Decorative pillars look extremely presentable and powerful, but at the same time they are distinguished by their simplicity and ease of installation, weight, design, and often financial ease of acquisition. Global protection of a site with a high fence is a traditional option for ensuring life in nature, but high-quality decor can successfully fulfill this role: a durable and inexpensive fence on decorative posts made of light blocks is an example of this.

PIX false pillars, imitating brick (as well as natural stone), are very popular due to their ease of installation and luxurious appearance. The dimensions are convenient for work; the weight of one block can be up to 0.5 kg. PIX block segments in the amount of 6-8 pieces form a decorative pillar with a standard height of 1.8 m, and if desired, blocks of different colors can be combined. Material - PVC, polypropylene and other types of polymers, designed for use in atmospheric conditions under the sun and showers, in heat and frost. Products from many manufacturers provide both covers for the hollow post and complete fasteners.

Design features and technical characteristics

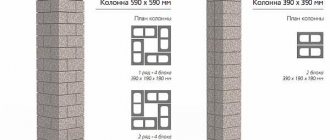

False fence posts for bricks are available in dimensions 380x150x300, 380x150x296 mm. The weight of one element is about 500 g. The thickness of the plastic is 20 mm. The U-shaped elements are completely ready for installation. One segment forms part of the decorative brick support. To form one support with a height of 1800 mm, 6 segments will be required.

Polypropylene withstands high and low temperatures (from -40 to +60 °C). The paintwork is guaranteed for 5 years. The color scheme is presented in only three standard options - red (cinnamon), yellow (straw), dark brown. Elements of all colors can be combined. If you want to make supports of any other shade, you can use the dyeing method. The paint is applied with a brush, roller, or spray can.

Parameters of ready-made panels Source yandex.ru

Kinds

All pillars, depending on the material of manufacture, can be divided into the following types.

Metal

They are pipes or profiles. The package usually includes a headband, tips, plugs, and mounting strips. They vary in thickness (cross-sectional size) and shape (can be round, square and rectangular). The thinnest (5 cm) are intended for fences made of chain-link mesh and other sheet materials. Racks with greater thickness (up to 10cm) can withstand the weight of forged sections.

Stone

Such supports can be made of artificial stone (bricks, cinder blocks, foam blocks) or natural (pebbles, sandstone, dolomite)

When choosing natural stones, you should pay attention to their surface and strength. As a rule, a metal rod is placed inside for reliability

Wooden

When choosing beams or logs, pay attention to how well they are dried, since raw wood can delaminate or become moldy and begin to rot. Naturally, this option will not last long, even if you take good care of it

Typically, wood species such as oak, birch, larch, and pine are used for the fence.

Reinforced concrete

As is already clear from their name, they are made of concrete reinforced with an iron profile. This type of support can be made independently by mixing concrete with sand or purchased ready-made (from a special high-strength and frost-resistant composition).

Asbestos

The most affordable option for poles. Their variety is asbestos-cement. They are produced in the form of round hollow pipes with an internal diameter of 10 cm. The thickness of the material itself is 1 cm. It is imperative to purchase plugs to prevent water from getting inside.

Plastic

Often, special pix panels are made from plastic, since this material is not very durable, and are used for the outer layer of supports. They are mounted on profile iron posts, simultaneously protecting them from the effects of natural forces and providing a presentable appearance.

Advantages and disadvantages

The finishing material is made from high quality polypropylene, so the coating is practically not subject to the negative influence of the environment. Positive aspects appear during operation. The following can be said about the new product: it is an environmentally friendly and safe material with the following properties:

- High aesthetic indicators.

- Practicality and easy care - the surface can be washed with clean water or with the addition of detergent.

- The structure is lightweight, so there is no need to create a powerful foundation for supports.

- Accuracy in imitation of brickwork, both in size and color.

- The ability to install poles in the shortest possible time. It takes from 20 to 40 minutes to install one decorative element, so this kind of work can be completed in 1-2 days.

- The absence of unpleasant moments that are inherent in natural brickwork. Owners will not have to worry about the appearance of lime stains (efflorescence) on the surface of the bricks and mechanical damage (chips, crumbling corners).

With temperature changes and high humidity, brick wears out faster Source ctep.ru

- Low price compared to natural facing bricks.

- Repeated use. After careful dismantling, the appearance of the panels does not deteriorate and can be reinstalled.

- Carrying out installation work regardless of the time of year and weather conditions.

- Polypropylene is resistant to sudden changes in temperature and moisture.

- A long period of operation, during which the appearance of decorative supports remains virtually unchanged.

A significant disadvantage of PIX panels is the lack of elements for corner posts, which significantly complicates installation work. The missing piece is created from two panels, which are cut at a precise 45° angle and joined in place using wooden strips. Only professionals can handle such work, so you need to trust the installation of fence posts to a construction company. Another negative factor is susceptibility to mechanical stress. If there is a strong impact, the surface of the pad segment will lose its shape. But this disadvantage is compensated by the fact that the damaged element can be replaced without dismantling the entire structure.

Individual elements are not difficult to replace if damage occurs in the form of cracks or dents Source market.sakh.com

When purchasing PIX panels, you should always take 2-3 more elements so that you can replace them with parts of the same color.

See also: Catalog of companies that specialize in the construction of fences and enclosures.

Do-it-yourself brick or stone fence repair

From this article you will learn how to carry out routine repairs to a brick or stone fence. We will tell you what tools and materials you will need for this, give advice on repairing the foundation and masonry, and list methods for eliminating cracks, sealing and undoing joints.

Foundation condition analysis

As a result of winter frosts, thaws and spring melting of snow, the foundation of a stone fence can be flooded, sag or swell. The appearance of such serious problems usually means that the following mistakes were initially made when constructing the foundation:

- ignoring the structural features of the soil and topography on the site;

- insufficient foundation depth;

- incorrect base (cushion) arrangement;

- lack of reinforcement;

- lack of drainage;

- low quality of the filling itself.

Preparatory work and tools

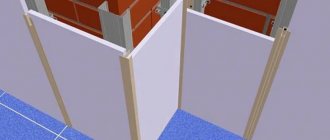

Installation of decorative elements begins after preparatory work. In addition to building materials, it is necessary to purchase fastening elements:

- Self-tapping screws (4 pcs. per PIX panel);

- 2 aluminum corners with a section of 20x20 or 25x25 per post (the length depends on the height of the fence) or wooden blocks of the same size, treated with antiseptic compounds that protect against rotting and insects.

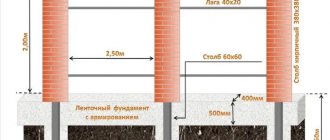

Markings are made along the perimeter of the site at the locations of the pillars. The optimal distance between supports is 300 cm.

Typically, posts are placed between sections of the fence to hide the seam and strengthen it Source palisadstroy.ru

Installation of Pix panels of fence posts

The assembly of the post-plate is carried out according to the Lego principle. The height of the support is determined for each individual case. The segments are connected to each other using a tongue-and-groove system, and attached to the fence using hardware or rivets. False fence posts are installed on one or both sides. In order to save time and money, you can limit yourself to arranging only the front part. But if aesthetic indicators are important not only from the street, but also from the yard, then double-sided decoration is more successful. You won’t be able to save on segments when using a metal picket fence.

After installing the entire support, a decorative canopy cover is attached to the last panel at the top of the post. This element improves the aesthetic performance of the entire fence structure. Calculation of the height of the column is done based on the parameters of the panels, but if not a whole segment is needed in size, then it can be easily cut using a grinder.

The panels fold into a column no more complicated than a children's construction set Source ok.ru

Installation

View of a finished fence post imitating brick with a protective cap

We fasten the corners to the fence canvas with self-tapping screws, bolts or rivets, and to wooden posts using self-tapping wood screws.

We install a decorative canopy on the first (top) panel, which, in addition to its main function, also protects the inside of the panel from precipitation. We attach the first panel, with the canopy installed, to the corners at the height of the fence.

Gradually going down, we connect the remaining elements together using connecting locks, and fasten them to the corners with self-tapping screws.

If the last (bottom) panel does not fit in height and needs to be trimmed, you should pay special attention to the direction of the post connecting latches. You can trim using ordinary metal scissors or a grinder. This completes the installation.

After wiping the surface with a damp cloth, the pole is ready!

Sometimes pix panels are used to cover the metal posts on which the fence panels are attached. Such work is carried out similarly to the construction of fence posts. These elements are not only well assembled, but also quickly and conveniently disassembled. Can be used several times without damaging its appearance.

The use of false panels is an ideal opportunity to get a cheap and beautifully designed fence or decorative fence.

Prices for PIX panels for fences

In terms of cost, imitation brick fence posts are significantly inferior to natural analogues - 5 times cheaper. Huge savings are also created through the installation of overlay panels, which is faster and less expensive compared to masonry work. Therefore, for those land owners who cannot afford to install expensive fencing, this option is considered the most optimal and cost-effective.

You can find out how much it will cost to improve your backyard area from the specialists of the construction company. Based on the provided data for a specific site, preliminary calculations will be made.

Manufacturing technology of fence blocks

There are two ways to make individual blocks. They were already mentioned at the beginning of the article; these are cast concrete blocks and pressed ones. Both types are fairly easy to make at home. You just need to make a shape, but difficulties may arise if you want to decorate the plate with patterns.

Concrete

Fence blocks are made by vibration casting by molding concrete mixtures. To make such elements with your own hands you will need: sand, gravel, expanded clay, cement, plasticizer, any coloring pigment, marble or quartz chips.

Plasticizer for concrete

To make a reliable and durable concrete block, you need not only high-quality raw materials, but also special equipment and devices:

- a vibrating table with a drive to create maximum structural density and remove voids from the solution;

- special forms;

- a concrete mixer that ensures thorough mixing of the components;

- auxiliary materials: tampers, trowels and water tanks.

The usual square shape is not suitable for making blocks. She must have:

- framework;

- steel inner insert;

- four fiberglass plates;

- external bolts;

- texture elements with grooves.

Sequence of work:

- the assembled form is laid out on a vibrating table;

- We make concrete for pouring fence posts in the following proportions: 2 parts sand, 1 part cement grade 400–500 and the required amount of plasticizer;

- to give a decorative effect, you can add 2 parts of granite screenings, small crushed stone, etc.;

- for high-quality preparation of the mixture you need a concrete mixer;

- the volume of the mold is filled and air bubbles are eliminated;

- the filled forms are placed on the table for drying;

- After three days, the form is removed, and the finished concrete block is left to dry completely.

Pressed

The process has significant differences. The most important thing is that one form is enough to work.

- as in the case of concrete mortar, prepare the mixture in the same proportions: 2 parts sand, 1 part cement grade 400–500;

- add 2.5-3 liters of water;

- mix the mixture well using a concrete mixer;

- gradually filling the volume of the mold, make tamping;

- remove the form;

- leave the blocks to dry.

Recommendations for block production

- the solution must be compacted very well;

- stands for forms when concreting must be sprinkled with sand or covered with polyethylene;

- After removal from the mold, the blocks are dried on each side for 2–3 days.

Photos of fences with PIX posts

Decorative imitation of brick fence posts made of corrugated board and metal picket fence is an ideal opportunity to beautifully and inexpensively decorate the site of a country house or luxury cottage. Before you decide to install PIX panels, you should look at photos of finished fences. Using illustrative examples - photo galleries of finished work - it is easier to understand what overhead supports will look like on a specific site.

PIX on vertical corrugated sheet Source bazar.babyblog.ru

Budget, but very beautiful fence Source www.prozabor-nn.com

Which ones are better?

Of course, each type of support has its own advantages and disadvantages. The same plastic, with its convenience, versatility and ease of installation, although it creates an imitation of a brick pillar, can never compare with it in strength.

Stone products have other advantages, for example:

- Durability.

- A huge number of facing materials provides a pleasant appearance.

- During operation, they require virtually no repairs.

- You can make them with your own hands, showing not only skill, but also creative qualities.

- Flexible pricing policy - if you lack funds, you can choose a cheaper type of stone or use artificial options.

And in this case, making it yourself will take much more time.

In addition, they need special processing, just like wooden ones. Only proper protection will protect them from corrosion and rotting. Used pipes, such as tubing, must be reprocessed.

But you don’t need to take care of them, and water only makes them stronger. Their price is more than affordable.

Application

The spread of the trend with decorative pillars began several centuries ago, and in order to get a rough idea of architectural traditions, just look at the design of palaces in St. Petersburg or Paris.

The classic combination of metal and stone has been borrowed by modern builders for fencing government buildings and luxury mansions.

Installation at the dacha

In a less expensive form, it is welcomed by the owners of new buildings or family homes.

The modern construction industry, which has mastered dozens of new materials, has expanded the concept of decorative fence posts. Brick and natural stone remain the classic option for any type of fence.

But concrete, mesh structures with crushed stone, and plastic appeared, which decorate the most primitive options. There are multiple price lists with numerous examples that give an idea of what decorative blocks for fence posts are.

Variety of options

The use of pillars has expanded the scope of demand, but has not limited it, and on modern construction sites you can find many unconventional options for using decorative pillars - from an enclosed atrium and veranda to a large balcony, observation deck, canopy in front of the house, equipped for decorative purposes.

The differentiation of the scope of use of pillars, pillars and columns has led to the need for a targeted choice made taking into account all components.

Fence of a private house

The criteria for selecting the necessary style components were:

- design options and methods of its installation, construction and stability;

- manufacturing material, in which there are possibilities for stylization, replacing natural decorative stone with no less expressive fakes made of plastic;

- durable frame devices, giving the chance to use lighter and cheaper raw materials without loss of visualization and strength;

- dimensions, parameters and configurations to create a unique or standard constant of the same familiar brick fence;

- additional decorative elements (balls and cones, lamps, combinations with metal elements, stucco or its imitation);

- color scheme (contrasting, similar in color perception and tone, combined, imitating geometric or abstract patterns);

- modification of shape (parallelograms, rounded outlines, cones, columns with pedestals or pedestals).

Storage of finished racks

Places of use

The usual options used for fences in the private sector, urban settlements and rural areas, as the trend towards the construction of country houses or luxury mansions spreads, led to the need to develop new projects that could fit into the open area.

Decoration

As mentioned above, the fence also serves a decorative function. Therefore, supports decorated with wood, brick and many other materials are often installed. Nowadays, prefabricated supports that can be assembled by one person are in great demand. For example, they may consist of “cubes”, which are decorated with ornaments on four sides. This fence element weighs little and looks attractive.

In the design of such concrete columns, the load-bearing element is a reinforced concrete core, in which an iron pipe or reinforcing grid is used.

Concrete supports

The use of sectional concrete blocks allows you to independently and in a short time build gate and fence posts that are quite attractive in appearance. Sections for decorative supports are made with patterned surfaces or relief that replicates the structure of natural stone.

Concrete supports and blocks

First, by pouring concrete into buried formwork, a foundation is made with reinforcing metal rods vertically inserted into it. And after the concrete has completely hardened, the blocks are strung one by one onto reinforcement and fastened together with cement mortar. The voids inside the blocks are filled with concrete and compacted.

Artistically designed supports

At all times, pillars as an architectural element provided not only their main functional purpose in the form of a load-bearing part of a building structure, but were also used as decoration. Decorative pillars made in the artistic genre add special attractiveness and aestheticism to any design idea. Supports are:

- parts of fencing structures;

- columns - as a component of the interior of premises;

- supporting part: roofs of gazebos and verandas, arches and outdoor lighting devices.

From stone

Decorative stone pillars are much cheaper than natural stones, but they still look much richer than simple iron ones or those lined with an imitation plastic layer. They are also made by vibration (using special vibrating machines) from sand concrete and dyes.

However, this method has gained quite a lot of popularity. Special forms and additives have been developed, which give the products the appearance of natural stone of various types and enhance even the simplest hedge.

Structural installation diagram

pros

Such supports have many advantages, one of which is their relative cheapness (much more affordable than natural stone). This textured product has excellent visualization, is lightweight and easy to install, and can be laid on any surface.

Price

The price of decorative stone depends on the complexity of the texture, the depth of the relief and the manufacturer. It can vary from 900 to 1600 rubles. for 1 m2.

In the village

Building a fence sometimes takes more time to select and purchase quality building materials than the foundation and walls of the house. This is due to the fact that a fence is not only a means to delimit territory and prevent the entry of strangers. A beautiful hedge, according to many owners, is the calling card of the entire land ownership.

Metal supports

Decorative pillars made of metal easily fit into any type of building structure. As a rule, they have a high cost due to the fact that their production often requires individual project development and special technological equipment. For example, prefabricated supports made from artistically executed cast elements.

Molded lighting pole

Still, with certain skills, you can independently make beautiful pillars from bent metal parts welded together.

One of the ways to make such supports is to take a pipe as a basis, onto which decorative elements are fixed - bent rods, strips or artistically made forged parts.

It must be taken into account that the aggressiveness of the environment contributes to the appearance of rust columns on the surface. Therefore, at the final stage of their production, the metal is thoroughly sanded, degreased and coated with special types of anti-corrosion primer and paint. Fences whose decorative elements have a copper or bronze galvanic coating look most aesthetically pleasing.

Metal support

Main Dimensions

The length of factory posts ranges from 1.7 to 4.2 m, which allows you to select the height of the supports taking into account the purpose of the fence. The minimum cross-section is from 13*13 cm and above.

Photo: size guide and various shapes of reinforced concrete pillars from the manufacturer

If the list of products does not contain sizes suitable for you, you can place an individual order.

What it is

The abbreviation PICS, well known in the construction world, means a panel that imitates a brick pillar. This is a decorative element used in the construction of fences. The dimensions of one design unit are 38x15x30 centimeters and weighs 500 grams. From such blocks the structure is assembled in the form of a pillar of the required height.

Brick posts look great: with a wooden fence, forged, or made of metal sections. In this case, you will have to attach PICS on both sides to get a full-fledged pole. To design the corner sides, you will need to cut the panel at an angle of 45 degrees and mount two similar halves into one.

Things to remember

In addition, a brick pillar floating in the air looks a little strange, and eloquently demonstrates the fact that it is just an imitation.

When performing work, make sure that all panels are tightly connected to each other. Be careful not to damage the protective coating, as this will cause the panel to begin to deteriorate.

If scratches or other surface damage appears on the false posts during operation, you can carefully clean the area with sandpaper and re-coat it with paint.

Subsequently, it is advisable to completely replace the damaged section.