Tongue-and-groove slabs and blocks have a low density compared to reinforced concrete, so they are quite easy to drill. A porous or hollow structure does not withstand loads well and a standard self-tapping screw may fall out of it. Taking into account the peculiarities of the material, fasteners and dowels for tongue-and-groove slabs must meet certain requirements. With the correct selection and installation of such elements, you can attach a piece of furniture or other structure to the wall that will hold firmly.

Installation features

To drive a dowel into, it is not necessary to invite craftsmen.

You can do everything yourself. You will need the following tools and materials: the dowel itself of a certain design, a sharp nail, an electric drill and a Pobedit drill (you can use a hammer drill), electrical tape, a small hammer. The main stages of fastening:

- The installation location is planned after careful design.

- Using a hacksaw, nail or anything else, make a small indentation in the marked area.

- A drill bit for an electric drill of the appropriate diameter is selected - it must exactly match the size of the screw and the required hole for it. The dowels must be inserted into the hole with force in order to securely fasten inside. It is advisable to make a mark on the drill with a piece of electrical tape along the depth of the hole with a small margin to limit drilling. The drill must be strictly perpendicular to the surface. A hole is made.

- You need to remove dust, debris, crumbs from the hole - it is better to do this with a vacuum cleaner, but you can use anything.

- Next, a plastic or metal dowel for concrete is carefully installed into the hole, driven with a hammer to the maximum stop with strong, precise movements, and a screw is screwed into it (if screws are supposed to be included in the construction kit).

Features of a hollow block

This building material has some features. Due to the voids in the rooms, heat is perfectly retained. Using this brick in the construction of a residential building, it is possible to ensure a high level of thermal energy conservation in cold weather. In addition, hollow types of materials have good sound insulation. These types of bricks can withstand various climatic conditions.

The blocks can withstand 40-degree frosts without problems. Hollow brick has a good appearance. The modern market offers a lot of options for facing materials. Products are available in various colors and textures. When building with hollow bricks, there is no need to create deep foundations. This greatly simplifies the work process. This type of brick is much lighter than all other materials. Therefore, even the simplest foundation will support a building made from it. It is very profitable to buy this brick - its price is much lower than solid analogues. If you build from such a block, you can save up to 30% of money. Also, hollow blocks are inexpensive to transport, since their weight is significantly lower than their solid counterparts.

Types of dowels

Before driving a dowel-nail into a concrete wall, you need to carefully study the designs and features of all existing fasteners in order to choose the only correct option. The most effective and popular are: spacer, chemical, facade, nail, butterfly, KVT, universal, GB, etc. Available without dowels.

Classic

This design consists of a plastic sleeve with notches along the entire length and antennae, as well as a special rod inserted into it, which guarantees the strength and reliability of the fastener. When the rod is driven into the sleeve, the plastic expands in the hole, ensuring high-quality fastening.

Self-tapping screw in concrete without dowel

The self-tapping dowel for concrete is made with a variable thread that is screwed directly into the monolith. First, as usual, a hole of a smaller diameter is drilled, then the dowel is tightened, during which the variable notch expands the cavity, and the thread secures the self-tapping screw.

The fasteners are distinguished by high load-bearing capacity, strength, and are very difficult to dismantle, and therefore belong to the type of stationary fasteners.

Spacer

This dowel is suitable for fastening rigid structures - usually made in the form of slate, driven into the monolith with a hammer. The fasteners may also be different (in the form of a cylinder or tubular shape), there may be 2-3 spacers, with spikes. The connection is strong, suitable for loose materials with voids.

Butterfly

This option is suitable when fastening with dowels and nails to a concrete wall that is very thin. The sleeve is attached to the hole, and its back side is folded during insertion, which securely fixes the dowel.

Universal

Universal metal dowels for concrete resemble spacer dowels. In hollow walls, during the process of screwing in the nail, the sleeve is wrapped into a knot, securing the fastener in a “butterfly” fashion. The same fastening can be used for a variety of types of monolith.

Regular fasteners are simply driven into the wall with a hammer or a special gun.

Facade

Used for installation of various thermal insulation structures. Similar to a spacer, but has a longer length and a larger cap. The rod and sleeve are made of impact-resistant materials.

Chemical

This type of fastener is different from all others. The structure contains a capsule with glue and a metal screw. Usually they use this one.

First, a capsule corresponding to its size is inserted into the hole, broken, an adhesive substance comes out of it, and a metal rod is inserted into it.

KVT

Relevant only for aerated concrete monoliths. It has a wide thread, which guarantees high-quality fastening in porous structures.

G.B.

Typically, such products are used when working with polystyrene concrete blocks. The sleeve is somewhat reminiscent of a spacer sleeve, but is made in the form of a spiral. The dowel is capable of withstanding heavy loads, so it can be used for fastening hoods, hanging cabinets, various types of shelves and household items with heavy weight, and equipment.

How to attach to plaster firmly and inexpensively

The picture shows that the fastening of the anchor to the wall material is almost perfect. As a result of forcibly pulling the anchor out of the wall, it was still possible to get it out, but only with a fair piece of the surface layer of the wall material (gypsum). Well, ideally, this piece can be much larger, i.e. the anchor should be attached equally reliably along its entire length.

Some practical tips

In general, there is nothing new here, you probably know all these “tricks” yourself, but it happens that they are neglected or forgotten, so I will remind you.

- Be sure to remove dust and debris from the hole you are preparing to drive the dowel into.

- The drill size should be two sizes smaller than the dowel size. Some people recommend a difference of 1 mm, but firstly, this is not enough, and secondly, choosing a drill that is a multiple of two is much easier.

- No matter how sophisticated your tool is, use only the drilling mode, otherwise the back-and-forth movements will break the pliable wall material so much that you will have to look for a dowel with an even larger diameter, and this is not always acceptable.

Hanging kitchen cabinets on drywall is a challenging but fun task. The seemingly fragile facing material is capable of withstanding quite significant vertical loads from hanging objects. It is important to choose the right type of fastener. Various support designs help hang cabinets stably on a plaster wall. In this article we will tell you 8 ways to manually attach kitchen furniture to gypsum plasterboard floors. Each section has a video that clearly demonstrates the fastening process.

What is a classic dowel?

The classic dowel for concrete and other solid materials has been preferred by specialists in the field of construction and repair for a long time. Consumers often call it a “dowel-nail.” Concrete fasteners can be made of metal, nylon and various types of plastic. Naturally, products made from different materials differ in their characteristics and, accordingly, in their area of application.

Polypropylene dowel-nail with a hidden side

The load-bearing capacity of a dowel on concrete is determined by its design features. In the classic design, a dowel-nail is a sleeve, the entire outer surface of which has special notches that prevent such an element from turning in a hole in a wall or in any other building structure. Special whiskers, which, due to their elasticity, are constantly in a decompressed state, help prevent the fastening element from being pulled out of the wall. When a screw is screwed in, the fastening element expands due to longitudinal slots on its surface, which ensures high reliability of its fixation.

Parameters of dowel-nails with a mushroom-shaped edge used for through installation (click to enlarge)

In addition to dowel fasteners, which operate on a mechanical principle, the modern market offers dowels for porous concrete and other similar materials, fixed in the holes through the use of a special adhesive composition. By filling the internal cavities of the porous material, the adhesive composition reliably fixes such an anchor element in a previously prepared hole.

The classic dowel-nail intended for concrete is such a universal fastener that it is quite difficult to list all the areas of its application. With its help, they install frames for various purposes, attach furniture and interior items to the surface of walls, fix household appliances at the required installation location, and also solve a whole list of other important tasks.

Metal driven dowel nails can be made of steel or aluminum alloys

What is the difference between a dowel for concrete and a dowel for brick?

High reliability of fastening obtained using dowel-type products will be achieved only if they are correctly selected not only taking into account their size, but also the material of the structure in which they will be mounted.

Experts do not recommend using concrete dowels for installation in brick building structures. This recommendation is especially relevant when it comes to hollow bricks. In this case, special fasteners are used for installation, which differ from a conventional dowel-nail both in design and in the features of use.

The extended dowel for hollow bricks has certain design features

Masonry fasteners have extended dimensions and a double thrust mechanism. Like a dowel designed for concrete work, such a fastener can be plastic or metal. The reliability of fastening a brick dowel is ensured by the fact that at least one of its spacer elements does not fall into the cavity in the brickwork, but into its solid part; it is this that ensures the required fixation of the anchor in the wall or any other building structure. The expansion of the dowel spacer sleeve occurs when a threaded rod or screw is screwed into it, the diameter of which must be selected correctly.

Some types of universal dowels (click to enlarge). It is simply impossible to show the entire numerous assortment.

A dowel intended for concrete works on a completely different principle and can only be used for installation in solid solid materials. Such a dowel is driven under pressure (which is why it is often called a nail) into a previously prepared hole. If you try to fix concrete fasteners in a brick wall, the internal structure of which has many air cavities, you can simply destroy the mounting hole. Even if such a dowel is metal and has a considerable length, you still will not achieve reliable fixation in brick or any other porous, hollow and not very durable material.

Considering all of the above, you should take a very responsible approach to the selection of fastening elements for structures made of various materials, differing both in their hardness and the characteristics of their internal structure. The markings applied by manufacturers on the packaging of such products helps to understand what a particular fastener is intended for.

It's hard to hang on a thin wall. How is it possible?

There is a thin plaster wall available, 5-8 cm. If you hang something heavy on it, at least 10-15-20 kg, then over time the screws and plugs will fall out. And I need to hang the shelf with the microwave securely.

Friends, how can this be done?

ASv

There is a thin plaster wall available, 5-8 cm. If you hang something heavy on it, at least 10-15-20 kg, then over time the screws and plugs will fall out. And I need to hang the shelf with the microwave securely.

Friends, how can this be done?

How to install a dowel correctly

Installing a dowel in the PGP is not that difficult. You just need to follow certain rules:

First of all, you need to make a mark at the location where the dowel will be installed. This is done with a pen or pencil; then a core is used to make a recess at the mark location for correct installation of the drill; When making a hole in the wall to fit a dowel, it is necessary to take into account its diameter; it is necessary that the fastening structure fits into it with little force

Be sure to pay attention to the length of the self-tapping screw used; it must be equal to the length of the dowel. Otherwise, the dowel may move during installation and damage the tongue-and-groove plate; Having installed such a fastener, the resulting gap in the form of a rim between the screw and the hole must be filled with acrylic or covered with putty - this will prevent the fastener from becoming loose; Using the automatic method of tightening the screw, you do not need to screw it completely into the dowel; you should make the last few turns manually with a screwdriver

This will help avoid unwanted movement in the hole.

How to attach to a loose base

There is no single technology. Of course, each master chose his own method, tested by time and practice, but in fact, even in this case there is no point in talking about universality. It doesn't happen once at a time.

The easiest way to attach to a plaster wall

The simplest, but not the most reliable method of fastening is the use of self-tapping screws with large pitches (for wood). If the load is small and static, then a self-tapping screw screwed into a plaster wall will cope with it, but only if certain conditions for this method of fastening are met.

- The holes can be used only once. Once screwed in this way, unscrew it and then try to screw it in again, it will not work, i.e. you will return it again, but it will no longer be able to stay in this hole.

However, the condition of disposability applies to all holes, regardless of how they were made, even if their diameter is nominal or smaller.

- In any case, you need to press the last screw (1-2 threads) with your hands, otherwise there is a risk of turning the screw and destroying the wall material. Then all the work will go down the drain, and you will have to fasten it in some other way.

- It is necessary to take into account that with self-tapping screws of this type and (not only) the weak point is the neck of the bolt, the rod between the thread and the head. It is in this place that self-tapping screws most often break when tightening and when working on a bend. Therefore, you should not rely on one attachment point, but, if possible, increase their number.

Types of dowels for brick walls

Dowels are used to attach furniture, paintings or other objects to brick walls, as they can withstand heavy loads. In order for the fastener to be securely held in the base, it is necessary to select the correct type and size depending on the grade of brick or concrete. If the dowel is not used for its intended purpose, it may not withstand the load and fall out of the hole.

Types of dowels and their features

1. Externally, the dowel looks like a cork and has a cylindrical shape with a cavity. When the screw is screwed in, its body expands and rests against the walls of the hole. The most common are nylon and polyethylene expansion dowels. To prevent a screw or nail from falling inside, the fastener is equipped with a special collar equal to the diameter of the screw head.

2. For walls made of porous or hollow bricks, anchor fasteners are used. As soon as such a dowel begins to be screwed into the brickwork, its end expands or twists into a knot. The resulting “nut” inside the voids securely holds any object.

3. Nail dowels are used for fastening slats under cladding with finishing material; they are small in size. They come with a nail. Install them together through a hole in the rail and wall. Then they hammer it in with a hammer.

4. Special umbrella dowels are used to attach thermal insulation. An umbrella is inserted into the hole in the wall and through the insulation, and then a nail (plastic or metal) is driven in. For large loads, for example, up to several tons, metal dowels for concrete and brick are used.

5. Metal fasteners are best suited for suspended ceilings. In the event of a fire, the plastic ones will melt and the ceiling will collapse.

- reliable fastening that can withstand heavy loads;

- easy to use;

- Can be used both indoors and outdoors.

Due to the presence of spikes and whiskers on them, they do not turn while screwing in the screw.

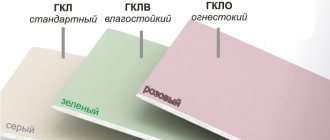

Selection of materials for reliable fastening

It is traditional to hang cabinets in the kitchen. A number of shelves are mounted on the wall above the desktop (a tabletop that combines several floor cabinets). If the vertical fencing is a metal frame covered with gypsum fiber board and gypsum board, then fastening the furniture has its own characteristics. Moisture-resistant cardboard is used in rooms with high humidity levels. In addition to the kitchen, cabinets in the bathroom are hung on such cladding.

Drywall by its structure is a fragile material. In order to attach kitchen cabinets and small cabinets to such a wall, there are a number of fastening elements such as:

- auger dowel (snail);

- butterfly dowel;

- molly dowel;

- Hartmut dowel;

- metal anchor;

- embedded timber;

- metal tire and hook bracket;

- support platforms.

These fasteners can withstand significant loads.

Screw dowel (snail)

The plastic fastener looks like a large screw with a drill-shaped end. To install it, you only need a screwdriver. The screw dowel will withstand any medium-heavy objects. In addition to plastic, screws are made of metal. The fastening technology is quite simple. Drill a hole with a screwdriver inserted into the cross slot of the dowel. After the screw head is recessed into the body of the cardboard, a self-tapping screw is screwed into it.

The installed fasteners can withstand loads of up to 6 kg. Accordingly, on 2 mounts you can hang a small cabinet with internal filling, the total weight of which is no more than 12 kg. With two-layer cladding, the total weight of furniture is allowed up to 30 kg.

Rules for installing dowels for brickwork

Considering the fact that installing a dowel fastener intended for brick is somewhat more difficult than fixing a dowel used for concrete work in a wall, you should understand this procedure in more detail. In this situation, it is very useful to take advantage of the experience of specialists, who are often faced with the need to securely fix objects that have even very significant weight on brick building structures.

During installation, the distances from the edges and between the dowels should be observed, depending on the size of the dowels and the anchoring depth

If in order to fix a dowel for concrete work in a building structure, which is driven in like a simple nail, it is enough to use a minimal set of tools, then to accurately and securely fix the fastener in a brick wall you will need:

- a hammer drill or drill needed to drill a mounting hole;

- drill of the appropriate diameter;

- adhesive intended for laying ceramic tiles;

- a set of rubber spatulas of different sizes.

Dowel installation procedure

The procedure for installing a dowel into a brick wall consists of the following steps.

The first thing to do is to carefully drill a mounting hole for mounting the fastener. This can be done using an electric drill or hammer drill with only drilling mode (no impact) turned on.

It is important that the diameter of the drill used to perform this procedure exactly matches the diameter of the dowel itself. After drilling, the hole must be thoroughly cleaned of construction dust and pieces of material that have crumbled into its internal cavity. You can check how thoroughly you have cleaned the hole using the dowel itself: it should fit in without difficulty or obstacles. When the hole is thoroughly cleaned, you can begin work with dry tile adhesive, which must be diluted with water in the proportion specified by the manufacturer

After the adhesive mass is ready for use, it is necessary to fill the hole drilled for the dowel. You can use a rubber spatula for this, and you can push the adhesive mass into the depth of the hole using the dowel itself or an ordinary pencil. When the hole is completely filled with adhesive, you can insert a dowel into it, which should go into it all the way. After this, you need to let the adhesive composition completely harden, which is quite enough for 24 hours. After the tile adhesive has completely hardened, you can screw a threaded element (pin or screw) into the dowel. Be sure to pay attention to the fact that screwing occurs with some force. This means that your dowel is securely fixed in the brickwork. Fasteners obtained using this simple technology are highly reliable and can withstand even significant weight loads.

You can also use this method if you need to install fasteners in a porous material (the use of concrete dowels for such structures is also prohibited). Such materials, in particular, can be gas or foam concrete, porous brick, etc. Taking into account their high popularity in the modern construction market, the choice of fasteners that could ensure reliable fastening of objects fixed on such structures is a rather serious problem.

In conclusion, we invite you to watch a couple of videos highlighting some of the nuances of installing dowels in bases made of various materials.

Features of dismantling

When choosing which dowel is good and which is not suitable for the task at hand, it is necessary to take into account the possibility of dismantling. If there is a possibility that the mount will need to be removed in the future, it is advisable to think about this before installing it.

To quickly and correctly perform dismantling, you will need a variety of tools that are usually in the arsenal of any master. Some types of dowels (chemical, for example) cannot be dismantled).

How to dismantle the dowel:

- To remove an ordinary plastic dowel, it is enough to find a self-tapping screw of the appropriate size. The self-tapping screw is screwed 2/3 into the dowel itself, the screw head is carefully clamped with pliers, then pulled out of the monolith together with the dowel. In some cases, a corkscrew will be enough.

- The head of the self-tapping screw, which is inserted into the dowel, can be pryed off with a nail puller. Here you need to ensure that the working part of the screw fits tightly in the hole itself.

- Homemade wooden dowels are removed in parts - first, a piece of wood is crushed (easiest along the grain) into separate pieces using a chisel (preferably with a thin blade) and a hammer. After the dowel is destroyed, it is pryed with an awl, a sharp knife or a nail and pulled out of the socket.

- In some cases, it is easier not to dismantle a dowel that sits firmly in the monolith at all - it is better to cut off the part that comes to the surface, carefully cover the recess with plaster and carefully level it.

- If part of the screw is stuck in the dowel, you will need a heated soldering iron. First, the plastic base of the dowel carefully melts, then the piece of fastener is pryed off with round nose pliers or wire cutters and removed.

- A metal dowel, which was hammered into concrete with a construction gun, is first treated with strong frequent blows of a hammer, affecting the protruding part of the product from different sides. Typically the anchor will become loose during the process and can be easily removed. If it is difficult to loosen, you can make a recess nearby with a drill with a carbide tip or a metal punch. Thanks to the circular funnel, the area of contact between the fastener and the wall will be reduced, making it easier to remove.

Dowels for concrete today in the construction market of Moscow and the region and other regions are presented in a wide variety, so finding fasteners that exactly meet the requirements and operating conditions is not difficult. The main thing is to choose reliable suppliers and focus on product quality.

Types of chemical anchors

This dowel consists of special adhesive compounds, as well as a metal insert. This is a sleeve with threads cut inside it. The structure also includes a stud and a reinforcing bar. This element is made of stainless or galvanized steel of different grades. The process of joining with fasteners of this type is carried out due to a special chemical composition - according to its characteristics, it is glue. It must be stuffed into a pre-drilled hole. And then, due to the polymerization process, a strong connection between the hollow brick and this connector will be ensured.

Tips and tricks from experienced builders

Recommendations on how to secure the dowel part in the wall correctly:

- Pre-clean the funnel where you will insert the self-tapping screw.

- The hole must be deeper than the length of the dowel.

- If the wall is fragile, before installation, wet the plastic part of the fastener with glue.

- If there are voids in the wall, it is advisable to use butterfly fasteners.

- It is advisable to drill the funnel at a slight angle, tilting the drill towards the floor.

- It is advisable to use new drills of the same diameter as the dowel.

- During installation, if complications arise, the fasteners are removed and a wire is used to check what prevents it from going deeper.

- Select fasteners according to the type of wall.

Previous post How to repair a laptop lid mount Next post Installing a hob

Mount selection

When choosing a particular mount, you need to know under what conditions it will be used. For internal use, there is no fundamental difference what the dowel is made of. External fastenings require a higher quality material such as nylon.

The choice of dowel largely depends on the structure of the partition slabs. For partitions with a solid structure, expansion type dowels are used. Anchor dowels are installed in hollow slabs.

Knowing what load will be placed on the fastening, you can correctly select the type and size of the dowel and the depth of its penetration. As it increases, the power of the dowel and the depth of the hole increase. To ensure strong adhesion of the dowel to the surface, PVA glue is used.

https://youtube.com/watch?v=oygpGPExVAE

Conclusion

As you can see, the dowels for GGP slabs are quite standard. They are expandable, made mainly of nylon, and have antennae to enhance the expansion. This allows us to state that in addition to the dowels recommended by the Knauf company in their technological maps, similar dowels from other companies are suitable for PGP. For example, these.

How to attach to a plaster wall? The question is not an idle one when it comes to hanging or fastening. It would seem that the most difficult thing is left behind, the renovation has been purchased, delivered, installed and suddenly an ambush, some stubborn screw (dowel, anchor) does not want to stay in the plaster wall. What to do?

How to choose a mount?

When choosing a fastener, it is necessary to take into account the operating conditions. If the work is carried out indoors, then there is not much difference what material the dowel is made of. For external work, nylon elements are used. The dowel is selected depending on the structure of the tongue-and-groove plate. If the slab is hollow, then anchor type dowels are used; if the slab is solid, spacer elements are used.

To choose the right type and size of dowels, you need to calculate the approximate load on a given element. The greater the load, the larger the dowel and its recess should be. To increase the strength of the fastening, you can use PVA glue. A hollow slab has almost 25 percent less weight than a solid element. When fastening in two or more places, it can withstand a weight of about 200 kilograms; furniture elements that are too heavy are not safe to install in residential premises.

Heavy furniture can be secured using double sleeve anchors; this type of fastening will be the safest. Partitions made from tongue-and-groove tiles are durable and suitable for placing not too heavy structures on them. You can hang mirrors, kitchen cabinets or a TV on such a partition. To secure the elements on such a partition, universal plastic dowels with a diameter of 8 to 10 millimeters are used. If the slab is solid, then use expansion dowels of the same diameter. The hole is made using a non-impact mode; the drill should be a millimeter smaller than the diameter of the dowel.

Specifics of furniture installation at PGP

The hollowness of the slab ensures a reduction in its weight by almost 25% with unchanged strength. Therefore, we can definitely say that it is possible to install cabinets on such walls. Manufacturers of this material have developed recommendations for the permissible load on walls made of PGP. It is believed that this wall can withstand a load of up to 200 kg if fastening is carried out at two or more points. With a slab thickness of 80 mm and above, additional fastening elements are not practical. Furniture that places a load on the GWP of more than 200 kg is not recommended for installation in residential premises.

It can be attached to the PGP using special fastening devices such as anchors. Choose anchors that have a double sleeve designed for hollow walls; you can also use dowels on self-tapping screws for solid slabs, as well as anchor dowels for walls with voids. The screw, moving in its spacer part, expands the end, turning it into a kind of rhombus or, when screwed into a knot, it becomes like a nut.

Types of chemical dowels and installation methods

Adhesive compositions are usually two-component. They are prepared immediately before installation work. Often, this composition can be purchased either in ampoules with a specific diameter and hole length, or in special cartridges and other packaging. This packaging consists of two compartments. One contains the glue itself, the other contains the hardener. During the installation process, an ampoule is inserted into the prepared holes, and then a metal mounting rod is inserted - it will crush the package with glue. Next, polymerization will begin, which will provide the connection with the necessary strength. Installation using cartridges is carried out by squeezing out the glue and hardener composition in the required proportions, mixing the substances. The resulting mixture is then pumped into the hole. Construction professionals speak very positively about these products. There is nothing easier than fixing a dowel in a hollow brick, porous ceramic block or aerated concrete. Additionally, specialists install a perforated sleeve in such structures. It allows you to prevent strong leakage of glue into the voids of the building material. The connection created in this way is highly durable and reliable. There are no analogues today.

Fischer UX universal dowel, nylon

Purpose. UX is a universal nylon dowel. It is used in attaching curtain rods, picture rails, baskets, motion detectors, mailboxes, lamps, lightweight mirrors, baseboards, towel holders, lightweight shelves and electrical switches. Design features. The UX nylon dowel has a special toothed locking element that prevents the dowel from twisting. Principle of operation. When a screw is screwed into the UX universal nylon dowel, the teeth of the dowel expand and are securely fixed in the surface. Fastening material. The UX dowel is made of nylon. Base material. The universal nylon dowel UX is suitable for use in concrete. It can also be used in plasterboard, fiberboard, chipboard, gypsum fiber board, in hollow concrete blocks, in hollow lightweight concrete blocks, in natural stone with a dense structure, in sand-lime solid bricks, in bricks with vertical voids, in solid lightweight concrete blocks. Installation. To install the UX dowel, you need to drill a hole in the surface. Then insert the dowel into it and screw the screw into it. In aerated concrete and hollow bricks, drilling must be carried out in rotation mode. It is prohibited to use a universal nylon dowel for attaching suspended products to the ceiling. For through-hole installation, a screw of the maximum diameter must be used.

What is a tongue-and-groove slab?

The tongue-and-groove plate is an environmentally friendly material that has tongues and grooves; it is used for quick installation of partitions. The dimensions of one slab are 667*500*80 millimeters. The material is made from gypsum elements with the addition of plasticizers. The thermal insulation properties of the slab are comparable to a concrete wall.

Single and double partitions for apartments are made from tongue-and-groove slabs, creating an air gap. There are slabs that are resistant to humidity, they are used in the kitchen or bathroom, and are green in color. The material can withstand loads from objects that are used in everyday life. The main advantages of the tongue-and-groove slab are its ease of installation; it is installed and secured by gluing. The surface does not require additional treatment, that is, plaster; you can immediately glue wallpaper onto it. If the slab is to be painted, then it is enough to perform the initial putty. You can hide communications in hollow elements; they are easy to cut and saw

When using a hollow slab, it is important to choose the right fasteners, then it will withstand the loads of household furniture. Usually a universal type expansion dowel is used

Another advantage of the slab is its non-flammability, which makes it possible to carry out hidden wiring in hollow elements. Making door or window openings is much easier compared to other materials, and it is not necessary to perform reinforcement. Thus, using tongue-and-groove material, you can save time and effort. You can do this type of partition yourself without putting too much effort. Finishing the slab will be minimal, which means saving money on materials. This partition has high sound-proofing and heat-insulating properties, which makes it possible to create walls between apartments. After fixing the partition, you can immediately glue the wallpaper or apply a thin layer of starting putty and then paint the surface. Finishing materials are selected depending on the interior of the room. Solid slabs are slightly heavier than empty elements, but they are also actively used as partitions.

In order for cabinets or other household items to be firmly and reliably held on the tongue-and-groove plate, it is necessary to select the correct fasteners; dowels are usually used for this. The element is inserted into a pre-made hole, and then a screw of the required diameter is screwed into it. After this, a spacer occurs in the dowel, it is firmly held in the wall, and has a low ability to be pulled out. Thus, mirrors, TVs, cabinets, and other objects that will be used for their intended purpose or serve as decorative items can be attached to the tongue-and-groove plate using dowels.

AKU-line (GSP-D) UK 2500x1200x12.5

Soundproofing gypsum board has increased soundproofing characteristics.

Certificate of compliance with the requirements of technical regulations of the Russian Federation

Certificate of conformity in the GOST R system

Expert opinion

Single metal frame sheathed on both sides with one layer of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with one layer of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with one layer of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with one layer of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with two layers of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with two layers of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with two layers of Gyproc AKU-Line boards

Single metal frame sheathed on both sides with two layers of Gyproc AKU-Line boards

Double metal frame, sheathed on both sides with two layers of Gyproc AKU-Line boards

Dowels for GGP slabs

Classic fasteners for building materials other than wood are a pair of dowels and screws. The dowel is fixed in the structure as a base, and the screw, screwing (hammering) into the dowel, expands it, due to which the entire structure is firmly fixed to the base.

It is worth noting that in terms of the load on the dowel + screw fastener, you can hang not very heavy objects. So the maximum load on a plastic dowel can be 95 kg (on average 50-60 kg), and the maximum lateral load on a metal anchor is 200-250 kg. (see table below)

For particularly heavy fastening to walls made of PGP, through fastenings with a spacer platform on the opposite side of the slab, as well as anchor fastenings, are used.

Let's look at the dowels for GGP slabs in more detail. And let's start with the universal classic dowel fisher for pgp.

Dowels Fischer

The correct name for this nylon dowel is “S Fischer”. The distinctive features of this dowel are its gray color, straight edge and the presence of characteristic tendrils to enhance the thrust.

The dowel tendrils are extremely important. Moreover, when installing this dowel into the hole, you must respect the location of the antennae. They should be located parallel to the corner (edge) of the structure.

This arrangement of the antennae will ensure the vertical direction of the expansion of the dowel, which will improve the strength of the fastening.

According to the table below, on a PGP Fischer dowel with a diameter of 10 mm, when drilled to 70 mm, you can hang 24 kg of weight. An excellent option for installing a TV on a PGP wall.

Table of maximum loads.

Dowels Upat

The correct name for this dowel is UPAT U. It is also made of nylon, but with more pronounced antennae and hooks.

This allows you to hang heavier weights on it. Thus, a UPAT U dowel with a diameter of 10 mm and a length of 65 mm can withstand a weight of 30 kg.

Table of maximum loads.

Dowels TOX

In the TOX fastening range, three types of dowels are recommended:

— Universal dowel TOX TFS, it twists when the screw is tightened. Can be used as a dowel for drywall;

– Dowels 4AS;

– TOX TRI.

Table of maximum loads of TOX dowels.

Low density

To begin with, it is worth noting that the low density of the GWP is not a disadvantage, but an advantage of this building material. Due to its low density, PGP has high thermal insulation performance. An 80 mm thermal insulation slab corresponds to a 400 mm concrete wall.

With GGP sound insulation the situation is not so clear, but it complies with regulatory requirements.

However, GGP slabs are fragile due to their low density. The fragility of the slab and its low density become clear when you start sawing the slabs during installation. They cut easier than wood.

All this brings us to the conclusion that in order to hang interior items and household appliances, for example, a TV, on partitions made of PGP, you will need special PGP dowels and special fasteners.

Hollow brick

What kind of material is this? In modern construction, two types of bricks are used - hollow and solid. The main function of the first materials is the construction of buildings, which should be as strong and durable as possible.

This brick is good in all respects. The material is light, strong, and easy to install. However, it has a significant drawback. It does not retain heat well in rooms. Although hollow brick is practically no different in strength from solid brick, it is more often used in finishing work. The internal void in such a building material can range from 30% to 50%, depending on the type and manufacturer. Low-melting grades of clay are used as raw materials for such blocks. It is from this that red brick is made. There is another option. This is a silicate hollow white type. Let's look at the features and properties of mounting blocks.

What is the strength of gypsum walls

Before attaching anything to a plaster wall, let's look at the material it's made of. We are talking about tongue-and-groove slabs (TGP), which are now popular among builders. Builders are pleased with the ease of installation, operational efficiency and small amount of subsequent finishing.

Residents who live in apartments with interior and sometimes inter-apartment partitions made of tongue-and-groove slabs suffer from the disadvantages inherent in this building material. There are many shortcomings, but now we are only interested in strength.