6411 0 0

Andrey June 20, 2017 Specialization: facade finishing, interior finishing, construction of dachas, garages. Experience of an amateur gardener and gardener. We also have experience in repairing cars and motorcycles. Hobbies: playing the guitar and many other things that I don’t have time for :)

What is GVL, what characteristics does it have and what is its thickness? I often have to work with this material, so I will try to answer the questions posed in detail. In addition, I will tell you for what purposes you can use sheets of different thicknesses.

GVL is a more durable material than drywall

Technical characteristics of gvl (gvlv) Knauf

Gypsum plasterboard supersheet has special properties that allow it to be used not only for covering walls, ceilings, but also for floors!

Thanks to a high-quality mixture of fiber and gypsum, as well as a special anti-chalking impregnation, supersheet can be used in buildings and premises for any purpose. The only fundamental difference in the use of gypsum board and moisture-resistant gypsum board is the possibility of installing the latter in places with high humidity. All main parameters of the sheets are given in Table 1. Table 1. Characteristics of gypsum fiber sheet

| Parameter | Meaning | Units |

| Dimensions | 2500x1200x10 2500x1200x12.5 | mm |

| Weight 1 sq.m. (sheet thickness 10 mm) | 10.8 | kg |

| Weight 1 sq.m. (sheet thickness 12.5 mm) | 15.62 | kg |

| Thermal conductivity | 0.22-0.36 | W/m °C |

| Parameter | Meaning | Units |

| Heat absorption | 6.2 | W/m °C |

| Bending strength | 5.3 | MPa |

| Brinell hardness | 20 | MPa |

| Humidity | 1.5 | % |

The moisture-resistant material differs from standard gypsum plasterboard in that its surface on both sides is treated with a special water-repellent agent. This allows it to be used in rooms with any degree of humidity.

If we talk about the properties of the materials, they are very similar. The dimensions and weight of moisture-resistant gypsum board are the same as those of a standard super sheet. The following characteristics are also identical: humidity, Brinell hardness, flexural strength and thermal conductivity gvl and gvlv. At the same time, the range of applications for moisture-resistant drywall is wider than standard, since even in the bathroom it will “stand idle” for its entire service life.

Peculiarities

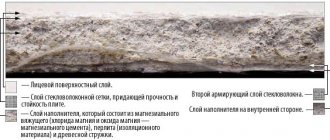

The basis for its production is gypsum, to which cellulose fibers obtained from waste paper are added, their percentage is 15–20% and they serve as a reinforcing substance. Externally, such a sheet is very similar to drywall, there is only no paper on the surface. But it has higher performance characteristics.

The service life of such boards is much longer, and the properties of moisture-resistant sheets make it possible to install them in rooms with high humidity.

This is a fairly popular building material lately, used for finishing interiors and exteriors .

It consists of two layers of cardboard paper used in construction, and a core, which includes a hardened gypsum-water mixture and some fillers that give the mixture the necessary beneficial properties.

It was first invented in the United States in the 19th century by Augustine Sackett, the owner of a huge pulp mill. But over time, the new composition and dimensions of drywall were patented by Clarence Utsman, an American engineer.

Now the usual sheet width is measured in the range from 60 to 120 cm . Used in rooms with dry and humid climates. Modern composition: 92% gypsum, 6% paper cardboard, 2% water, starch and other organic substances.

Types of GVL for floors: main types of markings, what it means

Gypsum itself is a hygroscopic material, so it is not recommended to lay gypsum board slabs on the floor if the room is exposed to humidity. For rooms with constant high humidity levels, for example, for kitchens, bathrooms, bathrooms, swimming pools and saunas, it is better to purchase GVLV, that is, moisture-resistant boards

Externally, the sheets do not differ from each other, so it is important to pay attention to the markings

What is laminated chipboard: sheet sizes, areas of application, how to choose (read more)

To decorate the floor covering, special GVL floor elements are produced, marked “EP”. Most often, the material is produced, which is the main supplier of sheet products on the domestic market. All products are distinguished not only by high quality, but also by increased strength characteristics.

Some people prefer to lay ordinary gypsum fiber boards on the floor, but for this, not one, but two elements are taken, which are located offset relative to each other. This distance most often does not exceed 3-5 mm. If special GVL sheets are used for Knauf flooring, they are laid in one layer, because they have sufficient strength.

Products intended for flooring are produced with the “EP” marking.

In addition, products are classified according to the type of edge. If the sheets have a straight edge, they are marked “PC”. Slabs with seam edges are also available, which minimizes the visual perception of joints. The fold size usually varies in width from 2.8 to 3.2 mm, depth - 1.7-2.3 mm. It is appropriate to decorate the floor with one or another type of material, but due to the fact that the price of gypsum fiber board for a floor with folded edges is higher, many prefer to purchase sheets with a straight edge.

As already mentioned, the production process of slabs is regulated by GOST standards. Based on this, the following standard size options are distinguished:

- width, cm – 50, 100, 120;

- length, cm – 150, 200, 250, 270, 300;

- thickness, mm – 12.5, 15, 18, 19, 20.

It is not always possible to adhere to these indicators, so a deviation in width is possible, but no more than 3-4 mm. As for the length, the deviations here should not exceed 2-3 mm. In rare cases, if the slabs are long, this figure reaches 4 mm.

The thickness of GVL sheets can vary between 12.5-20 mm.

In order not to make a mistake when purchasing a material, you should know what this or that marking means, for example, GVL-PK 2000x1000x12.5. Here you can see that a conventional slab is presented, which does not have moisture-resistant qualities, and is distinguished by a straight edge. If the abbreviation “VGLV-FK” is indicated on the marking, this means that the board is moisture-resistant with a seam edge.

One of the key advantages of gypsum fiber sheets is their fire resistance. Even cellulose, which is added to the gypsum mixture, does not burn or ignite; in the event of a fire, the material does not contribute to the spread of fire, which is especially important, for example, in wooden houses. In addition, the stoves will not emit toxic substances when burning.

Standard dimensions of canvases

GVL – sheet material. GOSTs provide for the dimensions of canvases in centimeters:

- width – 50, 100, 120;

- length – 150, 200, 270, 300;

- thickness – 1, 1.25, 1.5, 1.8, 2; with increasing thickness, the strength of such a slab becomes greater.

The standard sheet size for household work is considered to be 150 x 120 x 1 cm.

In addition to standard sheets, many manufacturers produce highly specialized products. For example, the Knauf brand produces special sheets for dry floor screed “KNAUF-superfloor”, their size is 120 × 120 cm with a thickness of 2 cm. They are slabs obtained by gluing two sheets of gypsum fiber board with an offset, due to which on both sides of each sheet a fold 5 cm wide is formed.

As thickness increases, bending strength decreases. This must be kept in mind during transport and installation. Arched structures are created from such sheets, as they are very durable when arched.

Manufacturers mark the back of the sheet for all three parameters (length, width, thickness). During the production process, cellulose fibers are added to the gypsum under pressure and the mixture is pressed. The result is a dense reinforced fabric. If such a fabric is impregnated with special hydrophobic substances, the result is a moisture-resistant sheet - GVLV. Since the surface of such sheets is not covered with paper, the resistance to fire also increases compared to gypsum board.

The standard thickness of a gypsum fiber sheet is usually 10 or 12 mm. Dimensions can be 1200 x 3000 mm or 1200 x 600 x 12 mm.

Compared to drywall, gypsum fiber sheets are much heavier. Therefore, their installation is mainly carried out using a metal or wooden frame. The adhesive method can also be used, but for sheets with small sizes.

And yet the material is quite light and will not create additional load on the walls. Therefore, it is perfect for arranging partitions.

Subtleties of work

The uniqueness of GVL lies in the fact that they can be laid on almost any floor, including wood. In this case, it is necessary to take into account several features of the material laying technology. This is relevant if special requirements are imposed on the thermal insulation of the room. This is where additional material (for example, polystyrene) will come to the rescue. It should be noted that the height of the floor in this case will increase significantly.

It is not recommended to use materials of increased thickness: sheets 10 mm thick are suitable. A trademark dry screed allows you to hide all engineering systems, which is completely impossible with a traditional screed. Anyone who has at least once dealt with a dry screed from a well-known manufacturer is unlikely to want to fill the floor with concrete. Even a teenager can handle laying Knauf gypsum fiber boards. The process will not take much time and effort, the room will soon be ready for further work.

Areas of application of gypsum plasterboard and gypsum board

Despite the fact that GVL has higher strength characteristics. It cannot completely replace drywall. Simple material is used to level and create walls and partitions. The simplest partition includes a lattice frame made of vertical beams.

Installation of sheets on the floor

Use for partitions and walls

GCR wall cladding is often used, since this material is light in weight and does not create significant loads on the surface of the walls. Drywall is suitable for installing interior partitions and cladding frame buildings.

GVL for walls have high strength, which allows them to be used for cladding industrial premises. Reliable sheets are also relevant for installation in gyms. They cannot be used to process complex surfaces, but they have a long service life.

Installation method for partitions

The construction of gypsum plasterboard partitions is determined by the optimal weight of such material. You can create lightweight screens for zoning, which can be easily dismantled if necessary. This material can be used to decorate walls in residential areas: children’s rooms, bedrooms, living rooms and corridors. When performing renovations with a high level of humidity: kitchen, bathroom or veranda, GVL is recommended.

Partitions with insulation

To decorate the walls of a boiler room, switchboard or other structures with rising temperatures, it is better to use fire-resistant gypsum board. This material is also suitable for decorative cladding of fireplaces and stoves. To line a smoke duct in an unheated attic, you can use GKLVO.

Features and secrets of installing gypsum boards on the wall can be seen in the following video:

Watch this playlist on YouTube

Application for ceiling

The technology for installing gypsum plasterboard on the ceiling differs little from installing gypsum fiber board sheets. But there are also some peculiarities. GVL slabs are heavy, so they are difficult to mount to the ceiling alone. Self-tapping screws are used as fastening elements.

When installing a gypsum fiber board ceiling, you need to cut the material. A hand-held circular saw or jigsaw is used. All slab joints must be treated with gypsum putty.

When installing a suspended ceiling from gypsum plasterboard, you can get the following advantages:

- the ability to create complex configurations;

- formation of beautiful arches;

- application of any facing materials.

When installing a suspended ceiling in a bathroom, you need to choose a material with water-repellent characteristics.

Interior use

The use of gypsum fiber on the floor is especially important. In this case, panels are used to withstand high humidity. Since the material has a minimal coefficient of expansion, the joining seams will remain sealed. Interior finishing using gypsum fiber boards allows you to reduce the period of finishing work. GVL sheets can be mounted on frames made of wood or metal. This results in a perfectly flat surface that is suitable for painting, wallpapering and tiling.

Drywall is used to create a convenient TV shelf and functional niches

A device made of gypsum plasterboard for window and door slopes is often used. Installation is carried out before finishing is done. Drywall can be glued to plaster. On door and window openings, the material must be glued over the entire surface, and not in fragments. The designs of arched openings made from gypsum plasterboard are wonderful and beautiful.

Classification and technical characteristics. Marking

GLV slabs are divided into standard (GLV) and moisture-resistant (GVLV).

The former are well suited for interior decoration of industrial and residential premises, in which there is a normal temperature regime and fairly dry air.

Moisture-resistant sheets are treated with a hydrophobic solution, thanks to which they can be effectively used in all wet rooms (kitchen, toilet, bathroom), as well as in attics, basements, garages and many other construction sites.

Both standard and moisture-resistant gypsum boards have a rectangular shape.

They can be with direct (PC)

And folded (FC) edges.

Marking

The marking is applied to the back of each gypsum fiber sheet and looks like this:

- The sheet type (GVL/GVLV) is indicated first.

- The group of type and manufacturing accuracy (A/B) is indicated

- Edge type (see above). PC or FC.

- Dimensions.

- Standard

Non-standard offers

Non-standard sheets are usually smaller in size than standard ones. As a result, they are much lighter and easier to work with. Such sheets are most often used in individual construction.

A moisture-resistant gypsum fiber sheet with a sheet size of 150 cm by 100 cm by 1 cm is perfect for covering a wall in a toilet, bathroom or small storage room . It can be mounted using an adhesive mixture.

Before installation, in this case, it is necessary to pre-treat the wall surface with special hydrophobic compounds.

Sheets thicker than specified in the standards are usually used as a substrate for flooring. This makes it possible to level the floor without excess dirt. Sometimes atypical materials with a length of 360 or 600 cm are found on sale.

GVL sheets measuring 150 x 120 cm, with a thickness of 1 and 1.25 cm can be installed independently. These sizes are suitable for arranging walls and floors in private homes .

Larger sheets must be installed by qualified builders. Mostly, industrial enterprises are finished with such slabs.

In addition, sheets come with a straight edge without chamfers, then the marking is applied - “K” and with a falsetto edge - “FK”. Additionally, markings may be applied indicating the type of surface. “NSh” – unsanded surface or “Sh” – polished.

Technology for laying gypsum fiber moisture-resistant sheets

If the room is equipped with a good ventilation system, then the sheet (weight from 40 to 42 kg) is even laid on a concrete screed. For this, experts recommend choosing medium-sized slabs.

A sheet weighing 40 kg is suitable for laying on a wooden or reinforced concrete surface.

Follow the procedure for laying gypsum fiber moisture resistant sheets

Laying is carried out according to the following scheme:

- The floor is thoroughly cleaned of debris and dust. If there are cracks or similar defects, they are repaired.

- Polyethylene is laid, which protects the laid floor from moisture.

- The edge tape, which acts as a sound absorber, is laid out around the perimeter of the room. Columns and similar interior parts adjacent to the floor are covered with tape.

- Altitude beacons are set along which the guides will be placed.

- The guides themselves are laid and leveled - they will allow you to accurately level the insulation layer.

- Expanded clay is poured. It is compacted and leveled along pre-installed guides.

- Next, GVLV (whose weight does not exceed 40 kg) is laid starting from the corners of the room. After the first slabs are laid, they are fixed with an adhesive solution or mastic. Another layer of slabs is placed on top, the weight of which does not exceed 40 kg.

- The layers are connected to each other using screws.

- When the main installation work is completed, the floor is primed and the outer covering is installed.

GVLV sheet

(weight - from 39 to 43 kg) is a new product in the field of repair, which is designed as an alternative to drywall, but without its weaknesses. Reinforcement with fluff pulp increases the technical characteristics of the material and makes its use for flooring or wall cladding more preferable.

Dry screed with GVL sheets

This technique was developed by Knauf, and a high-density tongue-and-groove gypsum board was developed for it. This material is called Super Floor. The essence of the method is that fine expanded clay (expanded clay sand) is poured onto a base (any, of any degree of curvature). Expanded clay is leveled, and floor elements made of gypsum fiber board are placed on it. The finishing floor covering can be laid on this base. You can make your own insulated floor very quickly and conveniently. In addition, the technique does not create significant loads on the floor.

GVL on the floor: dry screed

Instead of expanded clay sand, you can use regular construction dry sand. You cannot mix different materials or different fractions, as sooner or later they will shrink. And when laying gypsum fiber board on the floor, a flat base without dips is required. So it’s better not to allow drawdowns.

https://youtube.com/watch?v=JowehhYjIT4

GVL for walls

In this case, there are two ways to mount sheets to the wall.

Frameless method

With this method, GVL sheets are attached to the walls using special glue. The type of adhesive and quantity will depend on the unevenness of the walls. If the defects on the wall are small, gypsum glue is applied to the sheets and pressed to the surface. If the unevenness on the wall is significant, then it is worth applying a special strong glue around the perimeter of the sheet, and then in the middle, dotted every 30 cm. If in the future you plan to hang any cargo in the form of shelves or hangers on the gypsum board, you need to coat the entire surface of the sheet with glue for greater reliability.

Frame method

For this method, you first need to make an iron frame that can withstand heavy loads. You can also place additional insulation or sound insulation under the frame, and you can also hide electrical wiring and other communications there. The gypsum fiber sheets themselves must be attached to the frame using special self-tapping screws with double-row threads.

What to consider when choosing

When purchasing gypsum fiber board sheets, you should pay utmost attention to the manufacturer. The sheets of the Knauf company, which has long established itself in the building materials market, have very good quality. Although analogues from domestic manufacturers will cost less, their quality is noticeably inferior to German ones. When purchasing moisture-resistant sheets, you need to carefully read the product labeling. Such moisture-resistant sheets may not differ in appearance from standard ones, so it is important to read what is written on the packaging.

When choosing any building materials, cost should be the last argument in favor of choosing a particular product. Good moisture-resistant Knauf sheets, depending on the size, can cost up to 600 rubles per piece, but it is better not to be greedy, since the stingy pays twice.

Main characteristics of moisture-resistant gypsum fiber sheet (gvlv)

The very concept of “plasterboard” is quite broad, since it includes several types of this material. They differ significantly in operating conditions, and, accordingly, in their composition. In addition, there is such a thing as a “fiber supersheet”. Such material has a number of advantages compared to gypsum board and, according to the Knauf classification, is divided into:

- superlist (gvl),

- moisture-resistant supersheet (gvlv),

- small format supersheet.

Each of the above options is characterized by increased mechanical strength, excellent sound insulation, fire resistance and has a special fibrous structure. The latter property allows you to carefully cut drywall and process edges without much effort.

Technical characteristics of gvl (gvlv)

Gypsum plasterboard supersheet has special properties that allow it to be used not only for covering walls, ceilings, but also for floors! Thanks to a high-quality mixture of fiber and gypsum, as well as a special anti-chalking impregnation, supersheet can be used in buildings and premises for any purpose. The only fundamental difference in the use of gypsum board and moisture-resistant gypsum board is the possibility of installing the latter in places with high humidity. All main parameters of the sheets are given in Table 1.

Table 1. Characteristics of gvl supersheet (gvlv)

The moisture-resistant material differs from standard gypsum plasterboard in that its surface on both sides is treated with a special water-repellent agent. This allows it to be used in rooms with any degree of humidity.

If we talk about the properties of the materials, they are very similar. The dimensions and weight of moisture-resistant gypsum board are the same as those of a standard super sheet. The following characteristics are also identical: humidity, Brinell hardness, flexural strength and thermal conductivity gvl and gvlv. At the same time, the range of applications for moisture-resistant drywall is wider than standard, since even in the bathroom it will “stand idle” for its entire service life.

Advantages and application of moisture-resistant supersheet

Fibrous gypsum board has all the advantages of conventional drywall:

- environmental friendliness,

- high heat and sound insulation,

- non-flammability,

- mechanical strength and abrasion resistance,

- ease of installation.

It has only two drawbacks: price and significant weight of the gvl (gvlv) sheet. The first problem can be solved by minimizing waste, and the second can be solved by using a good assistant during the installation process.

Moisture-resistant plasterboard can be used in almost any type of building. Main use cases:

- in places with a high fire hazard as wall and ceiling cladding,

- for cladding attics, balconies and basements (if ventilation is available),

- for the construction of partitions in apartments with high humidity (for example, in bathrooms),

- for unheated rooms,

- for prefabricated floor subfloors.

In the bathroom, it is recommended to additionally treat the surface of the wall made of glvv from Knauf with special moisture-resistant decorative coatings (paint) or cover it with ceramic tiles.

Installation of gvlv on the floor

The slabs can be laid on almost any base: reinforced concrete or wood. For these purposes, the best option would be to use a 12 mm thick gypsum board sheet. The order of work will be as follows:

- Attaching a special edge tape.

- Filling with expanded clay or installing insulation.

- Laying a standard size gypsum board (gvlv) sheet on the floor.

- Treat the surface of the first layer with glue or mastic.

- Installation of the second layer.

- Tightening the layers with screws.

- Primer.

- Installation of covering (most often linoleum).

If you need to install bathroom floors, you should definitely treat the joints with waterproofing tape. This will help avoid moisture ingress and protect the structure from premature destruction.

Of course, gvlv is a “new word” in the development of the construction business. It is especially convenient to use this material during DIY repairs, as it is very easy to process. Moreover, the market offers gypsum board sheets of various thicknesses and sizes, which significantly optimizes marking and installation work.

The only important point is that you should not purchase materials from dubious manufacturers whose reputation on the market is not confirmed by real documents. After all, compliance with GOST sheets gvl and gvlv is the main guarantee of the quality and safety of the entire structure. Nobody wants to redo most of it a couple of tapes after the repair. I would like to hear the opinion of experienced drywall craftsmen on how to avoid the most common mistakes.

When is it possible to use?

The material is used during construction work in rooms with normal and low humidity levels. You can even use it in attic renovations, but only if there is sufficient air circulation. In the kitchen, bathrooms and other rooms with high humidity, moisture-resistant building material is used - GVLV .

The material is frost-resistant, which makes it possible to decorate unheated premises, for example, garages, sheds and other outbuildings. For wooden buildings, the use of gypsum fiber board provides fire protection.

Due to its ease of use, you can easily build a partition with your own hands or lay a floor footing. This will significantly reduce the cost of repair work.

Like any building material, this one also has its advantages and disadvantages.

Positive characteristics:

- Since gypsum fiber sheet contains only gypsum and paper, it is an environmentally friendly material. When working with it, no toxic substances are released, and there is no risk of respiratory diseases when sawing sheets. It does not contain synthetic resins or polymer inclusions; it can be safely used for interior decoration of residential premises.

- Resistant to temperature changes, so can be used in unheated rooms.

- Has high noise insulation characteristics. Can suppress noise of 30-45 dB.

- GVL tolerates moisture well. Therefore, it is used in finishing kitchens and bathrooms.

- High fire resistance makes it possible to sheathe wooden floors, beams, and walls.

- It has low thermal conductivity and is used for wall insulation.

- The high viscosity of the material allows nails to be driven into it and screws to be screwed in, and they will be securely fastened inside the sheet. This factor also influences the fact that gypsum fiber board practically does not crack and does not become painted. It can be easily cut to size using the same tools as drywall and plywood.

- Lightweight, so inexpensive profiles and frames can be used for installation.

- The material is easy to process, with minimal waste during installation.

- Thanks to the use of cellulose fiber, the sheet is more flexible than gypsum board. Its bending strength ranges from 5 to 6 MPa, which is significantly higher than plasterboard. Therefore, it is easier to make complex decorative structures from gypsum plasterboard - arches, curved surfaces.

- Gypsum fiber sheet can withstand up to 20 freezing cycles without loss of characteristics, which makes it possible to use it for finishing periodically heated or unheated rooms.

Despite the huge number of advantages, the use of GVL also has some disadvantages:

- heavy weight, one plate – about 18 kg;

- the price of gypsum board is higher than that of drywall;

- absorbs moisture well, this limits the use of the material or requires treatment with special water-repellent substances.

There is a large selection of products on the market. Typically, the best manufacturer is considered to be the brand that first produced the product. At the moment, Knauf is considered the best in all of Europe , although it is the most expensive. There are also products from domestic manufacturers on the market, but the technical characteristics of the material may be slightly worse.

When purchasing any building materials, it is better to make sure that there is a certificate for the product and compliance with GOST. Make sure there is a marking; it should indicate the size, type of edge, GOST.

Areas of application

For walls

Gypsum fiber sheets are used for walls to level the surface, for sound insulation and thermal insulation.

This material can be mounted in two ways: frameless and using a frame. The frameless method is used if the unevenness of the walls is not too large. Special gypsum glue is applied and pressed against the wall. With this method, it is better to take sheets of small parameters .

If the unevenness of the walls is large, up to 3-4 cm, the sheets are glued with a special glue, applied along the perimeter and in the center, every 30 cm. If you plan to hang any shelves and cabinets on the wall, then the entire surface of the sheet is smeared with glue. Before installation, the material is brought into the room 2-3 days in advance so that it adapts to the temperature and humidity conditions.

With the frame method, the gypsum plasterboard is attached using self-tapping screws with double-row threads to a frame made of durable galvanized profiles. You can put material inside for insulation and sound insulation. Profiles must be selected so that they can withstand heavy weight . Installation is carried out from the bottom up, starting from the corner of the room.

After installation is completed, sockets are cut and all joints are sealed with putty.

For floor

Mark the floor level. Lay a vapor barrier. The use of GVL makes it possible to use so-called heated floors. Expanded clay is poured onto the prepared surface and leveled. The sheets are coated with glue and fastened with self-tapping screws. The joints are puttied.

The main advantages and disadvantages of gypsum fiber boards for flooring

Many people prefer to use gypsum fiber board for “warm floors” because the material has good thermal conductivity and does not retain heat. At the same time, the slabs are suitable for organizing water, electric and combined floors. In this case, sheets of any thickness are used, but experienced builders recommend taking products measuring 10-12 mm.

Note! In addition to the fact that the material is suitable for decorating horizontal and vertical surfaces, it is also successfully used in arranging window and door openings, for creating decorative boxes that help hide utility lines, as well as for decorating partitions and false walls in technical and residential premises. . Gypsum fiber is suitable for leveling all types of floors. The main advantages of gypsum fiber boards:

The main advantages of gypsum fiber boards:

- Quick installation. A floor leveled with sheets can be immediately covered with finishing materials, and it is also possible to install any heating system.

- Easy transportation. Due to the fact that the flooring sheets are generally characterized by small dimensions, there will be no difficulties with transporting and lifting the slabs.

- Light weight. This allows the sheets to be laid on bases that are not particularly durable. For example, you can lay gypsum fiber sheets for the floor on wooden beams.

- Possibility of use in unheated rooms. Due to the fact that materials with a high moisture content are not used during installation, it is permissible to install the panels even in rooms with temperatures below zero.

- No debris during installation. When cutting, the sheets do not crumble or crack, as happens with plasterboard; as a result, there will be a minimum amount of waste during operation.

- Good performance characteristics. Unlike traditional flooring materials such as chipboard or fiberboard, after installation there is no likelihood of squeaks due to displacement and friction of the boards. With constant temperature fluctuations, the sheets do not change shape.

- Ability to withstand mechanical shocks. Even with a pinpoint impact, most likely, just dents will appear, but not cracks.

- High fire resistance. GVL belongs to the group of materials G-1, which according to the classification means low-flammability. In case of fire, the sheets retain their original shape for a long time, and when heated they do not emit harmful substances.

- Safety for others. The composition contains components of natural origin, so laying the slabs is allowed in premises of any purpose.

GVL sheets are suitable for use in both heated and unheated rooms.

The disadvantages of using gypsum fiber sheets for flooring include the following:

- Rough handling or improper cutting can break or damage the slab;

- the price of gypsum fiber sheets for flooring is higher than the cost of other rough coatings;

- many note that even moisture-resistant material is exposed to fungus and rot.