A steel bathtub is the cheapest option; if properly installed and additionally processed, its performance is in no way inferior to more expensive analogues. The main advantage of heavy cast iron bathtubs is that heat is retained for a long time. But in order to heat cast iron, you need a lot of hot water, and this is associated with additional losses of thermal energy. In addition, during water procedures, the water still cools down; heat escapes through a large area of unprotected surfaces. There is a simple way to eliminate this drawback; if desired, the performance characteristics of an ordinary steel bathtub can be brought to high standards.

Steel bath

Steel bath 180x80 cm

What to look for when choosing a steel bathtub

An important point: the correct choice simplifies installation and increases the comfort of use.

By what criteria are bathtubs classified?

| Parameter | Meaning and tips for choosing |

Linear dimensions, cm | 105x70, 120x70, 130x70, 140x70, 150x70, 160x70, 170x70, 170x75, 180x80. Choose the length and width of the bath taking into account the size of the room and the height of the residents. Try to ensure that the product is adjacent to the opposite walls as closely as possible, this will greatly simplify the installation process. |

Volume, l | 110, 120, 123, 136, 150, 170, 195, 210, 240. Volume directly depends on depth, and this parameter affects the height of the edge. If elderly people or children live in the house, then you should not buy a large bathtub; it is difficult to get in and out of. In addition, a large volume will require significant losses of hot water. But, on the other hand, the more water, the longer the comfortable temperature remains. |

Type of fastening of standard legs | On bolts or double-sided tape. The first option is used by serious manufacturers; bolt-on mounting is more reliable and in most cases does not require additional reinforcement or installation on bricks. Legs with tape are a budget option and are not stable. The legs can help level the bathtub horizontally; to increase the reliability of fixation, installation on brick linings is recommended. |

Internal surface coating | All steel bathtubs are covered with enamel. But the quality of the coating is different. Domestic manufacturers cover the worst. Insufficient enamel thickness and poor quality of the composition in terms of physical strength reduce the service life. As a result, there is a need to restore the enamel (long and unreliable) or replace it. |

Choose the size of the bath responsibly, taking into account the characteristics of the residents and the room. Poor quality enamel can be recognized by several signs.

- Run your hand over the surface. The surface must be perfectly smooth. Roughness or “sea waves” indicate a violation of the annealing conditions. Such a coating will quickly get dirty and requires constant cleaning.

- Inspect the coating from different angles. If the standard thickness is not observed, then in some places the shade of white changes.

- Pay attention to the area of the bottom near the drain. There are cases when the drain is in the same plane or protrudes slightly above the surface. In this bath, the water will not drain completely; a small amount will always remain near the drain. After drying, calcium is deposited in these places, and over time it acquires a yellow tint.

Practical advice. Steel bathtubs belong to the segment of inexpensive products; there is no need to buy the cheapest ones. Additional savings will ultimately bring losses; purchase products only from well-known, time-tested manufacturers with numerous customers.

The best manufacturers of steel bathtubs

Kaldewei Asymmetric Duo steel bathtub

Bathtub Roca “Swing Plus”

steel bath

Install mortgages

If the bathtub comes with a factory-installed screen, then the design already includes all the necessary fasteners. If not, you will have to install embedded parts into the front side, to which the screen frame is then attached.

YouTube channel “Ruslan Viktorovich”

To do this, you need to cut a piece of a wooden block and glue it to the inside of the side with silicone sealant or polyurethane foam. If the bowl is adjacent not to three walls, but to only two, another block should be secured to one of the free sides.

Some acrylic bathtubs already have ready-made embeds in the form of pieces of timber along the perimeter of the sides. If you see such pieces of wood, it means you can do without additional inserts.

Preparing the site

The location where the bathroom is installed should already have sewer and water pipes. Check the levelness of the floor and the corners of the room. If the angle between the walls is not 90°, then this disadvantage must be taken into account when installing the bathtub.

The floor covering must be horizontal.

How to evaluate the flatness and horizontality of a floor

Of course, with the help of legs or bricks, the bathtub will be installed level, but problems may arise with water drainage during leaks. The fact is that it is difficult to detect small leaks under the bathtub, all elements are closed. If water accumulates near the wall and the leaks are insignificant, then fungus will certainly appear in this place. Getting rid of it is difficult, time-consuming and expensive. In some cases, you will have to completely dismantle the bathtub, do a set of special measures and reinstall the bathtub. Minor leaks can appear for various reasons; their absence cannot be completely guaranteed. If water flows towards the screen, then the problem is immediately visible, the causes are promptly eliminated and the negative consequences are minimal.

Leaks in the bathroom can have negative consequences

Some “pre-installation” rules

You can begin installing a steel bathtub yourself only after completing the floor installation work. By this time, waterproofing should be completed, the floor level should be leveled and the floor covering should be laid.

In old houses, the floor in the bathroom was made with a slope of 1-2% from the door, referring to the current Construction Norms and Regulations, according to which the direction of the slope was placed in such a way that wastewater, when discharged into channels, did not cross the passages.

Modern current standards only require the presence of a threshold between the bathroom and the corridor, which must be at least 2 cm. Such an obstacle with a room area of 3-4 square meters can hold up to 50 liters of water.

Ideally, it is still better to arrange the floor in the bathroom, providing a uniform level difference, which is 2 mm for every meter of length

Before installing a steel bathtub, it is necessary to check the condition of the sewer system. By detecting and correcting problems, you will prevent yourself from troubles after installation is completed, which can only be eliminated by dismantling the system.

The structure must be placed in such a way that it can easily connect to all necessary communications.

Rectangular steel bathtubs are most often installed on stands included in the product package, the material for their manufacture is galvanized steel, which has increased resistance to moisture.

Models of non-standard curved shape require more reliable fixation, the role of which can be fulfilled by the included supports and an additionally constructed frame.

Installation of siphon and overflow

These elements must be installed before installing the bathtub in place. In terms of their design and connection technology, all systems are the same, the only difference is in price and material of manufacture.

Step 1: Turn the bathtub upside down. To protect the enamel from mechanical damage when tipping over, place cardboard or soft cloth on the floor. Do not do such work yourself, call an assistant. Together, the process not only speeds up significantly, but also the quality of installation improves.

Step 2. Read the assembly instructions and check that the siphon is complete. Pay attention to the gaskets, they differ in appearance and size. Do not mix up the gaskets; each must be installed in its place.

Instructions for assembling the siphon on the package

Step 3. Assemble the siphon and secure it in the drain hole. Do not use too much force to avoid damaging the seals and gaskets. To make assembly easier, it is recommended to use petroleum jelly or moisten the surfaces with soapy water.

You need to put a nut and a cone gasket on the siphon elbow

We connect two elbows with a nut

Place the gasket in the plug cover

Screw on the plug

Place a pad on the side of the knee

Screw on the neck (the part that will be located under the drain hole)

We put a union nut and a cone gasket on the corrugation, connect the corrugation and the siphon

Siphon with corrugation

The upper part is attached inside the bathtub, the lower part is mounted under the bathtub drain hole

We use corrugation to connect the upper and lower overflow holes

Important. The drain gasket has a groove dividing it into parts of unequal thickness. The thin side should go inside the bathtub, the thick side should be on the back side. Don't change your position. Otherwise, the plastic element will protrude above the surface of the bathtub and the water will not be able to drain completely. The remaining part, after drying, forms yellow spots on the bottom; they will have to be removed frequently. All cleaning products contain compounds that have a negative effect on enamel. Even though their concentration is insignificant, with repeated use the thickness of the enamel decreases.

Step 4. Turn the bathtub on its side, install the gaskets one by one and screw on the plastic parts of the drain and overflow. It's much easier to do this together. One should hold the parts, and the second should tighten them with a mounting bolt. Do not apply too much force, the plastic may crack.

Siphon assembly

Check the connections for tightness. It is better to do this before installing the bathtub in place, this will make it easier to eliminate leaks. Everything is fine - you can install the legs.

Install the legs

The first step is to attach the legs, which are usually included in the kit. To do this, turn the bathtub upside down without removing the packaging from the sides, and assemble the brackets according to the instructions. Depending on the material of the bathtub, the legs and their fastenings differ.

Acrylic bath

YouTube channel Cersanit Romania

These bathtubs have a special reinforcement insert made of plywood in the lower part, onto which the mounting plates are attached with screws, and the threaded rods of the legs are screwed to them.

You need to mark the mounting points in accordance with the instructions, then drill holes for the screws to the specified depth and tighten them with a screwdriver. To avoid making holes in the bathtub, use only the supplied self-tapping screws that have the calculated length.

Steel bath

YouTube channel “Alexander Cherepitsa”

Steel analogues are equipped with a pair of support-lodgments, which are glued with double-sided tape and pressed down with the weight of the bathtub. Another fastening option is four separate legs, fixed with special hooks on the bottom.

YouTube channel “Ruslan Viktorovich”

In the first case, it is necessary to degrease the surface with white spirit or another solvent and stick the supports. In the second, put the legs on the hooks and tighten them together with studs and nuts.

Cast iron bath

YouTube channel Craftstroy

Cast iron bowls also have four separate legs, which are attached to protrusions specially cast on the bottom with holes for bolts.

To install, you need to align the legs with the protrusions, secure them with bolts and nuts and tighten them with a wrench.

Warming the bowl

A very significant point, it makes it possible to significantly reduce the consumption of warm water, which is important given modern prices for utilities. After insulating the bowl, the bathtub’s heat saving performance is significantly superior to all commercially available expensive analogues. In addition, it does not add weight and perfectly dampens unpleasant sounds when filling with water.

How is the bowl insulated?

Step 1. Work must be done in an overturned position. Recommended immediately after installing the siphon with overflow and legs. Buy two or three cans of polyurethane foam. The cheaper the better. The fact is that cheap foam during hardening significantly increases in volume, and this is exactly what we need. More volume means more air bubbles, less heat loss. And the low price is explained by the low compression force; this parameter does not play any role in our case.

Steel bathtub turned upside down

Step 2: Clean the outside of the tub. If there is grease on it, you will have to wash it off with solvents. Working with solvents is unsafe for health; ensure maximum ventilation of the room. It is better to work outdoors rather than indoors. Be sure to use respiratory protection.

Step 3. After the solvent has completely dried, moisten the surface of the bottom with a spray bottle. Moisture increases the adhesion coefficient of foam to the bottom by an order of magnitude. In addition, water promotes optimal chemical reactions and the foam will harden much faster.

Step 4. Shake the foam canister thoroughly and put on a special plastic tube. Start covering the bottom with foam. The process will go faster if you apply it in sectors from bottom to top. The foam should lie in even rows at a distance of no more than a centimeter. Wider rows are not a problem; after hardening, the gaps will correct themselves. If the surface dries out, re-wet it with a sprayer. Do not touch the wet foam with your hands, do not try to “stick” it to the surface. You won't get anything other than additional problems. The foam will no longer increase in volume, and it is almost impossible to wash your hands. You will have to scrape it off for a long time and tediously with a knife.

Foam application

Applied foam

Step 5. Wait until the foam hardens, check the uniformity of the coating, and blow out any gaps.

Practical advice. If the foam falls off from vertical surfaces, then turn the bathtub in different directions and finish only the horizontal ones. It will take longer to work, but the result is worth it.

Step 6. Cut off the excess foam near the edge of the bathtub, it should not interfere with making the frame for the screen. The distance depends on the type and method of installation of the screen.

This completes the preparatory work for installation. The bathtub has a siphon, legs and insulation.

Selection of necessary materials

It is impossible to install and connect a steel bathtub to communications without installing a siphon. There are semi-automatic models on sale, equipped with a special washer, with which the water can be drained without “diving” with your hand: the plug itself rises and the water drains.

Semi-automatic siphons are much more expensive than conventional models, and the cost of purchasing them is justified when installing large-capacity baths

Some siphons are equipped with metal outlets that are attached to the overflow with a bolt. They are famous for their more aesthetic appearance compared to their plastic counterparts.

But low-quality products with frequent interaction with water can quickly become covered with rust. Fastening elements made of material susceptible to corrosion, after a couple of years of operation, are able to “stick” to each other so that, if necessary, it will be almost impossible to unscrew them.

The following materials must also be prepared:

- polyurethane foam;

- electrical tape;

- silicone sealant;

- waterproof paint.

Regarding the overflow pipe: it is better to use a corrugated flexible hose. If we compare the internal size of a corrugated hose with the lumen diameter of a rigid pipe, then this parameter will be larger with the same outer diameter. This seemingly small thing can reduce the likelihood of overflowing.

To carry out the work you will need the following tools:

- rule;

- building level;

- electric drill;

- fork key;

- electric welding machine.

Installing a bathtub on bricks

This installation completely eliminates the bathtub from swaying and tipping over; we strongly recommend using it.

Instructions for installing a bathtub on bricks

Step 1. Place the clawfoot bathtub in the desired location, mark their location, and draw horizontal lines. Bricks or blocks will be laid along these lines. The bathtub is pre-adjustable in height and inclination using leg bolts.

Step 2. Measure the distance from the bottom to the floor, prepare the required number of bricks. If necessary, use a mason's hammer to chop off the excess parts to the required height.

Distance from bottom to floor

It is necessary to mark the location of the bath

Step 3. Prepare a cement-sand mortar. For one part of cement, add about three parts of sand, water as needed.

Step 4: Lay two rows of bricks where the tub will be supported. Place about two more centimeters of solution on top. The solution should hold its shape and not spread over the surface of the bricks. If necessary, add a little sand and cement to it, mix thoroughly.

We recommend attaching a block to the wall, which will additionally hold one edge of the bathtub

We place spacers under the bath so that the bowl takes its position, but does not stand with its bottom on the floor

Laying bricks

Step 5. Carefully lower the bath vertically into place until it stops with the solution. Now, with a little effort, rock and press it until your legs touch the floor, repeat these actions on both sides. Take your time, let the bath gradually take its place and squeeze out the excess solution. Once the feet (if any) touch the floor, the installation is complete. Give the solution time to harden (about a day) and continue installing the bathtub.

Bath on bricks

Polyurethane foam

Installation of the structure using polyurethane foam

This is the easiest way to secure a steel bathtub so that it does not swing. The only disadvantage is the high consumption of polyurethane foam:

- The bowl is first placed on its legs, leaving a gap of one centimeter against the wall.

- Connect the drain.

- Fill a bowl with water.

- Fill the space between the bottom and the floor with polyurethane foam, taking into account that the composition gradually expands upon contact with air.

Be sure to leave access to the siphon.

Bath screens

Using screens, communications are hidden; it is possible to make shelves for storing various household items. In addition, they significantly improve the interior of the room. The screen can be brick with further cladding with ceramic tiles, MDF, plastic panels, plasterboard, OSB or in the form of an ordinary curtain made of thick fabric. We'll tell you how to do each option in turn.

Tiled bath screen

The photo shows a sliding screen for a bathtub with adjustable legs

Functional bath screen

The structures must provide convenient access to the siphon for periodic routine cleaning of the system. It is advisable to have an opening for the feet only if the bathroom is used for washing. As an option - a country house for temporary residence. It is unprofitable and dangerous to install an expensive washing machine in it; summer residents, out of old habit, use the bathtub to wash clothes.

What types of frames are there for installing screens?

Any type of screen, except brick, is mounted on a frame. They are made from metal profiles (the best option), wooden slats or square pipes. The latter option is very expensive and labor-intensive, and has no operational advantages. Why do you need a frame that can withstand a load of hundreds of kilograms, if it actually does not exceed a few? We believe that there is no point in considering it. The manufacture of the structure must be approached very carefully; in any case, a crooked structure will have to be redone.

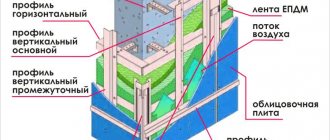

How to make a frame from metal profiles?

Step 1 : Count the number of profiles.

They need three vertical baths in height, two horizontal in length and two horizontal in the width of the bath. To strengthen the structure, use jumpers; you need to make a separate small frame for the door. Three jumpers in length are enough; in width you can do without them. Knowing the dimensions of your bathtub, it is easy to find out the total amount of material. Immediately buy self-tapping screws for attaching profiles.

Step 2. Make markings.

This is a very important stage, don’t rush, check the measurements several times. To increase accuracy, use a plumb line; the level does not indicate vertical planes accurately.

How to make markup?

- Apply the plumb line to the wall and corner of the bathtub, wait until it calms down. Make a mark of the upper and lower position of the thread, draw a line between the marks. Using the same algorithm, draw a vertical line at all free corners of the bathtub; there can be two or three of them depending on the size of the bathtub and the room. This way the junction of the screen with the walls is indicated.

- At a distance of about 3-4 centimeters, draw parallel lines next to them outside the perimeter of the bath. The specific distance depends on the frame material and finishing materials: plasterboard, OSB, MDF or glue and ceramic tiles.

- Draw the same parallel lines on the bathroom floor. Check all dimensions again to avoid mistakes.

Further work depends on the material used to make the frame. The best option is a metal profile, but you can also work with wooden slats.

Metal profile frame

Step 1. Cut the metal profile to size, we have already described how to determine them above. Don’t work on jumpers yet; make blanks only around the perimeter of the frame.

Step 2. Lay the long profile on the floor, one side should be exactly adjacent to the marked line. Carefully use a marker to mark the locations for drilling holes for the dowels. It's not good to work with a pencil, use a marker.

Laying metal profiles

Step 3. Remove the profile, drill holes with a drill, put the profile in place and fix it. Do not immediately tighten the dowels; the strips have perforated holes, with the help of which the element can be slightly moved in different directions and achieved an exact position.

Step 4 . Now fix the planks to the walls. The algorithm of actions is the same. If you plan to use a heavy OSB board for cladding, then the vertical and horizontal profiles at the corners are connected to each other with hardware.

Step 5. Fasten the profiles along the length and width close to the top side of the bathroom, you should have a strong frame. If necessary, make additional jumpers to strengthen the structure. They can have a vertical or horizontal position.

Profile racks

Step 6. Decide on the size of the door for the siphon inspection, make a small frame for it in the right place. Constantly check the position of all frame elements with a level. The door dimensions are at least 30 cm around the perimeter, otherwise it is inconvenient to clean the siphon.

The frame is ready, check its stability, apply multidirectional efforts from all sides. The structure is wobbly - add jumpers in problem areas, achieve high stability.

Screen covered with plasterboard

Bath after tiling

Frame made of wooden blocks

In terms of its performance, it is in no way inferior to metal profiles. Do not be afraid that rot will appear on the tree. If there are any concerns, soak it with antiseptics.

For the frame you can use slats of various sizes. When choosing, take into account the load of the finishing sheathing. A universal option can be considered to be the dimensions of the slats five by five centimeters. Make markings on the floor and wall as always. One feature - take into account the width of the slats; they should fit under the side shelves of the bathtub and not interfere with the finishing. To fix the frame, use metal corners and dowels; the width of the corners is slightly less than the width of the slats. This will make it possible to adjust the position of the frame without fear. In addition, possible errors when drilling holes for dowels can be easily corrected.

Step 1 . Place a long block on the floor and estimate the position of the corners. Make marks for drilling holes for dowels.

Practical advice. In order to completely eliminate the possibility of the corner going beyond the line, it is better to move it slightly inward. It’s not scary that it will be screwed to the block off-center, but nothing will interfere with the finishing.

Step 2. Drill holes, secure the corners with dowels and the block to them with self-tapping screws. Adjust its position. Install the short block in the same way.

Step 3. Measure the height of the vertical elements. Make a gap of approximately 1 cm to the bottom of the sides of the bathtub. Using corners, fasten the segments into a single structure with the bottom one.

Installing racks under the bathtub

Step 4. Prepare two more long and two short ones for fixing in the upper part of the frame. Why two and not one? We recommend installing the first one at a distance of approximately 10 cm from the side; these bars are needed to control the size and verticality of the frame. On an already stable structure, it is recommended to fix one more one close to the side. It’s much easier to do this, and the frame is more accurate. In addition, the strength of the structure increases.

Step 5. Make a frame for the door in the right places; if heavy materials will be used, then install several jumpers. To increase strength, you can fix several spacers in the corners.

The frame is ready, you can begin the finishing cladding, fastening is carried out with wood screws.

Brick screens

In terms of time, they do not take much time, and in terms of strength, reliability and durability they are much superior to the previously described options. Prepare materials and tools. You can use bricks or concrete blocks. The quantity is calculated in this way.

- Calculate the side and end area of the space near the bathtub that you are going to cover.

- Divide the resulting amount by the area of one brick or block. Round the quantity to a whole number. For reserve, you can take one block or two bricks.

One bath will require two buckets of sand and a third of a bucket of cement. In the future, the surface needs to be finished with ceramic tiles; we will give a step-by-step design in the next section.

Step 1. Place the first row of bricks on the edge, constantly checking its position with a level. You need to know that masonry on an edge has its own characteristics; if they are not followed, the wall may “float”. First feature. The solution should be slightly thicker than when laying flat. To increase the adhesion of the mortar to the side edge of the brick, it should be moistened with a spray bottle. Do not overdo it. The optimal degree of wetting will be determined practically. Second feature. After three rows you need to give the solution time to harden a little. Take a break for two or three hours.

The bricks are laid in a checkerboard pattern, the joints of the lower row are covered with whole bricks of the upper one.

Step 2. Continue working until the entire space is covered. It will be difficult to push the mortar into the gap between the masonry and the sides. It is advisable to make such an emphasis, it significantly increases the strength of the bathtub installation. Use any small means at hand for these purposes; such work cannot be done with a trowel.

Masonry brick screen

Important. Don't forget to leave a hole for siphon inspection. Check the structure, remove any remaining mortar that has emerged. Give it time to harden at least 24 hours.

Ceramic tile finishing

If the wall already has tiles, then the work becomes somewhat more complicated. The fact is that you need to take measures to match the seam between the tiles on the wall and the screen. There are situations when it is impossible to lay a whole tile, you have to cut it into pieces. If you have no practical experience in cutting tiles, use plastic inserts. They can even out jambs up to a centimeter, but the appearance, of course, will suffer a little. Real professionals do not use inserts for joints; their cuts fit tightly to surfaces without gaps.

Step 1. Count the number of tiles, the method is the same as for bricks. And you can buy one or two tiles as a spare; you won’t need any more, the surface area to be finished is very small. You need to buy about 10 kg of glue.

Step 2. Start laying tiles from the bottom row. Check the position with a level or a level lath, and check several tiles at the same time. They must lie strictly in the same plane.

Applying adhesive to tiles

Step 3. The tile is placed on an uneven surface; it is impossible to use a comb. Apply the glue with a spatula along the edges and in the center of the tile, about one centimeter thick. Next, the tile must be pressed and moved left and right until the position is leveled. The final adjustment is made with a level. Don't forget to use crosses. Some beginners install crosses flat on the four corners of the joint. This should not be done for several reasons. Firstly, it is much more difficult to level the tile; the cross will constantly move the nearby one. Secondly, there will be problems with removing the cross; you will have to pick out each one with a knife.

Gluing tiles

Step 4. No experience - use plastic elements in corners and joints, they make the work much easier.

Step 5 . After about two hours, you can start grouting the joints. The color of the material should be in harmony with the tiles and the overall design of the room. Excess grout is removed with a damp cloth or sponge. Do not wait until it is completely dry; dry material is difficult to clean.

Finishing with OSB boards or plasterboard

The boards must be moisture resistant. We recommend using more durable OSB boards; plasterboard boards are easier to work with, but in terms of load resistance they are far from ideal. Under force they begin to sag and the ceramic tiles fall off.

Finishing with slabs is much simpler than laying ceramic tiles. How is it done?

Step 1. Take the frame dimensions and mark the slab. As a rule, the length of the bathtub exceeds the length of the slab; it will have to be joined. This possibility must be foreseen during the manufacture of the frame and a vertical stand must be installed at the joining point.

Cut off all the blanks. Drywall is easily cut with a mounting knife; for OSB you will need a hand-held electric saw or jigsaw.

Step 2 . Fix the elements one by one with self-tapping screws, and work carefully with the drywall. When the self-tapping screws are tightened with great force, their heads fall inside the plaster, and new ones have to be screwed in.

Fastening drywall

Step 3. Screw small hinges where the door is installed. Check the functionality of the door.

Covering the frame with plasterboard

Inspection hatch door installed

Step 4. Proceed to finishing the surfaces. You can use ceramic tiles - it takes a long time and is expensive. There is a simpler option - cover the surfaces with self-adhesive decorative film; today there is a huge selection on sale - cheap and beautiful. In addition, you can easily change the pattern or repair the coating in case of mechanical damage. But the film also has a drawback - the surface must be perfectly flat.

Practical advice. Do not try to immediately glue the film without air pockets, it is almost impossible to do. Removing air is simple - pierce the pocket in several places with a needle and remove the air by smoothing the pocket.

Plastic lining

The option is not the best. It is recommended to use if the bathroom walls are lined with clapboard. The installation process is standard. The problem arises with the technological hole and the door. Practitioners recommend making them from OSB from plasterboard and not wasting time on lining.

DIY bath screen made of PVC panels

How to make sliding doors

A very simple and functional screen option. For manufacturing you will need two guides and an MDF board. The disadvantage of this material is that there is a possibility of spontaneous deformation. You can get rid of it only by making a separate small frame for the doors. It is advisable to use thin wooden slats; MDF is glued to them with special glue.

Step 1. Make a frame from a metal profile; we have described the algorithm for making such structures. Check the position of all elements.

Important. For a sliding screen, it is especially important to maintain the parameters; the racks must be strictly vertical.

Step 2. Attach the guides to the frame. They can be aluminum or plastic.

Plastic guides

Top guide

Step 3. Measure the exact distance between the guides; the spread in parallelism cannot exceed 1–2 mm. Otherwise, the doors will jam when opening/closing.

Step 4. Cut out the doors of the required size from the MDF board. For overlap, 2–3 cm is enough. You can cut the slab with an electric jigsaw or a hacksaw. Work carefully, place emphasis on the bottom - this will reduce the hairiness of the cut.

Step 5: Bevel the cut. Use sandpaper or a cylindrical sander. Install handles.

Plastic homemade screen doors

Step 6 . Install the doors into the guides. To do this, they need to be inserted into the lower guide, slightly bent and inserted into the upper guide. The thickness of MDF is approximately 5 mm.

Sliding screen

A guide profile is fixed to the floor. The cutout in the door is made to lead out the hoses from the washing machine.

The front surface can be finished in any way, taking into account the interior of the bathroom.

Below is how to make a screen for a bathtub with your own hands.

Durable fabric curtain

The simplest, cheapest and fastest option. The curtains can move along a wire or a thin tube. Material: durable fabric. You can use roller shutter fabric, it does not fade throughout the entire period of use, keeps its shape and is not afraid of moisture.

DIY bath curtain

Bath curtain

Make thermal insulation

Acrylic and cast iron bathtubs retain heat well and do not require a layer of thermal insulation. Steel ones, on the contrary, cool quickly and are also very noisy when drawing water. Therefore, before installation, polyurethane foam, spray insulation or automotive sound insulation is applied to the bottom and walls of such bathtubs.

YouTube channel “Ruslan Viktorovich”

To do this, turn the bathtub over, wipe it with a damp cloth and cover it with foam, moving like a snake from bottom to top. The average consumption per bowl is 2–3 cylinders. The foam hardening time is 3–4 hours. After this, you can install the bath.

YouTube channel Valiev Andrey DIY

Sometimes, before applying insulation, the bathtub is pre-pasted with automotive sound insulation. The surface is degreased with a solvent, then the protective film is removed from the adhesive base of the sheets. After heating with a hairdryer, the sound insulation is glued to the bottom and walls of the bathtub, and then rolled with a roller.

Sealing the joint between the bathtub and the wall

A very important point that requires a careful approach. Sealing joints can be done in several ways.

Silicone . It is used in cases where the size of the gap between the side and the bathtub does not exceed 2–3 mm. Silicone should be taken in white color and applied in several stages. Try to fill the gap as much as possible, remove excess with your finger. Once the first layer has hardened, apply the second. And so on until you reach the bathtub level. Next, make a finishing layer and level its surface.

Applying sealant

Sealing a bathtub with a wall

Practical advice. The process will be much easier if, while installing the bathtub, the surface of the rim adjacent to the wall is generously lubricated with silicone. Press the bathtub against the wall and carefully remove the excess. If necessary, apply a finishing layer of silicone.

The method is simple and cheap, but you need to be prepared that after a few years the silicone will peel off from the surfaces and the procedure will have to be repeated.

Cement sealant. A more successful and durable way. There is no need to be afraid that it will crack as a result of the difference in thermal expansion coefficients. This is all theory, but practice shows that no cracks appear. But such a sealant lasts for many years and completely prevents the penetration of moisture into the confined space between the bathtub and the wall.

If the gap is large, the sealant will fall into it. There are several ways to fix the problem, but it is best to use polyurethane foam. Wet the surfaces and apply foam to them, after hardening, use the sharp end of a mounting knife to cut off the protruding part of the foam and make a groove up to 1 cm deep. Fill the recess with sealant, carefully align the upper part at an angle of 45°. For leveling, use any available devices of suitable sizes. In most cases, the handle of a spoon or fork does the job perfectly.

Cement sealant

There is another way. It is the most reliable, but also the most labor-intensive. It is advisable to use it before covering the walls; if they are already finished, then the work becomes somewhat more complicated.

Step 1: Remove the row of ceramic tiles that are level with the tub rim. If it breaks, there's nothing to worry about. Put a new one in its place and make a pattern around the bathtub, this will only improve the appearance.

Step 2. On the wall, draw a line for the position of the upper plane of the side of the bathtub, at a distance of about 2 cm, draw another line. It indicates the position of the protruding side part of the side.

Step 3 . Make a groove in the wall along lines approximately 1 cm deep.

Step 4. Apply sealant to the ends of the rim and place the bathtub in place. The edges should fit slightly into the groove; remove excess sealant.

Connecting the bathtub to the wall

Step 5. Lay ceramic tiles around the perimeter.

The tiles were laid, decorative ceramic plinth was used to match the tiles

This method completely guarantees the tightness of the junction; water will never get behind the bathtub.

Use any method that does not present difficulties for you. If the technology is not violated, then the tightness of the junction of the bathtub with the wall will be sufficient. Find out about the shower drain by following the link.

Tools

First you need to prepare your tools. For comfortable work you will need:

- level - for setting the horizon line;

- roulette;

- construction marker - for marking;

- a set of wrenches - for adjusting the legs;

- corner - for inspection of right angles;

- hammer drill - for drilling holes in the wall;

- screwdriver or screwdriver .

Strengthening options

But the adjusted position of the supports does not always give the optimal result. Stability may be questionable, so additional stabilization of all components of the structure is used. There are several options for strengthening the legs of a bathtub using a variety of technologies. Typically, additional supporting structures - frames - are used to fix the position. The best option is metal versions of products. But you can make a structure from brick, gas block, or wooden beams.

Selecting suitable drain fittings

When choosing drain fittings, it’s no wonder how wide the range of products offered on the market is.

But really, what characteristics should you pay close attention to when purchasing, and what can you ignore?

Reinforcement material

The building materials market offers us two types of materials: PVC (polyvinyl chloride) and polyisopropylene. We come across PVC more often, that’s why we choose it.

But relatively expensive polyisopropylene is not only stronger than polyvinyl chloride, but also has a whole list of indisputable advantages, these are:

- Hardness. This material is significantly harder than its competitor, which reduces the likelihood of mechanical damage during bath installation.

- Durability. Its strength characteristics do not decrease over time.

- Surface quality. The surface of this material is smoother than PVC, which means that dirt sticks to it less.

The efficiency factor is also extremely important. The efficiency of polyisopropylene is higher than that of PVC, since the friction of water against the walls of smooth pipes made of this material is much less.

Qualities of drain elements

Most of the plums you see for sale are made in China. During their installation, a bolt is used. Regardless of what material it is made of, over time this bolt will oxidize, rust, or otherwise corrode.

You can buy a stainless steel bolt separately, but its contact with the mesh will certainly form a solder, which will significantly reduce the repairability of the product.

The industry offers drain fittings for bathtubs in two versions: made of PVC (polyvinyl chloride) or PP (polypropylene). If you are interested in the longevity and reliability of the device, it is better to prefer polypropylene as a material that is more resistant to household chemicals

When buying drain fittings, do not hesitate to check its contents and make sure that all the elements stated in the passport are present:

- Drain mesh. The most economical of all commercially available nets is a model that consists of two intersecting crossbars. It perfectly traps hair, preventing clogging. The most practical option is considered to be one with round holes located around the perimeter of the product. The most reliable is a mesh that has profiled oblique holes. However, this is also the most expensive model.

- Cork chain. It would seem that the chain is a detail that is not of significant importance. But that's not true. Usually we use the chain that we come across as part of the kit. It is not advisable to do this. Buy separately the one that fishermen use. Its surface is covered with protective paint, which prevents water from spoiling its appearance over time.

- Overflow pipe. In older bathtub models, the overflow pipe is made of metal, but modern production offers a better option. Use a corrugated pipe that has a large diameter, and, therefore, throughput. The high capacity of the pipe significantly reduces the risk of water overflow.

There are some installation nuances that are worth considering. For example, if the outlet valve of the drain fitting is wide enough, you can make the connection without using a collar. The resulting gap is simply filled with silicone-based sealant or silicone itself.

If you need something special...

Not all purchases come fully equipped with everything you need. In some cases, there is a desire or need to choose a different font mounting system, without using the provided add-on. On the website akvasan-shop.ru you can select any types of supporting structures of different types. You can find decorative types with designer shapes and colors. A huge selection of installation kits and fasteners will be a pleasant bonus. Preparation and planning With high-quality fastening of the supporting foundations, there is an exact guarantee of successful installation of plumbing equipment. It is difficult to evenly fix an already assembled structure if the floor surface is not prepared. What should be done:

- Dismantle the remains of old plumbing. Replace pipes and drains, check taps.

- Remove construction debris. Sweep, wash the floor.

- When the surface is clean, it is advisable to evaluate the evenness of the tiles. There may be a need to reconstruct the tiles if the masonry is too uneven. Sometimes it is enough to move just a few tiles.

Only after such measures have been taken and all possible defects have been eliminated can one count on simplifying the procedure.

Siphon group assembly

Bathroom fittings are purchased separately. They are divided into two groups:

- Prefabricated;

- Whole.

In the first case, the siphon group is assembled on threaded connections from small plastic parts. All bends are rectangular.

In the second case, the siphon is represented by a curved pipe. All its bends are smooth, there are no threaded connections.

A one-piece siphon looks trivial, but it has huge advantages.

- The more threaded connections and parts, the higher the likelihood of leaks;

- Smooth curves do not impede the flow of water, draining occurs faster and the likelihood of deposits and blockages is extremely low;

Besides this, the siphon is not an object for demonstration, and no one will see it except you. Therefore, the objective choice is a siphon with a solid body.

Its assembly involves screwing the overflow system through the cuff.