The cladding of the house, imitating a log frame, gives the building the appearance of a solid and respectable mansion.

At the same time, the walls can be made of any material that is free from the disadvantages of wood. That is, the house looks wooden, but the properties of all structures are completely different. The need to maintain the material is eliminated; the appearance of the building does not change over time, does not turn black or warp.

An imitation of a log building can be made of plastic or metal, which radically changes the performance properties of the cladding.

Metal block house

A log block house is a type of external cladding, traditionally a wooden panel. The cross-section of a block house is a segment of a circle, the side edges are equipped with a tongue and groove for connection. When assembled, the result is a canvas that looks like a log house made from a turned log.

Natural wood is not the best material for exterior finishing. Despite all the stabilization measures taken by manufacturers, a natural block house is susceptible to many harmful processes:

- Warping.

- Sensitivity to moisture.

- Fire hazard.

- Rotting, appearance of insects.

- The need for periodic staining.

These disadvantages have prompted manufacturers to find alternatives to natural wood. A block house made of galvanized steel has been developed for this purpose.

It is completely devoid of the disadvantages of wooden panels:

- Resistant to water.

- Not subject to rotting.

- The appearance does not change over time.

- Does not require maintenance.

- Installation is simple and easy to do yourself.

However, there are disadvantages:

- Quite a high coefficient of thermal expansion.

- Low sound insulation ability.

- Mechanical stress causes irremovable dents.

Actually, all qualities - both advantages and disadvantages - are common to all types of metal siding. If some precautions are taken when using the material, then no problems will arise.

The decorative capabilities of the material are much wider than those of natural wood . There is a wide range of panels in different color shades. Strength and resistance to all types of impact make a metal block house the most preferred material that imitates a log.

A complete set of components or, as they are also called, additional elements, allows you to design all elements of the facade without any tricks - window and door openings, external and internal corners, longitudinal joining of panels and many other functions are successfully performed by additional elements produced in absolute accordance with the basic panels by color, size, etc.

Photos of houses covered with imitation block houses:

Types of material

Metal sheets are processed by cold rolling using shafts on special equipment. In this case, the desired profile shape is achieved:

- under a log,

- Christmas tree,

- ship plank,

- flat/straight,

- block house.

Metal

log siding

accurately imitates the structure of wood with its characteristic rounded shape. This material has many advantages, unlike wood: it does not rot, is not destroyed by termites and other insects, and does not require periodic treatment with antiseptics and varnish.

Single or double herringbone siding

It is made by visibly overlapping sheets: the upper “board” overlaps the lower one at a slight angle.

Metal siding ship plank

made in the form of wooden panels similar to those used in the construction of ancient ships. This is a classic finishing option, thanks to which the walls take on a voluminous appearance. In the catalog you can familiarize yourself with and order similar products from leading manufacturers in Russia and the world.

Decorating a country house with wood-like metal siding

Smooth or straight siding is not inferior to other varieties, but has an increased service life (up to 50 years without changing the quality characteristics and shade).

Metal siding block house

popular in the design of facades of country and private houses of small heights, luxury cottages and adjacent buildings. It imitates a log frame and has invisible joining seams, which allows you to accurately convey the structure and appearance of the tree. More information about product options can be found here.

Decorating a house with metal siding to look like stone or brick

helps convey the texture and color of natural materials. It can be used to decorate the facades of buildings of any number of storeys, does not require special care and frequent restoration (the warranty period ranges from 25 to 50 years from different manufacturers).

Types of metal block house

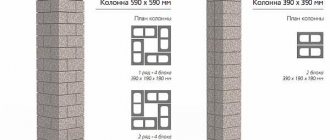

The wood-look metal block house has several varieties. First of all, there are panels with different numbers of waves - single or double wave.

Single-wavelength ones have a smaller width, but the wave itself is wider than that of two-wavelength samples.

This allows you to choose a material that will look more expressive and correct on the facade - the larger the wall area, the wider the wave of panels should be, and vice versa.

This ratio allows you to better design the surface and achieve a greater effect.

In addition, there is a wide choice of panel colors. You can select dark or light samples that have the color of natural wood with all surface elements - knots, cracks, etc. are indicated.

The main material for a metal block house is galvanized steel 0.5 mm thick. However, samples of material made from aluminum or copper sheets are available. They are much more expensive and not as widespread.

Preparation of lathing and insulation of walls

Installation of a ventilated facade

Metal profiles are widely used for the design of public and commercial buildings, country houses and private houses, verandas and gazebos. The specifics of panel fastening suggest cold and warm cladding options. The choice of thermal insulation is determined by the type of material from which the walls of the structure are built. For brick, concrete and sandwich panels, it is better to use inexpensive polystyrene foam or polyurethane foam. For “breathable” surfaces, the “ventilated facade” technology using mineral wool and membrane films is chosen.

The sheathing under the profile is mounted perpendicular to their location. The panels are installed on a sheathing, which can be made of wood treated with a special compound or metal profiles. The distance between the slats is taken within 50-80 cm, depending on the wind intensity in the construction area.

Specifications

Metal panels have the following dimensions and characteristics:

- Length - up to 4 m (some panels can be up to 8 m upon request).

- Width - 22.6 - 36 mm (without lock), 26-39 cm (with lock).

- The thickness of the material is 0.5-0.8 mm.

- Profile height - 3-4 cm.

- Weight - 2.4-3.6 kg/m2.

- The panels are equipped with anti-hurricane locks, providing increased resistance to wind gusts.

- Frost resistance - from -60° to +75°.

- The durability of the coating is up to 15 years.

- The service life declared by the manufacturer (average) is at least 20 years.

Main manufacturing companies

Among the most famous manufacturers are the following companies:

- Grand Line.

- Woodstock.

- Nord house.

- Metal profile, etc.

The number of manufacturers is much larger, but there is no need to list them, since when choosing a material you should be guided not by the name of the manufacturer, but by the performance qualities and technical characteristics of the cladding.

Where to buy metal siding?

Metal facade of an industrial building in the photo

You can purchase metal siding in construction stores and companies involved in the installation and finishing of facades and roofs of houses.

Moscow:

- "Facade panels", Moscow, Kholodilny lane, 3, bldg. 1. Tel.;

- "Metal Profile", Moscow, st. Admirala Makarov, 29. Tel. (495) 937-32-30;

- "Stroymet", Moscow, Kashirskoye shosse, 19, bldg. 2, shopping center "Kashirsky Dvor-1". Tel..

Saint Petersburg:

- “TopHouse”, St. Petersburg, Kolomyazhsky Ave., 15/1. Tel. (812) 244-95-15;

- "Steel Industry Company", Leningrad Region, Kommunar, st. Zheleznodorozhnaya, 2. Tel.;

- "GrandLine", St. Petersburg, st. Tsvetochnaya, 25, BC "Manufactory", office. 204. Tel..

In Novosibirsk:

- "AsTorg", Novosibirsk, st. Koroleva, 40, building 5, office. 106. Tel..

- "MasterDom", Novosibirsk, st. Planetnaya, 30. Tel. (383) 214-17-27.

- "Roof and Facade Center", Novosibirsk, st. Taiginskaya, 7, office. 504. Tel..

Preparing the surface for installation

The condition of the wall surface should be as close to ideal as possible. This is a very important point, since installing sheathing hides the walls and prevents access to them. If there are any flaws, areas of destruction or other problem areas, then all the processes occurring on them will become noticeable only when they reach critical sizes.

Therefore, the surface quality must be brought to the proper state, for which it is necessary:

- Remove all foreign objects and devices from the walls - air conditioners, lights, brackets, gutters, trim, etc.

- Carefully inspect the surface of all walls and draw up a defect report.

- Remove old paint layer.

- Any crumbling or peeling areas are removed.

- Detected defects must be repaired. The cracks should be expanded to determine their depth and configuration. Fill potholes and dents with putty.

- The best solution would be to completely plaster the surface. Especially if there are deep potholes, cracks or peeling.

- To strengthen the wall material and increase adhesion to the insulation adhesive, the walls should be impregnated with two layers of primer (primer).

NOTE!

The assertion of some experts that leveling the surface is not necessary is unfounded . The lathing is not so capable of correcting the situation, and the density of the insulating material, which directly affects its performance, completely depends on the condition of the plane.

Selection and installation of lathing

The lathing serves several purposes:

- Creation of a supporting system for block house panels.

- Formation of a ventilation gap.

- Support for insulation material.

From a design point of view, the sheathing is a system of strips located transversely to the panels, the surface of which forms a flat plane . It is customary to use wooden blocks as a material for it, but recently the use of metal guides for gypsum boards has been considered more practical.

They are free from the typical problems of wooden parts, have a perfectly flat surface, the same thickness and do not change properties over time. Prices for wooden and metal parts are almost the same, which is an additional argument in favor of metal strips.

There are two ways to install the sheathing. The first is a two-layer one, when a system of horizontal strips is first installed, between which insulation boards are tightly installed . The slats are carefully aligned on the plane, since then a layer of vertical slats is installed on them, which is the support system for the panels of the block house and, at the same time, provides a ventilation gap. This technology is good in cases where a thick layer of insulation is needed.

The second method is single-layer lathing. A system of brackets (direct hangers) is installed on the wall surface . The insulation is installed in a dense layer, the brackets are passed through it through the cut sections. On top of the insulation, on the protruding ends of the brackets, vertical sheathing strips are attached with careful alignment along the plane.

This technology allows you to significantly save on the purchase of planks and speeds up the process of creating lathing. In addition, dense installation of insulation reduces the possibility of the formation of cold bridges, which are dangerous for wall materials due to the possibility of wetting and destruction.

IMPORTANT!

The brackets are installed through plastic or paronite gaskets, which prevent the formation of cold bridges.

Installation of insulation, vapor barrier and waterproofing

The insulation is selected according to its technical qualities. The main one is vapor permeability - the ability to pass through water vapor passing through wall materials from inside the premises.

If impermeable insulation is used, the vapor is trapped inside the walls, which causes moisture, mold, rot, corrosion of metal elements and, ultimately, destruction of the walls.

Impermeable types of insulation, in particular, include polystyrene foam, EPS, penoplex, etc. Permeable types of insulation allow steam to pass through well, but can become wet, which significantly impairs their properties.

This type of material includes mineral wool; the best option is basalt (stone) wool. It allows steam to pass freely and has low thermal conductivity.

It should not be assumed that impermeable types of insulation cannot be used. They have excellent qualities, are resistant to moisture and do not lose their qualities over time. In addition, such materials do not need a ventilation gap - it does not make any sense. The only condition is the creation of a high-quality internal ventilation system that removes vapors from the premises and prevents the walls from getting wet.

The insulation is installed using special glue and, at the same time, using dowels with wide plastic washers on the cap. Some experts try to make do with only fungi, without using glue. This option makes the contact of the insulation with the wall less dense, which reduces its efficiency.

The glue is applied to the wall surface using a notched trowel and “combed” to obtain an even, calibrated layer . The insulation is laid on the surface and attached with fungi (about 5 fungi are needed for one slab of material). Gaps or cracks between the plates are not allowed; if they appear accidentally, the cracks should be filled with polyurethane foam.

NOTE!

A vapor-hydroprotective membrane is installed on top of the insulating material. This is the optimal type of waterproofing that does not allow moisture to enter the insulation from the outside, but facilitates its removal from the inside. The material is sold in rolls and installed in overlapping strips of about 15-20 cm. The joints are sealed with special adhesive tape.

How to attach panels

The panels are attached to the sheathing using self-tapping screws or nails through oblong mounting holes in the locking part . An important point is the need for loose fastening - for free movement of the material when heating or cooling, a gap of 1-2 mm is left between the head of the nail or screw and the panel.

If this is not done, the panels will begin to bend when heated, which can cause destruction of the protective coating or corrosion of the material.

For the same reason, the dimensions of all elements must take into account thermal expansion . For example, the length of the panels is made 6 mm shorter so that the corner or H-profiles do not expand when heated.

Photos of finishing houses with metal siding

House covered with metal siding in the photo

The facade of this house is covered with metal siding

The façade of this house has two-color metal siding.

Installation instructions

The house is sheathed according to the following scheme (more detailed instructions here):

- Setting the starting bar . It must be located strictly horizontally at the lowest point of the facade (or the junction of the facade and the plinth).

- Installation of corner profiles . External and internal corners of the facade, window or door openings are designed.

- Installation of H-profiles that carry out longitudinal joining of panels.

- The first panel is snapped into the lock of the starting strip , installed in the grooves of the corner or H-profile and fixed with self-tapping screws to the sheathing.

- Subsequent panels are installed in the same way.

- The canvas is completed by installing a finishing strip, which is a decorative element and protects the canvas from rainwater getting under the skin.

A metal (iron) block house gives the house the appearance of a wooden log house, but does not have the disadvantages typical of wood. The strength, resistance to external influences, and durability of the material make it a serious competitor to other types of cladding. The ability to install it yourself helps to save money and nerves; the ease of installation does not require any preliminary preparation. A metal block house is a high-quality durable material with high decorative and performance properties.

Additional elements for metal siding

Additional elements for metal profiles include:

- starting bar;

The picture shows additional elements for metal siding

- finishing simple plank;

- final complex plank;

- a simple strip for the inner corner;

- a simple strip for the outer corner;

- docking strip;

- complex plank for the inner corner;

- complex plank for the outer corner;

- complex docking bar;

- metal sheathing for siding. It includes: profiles;

- pendants.