The division of rooms using gypsum boards is very popular due to the characteristics of the material and the speed of construction. The thickness of a plasterboard partition can vary; the exact values are determined by many factors. This list includes the design concept, composition structure, as well as operating conditions.

Thickness of plasterboard partitions: selection and calculation

Greetings, comrades! Today we have to find out what the thickness of a plasterboard partition can be depending on the requirements for it, what factors influence this parameter and what are the minimum and maximum thickness of a plasterboard wall. Let's get started.

Construction of a simple plasterboard wall: vertical section.

Components

What does our design consist of?

In addition to ceiling and wall plasterboard, there is even thinner arched plasterboard (6 mm), but it is not used for wall cladding.

I deliberately do not consider wood frame structures. It has too many serious disadvantages compared to the galvanized profile:

- Imperfect geometry

- Tendency to deformation due to humidity fluctuations,

- Fragility : the tree is affected by fungus and insects.

The photo shows a wooden frame for an interior wall. Wood does not provide any benefit in terms of space saving and is less durable compared to profile.

What influences the choice of frame and sheathing sizes?

- Requirements for the stability of the partition with respect to horizontal loads. This parameter is especially important in rooms with high traffic (corridors, hallways, kitchens) and in cases where a plasterboard wall encloses a room with a suspended ceiling made of PVC film,

Reference: when tensioned, the vinyl sheet creates a horizontal load of 70 kgf per linear meter on the baguette.

- Requirements for wall strength in relation to impact loads. A typical example of a room with high demands is a children's room. Thin single-layer drywall can break when an aborigine hits it with a wooden machine or a pirate's cutlass,

Quiet games? No, we haven't heard.

- Requests for the soundproofing capabilities of the wall. The thicker it is, the larger the layer of noise-absorbing material placed between the frame posts can be,

- The need for hidden installation of engineering systems . Electrical wiring and a local network, water supply and sewerage, ventilation ducts and air conditioning lines can be mounted in the wall.

Examples of calculations

As an example, let’s do some calculations of a partition with our own hands for various requirements for it.

Space saving

If the main priority is saving the usable space of the room, the minimum wall thickness will be equal to the sum:

- Transverse size of the rack profile (5 centimeters),

- The total thickness of two gypsum board sheets (9.5 or 12.5 mm).

Total - 50+9.5+9.5=69 or 50+12.5+12.5=75 mm.

It couldn’t be thinner: a frame made of 50 mm profile and single-layer cladding.

The thickness of plasterboard for partitions of 9.5 millimeters is permissible only if it does not experience mechanical loads in principle. A sheet of ceiling gypsum plasterboard is easily and naturally broken by an accidental blow from the elbow or knee.

Thin but durable

If you want to combine space savings with maximum wall strength, its optimal design is a reinforced frame made of a thin (50 mm) profile and double cladding (single-sided or double-sided).

How can you strengthen the frame?

- Wooden mortgages made of 50x50 blocks, inserted into racks,

- By pairwise connection of rack profiles with a standard step between them of 60 cm,

- Reducing the pitch between the posts to 40 cm.

The final thickness with double-sided two-layer sheathing will be 50+12.5x4=100 mm.

The photo shows a wall with a reinforced 50 mm frame and two-layer cladding.

Noise insulation, hidden laying of communications

If you plan to install a water supply system, a 50- or 90-mm sewer inside the frame, or if the wall must provide maximum sound insulation, it is wise to opt for a frame of maximum thickness - from a 100-mm profile.

In the absence of special requirements for strength, the wall cladding is made in a single layer. The final thickness is 100+12.5x2=125 mm.

Frame made of profile 10 cm wide.

Extreme sound insulation

To absorb maximum noise, it is necessary not only to fill the frame cavities with sound-absorbing material, but also to acoustically decouple the sheathing on both sides of the partition. How to do it?

- Build two parallel frames from a 50 mm profile with a minimum (5-10 mm) gap between them,

For better sound insulation, a damper tape is laid under the guides. It eliminates the transmission of acoustic vibrations from the profile to walls and ceilings.

- Fill the frame with slabs of glued mineral wool. Its standard size (600x100 mm) allows you to do without additional fastening: the slabs are installed spaced between the posts,

The best sound insulation is glued mineral wool.

- Cover the resulting structure with plasterboard on both sides. It is better to resort to two-layer sheathing. The price of several additional sheets of gypsum board will be paid off by the greater strength of the wall and its lower permeability to high-frequency sound.

The maximum thickness of such a wall will be equal to 50 + 50 (two frames of thin posts and guides) + 5 (the gap between them) + 12.5x4 (two-layer gypsum plasterboard wall covering on each side) = 155 millimeters.

Structure and thickness of soundproofing partitions (C115 and C116).

Conclusion

What is the optimal thickness for a plasterboard partition of type C112?

Alexander, according to the thickness, gypsum plasterboard partitions are divided into 3 common types:

1. Partitions with a thickness of 7.5–15 cm. The thinnest structures are type C111 with a profile width of 5 cm and a thickness of gypsum plasterboard sheets of 1.25 cm. Two-layer sheathing C-112 adds another 2.5 cm.

2. Partitions with a thickness of 15–17.5 cm. This is category C-113, equipped with a frame made of PN100 profile, and its double-sided three-layer coating forms a total thickness of 17.5 mm.

3. Partitions with a thickness of 17.5–25 cm. These are double frames of partitions S-115 and S-116, using profiles PN75 and PN100, providing a total thickness of the structure of 20 and 25 cm.

The use of profiles with a width of 7.5 cm (PN75) or 10 cm (PN100) increases the thickness of the structure and the required layer of insulation. The standard width of the wooden beam from which some types of frames are made is 8 cm. The minimum thickness of such partitions depends on the number of layers of gypsum plasterboard and is equal to 8.5 cm (single-layer partition S-121) and 10 cm (double-layer partition S-122).

Connecting brackets and cross connections

Connecting brackets are used to connect CDs in a straight line when installing gypsum boards on the ceiling. If the room has a width or length of less than 3 m, then connecting brackets are not used. If the room has a large width or length, then:

N = (L / 0.4) – 1) xk

Where N – connecting brackets;

L – length of the widest wall in the room;

k – correction factor.

https://youtube.com/watch?v=FyMDu8ZQCsY

Depending on the width of the room, the correction factor has the following value:

- 3-6 m, k = 1;

- 6-9 m, k = 2;

- 9-12 m, k = 3.

and so on.

Cross connections (crabs), which are used to connect CD profiles at the places of their perpendicular intersection, are calculated according to the drawn gypsum board installation plan.

It should be noted that due to the high price of connecting brackets and cross connections, they are used quite rarely. As a rule, CD profiles are connected to each other by cutting out the appropriate size and bending the side walls with further connection to each other using metal screws.

An example of calculating materials for a plasterboard ceiling.

How thick should a plasterboard partition be?

GKL is a thin slab of gypsum with additives, covered on both sides with cardboard. Recently, the material has been widely used not only for leveling walls and ceilings, but also for making frame partitions. Thanks to lightweight structures, the room is divided into separate rooms or zones, communications are hidden, and sound insulation is ensured.

Features of plasterboard partitions, what determines their thickness

Externally solid design and low weight are the main advantages. It can be mounted even on light floors that cannot support the weight of a full brick wall. Device:

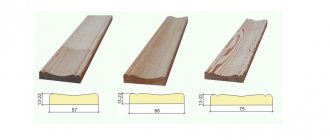

- Iron frame. It is most convenient to construct it from galvanized steel profiles - vertical (racks) and horizontal (guides). The posts make the structure more rigid, and the guides help attach it to the ceiling and floor. The width of horizontal and vertical profiles is 50, 65, 75 or 100 mm, wall thickness is 0.4, 0.45 or 0.55 mm. The cross-sectional height of the guides is 40 mm, and the height of the racks is 50. Sometimes wooden blocks are used to secure the wall. Compared to a metal frame, a wooden one has a number of disadvantages: it does not have ideal geometry, it deforms when humidity changes, and it is affected by fungus.

- Sheathing. It includes 1-4 plasterboard sheets (depending on the required number of layers). Their thickness is 9.5 mm (ceiling) or 12.5 mm (wall). The second option is much stronger and more reliable than the first.

A wall with a gypsum core regulates the balance of air humidity in the room, absorbs noise well, is resistant to fire, and opens up wide possibilities for designers. The sheet has two significant drawbacks: it can collapse in a damp atmosphere (at a humidity above 80%) and cannot withstand heavy loads. The increased thickness of the prefabricated wall will ensure strength, rigidity, and improve insulating properties. To increase it, the frame is strengthened, additional gypsum boards are installed, and more massive sound insulation is made.

Factors that increase the thickness of partitions

1. Resistance to horizontal loads. This parameter is relevant for rooms with high traffic (kitchens, hallways), as well as rooms with suspended ceilings. It is known that a PVC panel acts on a frame (baguette) with a horizontal force of 70 kgf per 1 linear meter. If there is a wall made of gypsum plasterboard, the load also acts on it. If you plan to install a sliding door, you need the most rigid frame possible.

2. Strength to dynamic loads. If a children's room is allocated, the thickness of the future partition should protect it from destruction during outdoor games and various pranks.

3. Increased sound insulation. To equip part of the room as a bedroom and make it impenetrable to external noise, a thicker layer of absorbing material is placed in the frame.

4. Installation of hidden utility networks. In the voids you can place electrical wiring, local network cables, water and sewer pipes, ventilation and air conditioning ducts. To install these communications, the thickness of the internal cavity must be maximum.

Types of partitions and a brief guide to their arrangement

The following varieties are distinguished:

- By application - decorative and functional. The first ones are usually made double-sided from two thin sheets of plasterboard (thickness 9.5 mm) - this is enough if a door is not installed and there are no other loads. For functional partitions, a sheet of 12.5 mm is most often used.

- By service life – temporary and capital.

- In appearance - with a door and deaf.

- By type of fastening - stationary or sliding.

- By type of frame - using a flat or partition profile. The first (standard marking ud, cd) is intended for cladding walls and ceilings; it is not designed for heavy loads and is used only for decorative structures. The second (denoted uw or cw) is used for fixation to all adjacent surfaces.

The steel profile frame can be single: this option is suitable for temporary, easily disassembled plasterboard partitions. If a door is being installed, powerful sound insulation or large utility networks are being installed, it is better to make a double frame.

The construction of particularly strong or fire-resistant structures requires the connection of two profiles using the I-beam principle. Sliding systems also use a double frame: one of them is movable, and the second is stationary.

Design and installation of gypsum boards

Instructions for design and assembly are set out in article SP 55.101.2000 (a special set of rules included in SNiP). According to this document, gypsum plasterboard structures are divided into several types, the data of which is given in the table.

Required quantity of hardware

Installing butterfly dowels in drywall.

They can be calculated using the above formulas for fasteners. The result is the following numbers:

- dowel-screws: 34/0.6 = 57 (pcs.), for work it is better to take 60-70.;

- “fleas” - 900 -1100 units;

- screws for metal - 20 x 50 = 1000 (pcs.).

The result can be derived from the calculations:

- UD profile - 12 and 9 (3- and 4-meter, respectively);

- CD slats - 29 + 21;

- plasterboard sheets - 20 pcs.;

- pendants - 55-65 units;

- dowels - 30 pcs.;

- “fleas” - 1100 units;

- self-tapping screws - 1000 pcs.

When performing calculations, you may need the following tools and devices:

- Calculator.

- Roulette and ruler.

- Pencil.

If you follow all the above recommendations and tips for performing calculations, then material losses can be minimized.

https://youtube.com/watch?v=Ppx2wQnfxvI

This will slightly increase the cost of money and will give you confidence that you won’t have to run to the construction market or to the store because you suddenly ran out of materials and the structure is not yet completed.

How thick should plasterboard partitions be made?

Very often during renovations we are faced with the need to redesign the premises. Thanks to modern building materials, such as plasterboard, redevelopment of any complexity will be easy and very simple. For these purposes, partitions or false walls are created.

Such walls are very popular today, because they have a number of advantages.

Advantages of the design

False walls, used to delimit space into specific zones, have a number of advantages:

- easy and quick installation,

- high strength and durability,

- safety,

- the ability to create partitions of various shapes and sizes,

- affordable price.

All these qualities are inherent in drywall, which puts it a step higher than such standard materials as wood or brick.

Size matters

When creating a false wall or partition from plasterboard, its most important parameter is its thickness. Here you need to know what the minimum and maximum thickness is for such walls.

Note! The size of the material must be selected based on the purpose of the gypsum board.

Today, false walls are constructed from plasterboard sheets for the following purposes:

- decorative It is usually made as a figurative and decorative element of the interior of a room and serves to emphasize its beauty. Usually it does not involve heavy loads and is not used from a practical point of view. Its thickness can be acceptable minimum,

- functional. For such walls, you should choose a thickness that will be maximum or approach it. The thickness of the plasterboard partition in this case depends on the degree of load that it must withstand. Such false walls often contain a number of shelves or niches in which books, flower pots, vases, etc. are supposed to be placed.

The choice of wall thickness should also be based on their dimensions. Today, this kind of construction can be made of the following types:

- in the form of a small partition that will partially cover the space,

- wall with an arch without doors,

- a complete and monolithic wall without decorative elements with an inserted door frame.

In each of these three situations, the size of the partition will be different, and the structure will serve a different function. Since plasterboard for such walls is attached only to a wooden or metal frame, during installation the thickness of the frame elements must also be taken into account. Do not forget that the design appearance of the planned partition also contributes to determining the thickness. The false wall must fully withstand the load I plan on it from all decorative elements, as well as household items placed on it.

We carry out calculations

At the base of any wall mounted using plasterboard sheets there will always be a frame. Most often, a metal profile is used as a frame. For assembly you need to use rack profiles of various sizes. Their choice should be made based on what thickness of the partition you want to get in the final result. In addition to the size of the rack profile, one should take into account such a parameter as the thickness of the drywall used. It can be different depending on what you want to get from a false wall: strength and sound insulation or curved lines and decorativeness. The thickness of the plasterboard sheet should be selected based on the expected load on the entire structure. This parameter is calculated in kilograms for one square meter of partition surface.

Selecting sheets

Today, the thickness of a plasterboard sheet can have different indicators. But you should know that in order for the sheet to be durable and last as long as possible, its minimum thickness must be 12.5 mm. Typically this is the size of a standard sheet for wall decoration. Reducing this figure will lead to a decrease in the strength properties of prefabricated walls. As a result, they will become deformed much more often and will not last as long.

12.5 mm is the minimum required for the simplest and most decorative partition. But what to do if the expected load is many times greater? Here you need to know the following nuances:

- with a load of 40-50 kg per square meter, the sheet thickness should be 15 mm,

- with a load of 50 to 70 kg, about 18 mm will be required,

- for loads above 70 kg, double sheets will have to be used, and the frame structure will also need to be fully reinforced. Here, reinforcement needs to be done around the perimeter of the false wall, as well as in the places where shelves or niches are placed.

Having correctly determined this parameter, you can be confident in the long-term operation of the structure, as well as in its high-quality assembly. Drywall will flawlessly perform its functions, and not crack, collapse and spoil the entire interior of the room.

Let's talk about the frame

When you have dealt with the plasterboard sheets, you can pay attention to an equally important element - the frame. For false walls, the thickness of the selected racks plays a very important role, since it is the prefabricated frame that will take on the entire load of the structure during its operation.

Here the choice is also based on the functionality of the device being designed:

- when assembling a simple partition without frills, which will trivially divide the room in half, the thickness of the rack profile can be 50 mm,

Note! The 50 mm profile is only suitable for decorative and simple designs. Therefore, many craftsmen do not recommend choosing such a profile for assembling more complex and functional walls.

- if the partition is functional, then the racks should be 100 mm thick.

In general, if finances allow, then it is better to use 100 mm racks even for simple partitions in order to be sure of their strength. This profile has the following advantages:

- will create a soundproof partition,

- will increase the strength and rigidity of the frame several times,

- the partition will play the role of a real, and not a purely decorative wall,

- allows you to use only one layer of plasterboard sheets. There is no need to use two-layer slabs,

- a door installed in such a wall will function normally.

Therefore, when choosing a profile, you should not cheapen, but it is better to immediately use a more suitable material.

Sound insulation and its role

When creating partitions that act as a full wall, the thickness of the structure will also depend on the soundproofing material. Or rather, on the presence or absence of it.

Sound insulation is placed in a false wall if it is used to create a separate room. As a rule, either glass wool or polystyrene foam is used as a soundproofing material. Soundproofing materials can have different thicknesses, so this must be taken into account when calculating the thickness of the overall structure. Now you are fully aware of the issue so that without hesitation you can choose for yourself the most optimal thickness option for both the partition and all its components. Remember that the quality and durability of structures made from plasterboard sheets depends on taking into account all the nuances of their assembly.

Types of self-tapping screws

Selected taking into account the selected frame type. For a metal profile, metal self-tapping screws are used: when installing in one layer - 25 mm long and for a two-layer version - 35 mm. They are available with a protective zinc or phosphate coating, have more frequent threads and a pointed tip. If the profile thickness is more than 7 mm, another type of fastening screws is selected. The base of their heads has special notches that prevent possible unscrewing. They are called "bugs".

Self-tapping screws exist for both wood and metal profiles

For wooden profiles, fasteners with a wider thread pitch are intended, having a length of 32 mm for installation in one layer and 45 mm for installation in two layers.

Self-tapping screws for wood and metal are not interchangeable. They must be used strictly for their intended purpose, otherwise the design will be weak. Self-tapping screws for metal simply will not be able to hold the structure on a wooden profile.

Which drywall is best to use for walls?

Using such plasterboard panels, you can quickly level walls, redesign a room, or assemble the necessary structures (boxes, suspended ceilings).

However, various types of sheets are produced with a wide variety of characteristics, and the main purpose. This should be taken into account when drawing up a repair project, and most importantly, an estimate.

Which drywall is best for walls to choose from a huge variety of materials?

Structure and material parameters

The use of gypsum plasterboard in combination with a frame and a large number of attachment points makes it possible to create structures with a significant margin of safety.

The material itself consists of two parts: a filler, which is gypsum, and a cardboard shell.

The usually common size of plasterboard is: width 1200 mm, length 2500 mm, with a thickness of 12.5 mm. However, before choosing drywall for walls, it is worth understanding the standard sizes and purpose.

Companies produce panels with thicknesses: 6.5, 9.5, 12.5, 15, and up to 24 millimeters. The length of the sheets ranges from 2000 to 4000 mm, and the width can be 600, 900, 1200 mm.

However, when choosing a material, you need to understand why certain types of panels are needed, and how to distinguish them.

Classification of plasterboard by purpose

Premises intended for different operating conditions are subject to renovation: kitchens, bathrooms, living rooms and basements. And everywhere the finishing is susceptible to various influences: humidity, temperature, mechanical stress and others. To solve these problems, companies produce plasterboard panels that can withstand certain types of influence.

The most common types of sheets, most often referred to as wall sheets. They are used when decorating living rooms, as well as assembling partitions between them.

The material is installed on a frame or in a frameless manner. This allows you to create durable wall finishing in the shortest possible time.

Marked in gray on the planes.

But, for use in a humid microclimate, you need a different type - moisture resistant.

Has green markings on the front side. The main purpose is to decorate walls and ceilings in rooms with a high level of water vapor in the air (moisture-resistant plasterboard sheets).

This is a good option for finishing the walls of bathrooms or semi-basement rooms; the filler contains an antiseptic additive that prevents the formation of fungus and mold.

In other respects, the slab does not differ from its wall counterpart, except for the price. Such panels are somewhat more expensive.

The plasterboard sheet is fire-resistant - it is able to withstand and maintain an integral structure even when exposed to an open flame (for a limited period of time!). The effect is achieved by adding fire retardants to the composition.

The main specialization of the panels is the assembly and finishing of specialized structures: ventilation duct boxes, fireplace surrounds and others.

Marking on the front side in red or pink. Like other types of slabs, they are more expensive compared to wall analogues.

Other specialized types of plasterboard sheets are also produced.

- GKLVO is a moisture- and fire-resistant sheet that combines both properties.

- Acoustic plasterboard - provides sound insulation of rooms and proper acoustics.

- Arched - the purpose of creating curved configurations, a more plastic material.

- Laminated - has a PVC coating, not intended for living rooms.

What type of plasterboard do we recommend for indoor walls?

Implementation nuances

There is one drawback to gypsum board - it is not recommended for use in places of high humidity. But technology is developing and you can increasingly find moisture-resistant drywall on the market. This can be successfully used even in bathrooms. The thickness of the material is still the same 12.5 mm, but the price is certainly higher.

With a little imagination and taste, plasterboard walls will not only divide the space, but also carry a very useful functional load when placing lighting sources on them, for example

Partitions made from plasterboard are quite reliable structures, but do not test them for impact and moisture resistance. (see also the article How to make plasterboard shelves: sequence of work and useful tips)

Treat your creation with great respect. Calculate everything exactly, watch the video on our website and get to work with a cool head, having enough time.

Main stages

Depending on the operating conditions of the partitions and the type of networks laid in them (engineering), their cladding, like the frame diagram, can be single or double. The work on installing partitions (carried out by 2 installers) is divided into several main stages:

- Preparation for work;

- Marking the floor, walls and ceiling;

- Installation of guide profiles – PN (UW);

- Installation of vertical racks from a rack profile - PS (CW);

- Installation of lintels (door and window openings);

- Covering the frame with gypsum board sheets on one side;

- Laying the necessary communications: electrical cable, pipelines;

- Laying (in the interstitial space) and fastening of thermal insulation;

- Sheathing of the frame on the reverse side;

- Finishing work.

Before starting work, try to leave behind all wet processes associated with the preparation and use of mortars, and clean the installation area of the future partition from debris, mortar buildup, foreign objects and protect it from sudden temperature changes.

If you have a smooth screed and well-plastered and puttied walls, consider yourself lucky - this is an ideal base for installing a metal frame.

Recommendations for material consumption

Although it is clear that the calculation of the material for the partition depends on the specific case and is calculated, as they say. Local. However, I will give a calculation table offered by the Knauf company.

This is the entire calculation of a plasterboard partition.

Other articles in the section: Plasterboard partitions

- Tall plasterboard partitions

- How to make a doorway in a plasterboard partition

- Interior partition made of plasterboard with a door

- Installation of a plasterboard partition

- General information about plasterboard partitions

- DIY plasterboard partition

- Partition made of two layers of plasterboard: technology of covering 2 layers of plasterboard

- Rules for installing plasterboard partitions

- Profile for plasterboard partitions

- Calculation of a plasterboard partition

This is interesting: Bathroom sink sizes: selection recommendations