Metal siding ship plank

Metal siding is a type of exterior siding consisting of long, narrow panels.

They have a specific longitudinal profile, which makes it possible to join them into one sheet of any size. The “ship plank” profile shape is one of the oldest; it appeared among the first samples of the material. Externally, it imitates a set of boards with a beveled edge that promotes water drainage, imitating the method of laying boards during the construction of a wooden ship.

The advantages of metal shiplap siding include:

- Easy to install.

- Light weight, no extra load on the walls.

- Relatively small size of thermal expansions (much smaller than vinyl analogues).

- A multi-layer protective coating reliably protects the panels from corrosion throughout their entire service life.

- Withstands large temperature changes, installation is possible at any time of the year and in any weather.

Disadvantages include:

- High cost of cladding.

- Possibility of dents from accidental physical impacts.

A feature of the material is the possibility of partial replacement (for example, one panel), but this will require disassembling the canvas to the desired area.

Metal siding is also divided into the following types:

- Under the tree;

- Under the beam;

- Under a stone;

- Under the brick;

- Under a log.

House with metal shiplap siding

Types of polymer coating for “Shipboard” siding panels:

Glossy polyester

. The most budget-friendly type of coating, which is a thin elastic film. Has a wide range of colors. Resistance to mechanical and ultraviolet stress is average, resistance to bending deformation is high. Standard service life is 10-15 years.

Matte polyester

. Plastic coating with Teflon composition. It is a smooth matte film. Has a wide color palette. Resistance to external factors is the same as that of glossy polyester. Average service life is 15-20 years.

Plastisol.

Wear-resistant polymer with a relief structure. Resistant to aggressive substances, corrosion and mechanical stress. It is frost-resistant, but when heated above +60 degrees it loses its performance characteristics. Average service life is 30 years.

Polyurethane

. Smooth coating, resistant to temperature changes, ultraviolet radiation, acid precipitation, and abrasion. Not resistant to bending deformations. The service life can reach 30 years.

Polyvinylidene fluoride

. Composite polymer containing acrylic. Provides a glossy or “metallic” finish. Highly resistant to ultraviolet radiation, aggressive environments and mechanical damage. The average service life is 50 years.

Specifications

Technical characteristics of ship siding:

- Sheet thickness 0.3-0.55 mm.

- The thickness of the protective coating is 25 microns.

- Profile height - 14 mm.

- The total width of the panel is 255 mm.

- Working width - 225 mm.

- The length of the panels is 0.8-8 m (it is possible to order the desired size).

- Number of profile waves - 2 pcs.

- Operating temperature range from - 50° to +60°.

- Warranty - from 20 years.

ATTENTION! Material characteristics are subject to change depending on manufacturing conditions and manufacturer capabilities, so some differences are possible.

Specifications

Main characteristics

The advantages of siding include its ability to self-clean from dust and dirt that appears on the surface over time. All it takes is a little rain and all the dirt will be removed as if by hand. If there is no time to wait for rain and you urgently need to get rid of dirt and dust, then you can use ordinary water and a hose.

Another advantage of metal siding is its long service life. For the manufacture of this finishing material, only high-quality cold-rolled steel is used. “Shipboard” does not change its shape under the influence of temperature. It retains its original appearance even after severe frosts and great heat. In addition, this material is fireproof: it is not flammable.

The profile of metal siding resembles plank siding. Each panel has two wide waves that are located on top of each other. This results in a surface that resembles wood siding with overlapping planks. The special pattern on the surface also creates the impression that it is not a metal structure at all, but a wooden one. True, not all types of siding have such a pattern: the cheapest models, as a rule, have a monotonous surface.

The shape of the panels is given for a reason. The fact is that this design has good resistance to mechanical influences, and also perfectly resists wind and is able to remove excess moisture.

Like other metal models, the “ship plank” is produced by stamping. The traditional panel has a complex structure and consists of seven layers. The base layer is made of steel and is usually about 0.5 mm thick.

The material must be coated with zinc on both sides. This protects it from moisture. Another required layer is an oxide film. This substance also performs a protective function, preventing rust from forming.

In the production of metal siding, a special primer, polymers, varnish and decorative coating are used.

Shiplap panels can come in different sizes. But usually the height of one element is 14 mm, the width is 260 mm, and the length can reach up to 6 m. Some manufacturers manufacture the material to order, and therefore can create panels of almost any size.

DIY installation

Regardless of the type, the installation of a ship plank is carried out according to a single principle; individual nuances depend on the manufacturer.

Creating a sheathing

The frame can be constructed from a metal profile or wooden beams. But the process begins only after careful preparation of the base, including sealing of all defects and treatment with protective agents.

Wooden structure installation procedure:

- Markings are made in increments of 50–60 cm. The racks are placed perpendicular to the sheathing.

General diagram of wooden sheathing for siding - The timber is impregnated with antiseptic agents and fire retardants.

- After drying, the products are drilled. The location of the holes is transferred to the existing lines and dowels are installed.

- The racks are fastened with self-tapping screws and leveled. If required, spacers are used.

On a note! Lathing can be used to lay a layer of thermal insulation.

Scheme of a wooden frame with insulation under the siding.

The metal sheathing is arranged as follows: hanging brackets are fixed along the marking line, the racks are leveled along them and the racks are attached.

Installation technology

Shiplap siding panels are designed to be mounted horizontally, so the sheathing is installed vertically.

In the vast majority of cases, the installation of siding panels is carried out with simultaneous insulation of the building, since metal cladding itself cannot reduce heat loss. For ease of installation, experts recommend using rigid or semi-rigid tile insulation.

Sheathing:

- Screw the starter strip along the bottom line of the frame to each vertical profile along the entire perimeter of the facade.

- Mount complex corner and connecting profiles (if available). Attach them to the racks vertically, level them and screw them with self-tapping screws in increments of 20-30 centimeters. Secure the slope strips around the perimeter of the openings. Screw the finishing strip close to the cornice.

- Insert the first panel into the lock of the starting bar, and its side edges into the corner profiles. Snap the lock. Insert self-tapping screws into the holes and secure the panels. To avoid deformation of the skin during thermal expansion, a gap of 1-1.5 millimeters should be left between the metal and fasteners.

- Mount the remaining panels in a similar manner from bottom to top. Each strip must be carefully aligned before being fixed to the sheathing. Cut the top panel to the width (if the dimensions do not match), insert it into the lock of the previous panel and snap it into place. Place the top edge into the bend of the finishing strip.

- Using galvanized self-tapping screws with seals, secure simple corner and connecting profiles (if available) to the front side of the sheathing. Screws should be screwed in on both sides of the additional element in a checkerboard pattern with a fastening pitch of 40-50 centimeters.

- Install slopes, platbands and ebbs in a similar way.

Types of material

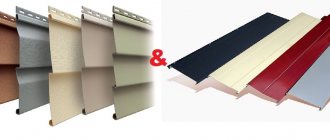

At the moment, there are two main types of products with imitation ship planks on sale. Each option has its own characteristics.

Configuration of the classic siding model under the board

Metal siding

This material is quite common and popular, which is explained by the coating, which perfectly follows the structure of wood. Panels of the desired shape are produced by rolling and stamping galvanized steel, after which they are treated with protective and decorative compounds.

Metal siding is considered one of the most durable coatings

Product advantages:

- Strength. The surface retains its structure even under severe mechanical stress.

- Decorative. Facade cladding gives the house originality and individuality. The front layer is resistant to ultraviolet radiation.

- Fire safety. The material does not support the spread of fire.

- Easy to install. Work can be carried out even at sub-zero temperatures. Houses that have not yet undergone complete shrinkage can be finished.

A significant disadvantage is the rather high price. Corrosion can also be a problem if it is damaged or improperly trimmed.

Vinyl products

Unlike the steel modification, plastic panels for boards have a more attractive price. For their production, PVC and special additives are used. The resulting mixture is molded and, after hardening, cut into parts of the required size.

Models simulating different types of boards

Advantages of the material:

- Resistance to precipitation. The panels do not rot, corrode, and do not contribute to the appearance and development of microorganisms.

- Ability to withstand various temperatures. The coating tolerates changes from – 50 to + 50 degrees, but in severe frosts the elements become fragile.

- Light weight. In this regard, PVC parts are significantly superior to the metal variety. This allows you to quickly finish the walls of the house and eliminates unnecessary load on the foundation.

Although vinyl panels have a uniform color, metal siding includes options with a more realistic imitation of wood. Also, plastic parts are subject to significant thermal expansion, which requires the creation of expansion gaps.

The color range of vinyl siding is constantly expanding

You should know! Regardless of the chosen variation, additional elements are purchased. They are necessary to fix the panels and give the house completeness.

Types of coatings

As mentioned earlier, this siding is made from a steel base.

However, to increase the efficiency of the material, a special polymer layer is created on the metal surface, which can be represented by the following compositions :

- Pural . The coating is made of polyurethane resin, which allows you to significantly expand the operating temperature range for steel siding.

- Glossy polyester . One of the most common coatings, as it has an optimal price-quality ratio . The covering layer has a thickness of up to 25 microns. Polyester is an elastic material, so sheets with such a coating can be bent without fear of cracks forming in the protective layer. Does not fade, can be used in any climate zone.

- Polyester matte . Unlike glossy, this coating is thicker (10 microns), which increases its protective properties . A characteristic feature is the lack of glossy shine, matte finish.

- PVDF . It is made on the basis of two materials - polyphenyl fluoride and acrylic. It is resistant to work in aggressive atmospheric conditions, does not fade under long-term exposure to ultraviolet radiation, and is self-cleaning.

- Plastoizol . Thick (200 microns) vinyl coating, which can be presented not only in different colors, but also with interesting embossing options. Due to its massiveness, it is considered one of the most advantageous options for covering metal sheets in terms of durability and resistance to aggressive influences.

Siding colors

Types of metal siding shipboard

Metal shiplap siding has many manufacturing options, since this profile is produced in many companies. Manufacturers use different materials for the protective polymer coating, different panel lengths and sheet thicknesses.

In addition, there is a fairly wide selection of panel colors, from brighter to soft pastel colors. Experts do not recommend purchasing colors that are too flashy; they quickly tire the eye and begin to irritate.

Shipboard siding is produced by almost all leading manufacturers; each company strives to add its own special nuance to production, which results in the presence of many types of material that are identical at first glance, but have differences in some parameters.

Most often there are options for the following qualities:

- Sheet thickness.

- Composition of the polymer coating.

- Width and length of panels.

In general, all samples of material from leading manufacturers are quite worthy of taking leading places in the ranking of cladding materials; the differences are not too great.

Types of metal siding shipboard

Appearance and dimensions

Externally, the profile of shiplap siding resembles plank cladding. Each panel has 2 waves. They are on top of each other. This allows you to create a surface that resembles overlapping boards. The special design enhances this impression. A person sees not a metal or vinyl product, but wood.

The form was invented for a reason. This design is characterized by high levels of resistance to mechanical stress, and also resists wind loads and removes excess moisture.

The standard dimensions of one element are 14x226 mm. Where 14 mm is the height, and 260 mm is the working width. The length of the panels reaches 6 meters. There is a separate material about siding sizes.

The color can be gray, ivory, oak and other natural types of wood. The cheapest panels are made in one color. Their board effect is much smaller.

Manufacturers

Most popular brands:

- Grand Line. Domestic company producing galvanized panels. The products have high performance characteristics and are very popular. The color range is represented by several dozen shades.

- "Metal Profile". A domestic manufacturer that produces various types of siding with excellent properties. There is a separate line of panels with imitation wood structure.

- Docke. A well-established foreign manufacturer that produces siding of excellent quality. The factory line for the domestic market is located in Russia, but all work is carried out using German technology. The color range of the panels is quite varied (see photo).

“Docke” is one of the most popular siding manufacturers in the CIS.

Every serious brand provides its products with a description of the characteristics and installation technology.

Varieties

The shipboard siding in question differs not only in color and size, but also in the materials used in production.

And there are 2 categories.

- Vinyl

. This is PVC material. They use modifying additives. Siding protects well from wind loads, as well as from rain and other precipitation. Does not absorb moisture, does not burn and is biologically inert. The price per m2 is low. Lower than the competitor. Durability is at a good level. Does not deform under temperature loads. But it will not be able to withstand strong mechanical loads. Sheathing the base is not recommended. But it is not prohibited either; - Metal

. It is made of galvanized steel with subsequent protective and decorative coating. They are more expensive than vinyl analogues. Produced by cold rolling. A polymer or other type of protective layer increases resistance to various external and internal factors. Excellent resistance to unstable temperatures and mechanical loads. Does not fade over time. The material is not subject to combustion. Suitable for cladding the entire house, including the basement. Due to the large weight of metal sheets, it is worth calculating the load on the façade of the building in advance.

Structurally, they are the same as other types of siding. There is a starting panel, strips, as well as additional elements, etc. Only the appearance imitates a ship's plank.

There are no distinctive features in terms of installation.

Polymer coating

Separately, I would like to talk about the polymer coating that is used in the production of metal siding for shipboards.

Such shipboard siding can have 5 types of protective and decorative coatings:

- Glossy polyester

. Standard layer thickness is 25 microns. Suitable for cladding in any climatic zones. UV resistant coating. Quite durable and elastic; - Matte polyester

. The layer thickness is increased to 35 microns. This makes the coating more resistant to negative factors, and also less susceptible to ultraviolet radiation than the previous option. But in both cases, the imitation of wood structure is weak; - PVC coating

. The thickness is 200 microns. It lasts for many years and also reliably protects against external factors. The surface can qualitatively imitate real wood; - Polyurethane resins

. The coating has excellent technical and operational characteristics. Easily withstands high and low temperature; - PVDF and acrylic

. The main advantage is a very long service life. The best choice for cladding buildings in harsh climates.

And you can decide for yourself which of these options is best for you.

How to choose the right metal shiplap siding?

The choice of material is made according to all parameters - aesthetic and technical qualities.

- First of all, you should familiarize yourself with the technical characteristics of the siding, clarify the type of protective coating and whether it requires maintenance. If one is necessary, it is better to refuse to use such cladding, since in practice, caring for the outer cladding of a house is too troublesome and very difficult. There will always be samples of material with a more resistant coating on the market.

- When choosing a color, it is best to choose soft, calm tones, since bright shades under a layer of dust significantly lose their appearance, which looks sloppy, especially if there are clean areas.

- An important factor is the price of the coating, but you should be careful in this matter: too low a price means that the material is of poor quality, it is better not to buy it.

- You should definitely check the presence of additional elements and their compliance with the main panels in all respects, otherwise the result of the installation will be a mismatched canvas of elements that do not match each other.

Metal siding ship plank

Buy metal siding “Shipboard” at the best price.

Siding

is one of the best finishing materials: lightweight, easy to install, durable, with excellent external characteristics.

It has many varieties, but the most popular can rightfully be called metal siding “Shipboard”

.

This coating gives any building a very neat, well-groomed look, and the combination of multi-colored panels allows you to make the facade different from the others. The production company

is engaged in the production and sale of siding and offers certified products

at the best price.

Our own production base allows us to produce a wide range of products with high performance characteristics in strict accordance with current standards.

For all questions of cooperation, you can contact our specialists at the contacts listed on the website +8(495) 374-90-92;;;

[email protected] You can also request a call back. We will definitely call you back at the time you specified.

Preparing the sheathing

Sheathing is a necessary element of the cladding design, a system of planks that support the siding fabric. Installation of the sheathing is done simultaneously with the external insulation of the walls (if required).

Wooden bars or metal guides used when installing gypsum plasterboard structures can be used as material for the sheathing strips.

- Installation begins with inspecting the walls and eliminating any defects found - dents, cracks, etc. After installing the insulation, access to the wall surface will cease, so all deficiencies must be eliminated in advance.

- The first layer (if there are two of them) of the sheathing is installed horizontally (i.e., coaxially with the direction of the panels). The pitch of the planks is equal to the width of the insulation boards, which are tightly installed in the gaps. After completing the installation of insulation and installing the planks, it is necessary to ensure waterproofing of the wall pie using a waterproofing membrane. It releases steam, but does not let moisture in in any form.

- Then they begin to install the second layer - the counter-lattice. It should be located perpendicular to the direction of the panels - vertically. The pitch of the counter-lattice strips should be 30-40 cm.

IMPORTANT! Additional strips are installed in the corners and around window or door openings, onto which the corner profile or platband will be attached. The sheathing strips are also reinforced along the slopes of the window openings.

The thickness of the counter-lattice must be at least 40 mm, which corresponds to the size of the ventilation gap according to the standards.

Lathing

Panel installation

The process of installing “Shipboard” panels is not particularly complicated and does not require special tools. At the first stage, the walls are inspected, existing irregularities, depressions, cracks are eliminated and, if necessary, the surface is treated with a fungicidal solution or antiseptic. There is no need for special leveling of the wall surface. Unevenness can be eliminated using mounting plates and supports for profiles.

Next, the sheathing and insulation are installed: 1. During the work, the wall is marked with vertical lines along the level at a distance of 15 cm from the top of the wall and from the bottom from the foundation. The width of the step between the profiles should correspond to the width of the insulation boards. 2. Places for attaching mounting hangers are marked on the wall. The distance between them should be 60 cm. 3. In the marked places, holes are drilled for dowels and mounting plumbs are mounted. 4. Installation of corner and remaining wall profiles is carried out. 5. The top and bottom of the racks are connected by horizontal profiles. During the installation of the sheathing, insulation is laid. The slabs are laid between the sheathing posts, preventing the formation of voids and gaps, which can be eliminated using polyurethane foam.

Sheathing installation stages:

1. On the lower profile of the frame, the starting strip is screwed horizontally with self-tapping screws.

The quality and appearance of the cladding depends on how strictly it is aligned. 2. When using complex corner profiles, they are installed in the second stage. This condition also applies to connecting profiles of complex shapes. They are secured to vertical posts with self-tapping screws. At the same stage, the slope strips are attached along the perimeter of the frame. Next you should screw the end strip. 3. The first metal panel is inserted into the lock of the starting bar, the side edges of which are inserted into the corner profile. The panel is fixed with self-tapping screws. There must be a gap of at least 1 mm between the screws and the metal to prevent deformation of the upholstery during temperature changes. To ensure clearance, you can tighten the fastener until it stops, and then unscrew it no more than 1 turn. 4. The remaining panels are mounted in a similar way. The topmost element is cut to width if necessary, and the top edge of the panel is inserted into the groove of the end strip. 5. When choosing simple corner and connecting profiles, their installation is carried out after installing the sheathing. Matching the color of the fasteners with the siding will improve the aesthetics of the siding. 6. At the final stage, the installation of slopes, ebbs, and platbands is carried out. An important condition for successful installation is strict adherence to the instructions developed by the manufacturer. Independent changes in work technology and the use of non-standard elements can significantly reduce the protective properties of the cladding. It is strictly forbidden to secure panels by driving fasteners directly through the material. As a last resort, it is recommended to widen the hole on the mounting plate with a hammer drill.

Siding Care

After completing the installation work, you need to clean the facade from any remaining construction debris and shavings. High-quality metal siding does not require complex maintenance. The process itself does not take much time and consists of regular inspection, cleaning and touching up any scratches that appear. Cleaning should be carried out with a damp cloth using mild, non-abrasive detergents or with water from a hose under pressure of no more than 3 and from - this is the most optimal combination of high quality, simple installation and reasonable price. Cladding with this material will provide your home with reliable protection and at the same time give it a stylish, complete look. In the Krovelson retail chain you can purchase all the necessary materials for facade, roofing and other construction work. We also provide services for construction and installation work and installation and maintenance of fences, automatic gates and barriers.

Sizes and color

When choosing siding, the dimensions of the product and the color palette presented are of great importance. Ship timber (depending on the type and manufacturer) may have slight differences in parameters.

Steel siding

Metal products can be of the following sizes:

- width – 26 cm;

- profile height – 1.4 cm;

- thickness – from 0.5 to 0.8 mm;

- length 50–600 cm. Optimal – up to 400 cm.

Two-strip metal siding is considered one of the most popular.

Parts are painted using photo offset printing, which allows you to obtain a bright, durable and deep shade. The color range of this variety is quite extensive and includes more than 50 tones. There are also panels that imitate the cut of natural wood.

Vinyl panels

This option most often has the following dimensions:

- width – 23.8 cm;

- thickness – 1.1 mm;

- length – from 3 to 3.66 m;

- profile height – 14–16 mm.

The variety of colors is not as great as that of metal products. The most widespread products are pastel colors: walnut, mimosa, cotton, linen. Naturally, different companies may call shades differently.

Colors and sizes of vinyl siding “Shipboard” from the Grand Line company

Popular manufacturers

The market offers a large selection of materials that can be used to decorate the facade: metal and vinyl siding, shiplap from various manufacturers. The quality of the product must be confirmed by appropriate documentation, since violations during the production process deprive the material of important qualities. Today, many manufacturers have already managed to gain trust among customers. Among them are both foreign and domestic.

Alcoa

The American brand produces shipboard metal siding made from aluminum. It is distinguished by its strength and long service life, resistance to atmospheric factors.

Alcoa siding

In addition, unlike steel, it weighs little, which greatly simplifies the cladding procedure. The manufacturer offers high quality products, the price of which corresponds to the stated characteristics.

Corus group

This company produces premium products. It is produced by a concern in two countries: England and Holland. The technology for producing shiplap siding has been modernized; only protective coatings of excellent quality are used. This in turn affects the cost of the product, but it is quite justified.

Ruukki

The Finnish manufacturer of building materials has been known outside its native country for a long time. A huge assortment of shades, ship siding of various textures and textures, polymer coatings of various types allow you to select the most suitable option for any facade. With the help of such cladding, you can create a harmonious exterior that will last a long time and will reliably protect the house from negative influences.

Grand Line

Grand Line brand siding has an ideal combination of price and quality. The color palette is quite wide. Grand Line ship siding is available in the entire RAL palette.

The company produces metal siding from steel. Various polymer coatings are used, which is why the appearance of the finished products differs. Proper packaging and compliance with transportation rules will prevent damage during transportation.

Metal profile

This domestic brand is widely popular. Like Grand Line siding, the available colors are striking in their variety. It is possible to purchase both ordinary colored panels and shipboard siding, which closely imitates natural wood: oak, pine, maple, etc. In addition, imitation of white stone is also possible. The manufacturer's materials are distinguished by high quality characteristics and a long service life.

What affects the cost

See also

Street stairs in front of the house and to the attic: what are they?

If you examine the range of manufacturers, you will notice one feature. Shipboard siding, which looks similar to each other, can cost completely differently per m2.

Appearance is not the only pricing factor. The cost is affected by the following points:

- Coverage

. The higher quality and better the coating on vinyl or metal panels, the higher the price per panel or square meter will be; - Number of panels

. Many manufacturers and sellers have this principle. The more siding you purchase, the lower the price per unit of product; - Texture and color

. There are cheap monotonous coatings. Their resemblance to a ship's plank is average. But there are textured panels. Externally, they cannot be distinguished from a wooden board. For this the price is higher; - Equipment

. The total cost is affected by all additional elements required when installing siding on the facade; - Manufacturer

. Each siding factory creates its own price list for its products. Alas, price does not always correspond to quality.

In connection with the last point, I strongly advise the following. Choose products only from trusted and well-established companies.

There is no need to save a lot, and there is no need to overpay for non-existent quality.