Metal siding ship plank

Metal siding is a type of exterior siding consisting of long, narrow panels.

They have a specific longitudinal profile, which makes it possible to join them into one sheet of any size. The “ship plank” profile shape is one of the oldest; it appeared among the first samples of the material. Externally, it imitates a set of boards with a beveled edge that promotes water drainage, imitating the method of laying boards during the construction of a wooden ship.

The advantages of metal shiplap siding include:

- Easy to install.

- Light weight, no extra load on the walls.

- Relatively small size of thermal expansions (much smaller than vinyl analogues).

- A multi-layer protective coating reliably protects the panels from corrosion throughout their entire service life.

- Withstands large temperature changes, installation is possible at any time of the year and in any weather.

Disadvantages include:

- High cost of cladding.

- Possibility of dents from accidental physical impacts.

A feature of the material is the possibility of partial replacement (for example, one panel), but this will require disassembling the canvas to the desired area.

Metal siding is also divided into the following types:

- Under the tree;

- Under the beam;

- Under a stone;

- Under the brick;

- Under a log.

House with metal shiplap siding

Siding Care

Metal siding requires virtually no maintenance. The maximum that is sometimes required is to spray it with water from a hose to remove settled dust .

Some people use a long-handled brush to clean, which makes sense if there is a lot of dirt, sand or dust (for example, if the house is near busy highways or dust storms occur in the area).

Actually, this is where all the care ends; no additional compounds, paints and varnishes, etc. are required to be applied to the coating . The factory coating lasts for the entire period of operation without loss of its properties, so you should not worry about the safety of the siding and try to somehow enhance the existing qualities.

Siding Care

Specifications

Technical characteristics of ship siding:

- Sheet thickness 0.3-0.55 mm.

- The thickness of the protective coating is 25 microns.

- Profile height - 14 mm.

- The total width of the panel is 255 mm.

- Working width - 225 mm.

- The length of the panels is 0.8-8 m (it is possible to order the desired size).

- Number of profile waves - 2 pcs.

- Operating temperature range from - 50° to +60°.

- Warranty - from 20 years.

ATTENTION! Material characteristics are subject to change depending on manufacturing conditions and manufacturer capabilities, so some differences are possible.

Specifications

Basic recommendations for working with metal siding

First of all, calculate the required amount of material. To do this, you just need to measure the width and height of the surfaces that will be covered with metal siding. At the place of purchase of the material, the consultant will help you calculate the required number of sheets based on the measurements taken.

Additionally, include in the estimate the need to purchase various related products mentioned earlier. It is better to buy all the components at once along with the main material, because otherwise, you may have problems finding accessories in the right shade.

It is not recommended to place any objects on sheets of material. Although metal siding is made on a steel base, it is deformed quite easily.

It is better to cut metal siding into the necessary pieces at the place of purchase. If you do the cutting yourself, use a jigsaw or a special reciprocating saw. Start cutting at the edge that is perforated for fasteners.

Do not use a grinder to cut metal siding. The disk of such a grinding machine heats up quite strongly during operation, which leads to disruption of the structure of the polymer and other layers of the material. Such damage will contribute to the rapid development of corrosion.

Do not forget that metal tends to expand and contract when temperature conditions change, so a sheet of metal siding cannot be screwed to the base until it stops. The optimal gap between the sheet and the screw head is about 1 mm. If you screw the sheets all the way, after a while the coating will simply deform and lose its presentable appearance.

The optimal gap between the sheet and the screw head is about 1 mm

The sheet must begin to be attached from the central point to the corners. Place self-tapping screws strictly in the center of the factory technological holes. If you install fasteners off-center, the fasteners may damage the material during thermal deformation of the metal siding sheet.

Study the design of the panels before starting installation. The material is equipped with a special mounting edge with holes. Fasteners, as already noted, must be placed in the center of such holes. If this condition is met, the mounting strip will be able to move during thermal deformations of the material without harm to the coating.

DIY installation

Regardless of the type, the installation of a ship plank is carried out according to a single principle; individual nuances depend on the manufacturer.

Creating a sheathing

The frame can be constructed from a metal profile or wooden beams. But the process begins only after careful preparation of the base, including sealing of all defects and treatment with protective agents.

Wooden structure installation procedure:

- Markings are made in increments of 50–60 cm. The racks are placed perpendicular to the sheathing.

General diagram of wooden sheathing for siding - The timber is impregnated with antiseptic agents and fire retardants.

- After drying, the products are drilled. The location of the holes is transferred to the existing lines and dowels are installed.

- The racks are fastened with self-tapping screws and leveled. If required, spacers are used.

On a note! Lathing can be used to lay a layer of thermal insulation.

Scheme of a wooden frame with insulation under the siding.

The metal sheathing is arranged as follows: hanging brackets are fixed along the marking line, the racks are leveled along them and the racks are attached.

Useful tips

Immediately after purchasing the material, it should be stored in a suitable dry place to protect it from atmospheric moisture

Before installing siding, you should familiarize yourself with important information that will help you avoid common mistakes:

- Immediately after purchasing the material, it should be stored in a suitable dry place to protect it from atmospheric moisture. It is prohibited to place heavy objects on the panel that could deform the product.

- If you wish, you can order cutting of elements directly in the store. But you will do this yourself during the installation process, then for such purposes it is better to use a reciprocating saw or an electric jigsaw. In this case, it is better to start cutting from the side where the mounting strip with holes is located.

- It is forbidden to use an angle grinder for cutting, since the quickly heating disk will destroy the polymer and protective layer, which will subsequently contribute to the development of corrosion.

- Calculating the amount of material is easy. It is enough to find the area of all sheathed facades. There is no need to subtract window and door openings, since a certain amount of material will be used for fitting and trimming.

- In addition to the panels themselves, you will need additional elements, without which installation will not be possible.

- To ensure thermal expansion of the material, the ends of the panel should not reach the inside of the guide additional elements by 8-10 mm.

- When installing metal siding, fasteners must be screwed into the central part of the elongated slot on the product. However, they should not be tightened all the way so that the panels can freely expand and contract with temperature changes. If you do not leave a gap of 1 mm between the fastening element and the product, then during thermal deformations the panel will move and the cladding will lose its presentable appearance.

In addition to the panels themselves, you will need additional elements, without which installation will not be possible.

Siding installation is carried out using the following additional elements:

- finishing and starting profiles;

- strips for framing windows and doors;

- slopes and ebbs;

- internal and external corner element;

- connecting profile.

Types of material

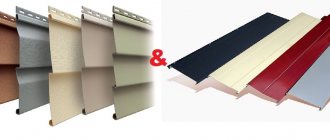

At the moment, there are two main types of products with imitation ship planks on sale. Each option has its own characteristics.

Configuration of the classic siding model under the board

Metal siding

This material is quite common and popular, which is explained by the coating, which perfectly follows the structure of wood. Panels of the desired shape are produced by rolling and stamping galvanized steel, after which they are treated with protective and decorative compounds.

Metal siding is considered one of the most durable coatings

Product advantages:

- Strength. The surface retains its structure even under severe mechanical stress.

- Decorative. Facade cladding gives the house originality and individuality. The front layer is resistant to ultraviolet radiation.

- Fire safety. The material does not support the spread of fire.

- Easy to install. Work can be carried out even at sub-zero temperatures. Houses that have not yet undergone complete shrinkage can be finished.

A significant disadvantage is the rather high price. Corrosion can also be a problem if it is damaged or improperly trimmed.

Vinyl products

Unlike the steel modification, plastic panels for boards have a more attractive price. For their production, PVC and special additives are used. The resulting mixture is molded and, after hardening, cut into parts of the required size.

Models simulating different types of boards

Advantages of the material:

- Resistance to precipitation. The panels do not rot, corrode, and do not contribute to the appearance and development of microorganisms.

- Ability to withstand various temperatures. The coating tolerates changes from – 50 to + 50 degrees, but in severe frosts the elements become fragile.

- Light weight. In this regard, PVC parts are significantly superior to the metal variety. This allows you to quickly finish the walls of the house and eliminates unnecessary load on the foundation.

Although vinyl panels have a uniform color, metal siding includes options with a more realistic imitation of wood. Also, plastic parts are subject to significant thermal expansion, which requires the creation of expansion gaps.

The color range of vinyl siding is constantly expanding

You should know! Regardless of the chosen variation, additional elements are purchased. They are necessary to fix the panels and give the house completeness.

What are the features of the material

Now manufacturers such as Metal Profile and other companies produce a wide range of siding. They imitate different surfaces and textures. Including siding panels imitating wood, timber, as well as block house and stone.

A variety such as shiplap creates the visual effect of cladding with wooden eurolining. Externally, it is almost impossible to distinguish it from a real board.

If we talk about the scope, then this is private construction, as well as high-rise buildings. The dimensions and characteristics allow the panels to perfectly adapt to buildings of any configuration. But it is not used as vertical siding.

Types of metal siding shipboard

Metal shiplap siding has many manufacturing options, since this profile is produced in many companies. Manufacturers use different materials for the protective polymer coating, different panel lengths and sheet thicknesses.

In addition, there is a fairly wide selection of panel colors, from brighter to soft pastel colors. Experts do not recommend purchasing colors that are too flashy; they quickly tire the eye and begin to irritate.

Shipboard siding is produced by almost all leading manufacturers; each company strives to add its own special nuance to production, which results in the presence of many types of material that are identical at first glance, but have differences in some parameters.

Most often there are options for the following qualities:

- Sheet thickness.

- Composition of the polymer coating.

- Width and length of panels.

In general, all samples of material from leading manufacturers are quite worthy of taking leading places in the ranking of cladding materials; the differences are not too great.

Types of metal siding shipboard

Metal soffits

One of the features of soffits is the presence of perforations, but they can also be solid. Thanks to this, soffits are used in places where additional air circulation is necessary, and the use of blank cladding is unacceptable.

Perforated metal soffit

The main use of soffits is for lining the eaves of private houses and the ceilings of office premises, including those with high humidity.

Hemming the cornice with metal soffit

Metal soffits are produced in the form of sheets up to 6 meters, simulating two or three lining boards or in the form of timber.

Manufacturers

Most popular brands:

- Grand Line. Domestic company producing galvanized panels. The products have high performance characteristics and are very popular. The color range is represented by several dozen shades.

- "Metal Profile". A domestic manufacturer that produces various types of siding with excellent properties. There is a separate line of panels with imitation wood structure.

- Docke. A well-established foreign manufacturer that produces siding of excellent quality. The factory line for the domestic market is located in Russia, but all work is carried out using German technology. The color range of the panels is quite varied (see photo).

“Docke” is one of the most popular siding manufacturers in the CIS.

Every serious brand provides its products with a description of the characteristics and installation technology.

Metal siding installation guide

Fastening metal siding

Metal siding is installed according to a very simple scheme. A step-by-step guide will allow you to do everything yourself.

First stage. Secure the corner elements of the metal siding. Place the element at the appropriate angle, level it using a building level and attach it to the sheathing with a self-tapping screw. Please take into account the fact that some corner elements are attached only after the installation of the main finishing panels has been completed. Please check this point in the instructions for the purchased material.

Second phase. Proceed to installing the main panels. Metal siding is done from bottom to top. Place the starter bar over the plinth. Align the strip and attach it to the sheathing using self-tapping screws. Self-tapping screws must be screwed strictly into the center of the technological holes. Remember the millimeter gap between the panel and the screw head.

Third stage. Cover the entire surface to be finished with basic panels. First remove the protective film from the metal siding. If the panels are not long enough, join them using strips specially designed for this purpose. The panels, as already noted, are fixed from the center to the corners.

At the stage of finishing surfaces near doors and windows, panels will most likely have to be trimmed. Small pieces of metal siding can be cut using tin snips. Cut large sections with a jigsaw.

Installation of metal siding panels

Fourth stage. Install slopes, platbands, window sill panels, ebbs and special strips that close the gap between the facade and the roof.

Now you know the sequence in which metal siding is installed, and you can handle the finishing yourself. Depending on the characteristics of the building and the type of metal siding, the finishing technology may undergo certain changes, but in general the work is carried out exactly according to the scheme considered.

Follow the recommendations received and you will create a beautiful, reliable and durable finish. At the same time, you will not have to spend money on anything other than materials, and in addition you can be confident in the quality of the cladding, because you will personally control the implementation of each stage of installation.

Good luck!

Roof and fence made of metal siding

How to choose the right metal shiplap siding?

The choice of material is made according to all parameters - aesthetic and technical qualities.

- First of all, you should familiarize yourself with the technical characteristics of the siding, clarify the type of protective coating and whether it requires maintenance. If one is necessary, it is better to refuse to use such cladding, since in practice, caring for the outer cladding of a house is too troublesome and very difficult. There will always be samples of material with a more resistant coating on the market.

- When choosing a color, it is best to choose soft, calm tones, since bright shades under a layer of dust significantly lose their appearance, which looks sloppy, especially if there are clean areas.

- An important factor is the price of the coating, but you should be careful in this matter: too low a price means that the material is of poor quality, it is better not to buy it.

- You should definitely check the presence of additional elements and their compliance with the main panels in all respects, otherwise the result of the installation will be a mismatched canvas of elements that do not match each other.

Metal siding ship plank

Siding for exterior home decoration from Mitten

The Canadian company Mitten, founded in 1959, produces high-quality vinyl siding for exterior decoration. Buyers from all over the world are familiar with the brand's products. PVC panels are available in America, Australia, Russia and other countries. For manufacturers, the Mitten finish is the standard.

Logo siding for exterior home decoration

Interesting fact - all siding for exterior home decoration is covered by a lifetime warranty of 50 years, which can be inherited. So Mitten Inc. shows the excellent quality of its products.

Main advantages of the company:

- Wind resistance up to 290 km/h.

- Impact resistance even in cold weather.

- Installation is possible in winter down to -20 degrees Celsius.

- The color scheme was developed with the participation of psychologists and time-tested.

- Absolute safety of products, no lead in the composition.

Mitten ship timber is made in two collections.

Oregon Pride

The most popular series of the Canadian company is produced in 14 soft shades:

Shades of the Oregon Pride PVC panel series

Oregon Pride is so popular due to the combination of high quality and low price.

Oregon Pride Exterior Siding

Since 1996, not only siding has been available on the Russian market, but also a full range of accessories for it. The collection imitates the surface of cedar and, in terms of technical characteristics, fully complies with international standards.

The color fastness guarantee is 50 years.

Preparing the sheathing

Sheathing is a necessary element of the cladding design, a system of planks that support the siding fabric. Installation of the sheathing is done simultaneously with the external insulation of the walls (if required).

Wooden bars or metal guides used when installing gypsum plasterboard structures can be used as material for the sheathing strips.

- Installation begins with inspecting the walls and eliminating any defects found - dents, cracks, etc. After installing the insulation, access to the wall surface will cease, so all deficiencies must be eliminated in advance.

- The first layer (if there are two of them) of the sheathing is installed horizontally (i.e., coaxially with the direction of the panels). The pitch of the planks is equal to the width of the insulation boards, which are tightly installed in the gaps. After completing the installation of insulation and installing the planks, it is necessary to ensure waterproofing of the wall pie using a waterproofing membrane. It releases steam, but does not let moisture in in any form.

- Then they begin to install the second layer - the counter-lattice. It should be located perpendicular to the direction of the panels - vertically. The pitch of the counter-lattice strips should be 30-40 cm.

IMPORTANT! Additional strips are installed in the corners and around window or door openings, onto which the corner profile or platband will be attached. The sheathing strips are also reinforced along the slopes of the window openings.

The thickness of the counter-lattice must be at least 40 mm, which corresponds to the size of the ventilation gap according to the standards.

Lathing

Features of installation of metal siding panels

Facing the pediment with metal siding is carried out in several stages:

- Installation of the starting line;

- Installation of complex external and internal corners;

- Installation of row panels;

- Setting simple corners;

- Soffit installation.

First of all, the starting bar is installed a little higher, 3-4 cm. The first level of panel fastening. Next, the initial strip is fixed at a distance of 5-6 mm. This gap avoids overlapping of panels as a result of thermal expansion. Then you need to secure the finishing strip installed under the roof eaves.

If complex additional elements are used with metal siding, they are fastened in increments of 20-30 cm. This is due to their complex structural geometry, therefore, to ensure reliable fastening, frequent drilling of self-tapping screws is necessary.

Installation of a complex joining strip is carried out only after preliminary marking of the surface of the pediment, as well as marking all places where the panels join. At the very top of the last metal siding panel, the top of the strip is fixed, and the bottom edge should protrude slightly beyond the initial strip, approximately 5-6 mm

When installing a complex docking bar, it is very important to ensure that it is strictly perpendicular to the starting strip

Around the door and window openings, the strip is fastened from below. In the corner joints it is necessary to cut out “ears”, which are then bent down. To prevent water from seeping into corners, it is recommended to install a universal seal around doors and windows.

Installing regular metal siding panels is no different from installing vinyl panels. The panels are joined using a simple strip or a complex H-connector.

Important! The protective film from the panels is removed immediately before installation, which will avoid accidental damage to the front side. Installation of panels begins from the corner of the gable in the following sequence: the first row of panels clings to the starting strip with the lower lock

Subsequent rows are hooked to the lock of the bottom row. When installing the last row under the window, a near-window strip is inserted into the sawn recess and snapped onto the lock of the bottom row. The last row of panels is installed under the roof in a similar way.

Installation of the panels begins from the corner of the pediment in the following sequence: the first row of panels clings to the starting strip with the lower lock. Subsequent rows are hooked to the lock of the bottom row. When installing the last row under the window, a near-window strip is inserted into the sawn recess and snapped onto the lock of the bottom row. The last row of panels is installed under the roof in a similar way.

Simple corner strips are installed after installing the metal siding panels on the front side. To fasten them, galvanized self-tapping screws are used, drilled through the metal. It is advisable to buy screws that match the color of the panel.

The final stage of covering the pediment with metal siding is the installation of the soffit. As a rule, it is installed on downward-facing horizontal surfaces - overhangs and cornices.

Sizes and color

When choosing siding, the dimensions of the product and the color palette presented are of great importance. Ship timber (depending on the type and manufacturer) may have slight differences in parameters.

Steel siding

Metal products can be of the following sizes:

- width – 26 cm;

- profile height – 1.4 cm;

- thickness – from 0.5 to 0.8 mm;

- length 50–600 cm. Optimal – up to 400 cm.

Two-strip metal siding is considered one of the most popular.

Parts are painted using photo offset printing, which allows you to obtain a bright, durable and deep shade. The color range of this variety is quite extensive and includes more than 50 tones. There are also panels that imitate the cut of natural wood.

Vinyl panels

This option most often has the following dimensions:

- width – 23.8 cm;

- thickness – 1.1 mm;

- length – from 3 to 3.66 m;

- profile height – 14–16 mm.

The variety of colors is not as great as that of metal products. The most widespread products are pastel colors: walnut, mimosa, cotton, linen. Naturally, different companies may call shades differently.

Colors and sizes of vinyl siding “Shipboard” from the Grand Line company

Advantages

If we compare metal siding with vinyl, the first has a number of advantages, including:

- bright and fairly durable colors;

- strength and fire resistance.

As for installation, there is no particular difference between the materials in this regard. And in terms of performance characteristics, metal siding is in no way inferior to vinyl. It is also different:

- beautiful appearance;

- does not fade in the sun;

- easy to install and clean;

- Moreover, it is quite durable.

Having chosen metal siding, you can be sure that you will easily find in stores all the necessary additional elements that you will need during installation. They will be needed to decorate corners, cornices and ebbs. Their color range is so diverse that choosing the right color will not be much of a problem.

Mounting diagram

The range of metal siding is also quite wide. It can simulate:

- tree;

- stone;

- or brick.

But recently, “Shipboard” metal siding has become particularly popular, the assembly of which is practically no different from the installation of conventional siding.

Dimensions