Ready-made masonry cement mortar grade 100 is intended primarily for filling joints in walls, including load-bearing ones, made of heavy natural stone and large bricks. It can be purchased from most concrete manufacturers or made directly on the construction site from a special factory-made dry mixture, diluted with water. Grade M100 indicates the compressive strength of the hardened mortar on the 28th day after completion of work - not less than 100 kgf/cm² (10 MPa).

Component composition

Portland cement and Portland slag cement GOST 10178, pozzolanic and sulfate-resistant cements GOST 22266 of high strength grades M400 and M500 are used to prepare the masonry mixture of grade M100. Cement M100 and M200 are not used. The solution may contain fly ash, but not more than 20% by weight of the main binder.

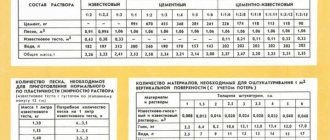

Proportions of cement and sand in masonry mortar M100, depending on the humidity of the room (the mass of binder per 1 m³ of aggregate is indicated):

- dry - 100 kg;

- wet - 125 kg;

- wet - 175 kg.

In winter, anti-frost additives must be added to ready-to-use cement-sand mixtures. To improve the characteristics of the solution during application, plasticizers can be added to the composition. If necessary, use water-repellent additives. If the mixture is used for laying facades of residential buildings, shopping and office centers, etc., then dyes can be used. A colored solution will help give the walls an original appearance.

All of the listed components are added to dry mixtures during the production process. Depending on the availability and type of additives, there are special formulations - winter, colored, etc.

What mortar is needed for laying bricks

Properly formulated masonry mortars must comply with the following standards:

- Competent choice of masonry mortar recipe, proportions of sand and cement and volumes of raw materials.

- Use of quality components.

- Careful preparation of materials.

- Compliance with production technology.

- Optimal plasticity of the mixture. This parameter contributes to the effective sealing of recesses in masonry layers.

- Hardening time. Large volumes of solution, which hardens quickly, are unsuitable for use. To eliminate this phenomenon, you need to add lime to the composition.

- Increased strength. When the mixture hardens, the strength characteristics of the cement layers will be increased, and the brick wall will become resistant to deformation and other negative factors.

To ensure effective formation of solid CPS, it is necessary to correctly select the proportions of the solution. During the reaction of the components with water, the strength indicators increase, and the connecting component combines the building materials into a solid structure.

Regardless of the recipe used, the masonry mortar and proportions of sand and cement must include the following ingredients:

- Knitting part. In most cases, masonry cement is used, which begins to harden when interacting with liquid, connecting with the rest of the mortar.

- Filler substance. Designed to improve performance properties and increase the volume of the mixture.

- Liquid. Water is used to react with the binder part of the additive and promote normal hydration.

The role of a substance with astringent properties can be performed by the following types of raw materials:

- Portland cement.

- Lime.

- Lime-cement mixture.

When figuring out which cement is best for bricklaying, you need to take into account the type of tasks for which it will be used and the characteristics of the brand.

Cement mortar for bricklaying must contain additional components, including:

- Additives to increase frost resistance. Their task is to prevent crystallization of liquid under the influence of frost and normalize hydration.

- Plasticizing additives. Promote the workability of the working composition and facilitate its operation.

- Hardeners. They improve the polymerization process of binder additives and reduce the period of strength development.

- Dyes. Using colored pigments, you can change the range of materials and improve the aesthetic properties of the wall.

The final grade of the composition is determined by the proportions of sand and cement for bricklaying. As the sand content increases, the grade decreases, and as the proportion of cement increases, the grade increases. To mix mortars, different brands of cement-sand mixture for bricklaying are used, but M75 is the most common. In this case, the proportions of cement and sand for bricklaying are selected in the ratio 1:5:0.8.

Masonry mortar may differ in different ratios of ingredients. They are selected taking into account the purpose and scope of application.

Lime

For the construction of brick fences and wall structures, it is customary to use brickwork mortars with high plasticity. Therefore, lime combined with sand is added to their composition. Dry additives are thoroughly mixed and then filled with liquid. Then the ingredients are mixed again until a creamy consistency is formed without lumps or solid impurities.

The optimal proportions are selected at the rate of 1 part lime to 2-5 parts sand.

Cement

When wondering how to prepare a mortar for bricklaying, the proportions of sand and cement need to be selected taking into account certain requirements. Depending on the brand of the second component, the ratio of ingredients is determined: for example, for 1 part of cement there may be 3-6 parts of sand.

Cement-lime

The composition of the masonry mortar based on a cement-lime mixture is created from the following ingredients:

- Slaked lime, diluted in water until thick. The lime mass is carefully filtered.

- Dry cement for masonry and sand.

Each part is thoroughly mixed. The presence of lime in the cement increases the plasticity of the mixture and allows it to be used with any type of brick.

Simple mixture

A simple mixture is created based on a binding additive and sand. Clay can be used as the first, but this option is in demand only for narrow-profile tasks.

Complex mixture

A complex mixture is a mixture of various additives and a binder base. These include cement-lime-clay and other solutions. The presence of clay in the composition makes for easy and neat installation.

Technical characteristics of the M100 mixture

Properties of cement-sand masonry mixtures grade M100:

- viability in an open container - 1-2 hours;

- adhesion strength to the surface - up to 0.5 MPa;

- work temperature - +5...+25°С;

- operating temperature - -30…+40°С;

- volume of water per 1 kg of mixture - up to 0.23 l;

- masonry joint thickness - 10-15 mm;

- consumption per 1 m² with a thickness of 1 mm - up to 2 kg.

Characteristics of the hardened mortar

The main properties of M100 cement mortar on the 28th day after completion of masonry or installation work:

- average density - for light solutions up to 1500 kg/m², for heavy ones - from 1500;

- frost resistance - from F10 to F200 (from 10 to 200 freeze-thaw cycles without loss of properties);

Each manufacturer has its own exact values; the required ones are included in the construction project.

Common mistakes and recommendations from experts

When working with CPR, you can make some mistakes:

- using stale mixture - it is advisable to use a fresh cement composition;

- incorrect choice of brand, non-compliance with the assigned tasks;

- failure to comply with mixing conditions;

- improper preparation of the base;

- Incorrect adherence to proportions when mixing independently.

Experts recommend strictly observing the proportions in accordance with the purchased mixture. If you do not have the skills to prepare solutions from individual components, it is better to abandon this idea in order to save money.

Other tips that will make working with cement-sand mortar easier:

- use beacons when leveling walls;

- look at the date when purchasing the composition - up to 6 months of shelf life;

- use the mixed solution within 2 hours;

- carefully add water and look at the volume;

- immediately wash containers and tools after work;

- use clay mixtures for finishing wood and plaster;

- use DSP only on a reliable basis;

- if you have no experience, choose the M300 brand, but no less.

If you have to work with the mixture for a long time, you can add 10-15% less sand to it, but so that the solution is not too liquid.

Scope of application of M100 brand solution

In addition to its main purpose, cement masonry mortar M100 is suitable for use for the following purposes:

- grouting;

- installation of partitions, columns, partitions;

- pouring floor screed;

- filling joints between heavy panels, concrete blocks;

- plastering of concrete surfaces;

- installation of ordinary lintels up to 2.5 m high;

- installation of the underground part of the brick foundation;

- arrangement of flat roofs;

- laying tiles, mosaics.

Requirements for the solution

GOST 28013-98 specifies the required ratios of components and properties of construction mortar mixtures, including masonry cement grade M100:

- mobility - from Pk1 to Pk4;

- water-holding capacity - at least 90%, homogeneity depends on this parameter;

- stratification in freshly prepared mixtures - up to 10%;

- temperature - -10...+25°С depending on the air temperature at the construction site, wind speed and type of masonry (brick or stone); when using a mixture for installation work, the temperature should be +20...+35°С;

- humidity (only for dry mixtures) - up to 0.1% by weight.

The solution, ready for use, must be plastic.

Mobility

Mobility or workability is the ability of a building mixture to spread under its own weight. The required value for cement mortar grade M100 depends on the type of masonry:

- rubble vibrated - Pk1;

- rubble non-vibrated - Pk2;

- from hollow brick or warm ceramics - Pk3;

- from solid brick or ceramic stone - Pk4;

- installation of walls made of concrete blocks, panels - Pk2.

Step-by-step instruction

It is important to note that it is necessary to lay elements, regardless of the parameters of the structure being constructed, from the corners, following simple technology. Step 1

Take a couple of bricks and place them, maintaining a right angle, on the foundation base, checking the accuracy of the location with a building triangle

Step 1. Take a couple of bricks and place them, maintaining a right angle, on the foundation base, checking the accuracy of the location with a building triangle.

Step 2. Lay the next pair of elements, and then lay two more on top of the resulting group of four bricks, allowing the next row to overlap the previous row.

Half-brick facing masonry

Half-brick brickwork

Step 3. Having drawn the area into three elements, you need to carry out the same work on the other corner, using the order and pulling the moorings, which will allow the rows to be oriented strictly horizontally. The lacing should be located approximately every 5 m, without sagging.

Laying corners using single-row dressing

Single-row masonry involves building the beginning of the outer wall, and then the inner one, after which the backfill is laid. Multi-row masonry involves arranging blocks in a mixed or stepwise manner.

Transportation and storage

Dry mixtures for preparing masonry mortars M100 are transported in plastic bags or paper bags. A quality document is required. The shelf life of the mixture is 6 months. After its expiration, the grade of material in terms of compressive strength decreases. This composition is suitable for use, but only when installing structures with low load-bearing capacity requirements. The finished solution is delivered to the buyer in a car equipped with a concrete mixer, or less often in bunkers. It is used immediately.

Preface

1 DEVELOPED by the State Central Research and Design Institute for Complex Problems of Building Structures and Structures named after V.A. Kucherenko (TsNIISK named after V.A. Kucherenko), Research, Design and Technological Institute of Concrete and Reinforced Concrete ( NIIZHB), with the participation of JSC "Pilot Plant of Dry Mixes" and JSC "Rosconitstroy" of the Russian Federation

INTRODUCED by the State Construction Committee of Russia

2 ADOPTED by the Interstate Scientific and Technical Commission for Standardization, Technical Regulation and Certification in Construction (MNTKS) on November 12, 1998.

Voted for acceptance

Name of the state construction management body

Some manufacturers and material costs

There are compounds on sale with a compressive strength of 10 MPa, but not marked for this parameter (price per 25 kg):

- Found Brickform MS 11 white and color - 310 rubles;

- Found Brickform MS 11/1 color with high water absorption - 360 rubles;

- Stroybrig Colored Kipirok - 215 RUR. and etc.

Ready-to-use cement masonry mortar M100 can be purchased from almost any company involved in the production of concrete. Price per 1 m³ - from 2500 rubles. The cost of materials is indicated for approximate calculation.

Calculator Solution-Online v.1.0

Calculation of the composition of mortar for brick (stone) laying and other masonry work. The calculator is based on data from SP82-101-98: Preparation of mortars. Implemented counting of batches in a concrete mixer and other containers.

General information

A characteristic feature of concrete is its composition, as well as proportions and preparation technology. It consists of cement, fine and coarse fillers, water and various additives. In addition, there are brands of concrete that do not contain coarse filler. There are different mixtures that are used for specific cases and also have different properties.

Designation and its interpretation

Concrete structures gain full strength within 6 months, and in 30 days concrete gains 70% strength. M300 is used in all structures that are subject to significant load, therefore, one of the main indicators is its strength. The MXXX designation template does not indicate a specific brand, but is an indicator of the maximum compression pressure.

In addition, there are other designation patterns, for example, FXXX and WXXX, indicating frost resistance and water resistance, respectively. The M300 class of concrete shows the totality of all grades whose ultimate strength is 300 kgf/sq.m. cm. The tensile strength is tested in laboratory conditions by applying force to parallel planes of a product cast from concrete, in the shape of a cube with a side of 150 mm. The grade of concrete in terms of strength is correlated with its class. These indicators should be selected for the construction and calculation of the finished structure at the maximum load that it can withstand.

M300 corresponds to class B22.5 with a coefficient of variation (CV) that is 13.5%. It shows the homogeneity of the mixture from which any brand of concrete is made. When this coefficient changes, the grade of concrete will also change, that is, if its value is low, the grade will increase and vice versa. If the concrete is M300, then with different values of the coefficient its class will change:

- At Kv = 5% the class is B25.

- At Kv = 13.5% - B22.5.

- At Kv = 18% - B15.

Main characteristics

Concrete is classified into grades, and this distribution is primarily related to the parameters of strength (B), density (D), water resistance (W), frost resistance (F) and workability (P). One of the best options for most construction work is M300 concrete, the characteristics of which are as follows:

- Strength: B22.5 with an indicator of 295 kg/sq. cm.

- Specific gravity of concrete M300: 1800−2500 kg/cubic. m.

- Water resistance: W6-W8.

- Frost resistance: F200-F300.

- Mobility: P2-P4.

The strength indicator is the main characteristic and shows the maximum effect of forces during compression, at which the structure collapses. The specific gravity or density of M300 concrete depends on the type of coarse filler included in its composition. When using limestone, the D value is about 1800 kg/m3. m., and when using harder rocks (crushed granite, granodirite, etc.) it can reach a value of 2500 kg/cubic. m. Due to its high density, this type is classified as heavy. The density indicator depends on the presence of violations in the manufacturing technology and air cavities.

Water resistance (WXX) is a value indicating the water pressure in MPa to pass through 0.15 m of concrete. For concrete grade M300, this indicator is equal to W5-W6; at a pressure of 0.5-0.6 MPa (approximately corresponding to 5-6 atmospheres) it does not allow water to pass through at all. By adding hydrophobic cement, additives and carefully compacting the solution, it is possible to increase the waterproof rating.

Frost resistance is indicated in the form of the FXXX pattern and shows the number of defrost-freeze cycles without loss of strength. This characteristic can be increased in several ways:

- The use of additives that prevent the formation of air bubbles.

- Removing air from the concrete mixture using vibrators, as well as using various compactors.

- Reducing the amount of water (impairs mobility).

- Using solid fillers instead of crushed limestone.

Application in construction

Since M300 has good strength, frost resistance, water resistance and mobility, it is widely used in construction. In addition, its main indicators can be adjusted by changing the components included in the concrete mixture. It is advisable to use it for the following work:

- Construction of platforms, roads and curbs.

- Installation of walls and various supports.

- Construction of stairs, landings and pouring of foundations in multi-storey buildings.

- Production of reinforced concrete products and fences.

- Production of sewer pipes that are constantly exposed to moisture.

- Construction of objects that are affected by constant temperature changes.

*Explanations for the calculator

- The calculator can calculate the volume for both whole numbers and fractions. Example: volume of concrete 3m 3, volume of concrete 50 l (0.05 m 3).

- The calculator implements calculations for a mixture with mobility P3 (9-10 cm of cone slump) for cement-lime mortars (according to SP82-101-98). Water consumption for mixtures with different mobility is based on experimental batches. The mobility you need can be viewed in the “Mobility” field, which is automatically filled in when you select “Solution purpose”.

Algorithm for calculating the composition of a solution

Selection of solution composition for 1 m3 of sand

To implement the calculator, the data and calculation algorithm were taken from:

1. Determine the consumption of binder (cement) per 1 m3 of sand depending on the selected brand of mortar and brand of cement.

We determine the cement consumption per 1m3 of sand using the formula:

2. Determine the volume of lime per 1 m3 of sand using the formula:

where Qв

– consumption of binder (cement) per 1 m3 of sand, kg

Vd

– inorganic additive (lime) per 1 m3 of sand, m3.

We determine the mass of lime per 1m3 of sand using the formula:

where Qd

– consumption of additive (lime) per 1 m3 of sand (kg);

λ

– bulk density of additive (lime) kg/m3;

3. We make up the proportion of the volumetric parts of the solution

You can also use the table of ready-made proportions in volumetric ratios (Table 4 SP82-101-98)

4. Determine the water consumption per 1 m3 of sand.

The approximate water consumption in SP82-101-98 is shown for a mixture with mobility P3 (9-10 cm depth of cone settlement). This mobility according to GOST 28013-98 is suitable for masonry made of solid bricks and ceramic stones. Water consumption for other mixture mobility is determined as a result of trial batches. We can select the mobility we need depending on the purpose of the solution using the table presented in GOST 28013-98

Calculation of materials per 1m3 of solution

An example of counting materials for 1 batch and for 1 m3 of solution is shown in Appendix A SP82-101-98.

Helpful Dosage Recommendations

It should be remembered that different types of building materials require mixing mixtures with different ratios of sand and cement for laying bricks. Solid brick requires one composition, and hollow brick requires another. Water for mixing should be used only clean, at a temperature of +15-20°C. If there is dirt or mold in it, it will show up later in the finishing. For cement-sand, the ratio of water to cement is as follows: 0.5-0.8 to 1 part of the binder component (depending on its brand). Sand is selected with a fraction of no more than 2.5 mm.

The proportions of cement consumption vary depending on its brand (the higher it is, the greater its viscosity). If M500 is used to mix the cement-sand composition, then 1 part of cement must be added to three parts of sand. For M400 their ratio will be different: 2.5 parts sand to 1 part binder component. The amount of sand can be greater, up to 8 parts - it depends on the purpose and brand of cement.

The finished mixture can be used within two hours, since after this the cement becomes less plastic and hardens. Therefore, you should mix exactly as much mortar as will be consumed on the masonry during this time.

How to cook it yourself?

First, the dry composition is mixed, sand is poured into the container, and then cement. It is better to sift everything first so that there are no lumps. The mixture is thoroughly mixed and water is added, after which everything is mixed again until the consistency becomes homogeneous. It is better to choose a container whose volume is almost the same as the amount of material required for a one-time job.

For greater strength and reliability, it is recommended to add detergent (50-100 g), it will increase its ductility. Cement consumption depends entirely on its brand. For 1 m3 you will need 510 kg of binder component grade M300, M200 - 410 kg, M150 - 330 kg. The consumption for masonry is affected by the building material used. For a solid brick it will be required less than for a hollow one. For 1 m2 of surface, about 0.2 m3 of composition is required for a single brick, and 0.25 m3 for a one-and-a-half brick.

A truly working legal way to save money. Everyone needs to know this!

How do you know if the mixture is mixed correctly and is ready?

You can determine the readiness of the cement mortar with your own hands using a cone or by touch.

You should pay attention to the degree of adhesion to the brick, as well as how mobile it is. Its readiness can be determined by making a dent in it: if its shape is maintained, then it is ready for use

You can also tilt the container by 40-45°, it should not leak out.

You can use a cone, its height and width are 15 cm, it weighs 300 g. The readiness of the composition is determined by immersing the cone in it. The depth of drowning depends on the purpose of the mixture. For an ordinary brick it should sink by 9-13 cm, for a hollow brick - by 7-8 cm, but no more.

The quality of the masonry mortar is determined by the amount of moisture in it and its plasticity. If it is too dry, it has weak adhesion to the building material, and if it is too damp, it spreads a lot. If it sticks to the trowel, then add the dry ingredients and mix everything thoroughly again. Mobility depends largely on the sand fraction: the smaller it is, the less mobile the composition.

Density can also be determined using a cone or by plasticity. If it spreads under its own weight, then it is not suitable for use; if it crumbles too much, then it also cannot be used for masonry.

Cost of ready-mixes

To avoid mixing by hand, you can buy masonry mortar. The use of such building materials greatly simplifies work and time costs, since there is no need to deal with dosing.

The purpose depends on the proportion of the binding component. Improperly prepared not only complicates the work, but also significantly deteriorates the quality of the structure being built. For example, a wall made from a poor-quality composition may become brittle and cracked. As a result, the heat capacity of the room decreases; in hot weather it quickly heats up, and in cold weather it cools down. When mixing the solution, you need to strictly follow the proportions. If they are disturbed, cracks may appear in the masonry.

What determines cement consumption for different solutions?

The preparation of cement mortar, the proportions of which may differ, requires strict adherence to technology and the correct determination of the ratio of components. To use different grades of concrete, different amounts of cement and sand are used. Remembering the proportions of cement and sand is not enough for high-quality construction; it is better to understand the principle.

Requires strict adherence to the technology for preparing cement mortar

Main factors influencing consumption:

- the amount of fillers in the mixture. The greater the proportion of crushed stone and sand, the higher the cement consumption per 1 m3 of solution. Cement is the binder of the components, which is responsible for holding all the fillers together. The ratio of bulk mixtures determines the amount of cement;

- brand of cement. As the grade increases, the strength of the final structure increases. It is worth remembering that the grade of the final mixture is significantly lower than dry cement, since sand is added to the composition, and gravel or slag can also be added;

- brand of solution. The cement-sand mortar is also divided by grade. For all types of work, GOST has recommended brands. After determining the desired brand of construction mixture, you can choose the right brand of cement. For example, to obtain an M100 mixture from M500 cement, you will need to mix 1 part Portland cement, 5.8 parts sand and 8.1 parts crushed stone. If the final goal is M450 solution, a proportion of M500 cement (C:P:SH) will be required: 1:1.4:2.9;

The density of cement plays a secondary role here, since it directly depends on the brand of cement, but it is necessary to know it during the calculation process.

Conclusion: how much cement is required per 1 m3 of mortar depends on the required strength of the mortar and the brand of the initial mixture.

The density of cement directly depends on the brand of cement

Ready-made heavy cement masonry mortar

Ready-made masonry cement mortar is intended for connecting individual elements into a single structure. These elements are aerated concrete and gas silicate blocks, natural and artificial stone, etc., but most often traditional cement-sand mortar is used for laying bricks. Thanks to the good adhesion of the masonry mixture to the brick surface, the strength and stability of the constructed structure is ensured for many years.

Brick buildings have always had an advantage due to their low thermal conductivity - the inside of such houses is warm and dry, they are not subject to freezing and dampness to the same extent as panel houses. The use of high-quality ready-made cement mortar for bricklaying plays an important role in heat transfer: it ensures good adhesion of the elements to each other, and therefore the integrity of the structure.

Ready-made masonry cement mortar: application and composition

The basis of any masonry mortar is cement. Heavy solutions have a high density - 1500 kg/m3 or more. They are universally intended for:

- masonry made of large natural stone and solid brick;

- sealing joints between panels made of heavy concrete;

- assemblies of vibrobrick panels;

- plastering and waterproofing concrete surfaces;

- high-strength screed devices.

The standard composition of masonry mortar is cement, sand and water. To make the mixture more mobile, plasticizers are added to it, and to prevent it from setting too quickly, lime is added.

Brands of heavy cement-sand mixtures are classified from M100 to M550. The most in demand are ready-made masonry cement heavy mortars from M100 to M400. In order to achieve good strength of the mortar after setting, it contains cement of a grade not lower than M400.

Share useful content with your friends:

Buy ready-made masonry heavy cement mortar in Moscow and the Moscow region

A large manufacturer of building materials offers to purchase ready-made cement-sand mortar for bricklaying and other construction work in Moscow and the Moscow region. You can order delivery of products to your destination or pick up the order yourself at one of our 9 concrete plants located in the region.

Each manufactured product is tested for strength and compliance with the stated characteristics using modern equipment in our own laboratory. Regular customers are offered discounts and bonuses. You can order the solution by calling the company or leaving a request on the website.

| Brand (class) | Characteristics | Price RUR/m3 |

| Masonry mortar | PC 1-4 | from 2350 rub. |

Compound

The selection of components for the concrete mass is carried out on the basis of GOST 7473-94. The provisions of this document provide for the following set of components:

- Cement powder. The best option is Portland cement grades M400 or M500. The lower the brand index, the greater the amount of binder you will have to take. Therefore, it is not economically advisable to use other brands: the gain from the low price for 1 bag is eaten up by the need to use more cement.

- Sand. GOST does not recommend taking material whose particle diameter is greater than 3.5 mm and less than 0.14 mm. Among all the varieties, river sand is best suited for mixing concrete mass: its particles have practically no sharp edges or pores.

- Gravel or crushed stone. Coarse aggregate should have particles no smaller than 20 mm and no larger than 70 cm in diameter. Preference should be given to hard rocks (marble, granite).

Both solid and fine aggregate should not contain debris, clay impurities, or organic contaminants. Ideally, before use, sand and crushed stone are sifted, then washed with a stream of water and dried.

In addition to the three main components, additives can be added to the solution (no more than 5% of the total amount of material). These substances give the solution additional plasticity (C-3), frost resistance (MB-10), accelerate crystallization (calcium and sodium salts) or, conversely, slow it down (Bitron type additives).

Types of building mixtures

The main component that determines the quality of the solution is the main binder - lime or cement. Using two of these substances or one of them, you can obtain various types of building mixtures for masonry or finishing.

Lime mortars are distinguished by good plasticity and excellent thermal protection properties, but they are used only for the construction of low-rise buildings, as they cannot withstand heavy loads.

- Cement mortars are most often used for working with brick or rubble masonry.

- It perfectly resists high humidity in the underground part of buildings, so it is used for laying strip or block foundations.

- Currently, it is widely used in the construction of buildings of various heights and purposes.

- Solutions based on two binders at once - cement and lime - are used in the installation of structures and finishing work without restrictions.

According to the classification, masonry mortars are also divided into three more types:

- Normal;

- Fat;

- Skinny.

The greater the percentage of binder put into the solution, the more “greasy” it is considered, but this affects shrinkage when the laid mixture hardens and the appearance of cracks.

Accordingly, the skinnier version is plastic, does not shrink much, but is inferior in strength. For ordinary private housing construction, it is recommended to use the formulation of normal masonry mortars.

Types and brands of mixtures

The introduction of the concept of “cement grade” helps to calculate the cement consumption per cube of mortar if the input parameters are known. To prepare a mortar with the same construction characteristics from different brands of cement mixture, different proportions of fillers will be required. Cement is produced in production, starting from grade M100, but due to the low structural strength, the material is practically not used.

The most popular cements are M400 and M500, but some other types have also become widespread. The choice of mixture depends on the scope of application of the material.

The main areas of use of cement grade:

- M300 cement is used in installation construction, as well as during the manufacture of monolithic structures;

- M400 cement is successfully used in monolithic construction and during the preparation of reinforced concrete;

- M500 cement is actively used in the construction of buildings or slabs that must be resistant to moisture or located in water. The scope of application of this concrete mixture is quite wide: the creation of sidewalks, the construction of asbestos-cement structures, the formation of large concrete masses and all kinds of foundations;

M400 and M500 cements are the most popular

- M600 cement is used to create prefabricated structures and foundations that are subject to high loads;

- M700 is a suitable grade of cement for the construction of highly loaded and stressed structures.

Heavy masonry mortar

Construction does not stand still. Every year new types of light and heavy masonry mortars appear on the market. Thanks to them, it has become much easier to implement the most complex tasks. The heavy solution is proof of this. Such masonry is not only high-quality and practical, but also allows the structure to perform its tasks properly for many years.

Features of heavy masonry compositions This type of mixtures has a number of significant advantages. The average density, in contrast to light with a low indicator of this parameter, is more than 1500 kilograms per cubic meter. This material is produced on the basis of a binder component - quartz sand with the addition of cement. There are several types of heavy mortars on the construction market. All of them are used in special applications. construction.

- M100-150. Necessary for the preparatory stages before the main pouring of the cement foundation. It is also used for the construction of roads, pedestrian crossings, garden paths made of stone, facing work and when installing street curbs;

- M200-250. Special areas are poured with such high-density concrete mixtures. They can also be used to create different types of foundations. The average density of the M250 masonry mixture allows the production of stairs, retaining walls and external ceilings;

- M300. Used for laying monolithic foundations and erecting brick walls;

- M350. This type of cement mortar is used to create slab foundations when constructing a large number of blocks of multi-story buildings. It is also used to make road slabs for airports, swimming pools and large load-bearing columns;

- M400-450. It has high average density and strength. Used for the construction of dams, dams, bank vaults and during the construction of subways;

- M500-550. This type has a high cement content. Thanks to this, it has the strength of stone. The average density of masonry mortar M500-550 is significantly higher than previous brands. Its use is appropriate in the manufacture of reinforced concrete structures of varying complexity.

All heavy types of cement mixtures are manufactured in accordance with GOST requirements. Each manufacturer must indicate this on the packaging. In construction, dry masonry heavy cement mortar of grades 200, 300 and 350 is especially popular.

Pouring concrete 200 - recommendations from professionals

Professional builders suggest concreting in compliance with the following recommendations:

- place the reservoir with the solution in close proximity to the work site;

In order for it to have the highest characteristics and greater strength, various additives are added to the mixture during its manufacture.

- pour from a height of no more than one meter to prevent delamination;

- use a chute to supply the mixture, which allows you to more accurately distribute the solution;

- prepare the concrete solution at a temperature of more than five degrees Celsius;

- concrete in one go, allowing breaks of no more than 2 hours;

- compact the array, especially in the locations of the reinforcement cage;

- Moisten the surface periodically.

Compliance with these rules will avoid cracks and ensure the quality of the monolith.

Color additives

The color of the seam has a great decorative effect. The masonry becomes more elegant, the seam lines are emphasized and make the wall surface more expressive.

To change the color of the solution and give it the desired color, special pigments are used, which are added to the mixture when mixing the solution. There are different shades that can be achieved using pigments.

The simplest and oldest way to color a solution is to add soot. The result is a deep black solution. Currently, oxides of various metals are used as pigments. They are sold in construction stores and are quite affordable for purchase.

Material consumption rates per cubic meter of different solutions

Today there are 4 main areas of use of concrete: foundation, masonry, screed and plaster. In each case, special requirements are imposed on the building mixture, which makes the choice of cement and its consumption different. The greatest consumption of cement per cube of concrete occurs when it is necessary to make masonry or plaster. The consumption of materials per 1 m3 of foundation mortar is slightly lower due to the use of a large filler fraction: slag, crushed stone or gravel.

GOST has records of cement consumption rates per 1m3 of mortar, taking into account the purpose of the mortar. Designation of concrete per cubic meter. meters is a generally accepted system of measurement.

Cement consumption rates per 1 m3 of mortar Consumption rates per 1 m3 using M500 cement:

- on M100 – 170 kg;

- on M150 – 200 kg;

- on M200 – 240 kg;

- on M250 – 300 kg;

- on M300 – 350 kg;

- on M400 – 400 kg;

- on M500 – 450 kg.

Consumption rates for cement and sand per cube of foundation mortar

Calculating cement for a foundation calculator is the easiest way to understand how much material is required and the number of necessary components. Concrete calculations can be done with high accuracy and manually.

To determine how much cement is needed per 1 m3 of solution, we recommend following simple instructions:

Cement consumption rates for foundations

- We determine the appropriate brand of cement mortar. Usually, when creating a foundation, it is advisable to use a solution of M100-M300. For low-level buildings, M100 is sufficient, if you plan to build several floors - M150, and M200 and higher are used in the construction of multi-story buildings and any structures that have increased strength requirements. If the foundation is being built for a wooden building, M50 mortar is sufficient.

- We select the brand of cement. For standard tasks, M300-M400 is suitable in the proportion of cement to sand 1 to 3. When using cement M500 - 1 to 5.

How many kg of cement in 1 m3 of solution:

- in M50 when using M400 – 380 kg;

- in M100 when preparing concrete from M300 cement – 214 kg;

- in M200 with cement M400 – 286 kg;

- in M300 at M500 – 382 kg.

The data is presented if the cube contains 2-4 parts of sand and 3 parts of crushed stone.

Consumption rates of cement and sand per cube of masonry mortar

To prepare cement mortar for wall construction, a proportion of 1 to 4 is most often used. Thus, the cement consumption per cubic meter will be 0.25 m3 or 325 kg, and the sand consumption per 1 m3 of mortar will be 0.75 m3 or 1200 kg.

Cement consumption rates for masonry

To calculate how much mortar will be needed per 1 m3 of brickwork, it is important to take into account the thickness of the wall.

Table 1: Mortar consumption for walls of different thicknesses

| Thickness in bricks | Consumption, m3 |

| 0,5 | 0,189 |

| 1 | 0,221 |

| 1,5 | 0,234 |

| 2 | 0,24 |

| 2,5 | 0,245 |

To calculate how many bags of cement are needed, just multiply 325 kg by the consumption per cubic meter, for example, walls of one brick - 0.221. You will get 72 kg of cement for laying 1 m3 of wall, provided that the composition does not contain other components (lime, clay, etc.).

Mortars with the addition of cement and lime

In order to prepare this type of mortar, water, sand, cement and lime are used. Thanks to the last ingredient, the finished solution is more plastic and also has greater strength than lime. This composition has the most optimal combination of properties, which is why this type of mixture is more often used in professional construction. When constructing plinths and foundations, this type of solution is used everywhere.

Preparation of cement-lime mortar - table

Preparation of cement-lime mortar - step-by-step instructions

We will make M100 grade mortar using M400 cement. This will require 10 kg of cement, 50 kg of sand, 0.5 kg of lime and 50 liters of water.

Step 1. As when preparing any other solution, you must first prepare the necessary components. The water must be clean, temperature +15-20 degrees, the sand must be sifted. Cement does not require additional processing before use.

Step 2. Next, you need to pour 2/3 of the expected amount of water into the concrete mixer, in our case - 30 liters. You can use a hose, or you can use a bucket.

Filling with water

Step 3. Now you need to fill in 10 kg of cement and 5 kg of lime. Next, you need to mix these ingredients for a couple of minutes.

We fill up the cement

Step 4. Now you should add filler, that is, sand, to the solution and add the rest of the water. Sand requires 50 kg, water - 20 liters.

We fill up the sand

Step 5. At this stage, you need to mix the solution for 5 minutes to achieve a uniform consistency of the mixture.

Step 6. The solution is ready, you need to pour it into a tub or other prepared container.

Pour out the solution

Making a solution with your own hands is not at all difficult; you just need to determine for yourself what mixture is needed for your purposes, correctly calculate the proportions and strictly adhere to them.

Application

Concrete mass of grade M200 (strength class B15) belongs to the group of heavy concrete. This brand is widely used in construction:

- Pouring foundations (both monolithic and strip) for the construction of low-rise residential buildings, public and industrial buildings.

- Production of reinforced concrete products: curb stones, FBS blocks, road slabs, flights of stairs, etc.

- Arrangement of paths in gardens and parks, sidewalks, etc.

- Pouring a floor screed (to learn how to make a concrete floor screed with your own hands: read the article here).

- Construction of blind areas around buildings.

- Construction of monolithic walls (including load-bearing ones).

This variety of applications for the M200 brand is due to its high strength and performance characteristics. Let's look at them in more detail to better understand what you can expect from M200 concrete.

Peculiarities

Dry mix M-300 is a ready-made masonry mixture, the components of which are selected in the required proportions. Before use, the composition is diluted with water in the volume specified by the manufacturer and mixed mechanically until smooth.

The mixture is sand concrete, since it is based on purified fine-grained concrete and Portland cement. The dimensions of the first do not exceed 3 mm; the Portland cement used has a grade strength of M-400 or M-500). To ensure certain characteristics (frost resistance, moisture strength, and so on), plasticizers are introduced.

Various reinforcing fibers may be present in compositions operated at subzero temperatures. To improve adhesion, a special type of clay, coarse sand, or granite chips are sometimes added.

Unlike conventional concrete mortars, M-300 sand concrete is distinguished by its ease of preparation, plasticity (suitable for laying in a thin layer, which is necessary for certain types of masonry), high strength, and economical consumption. The M300 mixture is a masonry mixture, that is, it is used for fixing bricks or masonry stones. In addition, it can be used as a concrete mixture for casting.

The composition is characterized by non-shrinkage, which allows it to be used as a floor screed. And thanks to its increased strength and wear resistance, the mixture is used even when organizing high-strength floors. The thixotropy of the composition allows it to be used also for leveling floors, as well as sealing cracks in concrete surfaces.

The material is suitable for both private housing construction and the construction of industrial and administrative facilities, as well as the installation of basements and garages. It is used when pouring the foundation, including in places where concrete and reinforcing sections meet. The mixture is also used to create paths in private suburban areas. In its properties, the material resembles fine-grained concrete, therefore it is used both outside and indoors.

How to do it yourself?

Making concrete is possible in two ways - manually and in a concrete mixer. Manual kneading instructions:

- Pour sand into a clean container of the required volume.

- Pour Portland cement on top, mix the dry mixture until a substance is uniform in color and consistency.

- Pour water into the container, mix, add liquid in small portions until a viscous mass or liquid solution is obtained, depending on the purpose of the material. The finished mixture should not contain lumps or undissolved clumps of cement/sand.

- Add gravel or crushed stone to the concrete and mix until the stones are evenly distributed. The mixture can be diluted with a small amount of water to increase plasticity.

The manual method is cheap, does not require the use of special equipment, and is used when there is no electricity at the site. However, the technology is very labor-intensive, so it is used mainly for the preparation of small volumes of concrete products (private construction, amateur production of reinforced concrete products, production or repair of paving slabs, paths).

If you need to prepare a large amount of solution, it is advisable to use a concrete mixer. Equipment can be purchased or rented; the production procedure is as follows:

- Pour water into the drum, add cement and mix slowly until gray cement laitance appears. After this, the drum should spin non-stop.

- Add sand and crushed stone inside and mix for 3-4 minutes.

- At the end, add another 1-2 liters of water to create optimal viscosity and uniform consistency. The finished solution can be used for finishing or pouring into formwork.

The solution prepared in different ways differs in the speed and characteristics of hardening. When mixing by hand, the mixture must be used immediately, because after 25-0 minutes it begins to separate, which leads to a deterioration in the quality of the finished product. The solution prepared in a concrete mixer is suitable for pouring within 60 minutes after complete mixing.

In what proportions should cement be diluted?

The correct proportions can vary significantly between different mixtures. Therefore, before mixing, it is necessary to decide for what purposes a particular solution will be used.

Important! The consistency of the solution changes depending on the proportions of the components.

The most popular mortars that require cement are:

Mixture for plastering walls. To prepare it, it is recommended to use 1 part cement and 3 parts sand. The volume of water is usually equal to part of the cement, but it cannot be added immediately, so it is poured into the dry mixture in small portions to obtain the desired consistency. If you need to carry out internal plastering work, then the M150 or M200 grades are selected, and if you plan to plaster the facade, then the M300 grade is suitable.

Brick masonry mortar. Here we use 1 part cement and 4 parts sand. The optimal brands for this work are considered to be M300 and M400. Often slaked lime is added to this mixture, acting as a binder. Its amount is calculated as 0.2 parts per 1 part cement. This substance produces a plastic solution, which is quite easy and convenient to work with. The amount of water may vary, as it is added gradually until a solution of the desired density is obtained

It is important to make a mixture that will not flow from the spatula, tilted at an angle of 40 degrees.

A mixture designed to create a floor screed. Typically the following proportions are used: 1 part cement to three parts sand. The M400 brand is considered optimal. Water is added in a volume of ½ of the amount of cement

To make a rare solution, it is recommended to gradually add water, as it is important that the mixture stretches well, which ensures that all voids in the base are filled.

Concrete. To create concrete, use 1 part cement, 2 parts sand and 4 parts gravel.

If this solution is made to form the foundation of a building, then it is necessary to purchase material grade M500. The amount of water is equal to ½ of the cement. The water must be clean and potable, and it is recommended to stir the composition with a concrete mixer (how to choose a concrete mixer for your home and garden). The entire solution must be used within an hour after receiving it.

Important! If you want to get a mixture in sufficient quantity to form the foundation of a building, then you will need a fairly large amount of it, for which special equipment is used, represented by a concrete mixer.

Often, ready-made solutions are purchased at the factory, and in this case you need to make sure that the mixture is created immediately before sending it to the customer. Before purchasing, we study all the documents for the mixture in order to know what components it consists of, as well as what parameters it has.

It is necessary to choose the right grades of material to form different solutions. If the mixture is intended to create brickwork, then you can use grades M50 or M100, and if you need to make a foundation, then it is advisable to choose grades from M300 to M500. The higher the grade of material, the more durable and reliable the solution will be.