Ursa mineral wool in rolls and slabs.

In the previous article we talked about mushroom dowels: their types and installation methods. Today we will help you understand what Ursa insulation is, the characteristics of mineral wool thermal insulation and extruded polystyrene foam. Ursa is a European company that has representative offices all over the world, including Russia. This brand is famous for the high quality of its product, the production process of which does not use toxic substances. Even the color of mineral wool and EPS from Ursa is not the same as that of competitors. The line is dominated by light colors.

Features of Ursa material

Ursa insulation based on fiberglass

Universal Ursa insulation effectively reduces heat loss and creates a comfortable microclimate in the room. Low specific gravity helps reduce the volume of building materials and energy consumption.

The URSA brand produces 2 types of products:

- thermal insulation based on Ursa expanded polystyrene (EPS);

- based on fiberglass.

The first category includes material made using extrusion technology. The foam particles combine with the foam under pressure and heat. The hot mass passes through the extrusion head of the unit and Ursa extruded polystyrene foam is obtained.

Insulation of the second category is produced by combining dolomites, quartz sand and soda. The substances are melted, and additives are added to the mass to glue the components together. The hot composition is forced through the nozzles of the extrusion unit.

What are URSA insulation materials and their varieties?

This thermal insulator is based on treated staple fiberglass. So this material is the closest relative of glass wool. When making it, sand, soda, dolomite and other additives are taken in certain proportions. The mixture is heated to the melting point and passed through a special apparatus. The result is a fibrous substance, the thin threads of which are glued with a special composition.

There are several products manufactured by URSA. The most common are the URSA GEO series insulation, made of fiberglass. In addition, the company produces polystyrene foam heat insulator URSA XPS, made by extrusion. A new product from the manufacturer, manufactured using the latest technologies, is PureOne insulation. Let's take a closer look at all these materials.

1. URSA GEO fiberglass mineral insulation is distinguished by the fact that only environmentally friendly components are used in its production. This is strictly controlled at all stages of the production process. So you can be sure that neither the raw materials nor the finished material contain harmful additives.

All materials in this group are fiberglass, but each is endowed with some unique properties and is intended for use in certain conditions and insulation of various objects.

The appearance of URSA GEO insulation is no different from glass wool.

2. Thermal insulator type URSA XPS also has its advantages and is an extruded polystyrene foam produced using a special technology. Its thermal conductivity coefficient is very low, especially compared to other thermal insulators. Plates made from this material last for many years, they are very hard and durable.

Therefore, it is advisable to use them when insulating flat roofs, floors on the ground floor, facades under plaster, basements and plinths. URSA XPS will fully withstand multi-ton loads - it is used to insulate railway embankments, airport landing strips and highway bases.

This is what PureOne, a new type of fiberglass insulator, looks like.

4. There is another fairly new product from URSA. This is TERRA mineral insulation, positioned by the manufacturer as a material of increased rigidity and moisture resistance and is intended for thermal insulation of private houses. But in terms of its performance, it is close to professional heat insulators. This insulation is very elastic, does not get wet and does not burn.

Technical characteristics of mineral insulation

Indicators of the density and size of roll insulation and Ursa boards

The category of mineral insulation includes materials made from natural components, for example, fiberglass. Products are sold in slabs or rolls. The structure does not include phenolic substances to bind the ingredients, so Ursa mineral wool is an environmentally friendly product.

The composition contains sand, soda, and other non-combustible materials, so the insulation is characterized by increased fire safety indicators. The manufacturer indicates a period of 40-50 years of operation without destruction or loss of quality.

Insulation density

The density of a material is determined by the ratio of weight to volume. For glass wool, the indicator is determined on a scale of 15-85 kg/m3, depending on this the area of use is selected. In private houses, material with an index of up to 30 kg/m3 is used, and industrial insulation requires penoplex of higher density.

Thermal conductivity

The characteristic shows the ability of rolled and slab materials to conduct heat from heated to cold layers. Energy transfer occurs due to the movement of elementary particles in the insulation composition. Ursa mineral wool has a low ability to transfer heat, so it provides good insulation of structures and pipelines.

The lower the thermal conductivity coefficient, the better the protection from cold. For mineral wool, the indicator is within the range of 0.031-0.045 W/mK. This amount of energy passes through the thickness, which indicates the high thermal insulation qualities of the layer.

Application temperature

Technical characteristics of flammability and thermal conductivity

The characteristic determines the temperature range at which the insulation retains its specified properties. The manufacturer guarantees that Ursa polystyrene does not change its declared qualities at ambient temperatures down to -60˚C. The upper value is +310˚С.

These indicators relate only to the atmosphere, since the insulation surface can withstand other temperature loads, the limit of which is +100˚С, and some categories retain properties at +180˚С. The insulation belongs to the universal class and is suitable for protecting various structural elements from cold in any climate conditions.

The material is sold in the form of rolls or in the form of slabs. Rolled products are produced in thicknesses of 5-20 cm, width varies in the range of 60-120 cm. The length of mats is 3-18 m, and sheets are produced in sizes of 1.25 m.

Price

The most pressing question that can dot the i's. How much does insulation with URSA cost? As you probably already guessed, Pure One will be the most expensive. You have to pay for health. For example, a roll of Pur Van 37 RN 6.2 m long, 1.2 m wide, and 50 mm thick will cost 1,212 rubles. A, Terra, density characteristics - 18 kg/m3, dimensions 1000 by 600 and 50 mm, will cost 420 rubles for 10 slabs. Ursa Geo M 25 cotton wool, 9 meters long, 1.2 meters wide and 50 mm thick, will cost 900 rubles. The number of slabs in each package is different.

We have tried to focus here on technical details in order to provide as complete information as possible. When insulating your home or office, pay attention to the properties of this brand.

A line of materials based on mineral components

Mineral wool differs in fiber depending on the initial component underlying it. The structure can be spatial, corrugated, the layers are divided horizontally or vertically.

The manufacturer designates products depending on the raw material composition:

- Fiberglass products are marked with the Geo prefix. The products fall into the category of materials that are safe for humans and environmentally friendly.

- A product with the PureOne index is created on the basis of glass threads. The composition contains acrylic components. This type of insulation is installed to protect against cold in children's institutions and hospitals.

- The non-flammable Terra material is ideal for insulating wooden buildings. The composition includes natural components, the insulation does not harm the environment and humans.

- Thermal insulation based on extruded polystyrene foam is marked with the prefix XPS and is a durable and reliable insulating option for insulation.

Ursa thermal insulation is manufactured in accordance with technological standards that regulate the content of the binder.

Ursa GEO

Material marked Geo is environmentally friendly and does not emit harmful combustion products.

The heat insulator is allowed for use in rooms with a high risk of fire, since the material does not emit harmful components when heated.

Ursa Geo products are available in the following range:

- Light;

- Pitched roof;

- Frame P;

- Mini;

- Facade;

- Noise protection%

- Universal plates.

Mats with one foil side are designated M-11F and M-11, double-sided - M-25F, M-25, M-15. The slabs are marked P-60, P-15, P-45, P-20, P-30.

With a low specific gravity, Geo brand products provide high-quality protection from cold and noise, thanks to the original fibrous structure. The material does not decompose, does not burn, and rodents and insects do not settle in the thickness.

Ursa PureOne

The Pure One material does not emit dust during installation.

The characteristics of Ursa insulation show that the material consists of 95% natural substances, which underwent quality control during the production process. The material is produced in accordance with sanitary international standards and is included in the class of environmentally friendly insulators.

Line names:

- 35QN rolls measuring 1200 mm x 3900 mm;

- slabs 34PN with dimensions 1250 mm x 600 mm);

- rolls 37RN size 1200 mm x 100 mm).

The products are flexible when installed in curved structures due to the thinned fibrous elements in the structure. The material does not emit dust or odor during installation. The white color is obtained through the use of quartz sand.

Ursa TERRA

Terra material is available in the form of slabs.

The products were developed for private buildings, but also meet the requirements of professional construction. Plates of this type are distinguished by their small size and rigidity with sufficient elasticity and flexibility.

The following range of Terra brand insulation is produced:

- slabs 34 PN;

- mats for insulation of highways and ventilation ducts 34 RN.

The sheets are characterized by a good index of thermal and sound conductivity and show moisture-resistant qualities. The production technology involves the use of water-repellent additives.

URSA Product Classification

For various purposes, there are different types of products under the Ursa brand, which have a certain composition, thickness and their own characteristics in terms of water absorption, thermal conductivity, temperature of use and other indicators. Today, the company’s product range includes five groups of insulation materials:

- Geo glass wool;

- boards based on extruded polystyrene XPS;

- staple glass wool insulation Pure One;

- TERRA mineral wool;

- films for steam, hydro and wind protection SECO.

URSA brand insulation has good strength indicators:

- do not burn;

- resistant to mechanical and other types of damage;

- do not rot;

- are not susceptible to mold.

But remember that some of them, in particular those made on the basis of mineral fibers, need additional equipment with vapor barrier films, since moisture negatively affects their structure and over time they will lose their integrity. And with proper equipment, insulation can last more than 20 years.

Description and technical characteristics of URSA Geo glass wool

Compared to basalt wool, glass wool has a lower thermal conductivity coefficient due to its large fiber and soft structure. Insulators are able to fit more tightly to the surface, regardless of its shape, without a single gap.

The Geo series is produced according to a patented technology in which the connecting link is acrylate resin, and not bitumen or polymer.

URSA glass wool is used mainly for the purpose of sound and thermal insulation in private and industrial construction. The series is divided into products of the following types:

- universal;

- for light building structures;

- for pitched roofs;

- insulation to provide sound protection;

- for insulation of frame buildings;

- foil insulation for rooms with high humidity;

- for pipe insulation;

- for facade insulation;

- products with additional properties;

- raised floors and floating insulation.

URSA glass wool insulation has the following technical characteristics:

- thickness from 50 to 200 mm;

- thermal conductivity at 10 degrees from 0.030 to 0.041 W/mK;

- non-flammable material;

- permissible humidity level from 0.035 to 0.046 W/mK;

- The permissible temperature of the environment is from -60 to +2200 degrees.

You should also pay attention to wall insulation and mats marked with the letter “F” (foil). They are suitable for frame buildings and provide complete protection from cold and extraneous sounds. The price of the products presented in this series starts from 94 rubles per square meter. Users also note the ease and efficiency of glass wool.

URSA XPS slabs and their description

These plates are mats based on extruded polystyrene foam, equipped with a tongue-and-groove locking joint of a stepped structure. This connection provides maximum compression without cold bridges. Such slabs are perfect for insulating large areas, in particular:

- flat roofs;

- walls;

- partitions;

- floors and ceilings;

- foundation;

- special areas.

Insulation should be laid preferentially in one layer.

Expanded polystyrene boards can withstand sudden temperature changes, do not rot or develop fungi and mold, and are almost incapable of absorbing water. It can be installed in places of contact with open ground or vegetation and does not equip the insulation with additional protective elements.

URSA insulation boards have special series designed for the following types of work:

- external and internal;

- for insulating walls in basements;

- equipping foundations;

- heated floors;

- flat roofs;

- for insulation work in industrial buildings with roofs with high loads;

- for car repair and road works.

The plate parameters are as follows:

- length is 1.25 m;

- thickness from 30 to 100 mm;

- width 60 cm.

The technical characteristics of this insulation are as follows:

- thermal conductivity at 10-degree temperature ranges from 0.032 to 0.033 W/mK;

- flammability degree G3 and G4;

- temperature limits from minus 50 to 75 degrees:

- water absorption maximum 0.3 percent with partial immersion during the day;

- vapor permeability 0.004 mg/mchPa.

But remember that polystyrene foam boards cannot be used on damp surfaces; they will remain damp and moldy, regardless of whether there is insulation there or not. To prevent this from happening, the surface should either be dried before insulation or treated with a water repellent along with a biocide additive, for example, Tiprom.

XPS boards have a price of about 150 rubles per square meter and more.

Glass wool staple URSA PureOne

This position of the URSA brand is suitable for premises that have special requirements in terms of safety, noise-absorbing characteristics and environmental friendliness:

- children's rooms;

- educational establishments;

- sterile rooms;

- acoustic installations.

According to the European standardization system, this insulation received the highest category as the most environmentally friendly.

In this series “Ursa” the following positions are presented:

- slabs with sound-absorbing characteristics of class A;

- mats for insulation of facades and roofs;

- mats for construction and repair work in children's institutions.

Mats can also be used as roofing insulation, because they have increased elasticity and are easy to cut. This insulation is installed quickly and does not require additional fixation.

Technical characteristics of spatula glass wool "Ursa" are as follows:

- thickness from 50 to 150 mm;

- thermal conductivity at 10 degrees ranges from 0.034 to 0.037 W/mK;

- permissible humidity level from 0.038 to 0.043 W/mK;

- flammability - NG;

- temperature limits - from 60 degrees minus to 220 degrees Celsius.

Another feature of this insulation is that it can be used where allergy sufferers and those with lung diseases live. The average price of such URSA glass wool is about 90 rubles per square meter.

Mineral wool URSA TERRA and its description

This position is intended for the construction and renovation of private houses. Thus, these insulation materials are used for insulation and sound insulation of external and unloaded walls, as well as partitions and cladding. The insulation boards have a high degree of rigidity and are equipped with moisture-repellent impregnation. Also, this position is not hot and is bioresistant. Key technical characteristics are as follows:

- thickness 50 mm;

- length from a meter to one and a half;

- width 60 cm;

- thermal conductivity (10 degrees) – 0.034 W/mK;

- permissible temperature of use from minus 60 degrees to plus 220;

- vapor permeability 0.51 mg/mchPa.

This mineral wool can be used to insulate uneven walls, since its structure allows it to adhere very tightly to the surface, creating a continuous coating.

The price for this product in retail outlets across the country fluctuates around 200 rubles per square meter.

Line of materials based on XPS

The materials have a low thermal conductivity (0.028-0.035 W/mK), have increased strength and low specific weight (45 kg/m³), which reduces the weight of the structure. Extruded polystyrene foam is characterized by closed cells in the structure, the diameter of which does not exceed 0.2 mm. This structure ensures moisture resistance in damp conditions.

URSA XPS

The insulation is resistant to loads and chemicals.

Only one type of product is produced in the EPS product category. The material has universal application, but is more often used for insulation work during the construction of railway embankments, runways, lower and underground floors of buildings.

Assortment of the URSA XPS line:

- high strength material NV, sold in slabs 60 x 125 cm;

- N-III sheets are available with straight and stepped side edges;

- N-III-G4 slabs are produced in thicknesses of 3-10 cm, size 60 x 125 cm.

The products do not react to the action of acids, fats, alkalis, lime, bitumen and other caustic substances, but decompose upon contact with tar, hydrocarbons, gasoline and formic acid.

Main advantages

The service life without loss of properties is comparable to the operating time of the structures; the insulator ages simultaneously with them and does not require replacement. The high tensile strength of extruded polystyrene foam is its positive quality, which is why the material performs protective functions and works as additional structural elements that can withstand some loads.

When cutting, fiberglass crumbles, so you need to work with gloves and a mask

Advantages of Ursa materials:

- environmental cleanliness;

- increased noise protection qualities;

- long service life;

- resistance to temperature changes;

- wide range of applications;

- elasticity and resilience;

- fire resistance;

- ease;

- vapor permeability and biostability;

- not subject to decomposition and rotting.

There are some negative points when using it. For example, mineral wool decomposes upon direct contact with alkalis, and small fibers fall out of glass wool during the cutting process.

Areas of application

Ursa slab insulation can be used as a substrate for asphalt.

Ursa universal thermal insulation is used in any construction process. Universal characteristics allow the protection to be used for complex curved surfaces.

Areas of use:

- pitched and flat roofs;

- foundations in damp places;

- walls outside, inside and as an intermediate layer;

- partitions;

- heating lines;

- highways and railway elevations;

- airfield strips;

- extensions, balconies;

- saunas and baths.

Reliable thermal insulation is set to a minimum thickness, which is comparable to thicker layers of other materials. Internal insulation made from Ursa material does not reduce the horizontal and height dimensions of the room.

Dimension

Types of packaging

Many buyers of this material are primarily interested in the dimensions of a roll of Ursa insulation - after all, only knowledge of the dimensions allows one to accurately calculate how many rolls are required to perform certain jobs. (See also the article Insulation of building facades: types.)

And the dimensions of Ursa insulation are quoted as follows:

- length 10000 mm, width 1200 mm, thickness 100 mm for GLASSWOOL on pitched roofs;

- length 9000 mm, width 1200 mm, thickness can be either 50 mm or 100 mm - GLASSWOOL for various purposes,

- length 18000 mm, width 1200 mm, thickness 50 mm - with one or two canvases in the package. Used as a material for various purposes.

Important! At the same time, the cost of Ursa insulation varies depending on whether the material belongs to one of these types.

Installation of Ursa thermal insulation

Installation of roof insulation in wooden logs

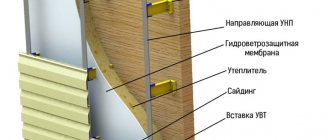

Mineral wool is attached to the walls and pressed with 50x50 cm bars so that there is an air space between it and the finishing layer. Wooden elements are mounted at a distance of the width of the roll so that they hold the edges of the canvas. Expanded polystyrene boards are glued to the surface of walls or floors using cement-adhesive solutions or polyurethane composition. Before gluing, walls, ceilings or floors are treated with primer for better adhesion. A screed or starting putty is applied over them using a plaster mesh.

For reliable fastening to vertical surfaces, use special dowels with a large head (up to 10 cm). The ventilation gap between the insulation and the wall of the house ends at the bottom and top with vents - installation holes for normal air flow. Rolls and slabs are stacked tightly next to each other. If the material is placed in 2 layers, the next layer overlaps the joints of the previous one for maximum efficiency.

If a frame is used, a finishing finish is attached to it in the form of sheets of chipboard, fiberboard, OSB, plastic panels or MDF. Ursa insulator works well with all types of building finishes.