Albes-Norma frame weight per 1m2

Using ordinary scales, we weighed each guide separately. Someone may have a question: why did they weigh each separately. Yes, because the profile height of the guides is different, and, accordingly, the weight is 1m.p. also different.

For convenience, let’s put the obtained data in a table:

| № | Name | consumption rate per 1m2 | unit. | weight 1 piece, kg | weight 1 m.p., kg | multiply the weight by 1 m.p. each profile for consumption rates |

| 1 | Main (bearing) guide, length 3700 mm | 0,84 | m.p. | 0,629 | 0,17 | 0,1428 |

| 2 | Long crossbar 1200 mm long | 1,68 | m.p. | 0,166 | 0,138333 | 0,2324 |

| 3 | Short crossbar 600 mm long |

So, we have calculated the weight of 1 m 2 of the Albes-Norma frame is 0.4802 kg

We'll continue to weigh in on different frameworks and add to this article.

Weight of suspended ceiling frame. Why know and where is this value used?

- Security

The suspended ceiling frame is a load-bearing structure. The purpose of creating a ceiling is a space that is comfortable and attractive for people. This means that accurate calculations will ensure the creation of a structure that is safe for the life of people in the premises.

- installation of suspended ceiling structure

Knowing the weight of the frame is necessary for accurate and correct calculation of the load on the ceiling and the number of hangers. The number of Armstrong and similar ceiling hangers is recommended by manufacturers, but if necessary, the number of fasteners can be increased. This will increase the safety level of the ceiling structure.

For the standard and most common installation schemes for the Armstrong ceiling, see the article “Installation of raster suspended ceilings of the Armstrong type. Stages of installing a suspended ceiling.”

When purchasing Armstrong suspended ceiling systems and similar ones for large objects, you need to know the weight of the components to select the carrying capacity of the vehicle. This will ensure timely delivery and start of work.

We help our partners with the delivery of such goods. For prices for delivery of suspended ceilings, see the “Delivery” section.

To calculate and draw up construction estimates and approve the budget, all calculated values must coincide with real ones and be consistent with prices. Therefore, cost rates are calculated, which includes the weight of the frame per square meter.

We talked about how to calculate the consumption rates for suspended ceiling components here - “Consumption rates for materials for an Armstrong ceiling”

Installation and installation of decorative ceiling cladding always begins with the calculation and selection of components for the Armstrong suspended ceiling. Most of the assembly work on installing the supporting frame can be done independently, especially since the process itself requires careful fitting and installation. As a rule, special skills are not required to work with components and assemble Armstrong ceiling panels with your own hands.

Calculation of the quantity of materials

DIY Armstrong ceiling

The calculation of Armstrong suspended ceilings must begin with measurements. To do this, you need to determine the perimeter of the room, its area, if there are ledges or niches, then their sizes too. Usually this is enough to calculate the ceiling using a calculator. But it often happens that inconspicuous elements are not taken into account. For example, ducts and ventilation grilles or lighting. Therefore, using a calculator the calculation will be approximate. The advice is to do it manually.

Where to begin? You need to transfer the ceiling surface onto paper to scale. After which you can divide the area into squares with cell sizes of 600 * 600 millimeters. The lattice obtained on paper is your Armstrong ceiling - the calculation of which can be carried out as easily as possible. The perimeter is the corners. Immediately mark the guides that are usually hung across the room. This means that the transverse profiles will be laid along the room.

Measure each frame element and multiply the resulting indicators by the scale. Here is the length of each hanging element individually. A quantitative indicator is obtained by dividing the length of all profiles by the length of one standard element. If the result is not a whole number, round it. Now count the cells - this will be the number of slabs.

A small digression. Not all of us want or know how to draw to scale.

Many people are simply lazy. Therefore, take into account the following formulas by which you can calculate the number of required elements of the Armstrong ceiling:

- The number of cladding elements is 2.78*S, where “S” is the ceiling area.

- Guides - 0.23*S.

- Transverse and longitudinal elements of the sheathing are 1.4*S.

- The corners on the walls are P/3, where “P” is the perimeter of the room.

- Suspensions - 0.7*S.

Note! If the suspended structure becomes heavier, for example, built-in lamps are installed, or the structure is thermally insulated, then it is necessary to increase the number of suspensions.

What is included in a suspended ceiling?

At first glance, the design looks quite complicated and cumbersome. The weight of the Armstrong ceiling with components per m2 can range from 2.5 to 8 kg, it all depends on the type and material of the panels and the size of the supporting profile.

Formally, the design can be divided into three basic elements:

- Armstrong ceiling frame or, in other words, a load-bearing structure. Its characteristics must be selected in advance according to the technical characteristics of Armstrong ceiling panels with components. The heavier the slabs and the larger the size of the room, the more massive the profile should be;

- A system of fixation or mechanical fastening to the sub-ceiling of a room. You can use ready-made Armstrong ceiling hangers from the kit, buy or use homemade hooks;

- Decorative panels or slabs 600x600 mm. Most often these are noise-absorbing, hygienic - washable or designer cladding options. Different material means different weight.

You just need to correctly take into account the weight of the components of the decorative panels.

Forum

This topic has 3 replies, 4 voices, and was last updated by Jimmmi 4 years, 9 months. back.

Armstrong ceiling: weight 1 m2

December 03, 2016 at 03:42 pm Say thanks Similar topics

- How to increase the size of the playground fence?

- by Davydovae

- July 18, 2016 at 10:29 am

- Do mice chew polyurethane foam?

- by Gareeva M

- July 18, 2016 at 10:29 am

- How much does it cost to raise a country house (6m x 5.5m)?

- by Colmogov Viktor

- July 18, 2016 at 10:29 am

Thanks: 9 Thanks: 164 Author of the 1st degree Expert of the 1st degree December 3, 2016 at 16:43

Attach a photo of the ceiling. Are we talking about a suspended or tensioned structure?

Say thanks Thanked: 7 Thanks: 289 Expert of the 1st degree Commentator of the 5th degree December 3, 2016 at 18:51

On average, the weight of an Armstrong ceiling ranges from 2.5 to 8 kg/m2. Everything, of course, depends on the type of material used. The thickness of the slabs may vary.

I'll attach a photo for the person asking the question. This is a suspended ceiling, it looks something like this:

Say thanks Acknowledgments: 125 Author V degree Expert I degree December 3, 2016 at 21:50

I agree with Zodchim! Typically, the thickness of the ceiling structure module does not exceed 25mm, and also has the smallest given parameter of 8mm. Based on this, the minimum ceiling weight will be 2.5 kg per m2, and the maximum up to 8, which is a decent spread. To find out why the weight of 1 m2 of Armstrong suspended ceiling is so different, the material with which the design modules are equipped helps. Metal and wood significantly make the ceiling heavier, while mineral or basalt fibers significantly reduce the weight of parts. I don’t quite understand why you need weight for the estimate, and not the cost per square meter.

Options for decorative slabs

For medical premises and sterile boxes, metal plates are used. The weight of one slab does not exceed 400g. In trading floors and industrial facilities, ceiling coverings are most often equipped with components with sound-absorbing boards. The weight of one such panel is 2.78-2.8 kg.

For rooms with high humidity, calcium silicate panels are used. The weight of one moisture-resistant Newton board is almost 3 kg. The load can differ by 6-7 times, so the type of ceiling panels with components significantly affects the characteristics of the Armstrong ceiling.

The slabs can be supplied together with other components for a prefabricated ceiling or purchased separately. One standard pack contains 16 pieces of 60x60 cm tiles to cover 5.56 m2 of surface, including seams.

Frame design

The list of components for arranging the frame includes:

- Ceiling corner Armstrong. Its dimensions and length must always be discussed separately, since the dimensions and shape of the room can differ greatly from traditional square layouts;

- Main guide rails for Armstrong suspended ceilings. Of all the components, this type of profile is the most important; the rigidity and absence of surface deflections depend on its rigidity and strength;

- Transverse load-bearing profile for the ceiling. As a rule, this type of component is produced in shortened form, 0.6 m and 1.2 m long.

In addition to the main supporting frame made of profiles, which carries the weight of the decorative panels, the components of the suspended ceiling include adjustable suspension systems. It is essentially a pair of steel bars equipped with two interlocking locks.

The use of an Armstrong suspended ceiling suspension may be optional; the main guide beams can be attached directly to the subceiling through perforated strips. This installation method is considered quite labor-intensive and is only justified when working in small spaces.

Consumption of materials

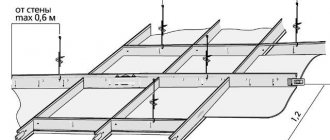

- when installing a suspended ceiling using standard installation schemes

Name of materials units change consumption per square meter diagram 2 diagram 3 Support profile L=3700 (a) linear m 0,84 0,84 Cross profile L=1200 (b) linear m 1,68 1,68 Cross profile L=600 (s) linear m 0,84 0,84 Suspension S-3 PC. 1,2 1,2 Dowel with half ring PC. 1,2 1,2 White steel corner 19/24 linear m consumption depends on the perimeter of the room Dowel for attaching the corner to the wall PC. at the rate of 2 dowels per 1 linear line. m perimeter Ceiling plate square meter 1,0 - when installing a suspended ceiling using a reinforced installation scheme, when installing heavy ceiling panels (6 kg/m2 or more), it is recommended to use this scheme without long transverse guides!

Name of materials units change consumption per square meter scheme 1

Accessory parts of auxiliary type

Non-main or supporting elements include the starting or wall corner for the Armstrong ceiling. Assembling the ceiling frame begins with choosing the level of placement of the future cladding and installing the corner. This type of component is most often made of aluminum. The corner takes up part of the weight of the ceiling, and in addition, covers the ends of the supporting profiles.

Corners, as components, can be selected arbitrarily, based on the design and interior of the room.

In addition to the corner profiles, you need to specify auxiliary components - hinges and dowels with hooks. They usually have a universal size and cross-section, so parts can be purchased separately or used from other kits.

Main guide element

The thickest and most massive metal strips are made mainly from galvanized steel using special pressing equipment. Of the entire list of component parts, the main guide element stands out for the thickness of the vertical wall, the widest shelves and size.

The standard length of one purlin is 3700 mm. In the vertical wall of the T-shaped rail, there are fastening holes every 40 cm, thanks to which the profile can be spliced to fit the size of the room.

In addition, perforation is used for hanger hooks when attaching guides for Armstrong ceilings. If beams are purchased as a set of suspended ceilings with decorative panels, then usually they are already painted white or gray, and may be chrome-plated or “gold-plated.”

Often, customers purchase suspended ceilings not as a set, but as separate components. In this case, the main guides and cross members can be painted with regular automotive spray paint. The costs are lower, and the color can be chosen at your own discretion.

Cross members

There are two types of crossbars used in the construction of suspended ceilings. A 120 cm long profile is installed between the starting corner and the main guide. Locks are mounted at the ends of the metal T-shaped rail, with the help of which the rail can be connected at its end to the side surface of the guide beam.

The width of the lower horizontal shelf on the profile is 24 mm, the height of the vertical wall is 38 mm. That is, this type of component is light and strong enough to not create additional load on the hangers and at the same time hold a fairly heavy slab.

To support the panel, 10 mm side shelves are used. This is not much, but it is impossible to make the supporting surface larger for all components of the frame; the cell window will be too narrow to push the panel into it.

In addition to the holes for suspension hooks, the vertical wall of the 120th profile has rectangular grooves-holes for coupling with additional crossbars, 60 cm long.

This type of component is made the same size as a 120 mm long profile, there are no holes or grooves in it, and therefore it is often replaced with homemade jumpers, for example, from a cut ceiling strip used for installing drywall.

Graphic method

All the most accurate data on the number of components can be obtained in the CAD computer-aided design system; the machine will give everything, right down to the number of dowels and the location of places for their installation. But only trained specialists can master such a method for calculating suspended ceiling systems.

All the most complex calculations of building structures can be performed graphically; sometimes this is the only possible and reliable method of calculation.

You will first need to draw in proportion an exact ceiling projection plan for the future Armstrong suspension system, approximately as in the diagram below.

For calculations, you can draw a version of the ceiling with lamps.

Or make a full projection drawing of the future cladding.

The degree of detail is good, but the depth of the drawing does not particularly affect the quality and accuracy of the calculation of the Armstrong suspension system.

For your information! The guide profile manufacturer has already calculated everything.

If the window size is 60 cm, the thickness of the metal included in the design, the height of the beams, the length of the shelves and the number of hangers will be sufficient to ensure the strength of the Armstrong ceiling frame for any weight of the tiles. The only thing is that when installing the lamps, additional installation of crossbars 0.6 meters long will be required.

Performance characteristics of Armstrong ceiling components

Structurally, panel cladding is just slabs of a certain composition and material, laid on a supporting frame made of galvanized profile. This entire mass of parts and components for the Armstrong suspended ceiling is held on the concrete floor using adjustable hangers.

The frame is assembled like a construction set from individual planks

The main difference in the different types of Armstrong ceilings is the material of the slabs. The specific type of panel is selected according to operating conditions:

- For premises of public institutions, shops and offices, warehouses with constant temperature changes, high dust loads and special fire safety requirements, mineral boards based on pressed granules of mineral wool, latex, gypsum and cellulose fiber are used;

- In medical, sanatorium and hospital institutions, in kindergartens and schools, panels with metal coatings that are highly resistant to ultraviolet radiation and sanitary treatment are used to decorate Armstrong ceilings;

- For swimming pools, baths, laundries, kitchens, slabs made of polymer compositions are used that can withstand humidity up to 98% and temperatures up to 120 o C;

- In retail and entertainment establishments, Armstrong ceilings are used with slabs of cellular structure made of mineral wool and fiber, which block noise and sounds well and at the same time have excellent fire-fighting characteristics.

With rare exceptions, when decorative slabs are made of glass, plaster or wood, the characteristics of Armstrong ceiling panels with components allow them to be used in almost any room.

Thanks to the suspension system, the slabs are easily removed and just as accurately returned to their place, on the supporting corner profile, so repairing the Armstrong ceiling is considered one of the simplest and most affordable.

Kinds

When choosing the type of structure, you need to determine the functional load that will be placed on the decorative surface. For example, glass slabs are fragile and break easily, so extra care will be required during installation. Soundproof ceilings must also be installed correctly. Otherwise, the declared properties will not work.

Photo of a mirrored ceiling in the bathroom

The type of Armstrong ceiling is selected in accordance with the purpose of a particular room. Some panels have increased moisture resistance and are installed in rooms with high humidity levels, others have decorative characteristics:

- mirrored Such decorative panels reflect the surrounding space, visually expanding the spatial boundaries of the room, creating an amazing effect of interior depth;

The photo shows the ceiling slab Lily 600x600x15 mm

- moisture-resistant (for example, “Prima”) are installed in rooms where the humidity reaches 99%;

- acoustic (“Ultima”) have increased sound insulation, relevant in those places where it is necessary to install a barrier that prevents sound from penetrating into or leaving the room (cinemas, concert halls, nightclubs, etc.);

- designer. This range includes model slabs that make ceilings interesting and original;

- hygienic (“Bioguard”). A special coating is applied to the surface of the tiles, which prevents the accumulation of steam or grease, as well as the formation and development of mold. Such ceilings are installed in hospitals, sanatoriums, etc.;

- economical (“Baikal” or “Oasis”). Cheap decorative coatings are suitable for finishing offices, shopping centers and other public premises.

Technical characteristics of Armstrong ceiling panels with components

The standard size of decorative slabs is 60x60 cm; for high-rise ceilings, for example, in industrial premises or entertainment facilities, Armstrong panels measuring 60x120 cm can be used. Structurally, this ceiling is no different from the previous one, the only thing is that there are fewer transverse strips and more installed wire hangers.

Main characteristics of standard mineral fiber board:

- Thickness - 12-15 mm;

- Moisture resistance – water vapor content in the air up to 70%;

- Thermal conductivity – 0.05562 W/m* o C;

- Sound insulation – up to 54 dB.

Disadvantages include extremely low mechanical strength and moisture resistance. As soon as you drop the stove once or fill it with water, the material completely or partially fails.

Calculation of the number of components for Armstrong

Armstrong ceiling weight with components per m2

The thickness of the panels may vary, depending on the material and category of the room. The standard thickness is 12 mm, but can be 8 mm or 22 mm. Accordingly, the mass of the structure also differs. For example, the weight of an Armstrong suspended ceiling per 1 m2, when using PVC or mineral fiber cladding, is 2.75 kg, metal panels are tightened up to 6 kg.

The weight of 1 m2 of Armstrong ceiling with panels in a vintage design, for example, made of mineral glass, can reach 11 kg. Decorative panels always come complete with a supporting profile. The edge of the slab must match the shape of the supporting shelf, otherwise it will be impossible to lay the material on the frame.

Of the most popular models, Stepped, Tegular, Square, the latter is most often used for making Armstrong ceilings yourself due to its simple installation scheme.

General information

The suspension system is designed for a distributed load of 4.5. 15.0 kg/m2 depending on model. It is necessary to take into account the load of the layer of insulating materials applied on top (if necessary). . The minimum distance of the frame from the base - the height of the suspension - must be at least 120 mm to ensure that the slabs can be dismantled during operation.

Armstrong ceiling guide system

The main guides are laid on the frame first. They are hung on hangers and at the same time leveled in height in order to form the plane of the future ceiling.

Main profile for suspended ceiling Armstrong

The frame or steel sheathing for decorative slabs is assembled from two types of steel slats, T32 and T38. The main profile differs from the longitudinal one in the presence of slots for inserting cross members and a higher height of the upper edge.

The standard length of the material is 300 cm, but the presence of petals makes it easy to splice the purlins into one without the use of additional fasteners.

The main profiles are installed first; after leveling the height, the cross members and longitudinal strips are installed. As a result, it turns out that the weight of the Armstrong ceiling is transmitted through the main slats and hangers, and the longitudinal profiles and cross members serve only to form cells for laying decorative panels.

Assembly diagram of longitudinal and load-bearing profiles

Cross profile for Armstrong ceiling

The transverse profile of the device is similar to the longitudinal one. The only difference is in length; if the latter is a 120 cm long bar, then the crossbar is a 60 cm segment.

Both profiles have petal locks at the ends, so during installation you must follow a certain installation sequence.

Requirements for work

Installation of slabs should be carried out only after completion of all construction and installation work, including all “wet” processes, as well as installation of floors and glazing of windows. The heating system must operate so that the room temperature can be maintained within the range of 15 – 30°C. Relative air humidity should not exceed 70%, if the material allows, then 90%. Installation of massive lamps, air conditioners, etc. should be carried out by hanging them on independent supporting structures. In the case of laying an additional layer of heat or sound insulating material on top of the slabs or installing built-in lamps, the number of pendants should be increased in proportion to the increase in the weight of the ceiling.

Suspension for false ceiling Armstrong

The frame can be installed on several types of hanging devices. The main characteristics are shown in the table below.

For small-sized ceiling structures, wire fasteners AP1 are most often used, consisting of two spokes and an adjusting bracket. In terms of adjustment accuracy, it is inferior to models with threaded adjustment, but is noticeably easier to install and operate.

Four main types of suspension

The minimum mounting height is 15 cm, the maximum is 60 cm. Unlike threaded rods, wire models do not sour and can be easily dismantled and reused.

Scheme of fastening on threaded rods

Anchor hook for Armstrong ceiling frame

The system for attaching the suspension to the rough ceiling is a split tube with a radial hole and a jumper for a loop on the upper spoke of the suspension. To install an anchor, simply drill a hole in the concrete and hammer in the fasteners.

The anchor can be installed on the ceiling even at an angle

When installed correctly, the anchor can withstand a load of up to 20 kg; with a total number of hangers per meter of up to 4 pieces, almost one and a half load safety margin is provided.

Additional elements of Armstrong suspended ceiling

In addition to the main elements, auxiliary and decorative parts are used in the design. These include:

- Plastic linings covering the joints along the perimeter of the walls;

- Embedded corners for fixing electrical wiring, lamps and panel lighting elements;

- Inserts for lighting devices of non-standard shape and configuration.

In addition, to fasten the panels, a number of additional springs, anchors and clips are used, with the help of which it is necessary to strengthen trim panels of non-standard width.