It turns out that the thickness of the plaster cannot be arbitrary; it has its own maximum and minimum, determined by the properties of the plaster materials and the type of base. This was found out in the practice of plastering and included in SNiP. It is understandable that property owners want to save on compounds and apply as thin a coating as possible. Why it is not recommended to apply plaster compositions thinner or thicker than specified in the rules, we will consider further.

How does the composition of the product affect the thickness of the plaster layer?

Professional finishers are well aware of SNiP, which contains all the important data regarding plastering work. They reflect methods of applying plaster, allowable layer thickness, control methods, etc. Various factors influence the layer of plaster that can be completed. Most often, during the work, the type of product and its components are taken into account.

Cement composition

Cement-based plasters are used indoors and outdoors. They are perfect for decorating building facades and finishing rooms with high humidity. Such compositions are sold at a low price, are durable, wear-resistant, and suitable for professional and home use. Almost all cement plasters can withstand freezing and temperature changes, and are resistant to direct contact with water.

If we consider the thickness of the layer of cement composition, it should be at least 1 cm. The maximum thickness will be 5 cm, and in one approach it is impossible to apply a layer of more than 2 cm. If the size of the layer is more than 1.5-2 cm, it is necessary to perform additional reinforcement with fiberglass or other mesh.

Gypsum composition

Gypsum plasters are suitable for interior use only. This is due to their low moisture resistance and inability to withstand exposure to sub-zero temperatures. Gypsum compositions have quite a lot of positive qualities:

- ideal smoothness, evenness of the coating;

- good adhesion to most building substrates;

- long period of operation;

- strength;

- elasticity, no cracking;

- ease of application, plasticity.

The minimum and maximum possible thickness of the gypsum mixture layer is determined depending on the additional components. So, when adding sand, the solution is applied in a layer of 10-25 mm, and in case of serious curvature and the presence of large defects, the figure can be increased to 3.5 cm. In this case, surface reinforcement will be required. Some manufacturers advise applying gypsum in a layer of 15 cm, in one pass, and then applying decorative plaster (even before the first layer has completely dried).

It is undesirable to allow direct contact between the plaster and the concrete wall. It is better to apply lime material (4 mm) to the building base, and only then apply gypsum mortar. Otherwise, the mixture may destroy the top of the concrete.

Coating thickness for Rotband gypsum compositions

Clay plaster

A solution based on clay and sand is applied to the wall in a layer of 10 mm - this figure is the minimum possible indicator. If cement is added to the composition, the norm can be increased to 1.5 cm, and the maximum figure will be 3 cm (with additional reinforcement). Without reinforcement with cement, clay if the layer is too thick can quickly crumble and crumble.

Maximum thickness of finishing with gypsum compounds

Plastering in one layer gives a durable monolithic coating. Unlike other materials, gypsum makes this easy. The maximum possible thickness for the popular mixture of the Knauf HP Start brand is 30 mm, and for Rotband - 50 mm. As a rule, the more expensive the composition, the more mineral and polymer components it contains, which expand its capabilities. When finishing surfaces of equal area, the consumption of such plaster is 2 times less than the cement-sand mixture.

Layer thickness depending on surface curvature

The smoother the walls, the less plaster will have to be applied to them. Simply put, the thickness of the layer will directly depend on the degree of evenness of the building base. For small differences in the plane, a minimum amount of composition will be required, which will be enough for perfect alignment. If the differences are significant, the layer will have to be made quite thick. If the size of the layer exceeds building standards, you will have to immediately cut off the most obvious bulges in order to smooth the surface as much as possible. This will reduce the risk of cracking of the plaster and reduce repair costs.

It is also equally important to adhere to the minimum possible thickness of the plaster - 5-10 mm, otherwise there is no point in carrying out leveling at all. When the height differences are significant, and there is no possibility to cut off the bulges, the work is carried out in this way:

- successively apply layers 1.5-2 cm thick;

- After each layer, a reinforcing serpyanka mesh is applied;

- finally level the base with a common “shell” of 7 cm (or less);

- if the differences are more than 7 cm, use drywall instead of plastering.

Applying the solution in several layers with a reinforcing mesh

Conclusion

Plastering walls is not such a complicated procedure as it seems at first glance. The main thing is to properly prepare the base and monitor the thickness of the laid coating. Remember a few practical tips.

- If the solution is applied in several layers, the total thickness of which exceeds 3 centimeters, be sure to use reinforcement.

- Prepare the base carefully. An influx on the wall with a thickness of only 1.5 millimeters will increase the amount of material used by at least 3-4 bags.

- Use beacons to make your work as easy as possible.

Layer thickness depending on placement

Working conditions indoors are very different from those outdoors. This cannot but affect the characteristics of applying plaster. The correct choice of formation size greatly influences the degree of foundation strengthening, work efficiency, money and labor costs. It is very important to strictly observe the maximum thickness of the layer, otherwise the risk of shrinkage of the plaster, its cracking or sliding will increase.

Plastering indoors

The thickness of the plaster layer on the walls depends on the design features. In general, the highest demands are placed on the cladding performed inside a building, so compliance with all standards is strictly mandatory. If the walls are filled up and the angles between them deviate from the norm of 90 degrees, you will have to apply a plaster layer of about 5-7 cm. You can increase the figure to 8 cm only on the densest reinforced concrete walls. Otherwise, you will have to consider other alignment options.

The easiest way to calculate the approximate size of the plaster layer is this way: the inner coating should be 2 times larger than the outer one. For example, if the façade finish is approximately 10 mm, then the interior may be about 20 mm. This will reduce the risk of condensation penetrating from the house to the base of the walls.

It is often necessary to level the ceiling surface. The thickness of the plaster layer on the ceiling will also depend on defects and differences. In any case, it should not be higher than 3 cm, otherwise the plaster will simply begin to fall off. The minimum layer of material is 5 mm. In case of more serious defects, it is better to install a suspended or suspended ceiling.

When finishing interior walls, it is also important to consider the location of electrical wiring. If it is carried out shallowly, then the size of the plaster layer will have to be increased by at least the minimum possible figure.

When cables with a round cross-section pass through the wall, their diameter can be even larger than the minimum layer of plaster. When the cables are placed in a protective corrugation, the coating is made even thicker.

Facade plaster

The finishing of facades must be as strong, reliable and durable as possible, because it will be regularly exposed to precipitation, wind, temperature changes and ultraviolet radiation. The basement part of the facade, among other things, is subject to high mechanical loads. Usually, for cladding buildings on the outside, cement compositions are used, or, if funds allow, polymer compositions based on silicone and silicates.

The minimum possible plaster layer on facades should be 10 mm. If it is thinner, the unevenness may not be smoothed out, and the protective properties of the solution will decrease. Among other things, too thin a cladding simply will not remain intact throughout its entire service life. At the slightest mechanical impact, it will begin to crumble and peel off. If insulation was used when plastering the facade, the protective “shell” must be especially strong, monolithic and quite thick (up to 4-5 cm with mandatory reinforcement).

Warm façade plaster with reinforcement

An exception

Layers of improved plaster.

Sometimes it becomes necessary to hide serious defects in the surface of the walls under a layer of plaster. In this case, the thickness of the applied finish can reach 50 mm. In construction practice, there are even cases where the thickness of the finish had to be increased to 70 mm.

And although these are isolated cases, when finishing the walls, you need to be prepared for such a turn. If this happens, then you need to take into account that it is not possible to apply such a thick layer of plaster without using several layers of fine-mesh metal reinforcing mesh.

Before starting work, you also need to make sure that the load-bearing capacity of the surfaces is reliable, since plaster is one of the heaviest finishing materials. In addition, with changes in humidity and temperature, a thick layer is much more likely to develop cracks, especially when it comes to exterior wall decoration.

A thick layer of finishing is also economically unprofitable.

After all, the thicker it is, the more expensive the materials and work will cost. Therefore, when finishing work, it is better not to thicken the finish, but to achieve greater strength of the plaster applied to the brick wall by adding special binders to the plaster mortar.

If it is necessary to apply an even larger layer of plaster to a brick wall, it is better to abandon this idea and level the surface by building an additional brick wall and plastering it in the usual manner.

Material thickness for different types of surface

When finishing any bases, you must always take into account the type of substrate material and the condition of the surface, selecting the optimal layer width.

Brick

If the walls are made of brick, they have a certain relief, because the individual elements are fastened together with a cement composition. When the base is laid perfectly and is fairly level, you can apply a plaster mass 0.5 cm wide. With additional reinforcement, plastering up to 5 cm is allowed, and without a sickle mesh - no more than 2.5 cm.

Concrete

In most cases, the surface of concrete slabs is quite smooth and there are no serious defects on it. The finishing size in such a situation can be 5 mm, which is quite enough for perfect alignment. If the old finish is very curvature, it is advisable to completely clean it off or cut off the protrusions with a grinder. The maximum size of the layer, taking into account reinforcement with fiberglass mesh, should be 5-7 cm.

If you intend to install various fasteners for hanging pictures, sconces, lamps, then the walls will have to be drilled with a hammer drill.

If the thickness of the mortar is minimal, this will not be possible - the finish may begin to crumble, and there is also a risk of the drill getting into the reinforcement. The solution is to increase the finishing layer in order to securely secure the decor and lighting fixtures.

Aerated concrete blocks

This base is similar to concrete and also has sufficient evenness. The minimum size of the “shell” should be 5-10 mm, the maximum - no more than 20 mm for internal walls and 15 mm for facades.

Wooden surfaces

Construction mixtures do not adhere well to wood and can quickly fall off due to the low degree of adhesion. Therefore, before starting work, shingles or metal mesh are fixed to the walls, which will help hold the solution. The size of the lathing cells should be minimal (no more than 4*4 cm). At the first stage, the shingles are completely hidden with a layer of plaster, at the second stage the final leveling is carried out. The total size of the layer will be 20-30 mm.

Plastering wooden walls

Drywall

GKL sheets are often used for arranging interior partitions, for leveling walls that are too crooked, and creating multi-level ceilings. They are smooth, have no defects and do not require additional leveling. Typically, a thin layer of putty is applied to the drywall, which is necessary for subsequent finishing (wallpapering, painting).

Instead of putty, you can use dry gypsum-based finishing plasters, acrylic or silicone compounds, as well as cellulose mixtures, or “liquid wallpaper”. Another option is to apply decorative plaster with the preliminary installation of a reinforcing mesh, which will reduce the risk of deformation of the plasterboard. It is better not to use cement-based products - they weigh too much and will cause the drywall to warp. In most cases, the plaster or putty layer on gypsum plasterboard does not exceed 3-5 mm.

Puttying plasterboard walls

Insulation materials

For external insulation, foam plastic, extruded polystyrene foam or penoplex are most often used. They are attached to the walls after rough leveling or without prior plastering. Afterwards, the seams between the insulation sheets are sealed and the mesh is attached. Reinforcement is required due to the softness of the insulation, because without securing the mesh there is a risk of the solution peeling off. Typically, a layer of building mixture 3-5 mm thick is applied, the sickle is embedded in it using a spatula, then subsequent layers are applied with a total width of up to 2-4 cm.

Plastering the facade using polystyrene foam

Surface preparation before plastering

Plastering the wall

Preparatory work is a rather labor-intensive process, but you can’t do without it. Such work includes:

- cleaning surfaces (sometimes it is necessary to remove hardened cement mortar that has remained on the wall since its construction);

- working out seams;

- coating structures with primer mixtures to increase the level of adhesion (the solution is applied only to walls that have been cleared of small debris).

To ensure that the plaster solution lays smoothly and is firmly bonded to the surface, you can use construction beacons. They are fixed on the walls and leveled using a water level applied in different places to the surface.

Thickness of decorative plaster

Most often, decorative compounds are applied in small quantities, because they are not intended for leveling and are sold at a fairly high price. Typically, the specific size of the interlayer depends on the grain size of the filler and rarely exceeds it. Venetian plaster, for example, is applied in the thinnest layers (1-2 mm), since it contains finely ground marble flour. Decorative compositions with the effect of silk and Moroccan are applied in a similar way.

Structural solutions are applied in a thicker layer, for example, “fleece”, “bark beetle”, “travertine”. The size of the grains in them is equal to several millimeters, therefore, the interlayer should not be less than this value. Textured and pebble coatings are thicker - up to 5 cm, otherwise it will not be possible to recreate the intended effect (imitation brickwork, waves, etc.).

Pebble decorative plaster

Composition of mortar for plastering walls

The solution can be mixed in different proportions. It all depends on the characteristics of the structure in which the composition is used. In addition, the experience of the master who plans to do the repairs plays an important role.

Of course, now in the hardware store you can find a colossal variety of mixtures for plaster, which you just need to fill with water. But they will cost much more than a solution prepared with your own hands. This nuance will be especially important for those who need to plaster a large surface and have a limited budget.

There are several types of simple wall plasters.

Possible deviations

According to SNiP, when plastering is carried out, minor deviations in the thickness of the layer may appear. The fact is that in practice, perfect compliance with all norms and recommendations is not always possible. Here are the permissible errors for applying conventional rough solutions:

- 15 mm on the entire wall along a vertical plane;

- 3 mm per square meter of area;

- the depth of remaining irregularities is less than 5 mm;

- permissible number of flaws - 3 pcs./4 sq. m.

For high-quality plaster, a deviation in the vertical plane of no more than 5 mm for the entire wall and 1 mm for each square meter is allowed. The possible depth of unevenness is less than 2 mm, while the number of flaws is up to two for every 4 square meters.

Limestone and gypsum mortar

This solution is used for plastering fiberboard, stone and wooden walls, as well as for foundations in rooms with normal humidity.

It is not recommended to mix such a composition in large quantities, because due to the presence of gypsum, the mass quickly hardens.

The lime-gypsum solution must be applied within 10-15 minutes. If it has frozen, then you don’t even need to think about diluting it with water, as you could do with clay.

To properly prepare the solution, you need to pour the gypsum into a container of water and stir until it becomes thick sour cream. Next, add limestone to the finished mixture. The mixture must be used within a short period of time.

Control of the plaster layer

Experienced craftsmen can already see by eye whether the completed finishing meets the requirements of construction documents. Usually, when performing thin-layer coating, the visual method is more than enough. In other cases, other control methods are used:

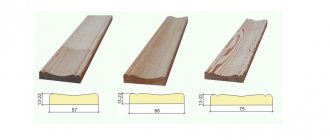

- Metal or plastic beacons (guides). Typically, products up to 1.5-3 meters long and 6-10 mm thick are used. They are attached to the boundaries of the site and evenly distributed over the entire wall, aligned by level or using a plumb line. After installing the beacons, the solution is applied between them, strictly monitoring the height of the mass. After completion of the work, the beacons are removed or left in place, covered with plaster.

- Lighthouses made of solution. They are small piles of quick-drying plaster (usually gypsum), which are distributed over the surface and leveled in height. Afterwards, plastering is carried out, making sure that the composition does not extend beyond the beacons. This method is considered more labor-intensive and is used mainly by professionals.

- Strings. At a short distance from the corners of opposite walls, screws or dowels are screwed in, their heads are leveled in the same plane. A fishing line (string) is attached to the caps, which is stretched along the perimeter and diagonals.

How to control the layer of plaster mixture

Of course, when applying a solution, it is difficult to determine the size of the formation thickness by eye, and without sufficient experience it is impossible. If you need to apply the solution in a thin layer on a flat wall, then use a 50-centimeter spatula and then level it using the rule. When performing decorative work, the size of the mortar thickness is checked by eye. In the case of applying the maximum layer of plaster, the thickness and evenness of the coating is ensured by the use of beacons.

Beacons are guide profiles made of metal, mortar, plastic or wood. Standard metal profiles have a height of 6 - 10 mm, a length of 3 - 6 m. Mortar profiles can be made to any desired height. Before starting the installation of beacons, the walls are examined, irregularities are identified, and the minimum height of the future covering is determined. Using the chosen method, they create an auxiliary vertical plane along which the beacons are placed (read about installing beacons here).

In addition to beacons, corner profiles are used to apply the proper layer, installing them on slopes. To make arched doorways, templates are made from plywood.

Craftsmen with extensive practice and accumulated experience can change the thickness of the plaster coating within small limits. However, this is not recommended for beginners. It is correct to follow the instructions and standards so as not to end up with a “broken trough” - cracking and falling off plaster mass.

At first, plastering looks not only dirty, troublesome, but also complicated. There are many nuances in plastering that affect the result. Thus, the factor on which the quality and reliability of the finish in operation directly depends is the thickness of the plaster on the wall. There are many numbers given here that make your eyes widen. In fact, you will need those that are easy to remember. With the beginning of practice, the plastering process will no longer seem difficult. And over time, such work will become habitual.

Three-layer plastering technique: thickness of each layer

Standard wall plastering technology includes three main stages. Each of them has its own characteristics and requires a different layer thickness:

- Spray. Apply directly to the building base by hand or using a plaster ladle. The permissible size of the layer is 2-3 cm. After application, the mixture is distributed over the surface, but not too thoroughly, which will enhance the adhesion of subsequent layers.

- Priming. The main layer, the size of which depends on the spray already completed and can be 0.7-5 cm. The soil is carefully leveled with a rule or other convenient tools.

- Cover. A finishing layer intended for final leveling of walls. Its thickness does not exceed 5 mm, and a solution of a rather liquid consistency is used.

Knowing the criteria on which the thickness of the plaster layer depends is a prerequisite for the master. Compliance with the requirements will help to complete the work efficiently, economically and with the most effective results.

Recommended coating thickness when applying traditional materials

Compared to gypsum compositions, leveling walls with cement and lime mortars requires more time, and the work process is labor-intensive.

Traditional materials are not plastic, since most of their composition is sand. They significantly make walls and partitions heavier, so the maximum permissible layer thickness is half that of gypsum and is 25 mm. The technology for performing such a coating includes several stages, in this case the final size of the plaster is equal to their sum.

To apply a thicker layer, the finishing surface is reinforced with a metal mesh and covered with Betokontakt adhesive primer.

What materials to use

The finished mixture must be passed through a sieve.

To create high-quality plaster, you need to use appropriate materials. The requirements for them are specified in the construction GOST and given in SNiP. Mixing the mixture for cladding is carried out according to the specified rules. The finished solution must meet the specified characteristics.

To carry out spraying and priming, the plaster mixture is passed through a sieve with a mesh size of 3 mm, for coating - 1.5 mm. Mobility varies from 5 to 12 mm. The water retention rate in a high-quality solution should reach 90%.

The composition of the solution for spraying and priming consists of sand with grains up to 2.5 mm, and for coating - up to 1.25 mm. Watch the secrets of good plaster in this video:

When purchasing a ready-made mixture, be sure to pay attention to its brand, production date and other characteristics.

Plaster options: simple, improved, high quality

What is the difference between simple plaster and improved or high-quality plaster? In what cases is each of these options used, and what requirements must the resulting coating meet? We will try to answer these and other questions within the framework of this article.

About the quality of the plaster coating

An untrained reader may think that the adjectives “simple”, “improved”, “high quality” in relation to plaster determine the quality of the mortar used. However, this is not at all true - we are talking exclusively about the characteristics of the plaster finish, the technology of work and the intended purpose of the coating. Thus, simple plaster can be used to prepare the base for subsequent cladding with tiles or other materials. In other words, in cases where subsequently applied finishing technologies will level out some of the nuances of plastering work.