Stone

Both artificial and natural stone are used to decorate support pillars.

The first one is especially popular due to its ease of installation and a large selection of textures and shades. In addition to traditional facing slabs, manufacturers offer corner and rounded elements, making stone finishing suitable for structures of complex and non-standard shapes. If it’s easy to do artificial stone cladding yourself, then to work with natural stone it’s better to turn to professionals. Here it is important to correctly match adjacent elements by color and not make mistakes in adjusting the dimensions when cutting. In order for the drawing to look harmonious, you will have to purchase material with a reserve.

Installation

When installing prefabricated fence posts, first check the modules for the absence of voids and moisture content in the material, so as not to impair the strength of the product.

Column cross section

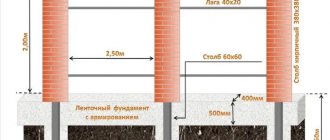

Supports used for concrete blocks for a pillar require a foundation, which can be columnar or strip. The position points of gates and gates are marked on the ground, the entire territory and space for installing supports of prefabricated structures are marked.

Installing the base

For a columnar foundation in the marked parts:

- Dig holes up to 1.5 m deep, with a diameter of 10–12 cm larger than the stand.

- Sand (40 cm) is poured onto the bottom of the pit, spilled with water, and compacted.

- Hammer a metal tube into the center of the pit or fasteners from fittings.

The height of the frame approximately corresponds to the height of the structure. After this, the pit is filled with concrete in several layers, compacting sequentially layer by layer.

The strip foundation is usually dug along the perimeter of the fence. The dimensions of the trench depend on the scale of the entire structure:

- if the foundation depth is 60 cm, then the hole for the racks is deepened by 1 meter;

- The width is made slightly larger than the width of the element.

Brick

The simplest way to finish concrete supports is brick cladding. It is practical, easily combined with a plaster facade, exterior in styles from country to high-tech. If necessary, to solve a purely decorative function, you can use clinker bricks. If you need to strengthen the column, facing is suitable.

There are enough color solutions on the market. You can choose traditional red, chocolate, ivory, etc.

Decorative plaster

The most cost-effective option for finishing concrete support structures is decorative plaster. It is easy to apply and relatively inexpensive. The variety of textures allows you to choose an option that harmoniously fits into the overall façade ensemble.

Among the disadvantages is a relatively short service life. Even when using facade plaster adapted to natural influences, the coating of the pillars will have to be renewed every 5-7 years.

Fence design

View of a fence structure with decorative load-bearing elements

There are many types of fencing depending on the material used. It can be wood, corrugated board, forging, brick, concrete and others. It all depends on material capabilities. But one thing remains unchanged - the design of the building. It is simple but must be followed to ensure long service life. Decorative fences are characterized by the following elements:

- foundation for supports;

- pillars;

- spans;

- logs;

- gate and wicket.

The design of the fence can be varied, but without a well-prepared base, the service life of even the most beautiful fence will be minimal.

Tiles and porcelain tiles

Ceramic and mosaic tiles in exterior design are not the most common, but quite original. Compared to rather expensive and heavy finishing made of natural stone, tiles have a number of advantages:

- The low weight of the material eases the load on the support.

- A simple installation method allows you to do the cladding yourself.

- Ease of cutting makes it possible to work with columns of complex shapes.

Quite often, modern design projects propose the use of porcelain stoneware for the facades of residential buildings. It is durable, visually attractive, and goes well with metal and glass. When choosing a ventilated facade for finishing a house, it is logical to use porcelain stoneware for decorating support pillars.

Types of raw materials

By origin, the material for the construction of supports can be natural or artificial. For the construction of natural stone pillars, the following is used:

- cobblestone - a rounded material of red-brown color, which is broken in half to obtain a flat surface;

- dolomite is a grayish-white or yellow-brown mineral that has strength, durability, resistance to temperature changes, and visual attractiveness;

- Limestone is a sedimentary material that can be easily processed but is capable of absorbing moisture. To eliminate this drawback, it is coated with a special water repellent. There are several types of limestone (marble, bryozoan, shell), differing in color and structure;

- pebbles - small, smooth, rounded sea stones. They are used in the construction of foundations, to fill the cavity of the column, but are not used to form the support itself due to their size;

- sandstone is a durable, water- and cold-resistant sedimentary rock. It can be chipped, hewn, polished, which allows you to experiment with the appearance of the fence;

- rubble - a rock derived from sandstone, dolomite, limestone, represented by rough irregularly shaped boulders with a diameter of 15-50 cm. Rubble stone pillars are erected by analogy with brick ones, but due to the unevenness of the raw material they require bandaging every 30 cm;

- granite is a hard mineral of volcanic origin, with high strength and aesthetic properties. Supplied in the form of slabs and blocks.

Metal support posts

Forged metal pillars in themselves are already considered a full-fledged decorative element. For durability, it is enough to cover them with primer and paint. The expressive supports will be accompanied by a forged canopy, railings, and street lamps. The ornate pattern can be repeated in the design of a fence or on the front door.

In modern design projects, they prefer not to mask poles made of metal pipes. They emphasize the geometry of the architecture and play in favor of a discreet and stylish exterior.

PICS - characteristics, application, personal experience

Fences made of corrugated sheets, although they are not particularly decorative, due to many other advantages they are one of the most popular fencing options. Columns made of facing bricks can significantly improve the external appearance of such a fence, but such tuning will greatly affect costs. Relatively recently, it became possible to decorate corrugated sheets with bricks without using the brick itself. FORUMHOUSE participants have already become familiar with the material and technology and are ready to share their impressions.

PIX - what and why

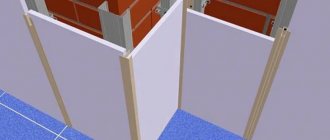

The abbreviation PICS stands for panels that imitate a brick pillar, so we note that the generally accepted designation “PIX panels” or “PIKS panels” or “PIKS panels for a fence” is redundant. The material consists of decorative panels with dimensions of 380x150x300 mm, weighing about 500 grams, from which a post-plate of the required height is assembled according to the type of constructor. The segments are attached to each other using a tongue-and-groove system, and to the fence - to a metal profile (for siding or drywall), using hardware or rivets. Depending on the parameters of the fence, the overlay can be only on the front side or double-sided. The end is protected from above with a special or ordinary cap for pillars; in its finished form, the panel really resembles a pillar made of smooth brick - volumetric casting, wide seam. Initially, the overlays were positioned as decor for fences made specifically from corrugated sheets, but they look quite organic with a metal picket fence, but in this option it will not be possible to get away with only half a post. There are no corner elements in the model range yet, only U-shaped ones, so to create a corner you have to use two overlays, cutting at an angle of 45⁰.

Panel imitating a brick pillar.

Production of PIX panels

PICS are made from polypropylene, currently in two color options - red (cinnamon) and yellow (straw). Alternatively, you can combine panels of two colors. The surface of the panel can be painted, so if you want originality, a brush/roller/spray can will help you create an exclusive shade. Operation of false poles is allowed in the temperature range from -40 to +60⁰С, which, in principle, removes territorial restrictions. However, the strength of even high-quality plastic is not comparable to the strength of stone, so if the panel is temperature-resistant, it is afraid of mechanical impact. Plastic panels are not decorative: they do not fade (five years warranty on lacquer coating), seams do not erode, efflorescence does not appear, and destruction does not occur under the influence of the external environment. According to the owners of fences with such overlays, it is very difficult to distinguish a plastic imitation from the original from a distance of several meters.

Installation

Due to their light weight, the overlays do not require a base, like real poles; they can be mounted directly on corrugated sheets anywhere. When the canvas is at a certain height, protruding metal pillars are masked with overlays. If the canvas starts from the ground or foundation strip, the panels are placed at equal intervals. To install the overlays on a sheet of corrugated sheets, guides (corners) are first attached, the interval between them is equal to the width of the panel. The segments are strung from bottom to top, the decorative panel is first attached to the corner with a screw or rivet (into the seam), and then the next one is lowered and a groove connection is made. The number of segments depends on the proportions of the fence, but on average, a two-meter post will require seven panels (fourteen for a double-sided fence). The final stage of installation is to put protective and decorative caps on the false posts.

PICS fences: from theory to practice

On our portal, in the forum thread on foundations and fence posts, there is an active discussion about the advantages and disadvantages of false posts in the topic about PICS. Among the mass of theorists interested in the performance characteristics of panels, there are also practitioners.

Mikst74FORUMHOUSE Member

I will make such posts on the picket fence, double-sided. Expensive at 4k for a plastic pole, but cheaper than a real brick. Therefore, there are only five pillars: corner (single-layer), and at the gate with a wicket - they are visible, so you need to do it on both sides.

Fence posts that do not “hang” in the air, but reach the level of the ground or foundation strip, if available, look more advantageous. If PIX is intended to be combined with a picket fence, it is worthwhile to provide a contact point in advance in order to hide the joints without creating gaps. But first the fence, then the decor.

Mikst74FORUMHOUSE Member

First the fence, then the decor, definitely. I attached everything to metal profiles from gypsum plasterboard (25x24, I think), and it was inexpensive, convenient, and reliable. On the front side, the risk rested on the center of the picket fence - the picket fence has just the right depression in the center.

Imitation of brick fence posts.

IKS can be easily sawed with a hacksaw for metal, or with a grinder, with a disc for iron, but the quality and speed of the cut differ. Using a hacksaw is slower, but you get a smooth edge, which is paramount when making cross cuts. If speed prevails and the cut along the seam or at the corner, the grinder will help out.

On the reverse side, Mikst74 saved money - instead of overlays, he used an OSB board, under which he also mounted a box from a profile.

When using overlays with welded fences and European picket fences, there are certain nuances.

BorodecForumHouse Member

In this case, it will be necessary to make double-sided posts, because the welded sectional fence is visible. One of the peculiarities of installing panels with Euro picket fences is that the guides on both sides are bolted to the logs, and slots were made in the panels on the inside for the logs. The caps can also be made of tin.

Mikst74 was pleased with the result.

Imitation of brick fence posts.

However, as the work progressed, some comments emerged.

- Assembly is complicated due to the weak cutting of the edge of the tongue and groove; pressure is required from both sides, which is problematic to do with one helmet;

- During the installation process, several corners fell off - the plastic is fragile, despite the summer assembly, and it is better to avoid impacts, although you can’t damage it simply by hand;

Portal participants who actively discuss fences with PICS are attracted not only by the appearance of the post simulator, but also by the price. If the perimeter is impressive, then the financial benefits are obvious.

sharpeiParticipant FORUMHOUSE, Moscow.

I also plan to make an imitation - I have 150 m of façade (triangle), I’ve stopped dreaming about brick or concrete pillars.

To be fair, it is worth noting that the difference in cost between the overlay and the brick original is not as great as PICS manufacturers and dealers position it, but it is there. And it is connected not so much with the cost of the pillar itself, but with the cost of the foundation required for it. A significant difference is obtained when ordering poles on a turnkey basis, but when producing them yourself, it is minimal.

Pillars made of brick or PIX - what to choose

But for the sake of the same fairness, it must be taken into account that not everyone has the opportunity to stack the pillars themselves, having spent a lot of time and effort on it. In this regard, plastic fence overlays are preferable - they are much simpler, faster and easier to install, and even a beginner can handle the process. Therefore, it is impossible to say that decorative overlays on fence posts are a full-fledged replacement for a brick post, but as a way of decorating a fence in a short time and with an attractive result, it is a completely workable option. And everyone decides to use it or resort to a proven method that has been proven for decades, based on their desires and capabilities.

Another quick method of transforming a typical fence is a photo mesh for the fence. If the fence is still in the plans, an article on the construction of a fence from corrugated sheets will help you make the correct calculations. The video shows a visual demonstration of the process of constructing a fence from corrugated sheets.

Stucco molding

Stucco decoration on the facade has been considered a sign of the taste and wealth of the owners of the house for more than a century. The materials used are stone, concrete, gypsum, polyurethane and even foam. The latter are lightweight, so they are especially often used to decorate columns, the additional load on which is undesirable. Stone and concrete significantly make the structure heavier, but are less susceptible to weathering and wear.

The nature of the stucco should be chosen in accordance with the general style of architecture. The supporting pillars of a country house in the Baroque style can be decorated with shells, plant motifs, and Atlantean figures. For modernism use asymmetry, for modern classics - moldings and flower garlands.

Top 3 manufacturers

Although the artificial brick substitute is not yet so well known to owners of private houses and summer cottages, three domestic leaders have already emerged with the largest sales volumes in our country.

LLC "Lama Plast"

The company's office and production are located in the city of Volokolamsk, Moscow region. The plant produces plastic products for household and industrial use.

PIX panels are available in several colors.

LLC "Modern Construction Technologies"

The company is located in Saratov. Engaged in the production and sale of roofing, facade, insulating materials made of plastic and metal. Produces plastic windows, fences, gates of varying complexity.

PALISADE BUILD

The plant in Moscow produces various building materials and fence structures. The company works without intermediaries and maintains its own teams of installers who install fences and cladding the facades of buildings on a turnkey basis. Installation work comes with a 3-year warranty.

Tree

When decorating façade columns, wood can be presented in several versions. These include full-fledged tree trunks, columns made of rounded timber, and strict, minimalistic beams. Wood fits equally well into the space of a country chalet, small country-style houses or modern architecture.

When using several finishing materials in the design of the facade, the finishing of the supporting pillars can be combined. The lower part is covered with brick or stone, and wood is left on top. The texture of the material is left to emphasize the environmental friendliness of the design or completely painted over to match the entrance door, roof or other facade elements.

Brick supports

Decorative pillars can be made using facing bricks that have high strength and protective characteristics. Modern technologies make it possible to produce bricks of mixed, figured and rounded shapes. The implementation of the artistic concept during the construction of pillars is facilitated by the variety of color shades of bricks and the many types of texture of their outer surface. A necessary condition for the manufacture of decorative brick supports is high-quality, professionally executed masonry.

Moisture entering cracks leads to rapid destruction, so the surface of the pillars and the seams of the brickwork should be treated in advance with special water-repellent solutions.

As a waterproofing agent, several layers of roofing material with bitumen mastic applied to its surface should be laid between the foundation and the lower part of the brickwork.

Carved decor

To decorate the facade of a house or gazebo in the traditional Russian style, it is appropriate to use carved supporting structures. The pattern on the pillar can be repeated in balusters, the design of a canopy or balcony. It is better not to hide the texture of the wood, but it can be tinted with glazes or stains and varnished.

When choosing a finishing option for external supports, you should take into account the constant influence of precipitation, sun and wind on them. The material must be strong, durable, resistant to frost and moisture.

Wooden supports

Wood is an affordable and easily processed building material. Its flexibility facilitates the production of intricately shaped pillars. Modern processing technologies make it possible to use wood not only for the manufacture of interior columns, but also for supporting parts of various outdoor structures: fences, gazebos, manor partitions. There are several processing methods that allow you not only to make beautiful wooden posts, but also to reliably protect them from external destructive factors: moisture, drying out, putrefactive and mold fungi. The main methods include:

- heat treatment;

- chemical treatment;

- brushing (artificial aging).

Blank for wooden support

Heat treatment

During this type of processing, the wood is gradually steamed and heated to a temperature of 135-140ºC in special chambers. This allows you to achieve good results: the structure and density of the wood changes qualitatively, the texture of the species is emphasized, which improves its appearance.

This method is one of the most expensive. Due to its energy intensity and the need for special equipment, it does not allow you to use it yourself at home.

Chemical treatment

This is an easily accessible and effective method that allows you not only to change the appearance of the material of the pillars, but also prevents its destruction. Chemical treatment is carried out in several stages:

- impregnation with antibacterial or coloring agents;

- applying a protective layer.

For impregnation, water-based chemical compounds (stains) are most widely used, which not only protect the wood from mold and putrefactive fungi, but also provide reliable fire protection. Available in a wide range of stains in various color shades, you can improve the appearance of the simplest wood. After impregnation and drying, the wooden posts are coated in several layers (with intermediate drying) with protective layers of varnish.

Method of artificial aging of wood

The technology of this method consists of treating the wood surface with metal brushes (brushing). The pillars are given their final shape and sanded. Then, using metal brushes placed on a grinder or drill, the surface is treated, selecting soft wood fibers.

The process is quite labor-intensive and time-consuming, since in addition to brushing it also requires sanding with nylon brushes and intermediate treatment with impregnations.