By understanding the technology for installing a toilet, you can save on plumbing services and get the job done to the highest possible quality. The toilet can be installed in the traditional way or using a more modern method - with installation. In the second case, the cistern will be hidden in the wall, which will have a positive effect on the interior of the room.

DIY toilet installation

You are provided with instructions for completing each of the listed installation options.

Types of toilets

Types of toilets

Drain system

| Types of toilets | H | h | h1 | L | l | l1 | B | b |

| With a solid cast shelf, mm | 370 and 400 | 320 and 350 | 150 | Not less than 605 (by agreement between the consumer and the manufacturer, it is allowed to manufacture toilets with a length of 575 mm) | 330 | 435 | 340 and 360 | 260 |

| Without solid cast shelf, mm | 370 and 400 | 320 and 350 | 150 | 460 | 330 | 435 | 340 and 360 | 260 |

| Children's | 335 | 285 | 130 | 405 | 280 | 380 | 290 | 210 |

Toilet with solid cast shelf

Set for work

- Hammer.

- Roulette.

- Adjustable wrench.

- Fan pipe.

- Flexible hose.

- FUM tape.

- Fasteners.

- Sealant.

In the case of installing a toilet on an installation, the listed list will be expanded with the corresponding set. Everything you need can be purchased at any plumbing store.

Related materials

In addition to a set of tools, before changing the toilet with your own hands, you need to purchase building materials for installation, including:

- pipe for connecting to the water supply system;

- sealant;

- corrugated pipe for connection to the sewer riser;

- tap;

- FUM tape;

- fasteners.

When exchanging a toilet - an old product for a new one - the main point is to ensure a reliable seal. Any loose connection or gap may result in a leak. When connecting a plumbing fixture to a sewer system, the best solution is to use silicone sealant in a cylinder.

Before replacing a toilet in an apartment or house, you should purchase plastic corrugated pipe products to connect it to the pipeline that discharges wastewater. This product is convenient because it is flexible and suitable in most cases. When bending, the corrugation can take different positions, compressing and stretching. It is suitable for both horizontal outlet and angled outlet.

To seal the joints, use sealing tape or do it the old fashioned way, using tow. The set of fastening elements includes screws, bolts, dowels, nuts, washers, plugs for connecting all components and carrying out installation work. If any fasteners are missing, they can be purchased additionally.

Types of connecting elements

If it is impossible to directly connect the toilet to the sewer due to the design features, auxiliary materials are used - connecting pipes. In most cases, the following types are used:

- corrugation;

- eccentric cuffs;

- corners and elbows made of plastic;

- pipes of various materials, but plastic is preferable.

Connecting the toilet to the sewer with corrugated pipes is used if the alignment of the pipes is not maintained. The advantage of this type is the ability to install the product at an arbitrary angle.

The disadvantages of using corrugations to connect the toilet to the sewer include the large minimum length. If the distance between the pipes is about 12 cm, it is better to opt for other connecting components.

Eccentric cuffs outwardly look like 2 bends with shifted centers. Before purchasing the part, it is recommended to measure the offset between the sewer line and the toilet flush.

This data will allow you to choose the most suitable cuff model in the store. The disadvantage of the eccentric part is its short length, which implies the possibility of installation only with a small distance between the nozzles (up to 12 cm).

Bends and corners are installed in cases where the corrugation cannot be used for some reason. Their advantage compared to corrugation is that the wall is smooth on the inside, which significantly reduces the risk of blockages.

The main disadvantage is rigidity, which leads to leakage even with a slight misalignment. Plastic products can be cut to fit, unlike cast iron.

In most cases, steel pipes are used when there is a risk of failure of the water seal mechanism (find out what a water seal for sewerage is, its operating principles, what types there are, etc.). If the throughput of the riser is insufficient, liquid from the siphon will be drawn into it.

As a result, the water seal does not work, and the stench from the sewer enters the room. In such a situation, a pipe product with an automatic valve is connected to the riser or pipe connected to the toilet. When draining, a special valve opens and air enters, which prevents the water seal from breaking.

However, to implement such a function it is not necessary to use steel pipes. There are also eccentrics and adapters that give the pipeline similar properties. To ensure reliable connection, it is recommended to use sealant when using any type of connecting elements.

For these purposes, it is advisable to purchase a special waterproof product intended for plumbing fixtures. By loosening the rubber sealing collar, the sealant will prevent leakage.

Corrugated connection

As a rule, installation of a toilet with direct and oblique outlet is carried out using corrugation. It has an affordable price, can be bent in any direction and used as a temporary connecting element. When purchasing, you should focus on the length from the sewer outlet to the toilet outlet; the corrugation should be a third larger than this value.

What is a toilet flush? This is a drain hole that connects the apartment’s plumbing to the sewer system. There are three varieties - horizontal, vertical and oblique drain outlet.

Brief algorithm of actions:

- Coat the joint with silicone and insert the corrugation with the seal into the hole in the pipeline. It is advisable not to move it until the silicone-based product has completely dried.

- Place the toilet and check its stability. If the product wobbles, it is necessary to level the floor or install special stands.

- Insert the corrugation into the toilet pipe; there is no need to lubricate the connection with anything.

- Pour in a few liters of liquid, wait 1 minute, then make sure there are no leaks. If the connection leaks, you need to disconnect the corrugation, check the correct location of the seals and carefully reinstall it.

- If there are no leaks, you can mark the mounting points of the plumbing fixture with a pencil or marker.

- Secure the product so that it does not swing.

- Connect to sewer.

- After 2 hours, carry out testing by performing several drains. Wait 5 minutes, if the pipe does not leak, you can begin installing the tank and other elements.

- Lubricate the joint with sealant from the outside to prevent future leaks.

If a small leak (a few drops) was detected during the last test, all liquid must be completely removed and the corrugation removed. Then apply silicone again to the elastic band of the product and install it on the toilet pipe.

Find out what you need to do if the toilet tank suddenly starts leaking: 9 reasons why it is leaking and video instructions for repair.

Preparatory work for installation

Regardless of what will cover the floor (tiles or regular screed), you need to wait time for the mixture to dry on the floor surface. This will take about a week. This is due to the fact that the toilet is fixed using fasteners and dowels, which require a reliable and solid base. In this situation, the hardened solution will act as a similar base.

Next, you should prepare those participating in the communication installation process. The area where the drain will be connected must be cleared of various contaminants and salt deposits in advance. Otherwise, it will not be possible to connect the toilet to the sewer riser as needed. That is, the corner or corrugation in the outlet cup will not fit tightly, and a leak will definitely appear.

A tap should also be installed at the connection point of the drain tank so that it is possible to carry out repair and cleaning work without completely turning off the water.

Prepare materials and tools

You will need:

- toilet with tank and fittings;

- fastening kit and flexible hose;

- eccentric cuff or corrugation;

- transition collar 123 × 110 mm (for connection to a cast iron socket);

- gas burner or hair dryer (for disconnecting a cast iron pipe);

- tile adhesive or repair compound (for filling a hole in the floor);

- hammer drill or impact drill;

- concrete drill with a diameter of 8 or 10 mm;

- tile drill 8 or 10 mm;

- a set of wrenches and a hacksaw;

- hammer and dowels;

- tape measure and marker;

- screwdrivers and knife;

- silicone sealant and rags;

- bucket and sponge;

- universal lubricant WD‑40 or equivalent (if necessary).

Dismantling

Unscrew the mounting bolts

Disassembly diagram

With the old Soviet fastening method, you must first remove the bolts. They can be unscrewed or simply broken. Most often, they are no longer susceptible to the influence of the tool, so it is easier to break off the heads. Then you will have to break out the toilet itself. It is very firmly mounted into the sewer pipe, because in those days they made it to last for centuries. Having completed dismantling, you need to clear the work area for installation of a new unit. If the model is relatively new, then you won’t have to break anything. You need to unscrew the bolts, which most likely are not too rusty yet. Next, you need to disconnect the plastic pipe from the sewer system.

The need to replace the toilet

It is not always necessary to change a plumbing fixture if there are malfunctions in the sewer system. If water is constantly leaking from the tank in the bathroom, this is a serious reason to think about it.

When it drips onto the floor, and all the pipe connections are in order, then the cause of the problem is usually a chip or crack. In this situation, it is possible to eliminate the leak only temporarily; the toilet should be replaced as quickly as possible.

If water from the drain tank flows into the sewer along the wall of the bowl, then, most likely, the installation of new plumbing fixtures will not be necessary, since the cause of such a malfunction is most likely a leaky valve. Since all internal elements for flush tanks are sold separately, they only need to be replaced with new products.

Plumbing faience and porcelain are rather fragile materials that are characterized by instability to sudden temperature changes. The enamel can become covered with a network of cracks, spoiling the external aesthetic component of the device and threatening complete destruction of the bowl. If this product develops chips or other problems, the toilet should be replaced as soon as possible.

None of the toilet users can know for sure when the ceramic coating on it will not withstand and will burst under the influence of water currents, the weight of a person or as a result of internal stress. It’s good if the residents are nearby at this moment and one of them can quickly eliminate the emergency situation, otherwise the toilet of the neighbors living on the floor below will need to be repaired.

Another sign of a plumbing problem is the presence of an unpleasant odor. Most often, it is caused by improper installation of the sewer system, as a result of which the drainage stagnates in the pipes. When everything turned out to be in order with the pipeline, and the earthenware is clean, the cause of the smell should be sought in the fact that the glossy coating has begun to deteriorate.

If the integrity of the enamel is damaged and the porous structure of the sanitaryware begins to come into contact with impurities, it begins to absorb unpleasant “odors.” It will not be possible to cope with these odors, since the destruction process is irreversible. In this case, it is impossible to do without replacing the old toilet with a new one.

Another important reason for dismantling old and installing new plumbing is the planned renovation of the bathroom. Few property owners decide to keep the same fixture when changing the design of their bathroom.

Since new, more modern products appear on sale regularly, updating a bathroom with replacing plumbing fixtures can transform its interior beyond recognition. Regardless of whether you choose a classic option or an unusual model from the catalog, the process of how to properly change a toilet occurs in the same sequence.

Installation location

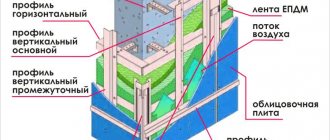

The frame is attached to the main wall or load-bearing partition profiles. The first option is convenient to implement in a spacious bathroom combined with a bathroom.

In addition to free space, the layout of pipelines is taken into account. Studs unscrewed to the maximum, factory extensions - reduce the rigidity of the structure.

For an open-plan apartment, the second method is suitable. In a narrow toilet, the installation of a support frame increases the reliability of fastening, allows you to hide the risers behind drywall, and simplifies tiling.

Typical dimensions are illustrated by the Cersanit drawing:

Installation of the device frame in a niche is possible with the appropriate room configuration. It is allowed to install a niche in the partitions. In small combined rooms, corner placement is advantageous. In order not to come up with designs, they purchase factory corner versions.

Removing part of a load-bearing wall without a reinforcement plan is a gross violation of building codes, fraught with an emergency situation, including destruction! Photos and videos with horizontal grooves and broken pieces of concrete are an example of the technical illiteracy of plumbers and the criminally negligent attitude of residents towards the safety of themselves and their neighbors.

For use and maintenance, inspection hatches, pipeline fittings and meters are located above or to the side of the structure.

Most common mistakes

Before changing the toilet in an apartment or house, you need to carefully study the instructions of the manufacturers of these products. It is almost impossible to avoid mistakes when dismantling and installing plumbing fixtures in the absence of relevant experience.

There are several types of plumbing work, during which novice craftsmen perform incorrect actions. Knowing them will help you avoid unpleasant surprises during installation activities.

To prevent liquid from stagnating in the sewer pipes, it is necessary to maintain a slope when installing the drainage system. According to building codes and regulations, it should be from 3 to 5 percent in the direction of the sewer riser. If the question is being considered not only of how to change the toilet, but also of moving it to another place, this should not be forgotten.

Some property owners rush to replace the toilet at the very beginning of the bathroom renovation. Experts advise avoiding such actions if possible. The fact is that earthenware plumbing is fragile and during further construction work in the room there is a high probability that it will be damaged. Therefore, it is advisable to change the toilet with your own hands as a last resort.

If a bidet is already installed in the bathroom, the hanging bowl should be positioned flush with its top edge. Only in this case the plumbing fixtures look harmonious in the interior of the room and are convenient to use.

When replacing sewer pipes, inspections must be installed. Access to hatches should always be free - you can use aesthetic doors to cover them. This requirement should not be neglected, since in the event of an emergency you will have to use audits.

Replacing an old toilet with a new one without the help of a professional is quite risky, especially if you have no experience. When installing plumbing yourself, the main thing is to take your time and follow the instructions.

Preparing to install a new toilet

Preparing to install a new toilet involves:

- removing debris remaining after dismantling the old structure;

- checking the level of the base on which the new toilet will be installed.

If the base is uneven or has defects, it is necessary to destroy it and make a new screed.

Tile

For the beauty of the room, the concrete base of the toilet is finished with tiles. You can use any design and color, as long as it fits harmoniously into the surrounding interior.

Tile

If you don’t have the money for tiles, use finishing tiles. In most cases, it is cheaper than tiles and is less expensive. In extreme cases, you can do without finishing, because, apart from the decorative function, it does not carry any special functional load.

If you plan to replace the tiles

If you plan to replace the old tile with a new one, it must be dismantled before installing a “fresh” toilet. Once the plumbing is installed in its proper place, subsequent facing work will become noticeably more complicated. To avoid this, make repairs after dismantling, and build a new toilet last.

If there is no finishing

In the case where there is no finishing, preparatory work is reduced to a minimum. Enough:

- level the floor;

- remove extraneous debris remaining after dismantling old equipment.

If both conditions are met, feel free to proceed with the installation.

Choice

Installation

Children's toilet

Most often, people do not consider choosing this device a difficult matter. The list of requirements for it is limited to convenience, lightness and, sometimes, color. Most buyers don't go further than this. But in addition to external characteristics, each model has its own technical indicators. Leading companies in the plumbing market regularly update their product range, releasing more and more interesting new products. Focusing only on the appearance and convenience of the toilet, you may soon encounter problems that will not be easy to solve. Before you make a replacement, you need to think about some characteristics.

When choosing a device, you need to take into account the size of the bathroom or toilet. For large spacious rooms, it is recommended to purchase designs with a bidet and a tank. If the size of the bathroom is very small, then you can organically fit a toilet without a tank into the space. Such models have a special built-in flushing system. They are very convenient and will save space in the room. The material used to make the unit is very important. By purchasing cheap products, the consumer runs the risk of receiving low-quality ceramics, which will very soon ruin all the pleasure of the purchase. Of all the offers for the home, it is better to choose models made of porcelain and earthenware in the middle price segment. The internal shape of the bowl is of great importance. Some of the models have a special surface that protects against splashing. The design of the flushing device is also important. It is selected taking into account the features of the communication system in the house. There are three types of such structures: vertical, oblique and horizontal. To make the right choice, you need to look at the features of the flush device in your system. Today there are many models of cisterns. It is necessary to take into account the noise level of the tank, its capacity and other indicators. You should also pay attention to the location of the tank relative to the toilet itself.

Without a tank

It is known that the simplest models are easiest to install. Usually they also do not cause any particular problems during operation. By choosing a design that is too complex, the consumer may later regret his choice. In the simplest models, most problems are associated with the drain tank, which is not difficult to repair.

Types and standards

The plumbing equipment market keeps up with the times, constantly offering customers new toilet configurations. This should not be alarmed, because, despite the wide variety, all equipment is manufactured on the basis of certain norms and standards. When dividing toilets into general groups, the following are distinguished:

- funnel-shaped design;

- toilets with shelf;

- toilets with a sloped back wall;

- equipment with horizontal drainage;

- equipment with a circular drain.

funnel-shaped

Funnel-shaped structures are considered one of the most common on the market, and their high demand is achieved due to the simplicity of the design and its hygiene.

With shelf

Toilets with a shelf are considered to be old designs that are gradually going out of use. The shelf prevents the formation of a splash during operation, but has low hygiene. Waste is washed away only under the influence of high water pressure.

With a sloped rear wall

Toilets with a sloped back wall are replacing similar products with a shelf due to a well-chosen ratio of hygiene and splash protection. Such designs are recommended for use by both professional plumbers and ordinary citizens.

Horizontal drain

Toilets with horizontal flush belong to the budget category of plumbing. In this modification, water washes only one wall, which reduces hygiene. The advantages include:

- durability;

- low cost.

The disadvantages include:

- noise during draining;

- strong splashing of water.

Circular drain

In toilets with a circular flush, water is directed in several directions of the bowl, which allows you to treat almost its entire area. The design is less noisy and more practical for horizontal models.

Preparatory work

Of course, you remember that if you have ceramic tiles on the floor, then the floor must be level. If you neglect this detail, the toilet may split or crack. But if you don’t have tiles, then be sure to make an even screed. After completing the work, leave the floor to dry for at least three days. This is due to the fact that the toilet will be mounted using toilet dowels, and in order to securely fasten them, you will need a reliable base. So it’s better to take your time than to redo it later.

Since you are replacing the toilet yourself, you can now proceed to preparing communications:

Replacing the tank

toilet cistern installation

Replacing the toilet tank yourself is the last stage of the work associated with replacing the toilet. If we are talking about a barrel that is attached to the toilet shelf, then the pipe must be connected to the neck using a rubber cuff. This will be quite enough to ensure a strong and tight connection. One third of the rubber cuff is put on the pipe, and the remaining two thirds are turned inside out. Then this part must be pulled over the previous one. Here we get a situation where the end of the pipe is released. Then the pipe and neck are combined with each other. The inverted part of the rubber cuff is pulled over the neck. Thus, we can say that the tank is perfectly secured. No additional action is required. The rubber cuff is enough to ensure a tight connection. At the same time, it is worth checking the tightness of the cuff nozzle so that unpleasant events do not happen to the neighbors below.

attaching the toilet cistern to the toilet itself

Sometimes a situation arises when the tank is mounted a short distance from the toilet on the wall. In this case, a rubber cuff alone is not enough. You'll have to put in a little more effort and skill. In this case, a pipe is screwed to the barrel, and its opposite end is lubricated with red lead and wrapped in tow. The neck of the toilet and the pipe itself are connected by means of a cuff. It is fixed to the pipe using a thin wire. Now you can energize the flush tank and adjust the water level in it.

Thus, the work on replacing the toilet can be considered completed. As you can see, all actions do not require any special training. The work can easily be done with your own hands. Of course, if we are talking about a toilet that is installed on the floor. Otherwise, it is difficult to do without the help of a plumbing specialist. By the way, even before starting work on replacing a floor-standing toilet, you should consult with a professional. He will help you understand all the intricacies of the work. For those who are well versed in the work associated with installing plumbing, this manual will definitely help. It is also suitable for those who have never tried to do such work on their own before. Here you can find detailed instructions describing all the main stages of the work, and also attach a video showing clearly how to replace a toilet with your own hands. Many will definitely find this guide useful. In addition to the work associated with installing the barrel and the toilet itself, it provides information on how to correctly dismantle the old unit so that there are no further problems in operation. The video will help even those who decided to save money and not call specialists, although this is the first time they are dealing with this type of work. Everything is shown clearly and will be understandable to absolutely every person.

Dismantling

Let's say it like it is - removing the old toilet with your own hands will not be easy. There are rare occasions when it is not too securely in place and all you need to do is disconnect it from the water and sewer supplies. But if you have an ordinary apartment in, then things are not so smooth, since, as a rule, the toilet is walled up in the floor, and it is not possible to get it out of there. Then you will have to break the toilet with your own hands.

When dismantling the cast iron tee, note that it has one outlet with a diameter of 10 cm for the toilet and 7.5 cm for other sewer pipes. Since you will be replacing the pipes with plastic, you will need a 5 cm bend so that you don’t have to install a reduction in the tee

You can replace such a tee due to its large dimensions - a plastic one will be more compact. It must be removed by carefully loosening it so as not to accidentally damage the intermediate tee standing on the sewer riser.

Toilet replacement process

Installation of a hanging bowl and a hidden tank

It should be noted that the work on how to change a toilet of a conventional design to a wall-hung product with a hidden drain container yourself differs from the previous option in greater complexity. In this case, it will be necessary not only to replace the plumbing equipment, but also to repair the floor covering, build a false wall with its further finishing with tiles or other modern materials.

You have to attach the hanging bowl to a durable installation. After finishing the walls, the fixed metal frame will not be visible. When carrying out renovations in a combined bathroom, when decorating the interior, it is advisable to install a wall-mounted washbasin and a bidet of a similar design.

A detailed description of how to change a regular toilet to a wall-mounted one is as follows:

- Mark the location of the plumbing fixture. A sewer pipe with a diameter of 110 millimeters and an inlet is connected to it.

- Try on the purchased installation, which is a rigid frame for installation. You need to decide on the height. The standard placement is 450 millimeters from the floor to the seat and 100 millimeters from the floor covering to the bottom edge of the seat.

- Using a marker, mark the places of fixation to the floor and wall of the bathroom so that they exactly coincide with the mounting holes.

- They are prepared using a hammer drill and the frame is installed. Using a level, check the correctness of the installation work.

- Water is connected to the drain tank.

- The installation kit includes a diagram for cutting plasterboard sheets to cover the installation site. GCR is attached to the metal profile and to the installation. It is better if they are moisture resistant.

- Finishing is carried out taking into account the personal preferences of residents.

- When replacing a toilet bowl, it is connected to a corrugated sewer pipe and a drainage system, not forgetting the need for sealing.

- The bowl is screwed directly to the installation frame through drywall and tile using pins.

- The device is connected to the sewer system and the drain tank.

Despite the fact that the process of replacing an old toilet with a wall-mounted product takes a lot of time, the result of such a repair looks stylish and expensive. The work of installing an electronic plumbing fixture with the addition of automatic hygiene functions has much in common with fastening and connecting a conventional product, but there are still some nuances.

The fact is that to connect a smart wall-hung toilet, you need to provide it with power. For this purpose, a separate line is usually laid, since smart equipment is sensitive to voltage drops in the network.

How to install a wall-hung toilet with installation

To install wall-hung toilets, the outlet of the sewer pipe must be located near the wall. The specific distance from the wall is indicated by the manufacturer, but it should be small - about 13-15 cm from the far edge. If the exit is from the floor, there is a solution - a special lining, with the help of which the drain is moved closer to the wall.

Installation of a wall-hung toilet begins with attaching stops to the wall installation frame. They are attached in two at the top and bottom. With their help, the distance to the wall is adjusted, the frame is raised and launched.

Install the top stops

The upper stops have the form of rods and are adjusted using a socket wrench and a screwdriver. The lower stops are more like plates; they are also adjusted with a socket wrench but with the head positioned on the side.

Bottom stops and height adjustment

The assembled frame is placed against the wall, its center is positioned above the middle of the sewer outlet. The mark on the frame rises or falls to the height required by the manufacturer (there is a mark on the frame, also indicated in the passport, usually 1 meter).

Adjust in height and away from the wall

Using a bubble level, the horizontal and vertical installation of the installation for a wall-hung toilet is checked.

Checking horizontality

By adjusting the height of the stops, an equal distance from the wall, specified by the manufacturer, is set. How to conveniently do this, look at the photo.

The specified distance to the wall is set

The exposed frame must be fixed to the wall. Mark them in appropriate places with a pencil or marker and drill holes. Plastic dowel bodies are installed in them. Most of the wall-hung toilets are imported, and they recommend sealing the dowel bodies with sealant. Some of the sealant is squeezed into the drilled hole and a dowel is inserted. Then, before installing the fastener itself, the sealant is applied to the plastic housing.

Connecting elements - pipes, couplings - can be installed in a fixed installation. They all come included and simply snap into place.

Installation of pipes and couplings

Installation of pipes from the tank and sewerage

Next, metal rods are installed on which the toilet bowl will be supported. They are screwed into the corresponding sockets, and silicone seals are put on top (in the bottom photo these are two rods above the sewer outlet).

Toilet holders are installed, the sewer pipe is fixed

The sewer pipe extends to the required distance and is fixed in the specified position using a bracket. It covers the pipe from above and is inserted into the groove until it clicks.

Next, water is connected to the tank. Open the tank lid (it has latches), remove the plug on the side surface. Right or left - depends on where your water supply is. A corrugated pipe is inserted into the opened hole, a mating part is inserted from the inside, everything is connected using a union nut. It is necessary to tighten without using excessive force - it is plastic.

Connecting the installation to the water supply

A tee is installed inside the tank, and a pipe (usually plastic) is connected to the desired outlet. This is done with the help of an adapter and an American one.

Connecting a water pipe

The hose from the tank is connected to the special inlet of the tee. It is flexible, in a metal braid. Tightened with a union nut.

Connect the hose from the tank

Replace the cover. In principle, the installation for the toilet is installed. Now we need to close it. To do this, make a false wall from moisture-resistant plasterboard. It is recommended to use two sheets, but one is also possible. Drywall is attached to the installation frame and to the mounted profiles.

Attaching the false wall to the installation frame is mandatory

Next, the wall is finished, after which the toilet bowl is hung and a decorative flush panel with buttons is installed.

The plugs are cut off

The toilet is placed on pins, its outlet goes into a plastic socket.

The connection is sealed, no additional measures are required. This completes the installation of the toilet. Result of work

Preparation process

Types of pipe supply from the tank to the plumbing

When choosing a toilet, it is important to consider the type of connection of the tank to the water supply system. There are side and bottom inlets

With the lateral type of supply, the tank is connected from the side; this option is more popular.

In the lower type of supply, the tank is connected from below; this option is considered quiet and allows the pipes to be hidden from view. The sideways type is gradually pushing out of the markets.

It is necessary to purchase a suitable type of supply for the existing sewer structure if there are no plans for a major replacement of water supply pipes.

Tools you will need when replacing a toilet structure

To replace a broken toilet, you will need standard tools. The composition of the kit varies depending on the characteristics of the out-of-service plumbing, the type of toilet, the condition and location of the pipes.

You will need a hammer drill, a screwdriver and an adjustable wrench, a chisel with a hammer, a hacksaw, a rubber spatula, a measuring level, safety glasses and work gloves.

An adjustable wrench is used when connecting a water supply. A hammer drill is used to make holes in a concrete wall or floor for attaching a tank or bowl. Screwdrivers are needed to tighten screws. Silicone sealant is used to process joints.

What items to prepare in advance

To quickly dismantle and install new plumbing fixtures, you need to buy the necessary items in advance, namely a compact toilet. The composition includes rubber sealing rings, fasteners, and a tank drain device. If there is a cast iron riser installed under the toilet, you will need a chisel and hammer. When installing the bowl for accuracy, use a measuring level.

Consumables you will need when replacing plumbing fixtures

If there is a shortage of bolts, screws, washers, or dowels in the mounting kit, you can independently purchase the missing ones.

The process of dismantling an old toilet

Dismantling modern equipment will not cause many difficulties. The process of dismantling outdated plumbing has its own nuances if the sewer system consists of a cast iron pipe.

If the toilet is attached to a wooden stand, it is quite easy to remove. The stand itself is removed and the floor hole is filled with a special screed.

A step-by-step description of the dismantling of modern toilets

First of all, we limit access to water, then drain the water from the tank. We remove the remaining water using a bucket and a rag. At the bottom of the tank, unscrew the bolts and remove it, take out the corrugated pipe or plastic eccentric connecting the sewer and the bowl. It is necessary to wipe the bowl dry with a cloth or sponge. Use a wrench to unscrew the fastenings under the bowl, and it can be freely removed from the floor.

Removing a toilet installed with cement mortar

In Soviet times, the installation of plumbing was done conscientiously; the toilet was installed using cement mortar. Dismantling the plumbing will be similar as for modern toilets until the bowl is removed. Using a chisel, hammer the base of the toilet in a circle and crack the cement, then rock the toilet, use the chisel to carefully split the outlet and remove the bowl. Then remove the remaining plumbing fixtures and cement mortar from the pipe.

Connection to the system

Schematic procedure for connecting to the sewer through a sewer pipe

The work is considered completed after the drain tank is connected to the water supply system. The bottom supply is considered preferable (less noise when filling), but many models of tanks also use side water supply.

To connect, use a flexible hose, one end of which is fixed to the outlet of the sanitary tank, and the other to the water supply pipe.

The length of the hose depends on the distance between these points plus a spare 20–25 cm.

Before use, the tank is filled and drained several times to check the tightness of the connections. If a leak is detected, the joints are re-treated with sealant, allowing it to completely harden.

The nuances of choosing a new plumbing fixture

Before carrying out renovations in the bathroom, you should carefully prepare for it. You especially need to think about how to change the toilet in an apartment with your own hands when the residents continue to use the toilet.

In this case, the plumbing fixtures should be changed as quickly as possible, but without proper organization of repair work this becomes impossible. First of all, they select a suitable model, prepare all the tools and building materials, and then begin to implement their plans.

The most important thing before installing and dismantling the toilet is to purchase a new plumbing fixture. Depending on the selected model, a set of tools and materials is prepared to perform the replacement.

There are two types of toilets:

- floor;

- hanging.

Floor-standing models are more popular and their choice is huge. They come in “compact” and “monoblock” types, with separate tank and bowl, as well as with a hidden drain system.

A monoblock is a product that combines a water tank and a bowl into a single system. In a compact toilet, these two parts are sold as a set and are connected during installation - this is the most popular option presented on the domestic market of plumbing products.

Retro models, during installation of which the tank must be placed under the ceiling and connected to the bowl with a pipeline, have become increasingly rare in recent years. In them, to flush, you need to pull a string or chain with a handle. Such plumbing fixtures look appropriate in a bathroom decorated in the appropriate style.

A modern solution is to install a hidden drain system. Before replacing an old toilet with a new one of this type, it is necessary to consider the construction of a false wall, behind which the flush tank with the installation system will be hidden. Externally, hidden models look very neat, since only the drain button will be located on the wall, and utility lines will remain hidden.

The bowl of a wall-hung toilet is not placed on the floor. It is hung on anchor bolts mounted into the wall. As a result, there is free space under the bowl and it can be used to advantage. This design is also advantageous from a hygienic point of view. It is not difficult to wash the floor underneath, but dirty residue often collects around the floor product.

Another important point that should be taken into account before replacing the toilet with your own hands is the direction of release from the bowl, which comes in three types:

- at an angle;

- straight;

- vertical.

As for devices with a vertical drain, they are usually used in homes in America and China. Its convenience lies in the fact that the toilet can be placed anywhere in the bathroom, and communications are laid in the interfloor ceiling. This arrangement option can also be implemented in domestic sewer systems, but only in private households.

Design options for modern models

The range of plumbing fixtures on the market is varied. Any owner has the opportunity to choose presentable and functional equipment to suit his own taste and budget.

In addition to traditional floor-standing models, manufacturers offer a wide selection of wall-hung and built-in devices. The drain tank in them can be attached to the wall or connected to the base of the plumbing fixtures.

The design of the bowl of floor-standing and hanging models can be anything, for example, a dish-shaped, funnel-shaped or even a visor modification

The latest toilet models also differ in the design of key components.

The output discharge is:

- horizontal;

- vertical;

- oblique.

The type of outlet drain should be taken into account when choosing a model. If your plans do not include altering the sewer pipe supply, then in the installed model the drain should be arranged according to the same principle as in the dismantled one.

Inconsistent drains and plumbing supply, provided that it is not a toilet with an outlet, are almost impossible to combine as tightly and efficiently as possible.

Fixation of plumbing fixtures to the floor is carried out using specially made two or four fastening points. But you can also find models in which the corners included with the product are used for fastening to the floor.

Instructions for replacing a toilet

wall hung toilet in the bathroom

Now the main problem remains to be solved, namely, installing a new toilet. The toilet installation option depends on many factors. The most important thing is the type of fastening and the type of toilet itself. A wall-hung toilet for a small bathroom is often installed by specialists, since its design is quite complex. If we are talking about installing a floor-mounted option, then you can use traditional installation methods. So, you can get to work.

Replacing a toilet can be done by installing it on a tile or concrete floor. This is the traditional method. In this case, self-tapping dowels serve as fasteners. the second option is to attach the toilet to a wooden board or taffeta. The best wood for this installation method is oak.

fixing the toilet to the floor using dowels

In this case, anchors are installed at the bottom of the board. They provide a fairly strong attachment to the floor. Nails that are driven in in a checkerboard pattern can be used as anchors. At the same time, they should protrude from the board by 30 centimeters. A recess is made in the floor, which is filled with cement mortar. Taffeta is placed in it. After the solution has hardened a little, you can screw the toilet using ordinary screws.

Regardless of the method used to secure the toilet, it is worth placing rubber washers under it to protect the base from damage. There are cases when fastening is done not with screws, but with epoxy glue. For proper connection, the surfaces must be thoroughly cleaned and then degreased. Only after this can you connect them to each other. It is worth pressing the toilet tightly to the floor to ensure a reliable and durable connection. The toilet cannot be used immediately. First, you need to soak it for 10-12 hours so that the solution or glue can harden.

You should also pay special attention when connecting the toilet to the drain line. The part of the toilet that connects to the sewer is called the outlet

Moreover, it can be straight or oblique. Any outlet has grooves that must be coated with red lead diluted in drying oil. The release itself must be wrapped with a resin strand. At the same time, you should ensure that it does not reach the pipe by 2-4 millimeters. If this rule is not followed, resin strands may get into the pipes and clog them.

The outlet itself must then be inserted into the socket. In this case, the annular gap is caulked using flagella made from linen yarn. After this, the gap must be sealed with cement mortar.

Connect to the sewer

YouTube channel Cersanit

Remove the bag or rag from the sewer outlet. Lubricate the O-ring in the socket with soap or detergent and insert the pipe into it, and then the toilet flush into it. Install the corrugation or eccentric collar in the same way.

YouTube channel “Good-natured Plumber”

On an old cast-iron sewer, first insert a special adapter collar with a diameter of 123 × 110 mm into the socket that has been cleaned and lubricated with sealant. For reliability, you can additionally coat the joint of the plastic pipe with the cuff with silicone.

Carrying out work to dismantle the old toilet

To change a toilet with your own hands, first dismantle it. If the device is not too old, there are usually no problems with this process. When the model of plumbing and cast iron sewer pipes are still Soviet-style, in this case you will have to work hard.

If the device is not in very bad condition, the dismantling process will not be too laborious:

- First, before draining the toilet when replacing it, turn off the water pipe.

- Prepare containers for collecting water and rags.

- Disconnect the tank by unscrewing the bolts from below.

- Remove the plastic eccentric or corrugation connecting the bowl outlet and the sewer system.

- Using a regular sponge, remove any remaining water in the container.

- Using a wrench, unscrew the fasteners located on the sides of the base; there are usually 2 or 4 of them.

- Use a knife to remove the silicone sealant from under the base.

- The bowl is removed from the tile.

In the past century, all installation work was done in such a way that the plumbing would last for decades. Until now, when replacing a toilet in a Khrushchev-era building, you can find the device mounted on cement mortar and embedded in a screed with rags wrapped around the base and finally covered with several layers of paint. In this case, its connection with the sewer pipe is covered with a thick layer of solution.

Now this installation method looks ridiculous, but until the home craftsman has to dismantle the rare device. In cases where ceramics are not a concern, the toilet bowl can be dismantled in parts. To do this you will need a hammer and chisel.

You must first knock at the junction of the bowl and pipe, while simultaneously rocking the mount. If the structure does not give in, you should hit the neck of the plumbing fixture and it will crack. After this you can remove it. The main thing is not to hit the cast iron pipe with a hammer, since it is fragile and will crack easily.

Install the toilet seat

YouTube channel “Good-natured Plumber”

Assemble the lid fittings. If there are “left” and “right” marks on the mounts, do not confuse them. Insert the rubber bushings into the holes, install the eccentrics on top and adjust the distance between them to the width of the toilet seat holes.

YouTube channel “Good-natured Plumber”

Tighten the mounting bolts with plastic washers from below. Place the decorative pads on the rubber part of the eccentrics and install the cover on them until it clicks.

Installation

Work on fixing and installing the toilet proceeds as follows:

That's all the subtleties of replacing a toilet. In conclusion, I would like to note the following: if you find out another way to change a toilet with your own hands, this does not mean that it is wrong. There are simply always several methods for solving a particular issue.

Replacing a toilet is required when the old product becomes unusable. More often, dismantling an old toilet and installing a new one is in demand in older buildings, where all communications need to be updated. Replacing the toilet tank and other parts yourself is not difficult. However, it requires basic skills in working with tools (a hammer drill, a drill, etc.) and the ability to fill and lay tiles. Read how to install a toilet in a private house with your own hands and watch the video tutorial below.

Installation process of a compact toilet: how to replace it yourself

In order to replace an old device with a floor-standing product of the “compact” type when installed on a tiled floor, you need to use a step-by-step description of how to replace a toilet yourself:

- First of all, determine the location of the new device. The bowl is placed in the bathroom without fastening. You need to try to sit on it. It is advisable to try on several options.

- Once the exact location is known, the base of the bowl is outlined with a washable marker. It is also used to mark the places where plumbing fixtures will be attached.

- The product is put aside, and after that all the necessary marks remain on the floor. Then, using a drill with a 12-bit drill bit, holes are drilled in the tiles. If the surface is concrete, then it is better to beat it with a drill number 12. Dowels are inserted into the prepared holes.

- Then they take a corrugation or cuff to connect the outlet of the device to the sewer system. The connecting element is placed in place, having previously treated the joint with sealant.

- The new bowl with corrugation is installed correctly. Bolts are threaded through the mounting lugs and screwed in using an adjustable wrench. The main thing is not to overdo it when performing this work and not to damage the ceramics.

- The device is connected to the sewer pipe, treating all joints with silicone.

- A tank is installed on the bowl.

- The elements are connected with bolts and the container is connected to the water pipe.

Finally, all joints and threaded connections are checked for leaks. If no deficiencies or deficiencies are found, you can use new plumbing equipment.

The process of how to change a toilet of this model yourself is simple, since modern products are designed in such a way that when they are replaced, the floor covering remains intact.

Try the toilet in place

YouTube channel Cersanit

Next, decide on the location of the new toilet. Move the bowl into place and try to sit down. To save space, you can press as close as possible to the wall, but not as closely as possible - it is advisable to leave a gap of 2-3 cm between it and the tank.

YouTube channel Cersanit

Align the drain with the sewer outlet. If you are using a straight pipe for the connection, measure with a tape measure and cut off the required piece. Use a knife to remove any burrs from the edge. If you use a corrugation or an eccentric cuff, try on how they become.

When is replacement needed?

If various kinds of problems appear with the toilet, this does not mean that it is necessary to change it. There are cases when it is enough to simply repair an element or simply replace it. This can happen for various reasons. So, for example, if there is a leak at the junction of the hose and the toilet, you just need to turn off the water, disconnect the hose and coat it with silicone sealant. This will fix the leak. Or, if the tank does not hold water and it constantly flows, then you need to open the lid and replace the drain system. These simple measures can extend the life of the toilet for a long time without the extra costs of replacing it.

Sometimes it happens that more serious problems arise that cannot be repaired.

In this case, you will have to buy and install a new toilet. The materials from which toilets are made are most often very fragile and cannot withstand shock or temperature changes. If cracks or chips appear on the toilet, this can lead to its destruction. It needs to be replaced as soon as possible.

It happens that an unpleasant odor appears from the toilet. This can be either a smell from the sewer itself, or if dirt has started to get into the cracks. Sanitaryware has a porous structure; microbes enter through chips. The only solution to this problem is replacement. Bathroom renovations can also be a reason to buy new plumbing fixtures. If you plan to carry out major renovations in the apartment, then it is best to buy and install new equipment, and not just replace the floor and walls. You can do this yourself if you carefully study and follow all the instructions.

Before installing a new toilet, you must dismantle the old one

, which most often already has an ugly appearance, is cracked in some places or covered with a thick coating. If the house is old, and the renovation was carried out many years ago, then it is unlikely to be possible to remove the old toilet without breaking it, since its base is firmly concreted into the floor. This method of cementing the floor and attaching the toilet to this place was very popular in Soviet times, when it was customary to do everything with high quality and for a long time.