Aerated concrete products are a high-quality alternative construction material, which is increasingly replacing the usual brick, stone or wood. This popularity is due to its wide range. Therefore, in the process of designing and subsequent selection of the brand of aerated concrete blocks, many questions arise. How thick should an aerated concrete wall be? What should you pay attention to when selecting the thickness of aerated concrete wall block? The answers are presented in the article.

How thick should an aerated concrete wall be?

The power value is calculated depending on the following factors:

According to the requirements of such standards as SNiP 23-02-2003, the minimum thickness (H) is calculated using the following formula: H = Rreq × λ, where:

The value of D is equal to the product of the difference in indoor temperatures during the heating period and the average daily outdoor temperature by its duration in days: D=(tin.room-toutdoor)×Rot.period.

Calculation of the power of structures made of cellular concrete for various zones of the Russian Federation:

Graph of changes in the thickness of wall structures depending on the region and brand of gas silicate blocks:

The “golden mean” and the most optimal strength-thermal conductivity ratio are characterized by D500-D600 blocks, most often used in the construction of residential buildings and cottages, as well as other buildings.

What to consider when choosing the power of wall structures?

In addition to the calculated values, there are also several other factors on which the thickness depends.

2. Type - load-bearing structures should be 10-15 cm thicker than the partitions inside the room.

3. Number and location of floors - as the height of the building increases, aerated blocks with greater strength are used. The thickness of the walls of a one-story building should be at least 25 cm, two or more - 30-40 cm.

4. Climatic conditions outside - the duration of the cold period and average temperature indicators directly affect the strength of the building's fences. Walls in Siberia are made thicker than in the southern regions.

GOST requirements

Construction work using cellular concrete material is regulated by special requirements. The main recommendations for using blocks are as follows:

- regulatory documents require that the maximum height of the wall be determined by calculation;

- building heights are limited. It is allowed to build five-story buildings with a height of two dozen meters from blocks that have undergone autoclave processing. Self-supporting walls in nine-story buildings should not exceed thirty meters. Foam block material is used in the construction of a three-story building, the maximum height of which does not exceed ten meters;

- The standard defines strength indicators taking into account the number of floors. Block B 3.5 is used for the construction of a five-story building, and for three- and two-story buildings, B 2.5 and B 2 are used, respectively;

- For self-supporting walls, block material B 2 - 2.5 is used.

Calculating the mass of aerated concrete blocks

As already mentioned, we present the calculation using a specific example of a 200x300x600 gas block.

For calculations, the formula is used: mass (kg) = volume of aerated block (m 3 ) x density index (kg/m 3 ).

Let's do the calculation:

When calculating the load that the house will exert on the foundation, it is worth considering the possibility of using blocks with different sizes and strengths - their mass per 1 cubic meter is completely different.

Making calculations using a similar principle, we can calculate that a product with dimensions 200x200x500 and density 500 (0.2*0.2*0.5=0.02*500) will weigh exactly 10 kg.

Marking: material characteristics

Aerated concrete blocks are divided into types in relation to their purpose, namely:

The walls of a building are usually built from a material belonging to the structural type.

The specific gravity of aerated concrete depends on the filler. In this regard, aerated concrete is:

The material containing expanded clay is of the light type.

A significant disadvantage of the material is the low coefficient of strength and bending to tensile parameters. A volumetric object requires mandatory reinforcement.

Wall classification

These elements are considered basic in any object. The quality of the aerated concrete wall determines the parameters of the future building - attractive appearance, comfort, insulation from extraneous noise, resistance to fire, the possibility of using furniture and hanging equipment, and environmental friendliness. According to their purpose, walls are divided into external, load-bearing and partition walls.

External

They must retain heat indoors. For construction, it is recommended to use block material grade D600 class B2.5 - 3.5. As a rule, the front surface is finished with facing material.

Bearers

This type of construction represents a natural continuation of the foundation, representing an integral part of the entire structure of the object. This type of wall is a support for load-bearing beams or reinforced concrete floor slabs, experiencing certain load effects.

Septal

With their help, the interior space of any room is organized. For the most part, partitions are not load-bearing structures and are loaded only by their own weight and objects placed on the surface. They are built from block material D500 - 600, the thickness of which is 10 - 20 cm.

Exact calculation

You can find out the weight of the block using a geometric formula, the parameters of which depend on the dimensions of the material and density, namely m = V multiplied by p, where:

- m is the weight indicator;

- V—volume;

- p—density.

Aerated concrete is a building material that is very popular due to its properties. It can be used for the construction of houses and industrial facilities. When choosing such a product, you need to know its size, density and weight.

We will also consider its advantages over other building materials.

Marking by density type

This indicator determines the area of use of aerated concrete. Measured in kg per m3, the numerical indicator indicates the grade of concrete that was used in the manufacture of the aerated block. Accordingly, this answers the question of which aerated concrete is better to build a house from.

The lower the numerical designation of the brand, the lower the density and specific gravity of the building material. But the thermal insulation value of “smaller” blocks is higher than that of a product with a “larger” label.

Blocks of various brands are conventionally divided into:

- Structural. They are also the most durable and have a high specific gravity. Used in the construction of load-bearing walls. The product is often used in buildings up to 3 floors. These brands also include D blocks. Such blocks are best chosen when building a cottage or country house

- Structural and thermal insulation. These include brand D. Recommended for the construction of load-bearing structures, as well as internal partitions of the building

- Thermal insulation. These are the least durable materials. We are talking about the marking of aerated concrete blocks D200 - D. They are used as a heat insulator. They are also suitable for creating partitions inside a building.

The marking is a guide for the user from the manufacturer. Thanks to this indicator, it is easier for a builder to understand which brand of aerated concrete is better to choose. The strength of the house, and even the safety of the people in it, depends on the correctness of this choice.

Numbers

You can read how to use blocks for internal partitions from the article.

You can find out what the price and characteristics of a gas block are by reading this article.

You can find out the opinion of experts about whether a foam block or a gas block is better by reading this article.

If you want to save money, then when purchasing you need to take into account the dimensions of the product, as well as correctly calculate the quantity. To avoid such problems, you should carefully study all types of aerated concrete and its sizes.

You can find out whether a foam block or a cinder block is better by reading the article.

The difference between a foam block and a gas block is indicated in the description of the article.

The video explains how to calculate the weight of a house made of aerated concrete:

Economic feasibility of insulation

Now that we have determined the thermal insulation characteristics of the building, we should evaluate the return on possible costs. To do this, you should estimate the amount of upcoming insulation costs, and compare the result with the cost of heating.

According to first estimates, the surface area of the walls of a 7 x 7 house will be 100 square meters. meters. The estimated cost of thermal insulation of such a cottage will be 100 – 150 thousand rubles. The service life of mineral wool exceeds 25 years.

A basic calculation shows that the game is worth the candle. The house should be insulated, especially since any subsequent increase in energy prices will result in savings for you: you have already invested the money.

You can ask your question to our author:

What does mass depend on?

Experienced designers prefer to calculate the weight of aerated concrete blocks at the design stage. This is due to the fact that this characteristic allows you to recognize and correctly distribute the load on the foundation of the building.

Preliminary calculations of indicators help prevent warping or subsidence of walls. In addition, if you know the size and weight of the blocks, you can calculate the costs of materials and their transportation.

The weight of aerated concrete depends on the size, composition of the solution, humidity and density.

Kawabanga! Online calculator for calculating building blocks

Density

To divide building blocks into categories based on density, manufacturers carry out labeling, which is regulated at the state level. The indicator is designated by the letter D, and the value is given in kg/m³.

Humidity

The composition of concrete-based solutions has a great influence on the mass of finished products. Domestic manufacturers adhere to GOST requirements, so there are no significant differences in the ratio of components.

What is aerated concrete

When building a house, pay attention to the different sizes of gas blocks

When choosing aerated concrete blocks (sizes and prices per piece will be discussed below), the following criteria must be taken into account:

- total load on the walls;

- thermal characteristics;

- proportionality of masonry;

- ways to simplify the construction process;

- dimensions of the gas block depending on the design dimensions of the building;

- price.

Aerated concrete blocks: pros and cons, expert reviews

Let's figure out what makes aerated concrete blocks so in demand and popular in the construction industry, and what doubts arise when using them?

Related article:

Technical characteristics, sizes and prices of foam blocks. Advantages and disadvantages of construction from foam concrete blocks. Sizes and prices of foam blocks. Areas of application. Selection of foam blocks: technical characteristics.

Advantages of aerated concrete blocks:

Scheme of insulation and cladding of aerated concrete walls

- this is an environmentally friendly material that is made from natural ingredients that do not emit harmful substances;

- gas blocks have a high level of heat saving. Due to their porosity, aerated concrete blocks almost do not conduct heat. This reduces the cost of heating the house in winter, and protects against overheating in summer;

- Soundproofing properties are provided by cells with air. External noise will remain outside the walls of your home. They absorb low-frequency noise especially well;

- aerated concrete does not burn - it is a fire-resistant material that can withstand direct exposure to open fire for a long time. Its fire resistance is given by its mineral composition;

- gas silicate concrete is frost-resistant. The degree of frost resistance depends on the technical characteristics of the individual blocks.

Level laying of autoclaved concrete blocks is carried out using a building level

Speaking about the pros and cons of aerated concrete blocks, it is worth mentioning their disadvantages, which you should pay attention to when choosing this material for construction:

Types of wall finishing made from aerated concrete blocks

- Due to the porosity of the material, conventional fasteners are not suitable for fastening massive structures to the walls of aerated concrete structures. It is necessary to purchase special ones - for porous fragile structures, which can also entail additional costs;

- When laying porous blocks, a cement-sand or special adhesive solution is used. In the first option, heat loss increases by 25%, in the second – by 10%. In addition, thermal resistance also decreases due to the use of jumpers and reinforced belts. Thus, some experts believe that manufacturers of aerated concrete products exaggerate statements about the high heat conservation of this material, since heat losses that are not taken into account in the technical characteristics occur through the laying seams;

- aerated concrete absorbs moisture, so it is necessary to make a vapor barrier in the structure from such material. An anti-steam effect is achieved using a deep penetration primer and plastering work;

The tongue-and-groove system performs the function of a “thermal lock” and allows you to avoid applying glue along a vertical seam

Kinds

Aerated concrete walls come in the following types:

- single-layer;

- multilayer.

The latter are popular. The construction of such a structure allows you to save on construction costs due to the insulating qualities of the material. But for private houses this option is not recommended, because it entails an increase in costs for design and construction work.

Single layer

The construction of such walls is a simple process.

The following materials are used for their construction:

- hollow ceramic block;

- aerated concrete stone.

This wall has a number of positive qualities:

- retains heat well indoors;

- muffles extraneous sounds;

- easy and quick to install;

- convenient to use;

- saves money;

- can be put into operation upon completion of construction work.

In addition to the positive qualities, there are also negative points:

- there is a need for isolation;

- there is a high probability of a “cold bridge” forming.

To build a high-quality wall, you must observe the temperature conditions inside the room. Optimal conditions are considered to be from 5 to 25 degrees Celsius.

You can use aerated concrete to install walls and partitions, create window and door openings using U-shaped stones.

Multilayer

When constructing this design, the following materials can be used:

- wood;

- bricks;

- foam concrete;

- expanded clay concrete;

- chipboard;

- aerated stone;

- blocks from sand-lime raw materials.

In addition to these materials, the technological process involves the use of an insulating and facing layer. In this embodiment, the masonry performs load-bearing functions, taking loads from its own weight and the structures located above.

By design, multi-layer walls are two- and three-layer.

The first option involves insulation using a wet or dry method. Wet installation work involves fixing insulating layers on the wall surface with an adhesive solution. Dry masonry is performed by installing thermal insulating material on a metal frame. In such cases, polystyrene sheets or mineralized wool are used.

The advantages of two-layer wall structures are:

- thermal insulation qualities;

- wide selection of materials;

- minimizing “temperature” bridges by following the masonry process.

There are a number of negative points:

- due to insulation, the cost of the structure increases;

- installation takes a long time;

- the work involves significant labor costs;

- short operational period of thermal insulation material.

When working with a three-layer structure, the following positive aspects are highlighted:

- thermal qualities of the material;

- large selection of products;

- maximum thinness of the supporting structure;

- use of various claddings.

However, such a wall will be too expensive, it will take a lot of time to install it and the participation of experienced specialists.

how to calculate how much 1 piece and 1 m3 of material weighs

What does mass depend on?

The weight of a gas block is influenced by two parameters:

- density;

- humidity.

Density

The density value is displayed on the material label and is indicated in units of kg/m 3.

Weight of aerated concrete 1m3 depending on brand

| Brand of aerated concrete | Density (kg/m 3 ) | Weight of 1 m 3 of aerated concrete (kg) |

| D300 | 300 | 300 |

| D400 | 400 | 400 |

| D500 | 500 | 500 |

| D600 | 600 | 600 |

From the table it follows that 1 cube of aerated concrete brand D400 weighs 400 kg, 1 cube of brand D500 weighs 500 kg .

Humidity

As for humidity, this indicator affects mass in a similar way. The higher the percentage of moisture, the greater the mass of the material.

Kawabanga! Composition of concrete for paving slabs; main components and manufacturing details

According to the production technology, autoclaved aerated concrete is subjected to long-term exposure in an environment of saturated steam under high pressure. Products leaving the conveyor contain 25-30% moisture.

Mass calculation

How much does a block weigh?

To carry out calculations, you must initially know the dimensions of the material and density.

Calculations are carried out using the formula m=V*p. The designations are as follows: m – block weight (kg), V – volume (m 3 ), p – density (kg/m 3 ).

In order to find out the volume, you need to multiply all the values. As an example, let's calculate the weight of a gas silicate block of 600x300x200 mm and density D500.

Given:

- Size: 200x300x600 mm

- Density: 500 kg/m3.

Answer: The weight of an aerated concrete block 200x300x600 excluding humidity is 18 kg .

Let's consolidate our knowledge and make calculations for the popular wall block 250x400x600 mm and density D400.

Given:

- Size: 250x400x600 mm

- Density: 400 kg/m3.

- V = 250 mm * 400 mm * 600 mm = 60000000 mm 3 = 0.06 m 3

- m = 0.06 m 3 * 400 kg/m 3 = 24 kg

Answer: The weight of 250x400x600 excluding humidity is 24 kg .

Note to the builder

In addition to standard blocks with straight edges, some modern factories produce blocks with hand grips on both sides.

This material is convenient to lift and carry.

At the same time, glue consumption does not increase, since the installation technology does not require filling voids.

So, in our first example, a fresh factory block, just coming off the assembly line, will be 30% heavier than the calculated values. Its weight for our first example will be:

m = 18 kg * 1.30 = 23.4 kg

For the second example, I propose to make this simple calculation yourself and estimate your capabilities for lifting such blocks onto the walls alone.

Pallet weight with blocks

This characteristic will be useful when planning the delivery of material to the site. Each truck has limits on its load capacity and the volume of goods it can carry.

Let's say visually it seems to you that 10 pallets will fit into the truck. But the driver, having found out the mass of the pallet, will say that he can only take 8 pallets. And he will be right, since the carrying capacity of the vehicle should not be exceeded.

Determining the mass of a pallet with aerated concrete is easy. Knowing the number of units of material in a pallet and the weight of one gas block, multiply these values.

By the way, many sellers release material from the warehouse in whole pallets. And in the price list they indicate the density and volume of the pallet.

We already know that the density of the blocks corresponds to the mass of one cubic meter. Accordingly, multiplying the density by the volume we get the desired weight of the pallet.

For example, as can be seen from the proposed price list, the volume of a pallet with blocks 600x200x300 mm is 1.8 m3. Let's calculate the mass of the pallet for density D400.

m = V*p = 1.8 m 3 * 400 kg/m 3 = 720 kg

If we bring aerated concrete from the factory, we will make an adjustment for humidity: 720 kg * 1.25 = 900 kg.

How much does a cube of aerated concrete weigh and determination of real density

At the beginning of the article, the very first table shows these values without any calculation. The weight of a cubic meter of gas silicate material corresponds to the density indicated in the marking (D400, D500, etc.).

However, situations are different. You may want to check whether the factory gas silicate meets the stated characteristics. Or you were short on a pallet of blocks, but your neighbor had some left over. At the same time, your neighbor does not remember the characteristics of his aerated concrete.

Once we know the real mass, we can calculate the real density.

In this case, we will need to weigh 1 block and calculate using the inverse formula p=m/V . Where:

- m – weight (kg) - you need to find scales and weigh 1 block;

- V – volume (m 3 ) – we calculated it above;

- p – density (kg/m3).

Don't forget to adjust for humidity.

Calculation of the amount of material in 1 m 3

The calculation is carried out in two steps:

This characteristic is usually indicated in the price list.

In the design documentation for the construction of a house, the calculation indicates the volume of required material, which is obtained by multiplying the area of the walls, taking into account openings for windows and doors, by the thickness of the walls.

Dimensions and weight

To summarize and taking into account the dependence of mass on the density of the material, we can give the following weight parameters for each brand. The data is represented by one of class="aligncenter" width="600″ height="306″[/img]

In conclusion, let me remind you that when choosing a brand and size, you need to take into account the length, width and height of the walls, as well as their functional purpose.

Useful video

How to lift a heavy gas silicate block to the second floor, showing ingenuity.

We tried to write the best article. If you liked it, please share it with your friends or leave a comment below. Thank you!

Table (thermal conductivity coefficient of aerated concrete)

The lower the value, the better.

For greater clarity, let's make calculations.

For example, you want to build a house in the Moscow region. The required value for thermal resistance in Moscow is R=3.28 . Your house is made of autoclaved aerated concrete D500 with a thickness of 300 mm, and you need to decide on the thickness of the insulation.

The thickness of the aerated concrete wall (0.3 m) is divided by the thermal conductivity coefficient of aerated concrete D500 (0.14).

Thermal resistance of the wall R = 0.3/0.14 = 2.14 m2 °C/W.

Next, we subtract the resulting thermal resistance R (2.14) from the required value R(3.28).

3.28-2.14=1.14.

This means the thermal resistance of the insulation should be 1.14 m2 °C/W.

Thermal conductivity coefficient of mineral wool = 0.04.

Multiply 1.14 by 0.04 = 0.0456 meters, that is, 45 mm.

That is, the required insulation thickness was 50 mm.

Thus, you can calculate the required insulation for any wall.

Weight of aerated concrete blocks

Next we will talk about the weight of an aerated concrete block and how it can be calculated using the example of 200x300x600 blocks.

What factors influence weight indicators?

There are two of them: density and size.

Kawabanga! How many expanded clay concrete blocks are in a pallet?

Density

It is worth considering that the weight of structural gas blocks will be much higher than that of thermal insulation blocks.

Dimensions

Approximate weight of blocks depending on size

Naturally, a gas block with dimensions 100x100x300 will weigh less than 200x300x600 (subject to the same compaction).

That is why it is impossible to do without taking into account the dimensional characteristics of a specific unit of material.

Calculating the mass of aerated concrete blocks

As already mentioned, we present the calculation using a specific example of a 200x300x600 gas block.

For calculations, the formula is used: mass (kg) = volume of aerated block (m 3 ) x density index (kg/m 3 ).

Let's do the calculation:

When calculating the load that the house will exert on the foundation, it is worth considering the possibility of using blocks with different sizes and strengths - their mass per 1 cubic meter is completely different.

Making calculations using a similar principle, we can calculate that a product with dimensions 200x200x500 and density 500 (0.2*0.2*0.5=0.02*500) will weigh exactly 10 kg.

We design according to STO 501-52-01-and SP 339.1325800.2017

When designing, we advise you to familiarize yourself with the Standard of the Russian Builders Association STO 501-52-01-2007 “Design and construction of enclosing structures of residential and public buildings using cellular concrete in the Russian Federation.” From the document you can learn about calculating the load-bearing capacity of walls, rules for carrying out work and other information that may be useful.

Let's highlight a few useful general points:

- For external walls, it is recommended to use adhesive with a density of less than 1500 kg/m

3in dry condition.

- The brand of glue is adopted based on the results of calculating the load-bearing capacity of the walls at least M50.

- Aerated concrete is intended for the construction of external and internal walls with indoor air humidity of no more than 75% in a non-aggressive environment. In aggressive environments, their use without additional protection is not acceptable.

- It is permissible to lay external walls in one or 2 blocks (of the same type or different types). In the first case, a “chain” ligation of small blocks is required with the seams overlapping by at least 10 cm. In the second case, it is necessary to ensure that the vertical seams are displaced by more than 10 cm.

- The pairing of internal and external walls is carried out by ligating small blocks or anchors (steel brackets 4-6 mm, T-shaped anchors or strip steel 4 mm thick).

- Aerated concrete walls must be waterproofed on the brick or concrete side.

- The thickness of horizontal seams should be from 10 to 15 mm, the thickness of vertical seams is taken from 8 to 15 mm. On average, these figures are 12 and 15 mm, respectively.

Since May 2022, by order of the Ministry of Construction, another useful document has also been approved for those planning to build with aerated concrete. This is the Code of Practice 339.1325800.2017 “Structures made of cellular concrete. Design Rules". In it you can find requirements for calculations for strength, crack resistance, deformation, and wall masonry.

The main characteristics of the strength of aerated concrete are the standard values of resistance to axial compression, resistance to axial tension, and shear resistance.

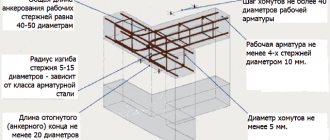

We reinforce walls made of aerated concrete according to SNiP 3.03.01-87 “Load-bearing and enclosing structures.”

To ensure that there are no cracks in the future structure, it is necessary:

- make a reinforced strip foundation, taking into account the depth below the freezing level;

- do reinforcement every 2-3 rows of masonry;

- make monolithic reinforced concrete lintels over window and door openings;

- provide a monolithic reinforced concrete belt on the load-bearing walls under the floor slabs.

When using the most common D500 and 600 blocks, it is recommended to perform reinforcement every three rows.

Reinforcement can be performed using the following methods:

- reinforcement with rods. According to the above SNiP, during longitudinal reinforcement, the rods are connected by welding to each other. The joints of smooth reinforcement do not need to be welded; the ends are overlapped by 20 diameters, finished with hooks and tied with wire. For wire with a diameter of 8 mm, the overlap should be 16 cm.

- mesh reinforcement. Using a mesh larger than 3 mm will increase the thickness of the solution layer. And for transverse reinforcement from small blocks, more than two diameters of the reinforcement used should protrude onto the inner surface of the wall by 2-3 mm.

Under the ends of the floor slabs, it is necessary to provide monolithic closed belts, for preparation for work on which Code of Rules 63.13330.2012 “Concrete and reinforced concrete structures. Basic provisions.” Here are a few requirements from this joint venture:

- the thickness of the concrete layer is taken to be no less than the diameter of the rod if the diameter of the reinforcement is more than 10 mm, if the diameter is less than 10 mm - not less than 10 mm;

- the distance between the reinforcement must be at least 5 cm for lower reinforcement, 3.5 cm for horizontal upper reinforcement and 2.5 cm for inclined or lower horizontal reinforcement;

- the diameter of the transverse reinforcement is considered to be 0.25 of the largest diameter of the longitudinal reinforcement, for frames without welding it is at least 6 mm;

- Anchoring is possible straight, with a bend, with welding, as well as with transverse rods.

Weight of 1 m3 of aerated block, formula for calculation, characteristics, price per cubic meter

- Weight of aerated concrete

- Calculation example

- Price

Weight of blocks of different sizes

According to their purpose, gas silicate blocks are divided into:

A practical option for a 1-floor residential building would be the D500-D600 brand. Dimensions also affect weight, so blocks measuring 600x300x200 mm will weigh more than 300x100x100, provided they have the same density.

Typical calculation of the mass of aerated concrete

The weight is determined using the example of a block 600x250x400 mm. The formula for calculation is as follows: density (kg/m3) x volume (m3) = mass (kg).

This method can be used for any size of gas blocks of different densities. However, it is important to consider the load that will affect the foundation.

Payment procedure

Aerated concrete blocks have precise geometry. Due to this, they can be laid on a thin layer of the binder mixture. When determining glue consumption, you need to adhere to a special algorithm.

The standard consumption of aerated concrete adhesive per 1 m 3 varies from 15 to 30 kg of dry mass. With a layer thickness of 1 mm, about 25 kg of mixture per cubic meter is required. This is one bag of composition.

Similar proportions are typical for blocks with a flat surface, without visible deformations. It is recommended to take one bag of glue in reserve. For example, if 20 cubic meters of aerated concrete blocks were purchased, then 21 bags of adhesive will be required to lay them.

It is not always possible to purchase a batch of ideal blocks. Therefore, in practice, glue consumption can be 1.5 bags per 1 m 3. All these figures are approximate and depend on various factors.

To accurately calculate glue consumption, you should use the following formula: ((L+H)/(L×H))×d×1.4

P is the glue consumption in kilograms per cubic meter;

L, H – length and height of the aerated concrete block, respectively (in meters);

1.4 – the consumption value of the dry adhesive mixture, provided that the layer thickness is 1 mm.

Today there are many specialized resources where you can determine glue consumption using an online calculator. This tool takes into account various factors that can affect the volume of block bonding compound.

Secrets of economical spending

If you follow some expert advice, the use of adhesive when laying aerated concrete will be more economical.

The use of special tools speeds up the construction process and minimizes the use of glue, and, accordingly, reduces the cost of work. It is recommended to use a ladle, a rubber hammer, a square, a grater with sandpaper, and a saw for masonry.

The glue should be applied with a spatula or a special spatula. Then the composition will apply more evenly and it will be possible to minimize its consumption. Before laying, the blocks must be cleaned of dirt. It is important to dry them well so that they are not wet.