Today on the building materials market you can find a huge number of a wide variety of products that serve to protect various types of surfaces.

Bituminous Kuzbasslak, which is used as a means of protection for wooden, metal and concrete surfaces, is gaining popularity today. Due to its wide range of applications, this varnish can be called a universal remedy. It is also worth noting that it can be used both indoors and outdoors. Another name for Kuzbasslak is varnish type BT-577. An important advantage of this mortar is its rapid drying and high quality coating.

In order to understand whether it is worth choosing this particular varnish among analogue products, let’s look at the topic - “Kuzbasslak” application and properties, advantages and disadvantages.

"Kuzbasslak" area of application

The BT-577 varnish in question is used to protect reinforced concrete, metal or brick surfaces from external factors, that is, precipitation, etc. Among other things, bitumen Kuzbasslak is used for treating wooden surfaces, namely to prevent rotting of such a surface.

Often, this product is also used to coat cars in order to prevent their corrosion, which often causes the entire body to become unusable. Trailers and carts are also often treated with Kuzbasslak.

In the construction industry, BT-577 is used for covering roofs made of sheet and roll materials, which prevents its fire. It can also be used instead of a primer layer.

Cooking specifics

The production process of bitumen-based mastic is absolutely nothing complicated; you only need to select the components according to the rules and follow the basic rules of preparation.

To carry out the work you need the following elements:

- pieces of bitumen, cleaned of dirt;

- exactly the selected fillers,

- various water inhibitors.

For example, to create waterproofing you need to have approximately 10 kilograms of mastic. To do this you will need approximately eight kilograms of bitumen, 1 kg of filler and 500 grams of water inhibitor.

For cooking mastic, choose strong cauldrons with a wall thickness of 3 mm or more. There should also be a lid. Due to the heating of the walls, the bitumen heats up equally.

The boiler must be loaded no more than 70% - otherwise the mastic may begin to splash out. For cooking, you must strictly follow these rules:

- The boiler is not placed above the fire, but is mounted to the side.

- The temperature should be at 190 degrees, which does not lead to decomposition of the material.

- Temperature changes are not allowed, which can lead to the appearance of a heterogeneous mass of mastic.

- To prepare the mixture as quickly as possible, you need to divide the bitumen into very small pieces.

- Cooking the mastic should be done slowly and uniformly.

- Filler and additives should also be crushed.

- Adding elements is done in stages.

- The solution is constantly stirred and sometimes the forming foam is removed.

- After the foam disappears, fillers can be added.

- After the addition, the resulting solution is thoroughly stirred - and the bitumen-based mastic is ready for use!

Now that you have learned how to dilute bitumen-based mastic for the foundation and how to prepare it, you need to know how to apply it to the surface correctly.

Precautionary measures

Before you start using BT-577, you need to know some operating rules and precautions:

- The surface where Kuzbasslak will be applied must be clean, there should be no dust or any dirt on it. There should be no rust either;

- apply the product in several layers, even 4;

- the layer does not dry too quickly, so you will have to wait some time until the layer dries completely (the factor depends on temperature and atmospheric conditions);

- it can be used in a temperature range from plus 11 to plus 25 degrees;

- can be stored at temperatures from -30 to plus 300.

"Kuzbasslak", the use of which is not entirely safe, because such a varnish is considered poisonous, should be used only with protective clothing.

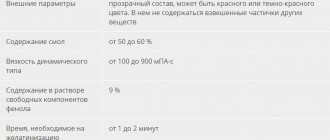

Technical characteristics and properties of Kuzbasslak

In order to fully understand the necessity and quality of the varnish in question, let’s move on to a thorough analysis of the technical characteristics. Kuzbasslak has a number of waterproofing and protective properties:

- apply the varnish in an even layer, and on all surfaces where it can be used;

- a layer of varnish creates a surface without any pores, and is durable and glossy;

- Kuzbasslak is not susceptible to significant mechanical loads, and after the load is removed, the properties of the coating are restored to their original values;

- cracks do not form on the surface in the case of low temperatures, in addition, sharp changes in temperature indicators do not in any way affect the quality characteristics of the product in question;

- weather conditions, whatever they may be, do not in any way affect the main characteristics of the BT-577;

- in the presence of the layer in question, no microorganisms multiply or appear.

If the surface is treated with Kuzbasslak, you don’t have to worry that it will be in constant moisture or exposed to sunlight. Such a surface is not afraid of corrosion, so with such a coating the surface is under reliable protection.

Bituminous “kuzbasslak”, the use of which is discussed in detail above, can also be washed with various detergents (only after it has dried). If during long-term storage the consistency of the varnish has become thicker, there is nothing to worry about; such a change in viscosity is acceptable.

The use of long-stored BT-577 is possible by diluting it with various types of solvents (the amount should not exceed 11%). Diluting the varnish with such proportions of solvent will not affect its quality characteristics in any way.

The main advantages of Kuzbasslak include the following characteristics:

- protective qualities at a high level;

- purchasing it is not difficult, you can find it everywhere and the price is affordable;

- protects against corrosion by 100%;

- easy to use.

It should also be noted that this composition is economical, because its consumption is really small; only 150 ml of product is needed per square meter. The only negative aspects include the color scheme of the cream (black), because it is difficult to cover with any other similar product.

SOS!! Why did the bitumen varnish start to smear with the finishing varnish???

I ask for urgent help!!! So sorry for the job. I’m not an expert in this matter, but I seem to know something, since this is not the first time I’ve been decorating boxes, furniture, etc. Not for sale for yourself. But I didn't expect this ((

Here's a table I made

I painted on top with acrylic paints and bitumen varnish for aging (bitumen patina).

I survived for a day. Today I decided to varnish it with acrylic matte varnish, and, oh horror!! bitumen varnish began to smudge along with the varnish!!! I immediately stopped varnishing and urgently ran to you for help!!!

What did I do wrong???

Here is a photo of bitumen varnish and acrylic

How can I save my table and what is the best way to varnish it?

By the way, one more question. I painted the legs of the table with alkyd spray paint, the same bitumen varnish on top, and then I went over the reliefs with acrylic gold paint just a little bit. How to varnish this whole thing now?? Now it's kind of scary

www.livemaster.ru

Analogs

BT-577 has many analogues.

- Varnish BT-350. Recommended for periodic protection of metal, wood, brick or concrete from mechanical damage and moisture.

- Varnish BT-123. Used to protect metal and other structures during transportation or long-term storage.

- Bitumen-rubber mastic. It is used in roofing work, for waterproofing constructed structures, and in the construction of underground steel pipelines as an insulating composition that prevents soil corrosion.

- Hyperdesmo PB-2K. This is a polyurethane-bitumen mastic. Used to protect metal, concrete and other substrates from corrosion and moisture.

- Hempinol is a fast-drying, highly structured bitumen coating.

- Nova vulture. This is a bitumen-based anti-corrosion mastic, which also includes other components - synthetic resins, targeted additives, solvents, etc.

What temperature can the varnish withstand?

Enamels based on epoxy ester and ethyl silicate resins can withstand

up to 400 degrees. Paint based on silicone resins is resistant to temperatures of 650 degrees. Painting compositions with heat-resistant glass and composites - up to 1000 degrees Celsius.

Interesting materials:

How to prune a herbaceous peony? How to prune a Crassula flower? How to trim flowers after blooming? How to prune thuja in summer? How to prune thuja occidentalis? How to trim Vanilla Frize? How to prune Weigela in spring? How to trim the top of a dracaena? How to trim the top of a ficus benjamina? How to trim the top of cucumbers?

How to apply correctly

Why do the leaves of indoor geraniums turn yellow: what to do, they dry in the room, they curl inward, the reason is, they wither in the pot

Before using bitumen varnish BT-577, the material to be treated must be thoroughly cleaned of corrosion, dirt, oil and grease stains, and salt deposits. If it is necessary to cover wood with it, the base must be freed from traces of rot, mold, and dirt. The surface to be varnished does not need to be primed.

If Kuzbasslak turns out to be too thick after opening the container, it needs to be diluted.

You can use several of the listed means at the same time.

After adding the solvent, the mixture must be thoroughly mixed and left alone for 10 minutes. This is enough for air bubbles to come out of the product.

If small surfaces are being varnished, you can dip the tool in the varnish. If horizontal walls of a large area are being opened with the composition, it is better to use the pouring method.

The work must be carried out in a room with an air temperature of +5 to +35 °C. The average drying speed of one layer under such conditions is 24 hours. If you dry the composition at the boiling point of water, it will harden in just 20 minutes. It is better to apply the product in two layers. Sufficient time should pass between each application for the previous layer to dry completely.

How long does it take for varnish to dry, depending on the type and purpose?

Experts recommend varnishing in several layers, with each subsequent layer applied only after the previous coating has completely dried. If the paint material takes a long time to dry, it will slow down the repair process and cause some inconvenience. In order for the varnished coating to be of the highest quality and the finish to last for a long time, you need to know exactly how long the varnish used for the coating dries. This article will discuss the main types of popular varnish compositions, their properties and drying period.

Different categories of drying periods

There are 3 main categories of drying periods for the varnish layer:

- Touch dry. This period implies a period of time after which debris and dust will no longer stick to the varnished surface. Different types of varnish dry touch differently, some dry in 10 minutes and some take an hour or longer.

- Drying period of the layer. This category implies a time interval starting from the moment the composition is applied to the surface and ending with its drying, when it can be covered with the next layer. Each type will dry differently, this interval ranges from one hour to a day.

- The time required for the final drying of the varnished material. Only after this time interval can you begin to use the treated surface. Each type of composition will dry differently, it depends on temperature, humidity, and other factors, usually this time ranges from 3 hours to 3 days.

If the floor has been varnished, for example, wooden boards or parquet, and the composition has already become quite viscous, but has not yet completely dried and continues to dry out, then you can put cellophane or plastic bags on the floor. You can also lay carpet during the period of incomplete drying, but it may leave fluff on the floor that will be very difficult to remove.

Types of varnishes and their drying speed

Many people purchase varnish based on how long it will take to dry. The drying period is one of the most important properties of paint and varnish products. Practice has shown that when varnishes dry very quickly, their other technical characteristics suffer.

A mixture that will dry very quickly is quite expensive, its price is much higher than the cost of slow-drying solutions. In addition, varnishes that dry quickly are not environmentally friendly for human health, and usually the service life of such coatings is shorter than other mixtures. Each specialist has his own requirements for drying a varnished surface. Some people want the base to be dry within an hour, while others are willing to wait a couple of days for the coating to be of the highest quality.

How long it takes for floor varnish or furniture composition to dry depends on various factors. The main factor is the composition of the mixture. Nitrocellulose products dry as quickly as possible, while, for example, acrylic aqueous solutions dry much longer. Many people are interested in how long does wood varnish take to dry? Typically, liquid dries on wood in the same amount of time as on other materials.

Nitrovarnishes

Transparent nitro varnish is made from colloxylins, plasticizers, solvent and various resins. This type has good resistance to moisture, after application it dries to the touch in half an hour, a maximum of an hour. Nitrovarnishes are solutions characterized by the highest drying speed.

They dry to the final stage in about 3-5 hours. Although they have the shortest drying period, they are not environmentally friendly materials, since they contain a solvent that is toxic and harmful to humans. This varnish should not be applied in rooms where people live. Nitrovarnish has low stability and weak protective coating strength.

Polyurethane solutions

Polyurethane-based varnishes are often used to cover parquet floors, polymer and self-leveling floors. The polyurethane composition provides excellent resistance to aggressive substances and mechanical loads, and is also resistant to high humidity and water.

Many people are interested in how long it takes for parquet varnishes to dry? Before the first stage they usually dry out in about an hour, and before the final stage, category 3, 4-12 hours. Varnishes containing a hardener dry very quickly, but under different conditions they dry differently, this is influenced by many factors. Polyurethane mixtures can be applied to both wood and concrete; they dry equally well on them.

Water based

These solutions do not have any unpleasant odor when applied; water-based acrylic mixtures are the safest. However, they take longer to dry than other compounds. Complete polymerization requires 10-14 days. Such a long period is associated with the main component - water, which evaporates for quite a long time, compared to solvents.

Water mixtures are usually made on an acrylic basis; they do not withstand the negative effects of temperature changes, humidity, and mechanical stress. Many people are interested in how long does acrylic varnish take to dry? Touch-drying time is about 2-3 hours, and a layer of varnish usually has time to dry in 18-35 hours.

Oil mixtures

These paints and varnishes are oil or resin based and contain organic solvents. Although oil products have their advantages, however, their drying time is the longest. It takes 2 days or more for the applied oil varnish layer to dry completely.

Alkyd solutions

They also contain organic solvents, are resistant to moisture, and create a durable, protective layer. It is best to apply varnish from an aerosol can. Many people ask how long does alkyd varnish take to dry? It takes about 4 days for it to dry completely, but if you add a hardener to the composition, this period will be reduced to one day.

They produce quick-drying alkyd solutions called alkyd-urethane varnish solutions. Due to the presence of urethane alkyds, the drying time is 10-12 hours.

Epoxy mixtures

These solutions are used for both external and internal work. Epoxy compounds are used for application to parquet, furniture, and many other wood products. How long does furniture varnish based on epoxy resins take to dry? They usually dry out within one day.

Yacht paints and varnishes

This group of varnish solutions has different drying times. How long does it take for yacht varnish to dry? For example, Aurlak dries in about 8 hours, Akidlak dries in 16 hours, and yacht Polyurlak dries much faster, in about 45 minutes.

Why do varnishes take a long time to dry, and how to speed up drying?

The compositions dry out for a very long time if they are of low quality. In addition, if you apply too thick a layer to a wooden product, then, of course, it will dry out for quite a long time. If you choose the wrong varnish mixture and it does not match the type of surface being treated, the drying process will be lengthy. In addition, if the varnished product is kept at a low temperature and high air humidity, drying will take quite a long time.

To speed up drying, you can heat varnished items with a regular or industrial hair dryer. For quick drying, you can use fast evaporators, or buy expensive, quick-drying varnish.

nakrasku.ru