Features of choosing insulation for walls inside a country house

The peculiarity of choosing the appropriate option is that all the positive and negative properties of the material are assessed. Currently, there are many types of thermal insulation products with different technical characteristics.

Mineral wool

Mineral wool is a product made from inorganic fiber. The material has certain requirements for subsequent finishing: it should consist of covering the walls with dense sheet or panel products. This is due to the fact that mineral insulation contains allergy-causing substances.

Mineral wool does not support combustion, but is highly hygroscopic

Advantages:

- Great for DIY styling. There are two varieties: sheet and roll. The first type is considered preferable; it has less shrinkage over time.

- Good resistance to temperature changes. Additionally, a layer is created that will level out noise pollution penetrating from the outside.

- Non-flammability. It is worth considering that not all varieties have this property.

- Price. Although the products belong to the category of affordable ones, taking into account the not entirely ideal characteristics, their cost can be somewhat inflated. Therefore, it is better to choose large construction stores for purchase.

Of course, there are also significant disadvantages:

- The work can be complicated by the fact that the material breaks easily. That is, the integrity of the coating is compromised.

- High hygroscopicity. Mineral wool absorbs water well, after which it completely loses its qualities.

- During the installation process, you must use a respirator, goggles, protective clothing and gloves.

Styrofoam

Advantages:

- Low thermal conductivity. This ensures comfortable living.

- Durability. If the installation technology is not violated, then the service life is more than 20 years. But the product may be damaged by rodents.

- High strength. Parts are difficult to damage.

- Light weight. This makes installation easier.

- It’s easy to choose the right size; the range is quite diverse.

- Insensitive to moisture. Polystyrene foam does not lose its properties and is not a source of mold and mildew.

Foam plastic has an affordable price and low thermal conductivity

Disadvantages cannot be ruled out:

- Such insulation is not able to withstand point impact. Therefore, you cannot use broken slabs; they will serve as a place for cold penetration.

- Although the parts do not support combustion, they melt and release toxic substances. Therefore, you should not use them to insulate a frame or wooden house that does not have a durable fire-resistant treatment. The material is excellent for thermal insulation of a brick building.

Extruded polystyrene foam is an excellent alternative to polystyrene foam

Foil insulation

Foil insulation is a special polymer material that has several layers of foil and a heat-insulating element. It is believed that this particular product is the most effective in comparison with standard options. Of course, the cost of such a product is noticeably higher, but the difference is offset by the result.

The most popular type of this insulation is penofol

It is important to consider that the roll must be laid correctly: the reflective side must be directed inside the room

Material Features:

- Withstands moisture.

- Allows you to significantly reduce energy costs and create the right microclimate in the house.

- Installation is not difficult and does not require special structures. The product is fixed in any convenient way, literally covering the wall.

Foil insulation is impervious to moisture and retains heat well inside a country house

When choosing, the manufacturer is of great importance. Often there are products that do not meet the declared characteristics.

Of course, the range of thermal insulation materials is wide, but it is the presented varieties that allow you to reliably insulate a country house and achieve a balance in the price-quality ratio.

Nuances of choosing insulation (very useful video)

What thickness of insulation will be required?

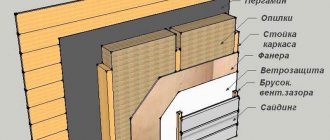

Before work, it is necessary to carry out thermal calculations. The multilayer structure consists of a wall with external finishing. From the inside there is an insulating layer and cladding. It is important to correctly determine the thickness of the insulation.

For a comfortable temperature, the layers inside and outside, regardless of the time of year, must have a total resistance to heat transfer. The sum is obtained from the resistance of each layer.

The total resistance is established by SNiP standards for each region, taking into account the climate. The value is easy to find out in any construction organization.

An online calculator will simplify the calculations, where the result is usually shown in millimeters. It is necessary to round up.

Types of insulation

They produce various types of insulators, which stand out for their performance characteristics.

Mineral wool

This category of insulating materials is made on the basis of mineral substances and is divided into the following types:

- slag wool - made from metallurgical waste;

- glass wool - produced from waste from glass production;

- stone wool - created on the basis of rocks such as limestone, dolomite, diabase, basalt.

Mineral wool is produced in mats and rolls and is used as a heat and sound insulator when arranging walls, floors, and floor slabs.

Features of mineral wool:

- low thermal conductivity coefficient;

- high rates of heat and noise insulation;

- resistance to high temperatures;

- resistance to microbiological threats;

- zero flammability, ability to resist the spread of fires.

Mineral wool - insulation for a country house The disadvantages of mineral wool include vapor permeability and reduced service life when exposed to moisture, so it is necessary to use it in combination with a waterproofing layer.

Expanded polystyrene foam

Foam plastic - expanded polystyrene foam - is on the list of undisputed leaders in the market of thermal insulation materials. The product is ideal for insulating the outside of a country house, especially if work is planned on a limited budget.

Features of expanded polystyrene foam:

- low thermal conductivity;

- light weight – loads on supporting structures are eliminated;

- low hygroscopicity;

- frost resistance;

- biological inertia;

- low flammability, self-extinguishing ability.

Foamed polystyrene foam attracts rodents, which easily gnaw through it, making passages. Also among the disadvantages are the reaction to chemicals and UV rays. However, polystyrene foam is always used together with a finishing coating that protects the insulation from aggressive environmental influences.

Expanded clay

Loose insulation with a porous structure is produced by foaming fusible clay and shale with inclusions in the form of sawdust, peat and solar oil, followed by firing at high temperatures.

Features of expanded clay:

- high fire resistance;

- excellent sound and heat insulation properties;

- absolute environmental friendliness;

- availability;

- high resistance to pathogenic microflora;

- resistance to chemical compounds.

Expanded clay granules can easily fill a cavity of any size. The material is actively used in the construction of floor systems, insulation of floor slabs and wall structures.

Liquid penoizol

Foam insulation - modified polystyrene foam - has high adhesion and is used to fill voids in ceilings, walls, and various horizontal and vertical surfaces.

Features of the use of liquid penoizol:

- the heat insulator is prepared directly on the construction site using a special installation;

- the composition is sprayed under pressure onto the surface to be treated;

- For sealing joints and air gaps, they offer liquid penoizol in cylinders.

Thermal insulation with liquid foam insulation provides for the solidity of the layer, the absence of cold bridges.

Fiberboard

Fibreboards are produced from wood waste by gluing fibers with natural resin compounds under high temperatures and pressure. The material is in demand as an inexpensive solution for internal thermal insulation of the walls of a country house. Fiberboard slabs are mounted using a metal frame or wooden sheathing.

Other materials

When arranging thermal insulation for a country house, a number of traditional and innovative construction resources are in demand:

- penofol - foamed polyethylene with a foil coating is produced in rolls;

- jute fabric - the insulator is simply and quickly laid on the walls using a stapler;

- insulation made of flax fiber - produced in slabs, has antiseptic properties;

- ecowool - consists of cellulose with the addition of antiseptics and fire retardants, sprayed with special equipment.

Penofol - insulation for a country house. Polyurethane foam insulation also deserves attention. The air-foam mass is applied using a special installation, the coating is monolithic and durable with high heat, sound, and waterproofing abilities.

Insulation with polyurethane foam

It also needs a sheathing underneath, although vertical posts are enough. The material is produced in liquid form in cylinders, from which it is then sprayed onto the walls under pressure. Very soon, after about half an hour, the foam increases in size and hardens. The excess needs to be cut off.

Photo: Instagram uteplenie_ppu_krasnodar

Photo: Instagram uteplenie_ppu_krasnodar

In addition, polyurethane foam is used when the owners decide to additionally insulate the house without removing the finishing. Polyurethane foam is poured between the outer wall and the sheathing.

Photo: Instagram nsfera.ru

How to choose inexpensive wall insulation

When choosing the optimal material, you need to pay attention to many nuances. It makes sense to consider the most common materials in order to understand their features, advantages and disadvantages in table form

Table. Comparative characteristics of popular materials

| Insulation | Advantages | Flaws |

| Basalt wool | low thermal conductivity; easy to cut to required sizes; excellent vapor permeability; does not burn; light weight; thickness from 50 mm to 200 mm; optimal density indicators. | may lose shape over time; absorbs water well; during work it is required to use personal protective equipment; high price. |

| Expanded polystyrene | good compressive strength; thermal conductivity is low; poor water absorption; retains its shape for a long time; thickness from 20 mm to 50 mm. | requires cutting quite accurately; cannot be used for roofing; highly flammable materials; high price; susceptible to damage by rodents. |

| Styrofoam | low price; not afraid of water; retains its shape perfectly; environmentally friendly material; not interested in rodents; thickness from 20 mm to 50 mm; light weight. | flammable material; it is necessary to cut accurately; may crumble during operation; thermal conductivity is low; low density. |

| Glass wool | low price; compacts well; does not burn; environmentally friendly material; thickness from 50 mm to 200 mm; light weight. | personal protective equipment is required when working; hygroscopicity; loses its shape over time; relatively low chemical resistance. |

| Polyester fiber insulation | retains its shape and does not absorb water; low thermal conductivity; phenol is not used in the production; hypoallergenic material; light weight. | flammability; high price. |

When choosing a material, you should also consider the following parameters:

- thermal conductivity - the lower the indicator, the less heat loss will be;

- vapor permeability or the ability to allow moisture to pass through;

- shrinkage – over time, materials lose their shape, so this parameter is critical;

- mass and density;

- water absorption or hygroscopicity;

- Operating temperature range;

- flammability;

- thickness;

- material form - roll or in the form of a sheet or plate;

- environmental friendliness;

- chemical resistance.

Calculator for calculating the thickness of ceiling insulation in a house with a cold attic

It is highly recommended to ask for a certificate from the fire department before purchasing. This will allow you to check whether the material meets safety requirements. If this certificate is missing, then you should refuse to purchase.

Bottom line

Let's summarize. When choosing a particular insulation material, it is necessary to take into account its technical characteristics, such as the level of thermal conductivity, ease of installation, and level of resistance to sudden temperature changes.

You need to pay attention not only to the technical characteristics of the thermal insulation product; the material from which the house is built plays a vital role. For many, cost is not the last parameter to which you should pay attention.

If you choose a high-quality heat insulator, and the installation is carried out in compliance with all the rules, you will be able to achieve unique comfort and coziness in your country house.

What types of insulation are there?

There is a wide range of thermal insulation on the market. This makes the choice somewhat difficult. To find the optimal solution, you must carefully consider each available option. The following types of wall insulation are distinguished:

- glass wool;

- basalt eco wool;

- extruded polystyrene foam;

- polyurethane foam.

Glass wool

Glass wool is made from broken glass and a mixture of sand under high temperature (15000C). It is used to insulate various structures both outside and inside. The main advantages of glass wool include:

- High heat and sound insulation properties.

- Environmental friendliness. Natural components are used to make glass wool. Therefore, it is completely safe for humans, which makes it possible to use it to insulate walls inside the house.

- Strength and durability. Thanks to the special structure of the structure, cotton wool can easily withstand heavy loads. Thanks to this, it is a durable material.

- Non-flammability. The fiberglass-based material can withstand high temperatures (4500C). This increases its resistance to open fire.

- Resistance to negative environmental factors. Glass wool easily tolerates vibrations and high humidity. The risk of mold and mildew is minimized.

- Mice and rats do not breed in glass wool. This feature is very important when it comes to a country house.

Unfortunately, this material has some disadvantages, including:

- Fragility. Over time, cotton wool shrinks, which negatively affects its service life.

- Hygroscopicity. Glass wool easily absorbs moisture, which reduces service life. To eliminate this phenomenon, it is necessary to carry out a vapor barrier. As a result, the cost of work will increase slightly.

- Installation features. To protect yourself from glass fibers, you must use protective equipment such as goggles, respirators and gloves when laying glass wool.

Despite its disadvantages, glass wool is widely used for insulating various structures, including interior walls.

Insulation based on basalt wool

Such tile and roll insulation materials are made from rock. To obtain fibers, it is crushed and then heated in special ovens. In the next step, fiber formation is performed using drums and air flow.

Among the main advantages of basalt wool are:

- Low thermal conductivity and good thermal insulation. Thanks to numerous layers of air inside the material, it optimally retains heat in the room.

- Low moisture permeability. The material easily withstands the negative effects of high air humidity. Water is not absorbed into the cotton wool, eliminating the risk of damage, mold or mildew.

- Excellent vapor permeability. Moisture easily passes through the material without accumulating in it. Therefore, it is often used to treat buildings with high humidity.

- Resistant to open fire. Insulation based on basalt wool can withstand heating up to 11140C.

Basalt wool is a safe, highly effective and cheap insulation for walls. Therefore, it is recommended to use it for cladding the inside of a house.

Extruded polystyrene foam

This material is a modification of conventional polystyrene foam. The peculiarity is that during the production process polystyrene foam undergoes extrusion. As a result, it is given properties that make it better than foam.

In addition to high heat and sound insulation qualities, extruded polystyrene foam has high density and strength. This greatly simplifies installation. To fasten the slabs, you can use large dowels without fear that they will collapse.

Due to the high density and thermal insulation, thin slabs will be needed for insulation. Especially when compared with polystyrene foam.

Polyurethane foam

Polyurethane foam is an insulation material that has many advantages. Depending on the density, the material can be soft, hard or sprayable. The last option is the most popular. Among the main advantages are:

- high heat and sound insulation;

- creating a seamless coating;

- excellent resistance to mechanical damage and negative environmental factors;

- efficiency;

- versatility and much more.

Insulation materials for thermal insulation of a cottage from the inside

To insulate a dacha, you can use various types of thermal insulation materials, differing in the composition of the raw materials used for their manufacture, technical characteristics, sizes and shapes.

Based on the type of raw materials used for production, thermal insulation materials are divided into products from:

- mineral wool;

- glass wool;

- ecowool, the raw material for which is cellulose;

- expanded polystyrene;

- polyurethane and penoizol.

At the same time, materials based on mineral wool, glass wool can be made in the form of slabs or rolls, ecowool is represented by slabs, as well as a scattering of compressed fibers, although this option is used less often for walls, as it requires special technology.

Expanded polystyrene insulation is presented in the form of foam boards and extruded polystyrene foam, and polyurethane-based insulation is a sprayed material, for the application of which special equipment is used.

How to attach penoplex to the wall? Video:

Mineral wool

Mineral wool for insulating walls inside the house is one of the most popular and widespread materials.

Mineral wool is the most popular material for insulationSource eurodach.lutsk.ua

It is a fibrous material. The fibers are formed by atomizing certain types of slag or basalt. Thanks to this production technology, the material is environmentally friendly and natural.

Properties of mineral wool

Cotton wool does not burn, which is important when used in wooden houses. Characteristics of different types of mineral woolSource pro-uteplenie.ru

Characteristics of different types of mineral woolSource pro-uteplenie.ru

This insulation has several more advantages:

- Resistance to biological organisms. Does not contribute to the formation of fungus and mold.

- Good soundproofing characteristics. Mineral wool fibers randomly superimposed on each other perfectly retain sound waves.

- It is not subject to shrinkage, which retains the properties of this type of insulation throughout its entire service life.

- The ability to allow air to pass through, which allows you to maintain a healthy indoor microclimate.

Proper functioning of the insulation is only possible in combination with additional moisture-proofing materials. When exposed to water, mineral wool loses some of its thermal insulation properties. Over time, mineral wool can disintegrate into fibers, which requires replacing the thermal insulation

Mice have chosen glass wool for making nestsSource ecousadba.orgFeatures of mineral wool insulation: the need for additional materials

It is necessary to work with cotton wool using personal protective equipment - small particles of fibers can get on the mucous membranes and cause irritation.

With such insulation, the finishing material for finishing the walls is plasterboard. To attach it to the wall, a metal profile and hangers are used. Warming is carried out in the following order:

- Waterproofing is fixed to the wall - any rolled material will do. Using a construction stapler, the waterproofing is attached to the wall; at the joints, the material is laid with an overlap of about 15 cm.

- Vertical markings are applied to the wall in increments of 60 cm for easy fastening of plasterboard sheets (its standard width is 120 cm).

- After marking, metal hangers are attached to the wall - dowel-nails are used for this.

- Mineral wool is placed on the hangers and the entire wall is sequentially filled.

- After this, metal profiles are attached to the hangers, and a vapor barrier film is attached to them.

- Drywall sheets are attached using self-tapping screws, and the joints are puttied.

The result is an insulated wall, ready for finishing. This can be either puttying and painting, or wallpapering.

Cost of mineral wool

Mineral wool is a relatively cheap insulation material. Sold in slabs or rolls. Standard slab sizes:

- 800x600 mm;

- 1,000x600 mm;

- 1 200x600 mm;

- 1170x610 mm;

- 1250x610 mm.

The material in rolls can be selected in various lengths - from 5 to 12 m.

Cost per 1 sq. m of mineral wool is:

- 50 mm thick – from 50 to 100 rubles;

- 100 mm thick – from 105 to 210 rubles.

When choosing mineral wool, it is necessary to take into account not only the size of the slabs, the thickness of the insulation, but also the need for additional materials necessary for installation work.

Cellulose insulation

It is difficult to lay ecowool manually, especially on vertical surfaces: it is too loose. First, the material is transferred into a large container, fluffed up using a mixer or a puncher, and placed into the cells of the frame by hand.

Photo: extrawool.ru

Construction companies use compressors that blow in ecowool. They also have installations that wet the material with water and allow you to spray it on the wall. This is much faster than laying it yourself, but for uniform application the craftsmen require high qualifications.

Photo: Instagram fiberwood

Walls

Insulation of walls is the main stage of work, since they occupy the main area of any building and have the highest heat transfer.

Surface preparation

Before insulating wooden walls, be sure to clean the entire surface of dirt. Carefully treat the inside of the walls with special solutions and aerosols that will protect the wood from insects. Then caulk all the gaps using dry tow and a thin chisel.

Insulation

Jute fabric is very suitable as a heat insulator for walls. It is quickly and easily laid with a construction stapler, does not rot, is not blown away by the wind and is not of interest to moths. Tow and jute fiber have low thermal conductivity due to their capillary structure and easily release moisture. In addition, as bactericidal materials, they successfully resist the spread of fungus.

It is not recommended to use improvised materials to insulate the walls of a country house: felt, batting, wool. They accumulate moisture abundantly. As a result, the process of rotting quickly begins, and moths are sure to appear in the wool.

Energy saving when insulating walls outside

- Brick and concrete tend to accumulate temperature and return it gradually. When the walls of a house are insulated from the outside, the cold does not reach them, but they warm up from the inside. After 10 minutes of airing the rooms, the temperature in them hardly drops a couple of degrees.

- Porous thermal insulation material only impedes air movement. But it is not able to accumulate heat. When the insulation is located in a house whose walls are frozen through, an open window cools the room in 5 minutes. It will take a long time to restore a stable temperature regime.

- In addition, the internal placement of insulation does not cover the cold bridges formed by the floor slabs. Enormous heat losses are inevitable. External insulation of walls removes them from the zone of influence of external factors, which significantly extends their service life.

Liquid ceramic thermal insulation

Liquid internal thermal insulation based on ceramics, made using the most modern technologies, has the following features:

- high level of environmental friendliness, allowing the material to be used in any premises;

- resistance to steam and moisture, ensuring maintenance of performance characteristics even after getting wet;

- long service life (at least 15 years);

- resistance to rodents, insects and ultraviolet rays.

The material is applied to the protected surface at any temperature and has a relatively affordable price. The disadvantages of liquid-ceramic thermal insulation include insignificant noise protection and low resistance to mechanical stress.

Recommendations for choosing materials

To choose the right insulation, you need to take into account several more factors that may affect the quality of the work performed.

Condition of walls and foundation. If the house is old, and the foundation or brickwork is already cracked, then it is necessary to abandon heavy insulating structures. In this case, it is best to install lightweight and durable materials. It is better to attach them using special adhesives.

Architectural complexity of the building. Polystyrene foam and mineral wool are well processed and make it possible to provide reliable insulation of walls with recesses, patterns and other decorative elements.

Any type of building can be reliably insulated without extra costs. The main thing is to choose the right materials for insulation and an experienced contractor

Resistant to insects and rodents. Often, small rodents and insects, such as mice or ants, can make nests under a layer of thermal insulation.

If there is such a problem on the site, then it would be advisable to carry out insulation using bulk materials. Expanded clay is good because it does not attract animals.

It is also necessary to take into account other factors, such as the price of insulation, features of its installation, wall material, impact on the environment, fire resistance, etc.

If you plan to install a thermal insulation system from the inside of the house, it is worth reading the following article, which details the materials and methods of their use.

How to choose?

In order to choose the appropriate insulation for a country house, which will be located from the inside, it is important to know what you have to work with. If you need to insulate the second floor or turn the room into a living area instead of an old cold attic, it is important to choose the right type of insulation

It is important to analyze what material the house is built from. Wooden huts must have a breathable heat insulator, and brick or foam concrete structures can do without it.

When choosing a material for working with walls, you need to evaluate its moisture resistance, which will be one of the main criteria. Heating is also worth considering. If the stove is running inside, the difference between the temperature outside and in the house will become very large. This process will lead to the formation of condensation, which will affect the insulation and contribute to its soaking. In such conditions, the material will not last long and will soon begin to deteriorate. To avoid this outcome, it is necessary to use a vapor barrier film, which will protect the insulating sheet from moisture.

To choose the right insulation, you should pay attention to the following indicators:

thermal conductivity, which must be low in order to be able to maintain optimal conditions in the living room; resistance to frost - this is important for those dachas that are not heated in winter and the temperature in the house can be zero, which negatively affects some types of thermal insulation; ease of installation work, which is important in the case of a country house, the work on which is often carried out by the owner himself, therefore the simplicity of all actions is extremely important in this case; pricing policy, which is especially important in the case of furnishing a country house, where cheaper materials are taken.

If, in addition to the walls, it is also necessary to insulate the ceiling, then you should take care of the availability of materials for this procedure. If the attic spaces in a house are being converted into living spaces, then finishing and using insulation are indispensable

To cover the ceiling, it is important to choose materials that are resistant to precipitation and significant temperature changes. The density of the slabs must be high so that they can retain heat in the room without letting in external cold from under the roof

When reconstructing an attic, you may also need to insulate the floor, especially if it is on a reinforced concrete slab. To do this, you need to make a sheathing, lay insulation, on top of which place a covering material such as plywood, fiberboard, etc.

In this case, almost all surfaces should be supplemented with a layer of thermal insulation material in order to create conditions suitable for living inside the living space. Having the necessary materials for this process, you need to know how to use them correctly.

Tips for choosing

Let's look at just two tips:

- The material from which your country house is built is the most important factor. You need to pay attention to it. For example, for houses built of wood, a thermal insulator is needed that has excellent air permeability. For houses built of brick, this criterion is not particularly important.

- The level of moisture resistance is also the most important parameter that you should pay attention to when choosing insulation for the internal walls of a country house. Ask yourself: will my home be heated during the winter season? This factor determines whether condensation will form due to the large temperature difference (indoors and outdoors). Condensation can cause the thermal insulation layer to become wet; it will deform in a short period and lose its technical characteristics.

But this problem can be easily eliminated if you use a specially designed vapor barrier film, which will protect the heat insulator from the harmful effects of moisture.

What building products exist for thermal insulation of walls from the inside?

Algorithm and features of internal insulation

The internal complex of works includes the treatment of wall surfaces, window and door units, floor systems, and roofing pie.

Thermal insulation of roof and ceiling

Work on internal insulation of the roof of a country house with mineral wool or expanded polystyrene begins with the installation of the frame. Moreover, you should first take care of vapor barrier, wind and water protection of the system. Wooden bars or metal profiles are attached to the roof with self-tapping screws, and thermal insulation boards are laid between the structural elements. Anchoring is used to fix mineral wool. Expanded polystyrene is cut to the required dimensions for installation between the profiles.

Thermal insulation of the ceiling of a country house is most often done using polystyrene foam:

- the surface is cleaned, irregularities are sealed with plaster;

- the slabs are mounted using adhesives;

- after the glue has dried, the slabs are secured with umbrella dowels;

- Next, the putty mesh is laid.

At the final stage, a layer of putty is applied, after the composition has dried, they begin to decorate the ceiling.

Thermal insulation of walls

Do-it-yourself insulation of the walls of a country house from the inside with sheets of expanded polystyrene is carried out in the following sequence:

- remove the old finishing coating;

- Wall surfaces are cleaned of dirt, dust and stains. The defects are sealed with plaster, after the mortar has dried, the walls are covered with 2 layers of primer;

- make markings using a level, taking into account that the slabs are laid from the lower perimeter of the wall structure;

- a strip of special glue is applied to the perimeter of the back side of the insulation, and a fixing composition is additionally applied pointwise - in volumetric masses - over the entire area of the slab;

- install foam plastic in the direction from bottom to top using the brickwork technique or in straight vertical lines.

Expanded polystyrene for internal insulation of the walls of a country house does not require a vapor-tight membrane.

Insulation of floors and ceilings

The structure of the floor of a country house is insulated in various ways; most often, the option of arrangement along joists is used. To do this, adjust the insulator slabs according to their dimensions and lay the material between the frame guides. If you plan to insulate the floor with polystyrene foam before pouring it with a concrete screed, the algorithm of actions includes the following items:

- a waterproofing film is laid overlapping with the edges along the perimeter of the wall, the joints are sealed with construction tape;

- polystyrene foam is laid in 1 or 2 layers;

- A reinforcing mesh is installed on top and fixed to the mortar.

Expanded polystyrene is a material for insulating the floor of a country house. Next, a finishing screed is performed with a thickness of 60-80 mm, depending on the characteristics of the upcoming work on arranging the floor covering.

Insulation of door and window openings

Old-style wooden window frames are insulated using polyurethane foam and sealing tapes:

- after cleaning the surfaces, seal the gaps between the frame and the wall, the perimeter of the sashes, and the window sill area;

- You can use silicone sealant in a special gun. If polyurethane foam is used, care must be taken to protect it from UV rays;

- to seal cracks around the perimeter of the sashes, use D-profile sealing tape with an adhesive base;

- It is important to use polyethylene foam for insulation of slopes.

For maximum thermal insulation of window systems of a country house, it is recommended to cover the glass with heat-saving film.

The door leaf should be sheathed with insulating material, which is selected depending on the design features. It is also necessary to seal the joints between the perimeter of the door frame and the walls, while the threshold areas and the top line of the opening require special attention.

Video description

Insulation instructions in the following video:

Advice from professionals

When carrying out such work, you need to pay attention to the following points:

- Vapor barrier will help if you make a hermetically sealed joint at the seams.

- The thermal insulation layer should not have a high vapor permeability parameter. In the case where this indicator is higher near the wall than that of the insulating material, steam will escape outside.

- To achieve complete adhesion of polystyrene foam to the wall, the beacon method of applying plaster and the method of leveling the glue with a comb are used. This allows air bubbles to pass between the wall and the insulation.

On a note! To prevent moisture from appearing on the walls, a high-quality ventilation system must be installed in the house - hoods and valves on the windows.

Natural ventilation must be calculated no less carefully than forced ventilation Source sovet-ingenera.com