supplied in a viscous-flowing state.

- The working fluid is almost odorless.

- Drying time – up to 4-6 hours.

- The best acrylic varnish, when the applied composition dries, forms a transparent, shiny and colorless film that is resistant to negative factors.

- It is allowed to mix varnish with water-dispersed paints.

- To reduce the thick consistency, it is diluted with an aqueous solvent.

- Acrylic varnish for furniture must not be diluted with chemicals: drying oil, acetone, gasoline, white spirit.

Pros and cons of acrylic varnish

Before purchasing, it is advisable to familiarize yourself in more detail with the qualities and methods of use. Acrylic varnish for interior work has a lot of positive characteristics:

- Good adhesion to almost any cleaned surface.

- The resulting coating is elastic and can protect against accidental scratches or other mechanical damage.

- Environmental Safety.

- No foreign odors.

- Thermal stability.

- After drying, the film becomes water resistant.

- The protective layer of acrylic varnish does not change color in the sun.

- Dries quickly.

- You do not need to purchase expensive equipment to work.

- Colorless glossy acrylic varnish does not cover the natural texture.

- Improves the aesthetic appearance of the treated surface.

- Good resistance to pathogenic organisms.

Disadvantages of acrylic varnish:

- Storage at low temperatures leads to deterioration of basic qualities.

- During the cold period, drying time doubles.

- Relatively high cost.

How to choose a varnish, what points need to be taken into account

To obtain the required parameters of protection and decorative effect, you need to choose the right varnish. Beginners can be helped by knowing the parameters that need to be taken into account when choosing a material:

- Level of wear resistance, you need to know what loads will be placed on the item;

- Fire resistance, wood ignites easily, it is advisable to reduce the degree by varnishing;

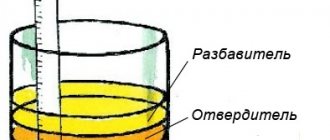

- Type of varnish – one- or two-component. The first can be immediately applied to the base, the second must first be mixed to obtain a ready-made solution;

- The resulting effect after coating is gloss or matte;

- Required drying period;

- Moisture resistance level.

Thus, it is necessary to know exactly how the product will be used in order to choose a varnish that can protect the material from negative influences.

To obtain the required parameters of protection and decorative effect, you need to choose the right varnish.

Types of acrylic varnish

There are several characteristics by which paint and varnish materials are classified. Let us first consider its varieties depending on the internal composition:

- One-component products

- the binder is only acrylic. - Two-component products

- the binders are acrylic and polyurethane.

Classification of acrylic varnishes in accordance with the external characteristics of the resulting surface:

- Acrylic matte varnish

- the surface texture is pleasant to the touch, silky, with notes of velvety. - Acrylic gloss varnish

– increases shine and helps emphasize the depth of texture. - Acrylic semi-matte varnish

- in terms of reflectivity, it occupies an intermediate niche; a well-lit surface emits a slight flicker.

Composition of wood varnish

The structure of materials that are intended for application to natural wood coatings includes resins, complex polymers, and solvents.

Once the substance is applied to furniture or other wood surfaces, a thick film remains as the solvent dries and evaporates. It protects the surface from the effects of environmental factors.

Colored acrylic varnish

Often the surface texture has an unsightly appearance or is required for some other reason to mask minor errors. In these cases, it is recommended to use acrylic white wood varnish or compositions with color additives instead of a transparent paint material. It's simple: we purchase a suitable water-based color and mix it in the required proportion. The second option is to find a specialized retail outlet and order precise computer tinting of the required volume of product.

Review of manufacturers

There are a large number of manufacturers on the modern market that produce high-quality acrylic varnishes for wood with excellent adhesion properties and a long service life. One of them is the German company Zobel, which offers consumers weather-resistant materials of the Deco-tec series for interior and exterior decoration. Its products are weather-resistant and easy to apply due to the effective suppression of droplet formation.

Acrylic parquet varnishes manufactured by another German brand, the Hesse company, are characterized by excellent moisture resistance and durability. The manufacturer produces polyurethane varnishes based on acrylic resins, characterized by short curing times and excellent performance parameters. Many consumers prefer acrylic varnishes from the Rhenocoll brand, which brings to the market thin-layer water-based glazes with high film elasticity and good protection from moisture, UV rays and mechanical stress.

By contacting the TBM-Market store, you can buy acrylic varnishes for wood from all of the specified suppliers and order delivery of goods throughout Moscow and regions of Russia. We guarantee the impeccable quality of our products, which allows us to create a durable coating for complete protection of wooden surfaces.

Buy varnish for exterior finishing

|

|

Acrylic varnish rating

When searching for quality materials, any practical and experienced person takes into account the brand. Acrylic varnish for exterior use or decorative finishing of premises is a relatively expensive product, so it is better to purchase the product from a trusted company. We offer a small TOP of excellent paints and varnishes with good reviews:

- Tikkurila acrylic varnishes

– excellent wear resistance and reliability. The treated surface can be washed by any means. The varnish is ideal for corridors and other walk-through areas. - Neomid Sauna

is a varnish from a Russian manufacturer, suitable for rooms with high temperatures or humidity. Heat resistant, easy to use, durable. - DULUX

- paints and varnishes from a well-known international brand, form a uniform, strong coating. This results in excellent protection against mechanical stress. - PARADE

is a one-component product from a Russian brand. The layer is formed homogeneous and elastic. The varnish has a relatively affordable price. - LOBA

- varnishes of the German brand. A choice of one-component and two-component formulations of the highest quality.

TOP manufacturing companies

There are quite a few worthy manufacturers on the current construction market, and we invite you to consider the best.

- The quality of the products of the Finnish brand Tikkurila speaks for itself. The company produces several product lines that are designed for different types of work. They will be characterized by high leveling, protective, antiseptic and decorative qualities. Tikkurila produces both glossy and matte coatings for interior and exterior use, and they are resistant to various damages. This company is famous for the best quality of goods, but the cost of such products is not cheap.

- The group's products are incredibly popular on the Russian market. It is the largest distributor of paints and varnishes in the Russian Federation. The group has connections with most manufacturers from Europe and offers a line of products with high consumer qualities.

The products offered are suitable for various types of work. All of them have a quality certificate, compare favorably in terms of environmental indicators, and therefore are ideal for cladding a room where the requirements for the finishing coating are quite high. The products are popular not only for their convenience and ease of use. They will provide a beautiful appearance to the product, increase their resistance to wear, and do not allow moisture to pass through, which ideally protects them, increasing the degree of strength. The products 100% meet the requirements of the most demanding customers and at the same time have a completely normal price.

How to dilute acrylic varnish?

Mostly ready-to-use emulsions that do not require special preparation are available for sale. During long-term storage, the substance may thicken slightly and then a solvent must be added. When asking whether acrylic varnish can be diluted with water, the composition and purpose of the existing product should be taken into account. There are two options:

- Water is suitable for water-based varnishes used for interior finishing and decorative purposes. The working fluid is as environmentally friendly and safe as possible, without any harmful odor.

- Organic solvents - consist of ethers, plasticizers, ketones, aromatic hydrocarbons. The liquid has an odor, but when it dries, extraneous aromas disappear. These solutions help reduce viscosity, help give the coating the desired shade, regulate the quality of gloss, and significantly speed up drying.

Examples of factory-made acrylic varnish solvents:

- PROFESSIONAL NOVOL THIN 850

is a mixture of organic solvents, suitable for acrylic-based primers and varnishes. - Solvent 301 Vika

is a mixture of organic liquids, recommended for acrylic primers, enamels and varnish. - Solvent P 12

– based on toluene, improves the resistance of the resulting film to ultraviolet radiation.

Qualities and features

According to the decorative effect that is obtained during application, the varnish is divided into certain groups:

- Matt acrylic varnish. It perfectly hides all surface irregularities. The varnishing is velvety without shine, the film is durable and does not overlap the surface pattern.

- Glossy. Gives shine to the processed product, emphasizing depth. Its main disadvantage is that it reveals all the imperfections that exist on the surface of the product.

- Semi-matte varnish. It gives a slight shimmer, but also highlights existing imperfections.

How to apply acrylic varnish?

Even when working with the highest quality modern paints and varnishes, technology and surface preparation are required. Let's look at the basic tips for using acrylic varnishes:

- First, the surface to be treated is coated with water-based primers or suitable tinted impregnations.

- Grease stains are removed with soap solutions and dried.

- After opening the container, the varnish must be stirred until a uniform color is obtained throughout the entire volume.

- If the solution is very thick, then add no more than 10% clean water.

- It is necessary to dilute with water with a reserve so that there is enough paint material for work, otherwise with subsequent dilution you can get a substance with a different shade.

- Humidity in the room should be maintained at least 50%.

- Parts treated with acrylic varnish should be stacked on the first day using rubber gaskets.

- If you want to apply tint, first use impregnation, and on top a layer of colorless acrylic varnish.

- The material is applied in several thin layers.

- To enhance the decorative effect, the lower layers are coated with a dark-tinted composition. The finishing layer is applied with colorless or light acrylic varnish.

- Aerosol acrylic varnish is better suited for obtaining a colored or tinted surface.

- When painting by hand, it is recommended to use a swab; a brush or roller often leaves stains.

- It is advisable to remove old varnish with bald spots, otherwise areas with defects will show through.

- It is necessary to monitor the uniformity of the varnish thickness over the entire plane. When working with a brush, a thicker layer is formed on the edges and joints, which is why the shade turns out darker.

Dispersion composition

Water-based varnish for interior woodwork is odorless, colorless, and when tinted, it practically does not differ from the declared result. When finished, the composition may be whitish, but after drying, the tone of the base does not change. Depending on the purpose, various functional additives are added to the liquid:

- polyurethane to enhance mechanical strength;

- antiseptics to render inert to fungus, mold, bacteria;

- solvents to form a wear-resistant film.

As a result, finished materials are classified into one-component and two-component. In the first, there is only one binder - acrylic resin. Such compositions are used for decorative purposes, but not for protecting floors, countertops, and window sills due to their relatively low strength and moisture resistance. The second type of water-based varnish, due to the strengthening polyurethane, copes with high mechanical loads. There are materials suitable for work in public places with high traffic.

Gym varnishing Source fb.moystroitel.ru

When working with dispersion acrylic varnish, it is important to observe the following conditions:

- the range of operating ambient temperatures is observed from +5 to +30℃;

- drafts and direct sunlight are excluded;

- Before application, the composition is thoroughly mixed.

The upper limit of operating temperatures is often neglected and increased ventilation is organized. This causes water to drain from the varnish too quickly. Then the film is formed with defects: it swells, peels off, cracks, and forms unevenly. This is reflected in the wooden base, which will subsequently have to be additionally sanded and re-coated.

The topcoat can have varying degrees of gloss:

- matte or silky visually hides minor defects of the coated object;

- glossy with a mirror effect is inferior in camouflage properties and durability;

- semi-matte emphasizes the texture of the wood along with its imperfections.

Use dispersion varnish for wood for interior and exterior work. These can be decorative items, interior items, floors or facades.

Material for facade Source ru.all.biz

See also: Companies specializing in paint and varnish materials.

It is important to note that the versatility of materials includes the concept only in relation to indoor operating conditions. It is better to make a choice in favor of specialized compounds, as they will better meet the stated characteristics.

Wood varnish for interior work is often applied to liquid or paper wallpaper. This provides additional protection to the decorative coating from abrasion and clogging; it can be washed and will last longer. There are also materials for treating mineral surfaces (stone, concrete, tiles) or metal for the purpose of providing anti-corrosion protection. But products with organic solvents, as a rule, cope better with such tasks.

If the temperature conditions are observed during varnishing work, a film is formed within an hour or less. This explains the recommendation to use a roller or spray gun for processing large areas. If you distribute the liquid with a brush, the bristles begin to stick together and leave streaks on the surface.

Drying the brush Source stroy-podskazka.ru

Advantages and disadvantages

Wood varnish for interior work, odorless and without harmful substances, can be easily washed with running water before drying. It is easy to work with, which is important for people without painter experience. With or without pigments, the coating does the same job of protecting the surface being treated without tightly covering the natural pattern.

In addition, the following positive properties of the material are noted:

- does not turn yellow when exposed to ultraviolet rays;

- does not collapse under temperature changes (in the range recommended by the manufacturer);

- exhibits inertness to biological activity, therefore it provides reliable protection of wooden products from rot, mildew and mold;

- refers to materials resistant to moisture and open flame;

- has high adhesion to wood and mineral substrates.

In addition, acrylic wood varnish forms a film that can be cleaned using household detergents. There are practically no shortcomings in the material. The main thing is storage conditions. It is not recommended to use a water-containing composition after freezing and thawing, as it will lose its quality characteristics.

Washing parquet Source dizainkyhni.com

How to remove acrylic varnish?

High-quality water-dispersed material forms a strong layer after drying. Old stains are a serious problem, so it is better to wipe up any accidentally spilled polish immediately. If you cannot clean the surface with heat treatment or an abrasive tool, you can use the following chemicals:

- Waterproof acrylic varnish can be removed from clothing using gasoline or solvent. The exception is brightly colored fabric; after processing, unwanted stains may appear on it.

- For furniture and other wood coatings, it is better to use a professional remover - Zip-strip 1Q, APP, Kompozit, Neomid SU-30 and others. The product is applied for 3-4 hours, and then the split varnish is removed with a spatula. Finally, the remaining chemical solvents are washed off with water.

Varnish application technology

To work you will need a brush, roller and spray bottle. The material should be at room temperature. It is necessary to work with it strictly following the instructions, and during the work process strictly adhere to a certain sequence:

- Surface preparation. Before starting work, you should carefully inspect the surface. It should be clean and even. The presence of defects and deformation of the plane will cause poor quality work.

- Application of material. After cleaning and leveling the surface, you can begin applying varnish. For large surfaces it is more convenient to use a spray bottle, and for small surfaces brushes of different sizes are well suited.

Why does acrylic varnish stick after drying?

If the deadlines specified in the instructions have passed, and the finishing layer remains soft, it means that at some stage the technology was broken. Extremely long drying of the surface brings a lot of inconvenience and prevents items from being used for their intended purpose. The reasons why acrylic-based varnish remains sticky are the following:

- The paint material is old.

- Furniture acrylic varnish is initially of poor quality; the amount of driers (auxiliary elements to speed up drying) in the material is insufficient.

- The solution was criminally diluted in the warehouse by sellers to increase the volume.

- High content of tannic acid in the wood surface.

- Acrylic-based varnish contains an unspecified plasticizer that leaves the surface soft.

- Working in a damp and cold room.

- Application of excessively thick layers of varnish.

- The finishing layer was applied before the previous one was completely dry.

- Using contaminated tools.

What can replace acrylic varnish?

A situation often arises when the amount of material was calculated incorrectly or the required composition is not available in the distribution network. If you have a question about how to replace acrylic varnish, you should use the following options:

- Acrylic floor varnish can be replaced with parquet compounds. These substances have a strong chemical odor, but as they dry, the aromas disappear, and the resulting coating is extremely durable.

- Yacht varnishes are famous for their good sun protection and moisture protection properties. The disadvantage of this material is that the treated surface after hardening turns out to have an amber tint. This option is suitable for obtaining a light touch of antiquity on a wood surface.