You need to know the dimensions of ondulin in order to calculate the required amount of material.

Ondulin - it is also called Euroslate. This modern type of roofing material is now increasingly used to cover roofs. Ondulin today is a serious competitor to asbestos-cement slate, metal and bitumen tiles, and corrugated sheets. To correctly carry out the calculation, it is important to know the size of the ondulin. I will tell you about it, as well as other characteristics of this material, in today’s article.

Before installing the coating, you will have to make an accurate calculation of the required amount of material. This way you will avoid many problems, for example, differences in the color of the cladding from different batches.

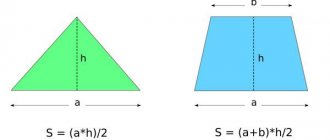

Technique for calculating material for a conventional roof

Let's return to the technique itself: ondulin - how to calculate. When calculating the roofing material, the following points must be taken into account:

- Sheet size. As we said above, the length of the sheet is 2 m, the width is 0.95 m. The standard issue is a ten-wave sheet;

- Size of laps. When arranging a roof with different angles of inclination, overlaps of different sizes are carried out. As a rule, they exceed 15cm. If the roof slope is 10 degrees, then the size of the overlap is 30 cm (along the continuous sheathing). If the angle of inclination exceeds 15 degrees, an overlap of 15 to 20 cm is made;

- Size of side overlaps. Again, depending on the slope of the slope during installation, the overlap can be 1 or 2 waves (an inclination angle of 10 degrees - 2 waves overlap, an inclination angle above 15 degrees - one wave overlap).

When purchasing ondulin, you should not forget that overlaps reduce the length and width of the sheet (usable area), so be sure to take the size of the overlap into account.

Thus, the net length will be 1.85 cm and the width 0.86 cm. This means that the usable area will decrease from 1.92 sq.m to 1.6 sq.m. As a result, when purchasing it is necessary to increase the number of sheets.

There are many programs for performing calculations. Basically, they are used in their work by professional builders.

Advice. Taking into account all dimensions, ondulin should be carried out - calculation with a supply of material (10-15% on a simple roof, 15-20% if there are many transitions and corners on the roof).

The history of Ondulin

To understand the characteristics of the material, you need to start with the history of this roofing product.

It is generally accepted that Ondulin is a new product on the roofing market, but this is not at all the case. The history of this French brand began back in 1944, when Gastome Gromier opened a factory near Paris. Less than 20 years later, the company began to expand into other European markets, first in countries such as Italy and Germany, and then spread to other parts of Europe.

And only in 1994 Ondulin appeared on Russian territory. Almost 15 years later, in 2008, a modern production facility with a colossal capacity of 7,500,0000 sheets per year was built in Nizhny Novgorod, today this figure is even higher. Since this year, the active development of the brand and material of the same name - Ondulin - has begun in our country. It has become more accessible, deliveries are carried out faster, and a wide dealer network throughout Russia allows you to buy material in almost any corner of our homeland.

Today Ondulin is the largest manufacturer of roofing materials based on bitumen-cellulose, which occupies 75% of the world market. Geographically, Ondulin is represented in more than a hundred countries and is extremely popular both in the construction of new roofs and in the restoration of old ones.

Ondulin prices per sheet, sizes, photo samples

Plastering walls made of aerated concrete, internal and external finishing of the facade of a house made of aerated concrete blocks, how and how to plaster an aerated concrete block with your own hands, photo-video and price.

You can get acquainted with the product line and technical characteristics of Euro slate on the official website of Ondulin, as well as on the web pages of companies involved in it implementation. Knowing the price and dimensions of ondulin, as well as other parameters, you can most accurately calculate the amount of material required and get an idea of the cost of ondulin to cover the entire roof.

Related article:

Technical indicators and dimensions of ondulin sheets for roofs

An ordinary sheet of ondulin for a roof, the size of which is 2 x 0.96 m, weighs a little more than 6 kg. Thanks to such light weight, the sheets are convenient to lift onto the roof and install without assistants. If the installation is done correctly, the roof covering will withstand severe (170 km/h) gusts of wind. The material is not afraid of temperature fluctuations, withstanding from -50 °C to +110 °C.

The fact that ondulin becomes brittle in frost completely compensates for its ability to restore its properties when heated. The structure of the material remains unchanged even after 25 times of freezing and thawing. The stated warranty of the ondulin manufacturer is 15 years (if special nails were used during installation). However, experience shows that the service life of the material reaches 45-50 years.

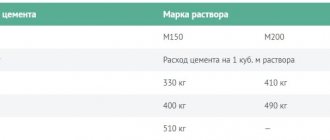

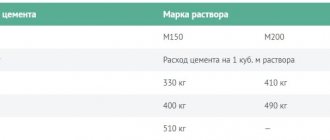

The strength characteristics of ondulin are quite sufficient not to deform under the weight of possible snow loads. It can withstand Euro slate and the weight of one or two people. The nominal load per 1 m² of coating is 960 kg/cm, the strength is 1800 kPa. Depending on the country of origin, some ondulin indicators may vary, as evidenced by the data in the table:

| Roofing material parameters | Manufacturer country | |||

| France | Poland | Belgium | USA | |

| Length, m | 2 | 2 | 2 | 2 |

| Width, m | 0,95 | 0,95 | 0,92 | 1,22 |

| Total area of ondulin sheet, m² | 1,9 | 1,9 | 1,84 | 2,44 |

| Useful area of ondulin sheet, m² | 1,6 | 1,6 | 1,54 | 2,11 |

| Sheet thickness, mm | 3 | 3 | 2,4 | 3,5 |

| Number of waves, pcs | 10 | 10 | 10 | 12 |

| Wave width, mm | 95 | 95 | 92 | 100 |

| Wave height, mm | 36 | 36 | 32 | 35 |

| Ondulin sheet weight, kg | 6 | 6 | 5,6 | 8,6 |

| Guarantee period | 15 | 15 | 10 | 15 |

| Colors, quantity | 5 | 5 | 6 | 12 |

Prices per sheet of ondulin SMART

Ondulin Smart replaced traditional ondulin. This product offers the possibility of convenient and quick installation due to special guides, with the help of which the sheets are fixed as evenly as possible. Each sheet of such material has an installation marking along which nails are driven in. The fastening scheme provides the same number of holes as the number of nails that need to be hammered onto the ondulin sheet, namely 20 pieces.

The total area of the Smart ondulin sheet is less important compared to traditional sheets. Parameters 1.95 x 0.95 m - new dimensions of the ondulin sheet. The usable area is not reduced due to the technology of laying these sheets, which involves installing them with an overlap of 5 cm less than when installing classic ondulin. Reducing this value also affects the weight of the roof. Knowing how much a sheet of Ondulin Smart weighs, you can calculate how much the total weight of the coating will decrease.

| Colors | Product name/price, rub. | |||||||

| Ondulin 1.95x0.96 m | Ondulin skate (size 1x0.36 m) | Endova (length 2 m) | Tong (length 1 m) | Nails for ondulin | ||||

| sheet | 1m² | PC | m.p. | PC | m.p. | PC | 100 pieces | |

| Green | 460 | 245 | 298 | 298 | 298 | 149 | 298 | 138 |

| Red | 440 | 235 | 288 | 288 | 288 | 144 | 288 | 138 |

| Brown | 440 | 235 | 288 | 288 | 288 | 144 | 288 | 138 |

| Slate | 370 | 198 | 288 | 288 | 288 | 144 | 288 | 138 |

In addition to the price, size and other characteristics of the product, you can see the possible colors of ondulin in the catalogs: the photos will help you with this.

Ondulin: price per sheet, sizes. How much does ondulin tile cost?

Another product presented in the catalogs are sheets of ondulin tiles. Photos of material samples demonstrate the presence of dark transverse stripes in the color, thanks to which the sheet imitates tiles. Covering the roof with such ondulin (the photo confirms this) makes its appearance almost indistinguishable from the appearance of a metal tile roof.

The qualitative composition and all characteristics of Ondulin Tile are similar to Smart products. The sheet contains 7 waves; 18 nails are used for fastening. The price of ondulin tiles per sheet is identical to the Smart version. Sheet size - 1.95 x 0.96 m with a thickness of 3 mm. The manufacturer provides a 100% guarantee against leaks for 15 years.

All additional elements and related accessories for roofing made of this material are offered in the appropriate colors. The prices of soft slate ondulin are shown in the table:

| Material color | Price of ondulin tiles per sheet, rub. | Price of ondulin tiles per 1 m², rub. |

| Green | 460 | 245 |

| Red | 440 | 235 |

| Brown | 440 | 235 |

With the affordable price of ondulin tiles, the appearance of a roof made of this material gives the impression of being expensive. And the reason for this is the interesting color scheme.

Standard size of corrugated sheeting for a fence according to GOST

Standard dimensions of corrugated sheets for fences can be found in GOST 24045-94 “Bent steel sheet profiles with trapezoidal corrugations for construction.”

From the figure below it is clear that the standard strictly regulates all the main dimensions of corrugated sheeting for a fence; its price depends on the grade of steel, the thickness of the corrugated sheet for the fence and what its protective and decorative coating is made of. Corrugated sheeting for a fence - dimensions and characteristics of profiles C10 and C18

| Brand of corrugated sheet | Main characteristics | Profiled sheet for fence, weight 1 m length, kg | Corrugated sheeting for fence, weight 1 m², kg | Workpiece width, mm | |||

| B | B1 | t | n | ||||

| S10-899-0.6 | 918 | 899 | 0,6 | 9 | 5,1 | 5,7 | 1000 |

| S10-899-0.7 | 0,7 | 5,9 | 6,6 | ||||

| S10-1000-0.6 | 1022 | 1000 | 0,6 | 10 | 5,6 | 5,6 | 1100 |

| S10-1000-0.7 | 0,7 | 6,5 | 6,5 | ||||

| S18-1000-0.6 | 1023 | 1000 | 0,6 | 10 | 6,4 | 6,4 | 1250 |

| S18-1000-0.7 | 0,7 | 7,4 | 7,4 |

As can be seen from the table above, the standard specifies all the main dimensions of the profiled sheet

It is necessary to pay attention to the fact that the width of the corrugated sheeting for the fence is given in two columns. These are two different quantities. One of them is called the working, or useful width of the profiled sheet for a fence, and the other is simply the width of the sheet

One of them is called the working, or useful width of the profiled sheet for a fence, and the other is simply the width of the sheet.

The difference between them is the overlap required when attaching the corrugated sheet. Therefore, the working width of the corrugated sheet is less than the width of the sheet precisely by the amount of overlap. At the same time, as can also be seen from the table, in all symbols of corrugated sheets the usable width is indicated.

The width of the profiled sheet may not correspond to the standard. Many manufacturers produce profiled metal sheets according to departmental technical specifications (TU), so the width of the corrugated sheet for a fence can be from 800 to 1850 mm.

A wider sheet allows you to significantly increase the span of a corrugated fence, significantly reducing the cost of installing support posts and minimizing the number of joints and fastenings. This is convenient, but it also creates difficulties in transporting and delivering such sheets to the construction site.

The standard also regulates the thickness of corrugated sheeting for the fence. In general, a metal profiled sheet can be made of metal with a thickness of 0.35 to 1.2 mm.

The thickness of the profiled sheet for a fence is 0.35 or 0.40 mm and belongs to the lowest price segment. However, we should not forget that the main function of the fence is to protect the site from entry by strangers. Therefore, when choosing what thickness of corrugated fence to install on their site, most developers prefer a standard metal profile of 0.6-0.7 mm. Such a profile is more difficult to damage and cannot be bent perpendicular to the stiffeners without special tools.

The standard also sets the length of corrugated sheeting for the fence. More precisely, not the length of the sheet itself, but its multiplicity. Since corrugated sheeting is made from rolled steel, the length of its sheets can be almost any. But the standard stipulates that wall corrugated sheeting must be made in measured lengths from 2.4 to 6.0 m, with a multiplicity of 300 mm.

This length of corrugated sheet for a fence allows you to build a fence of the height you need without intermediate fastening. This increases the strength of the fence and also seriously increases its service life.

It is worth noting that not all standard sizes regulated by GOST are equally common. This is especially true for sheet length. Many companies prefer not to purchase long profiled sheets due to difficulties in transporting them.

Therefore, be prepared that if you need a 6-meter profiled sheet for a fence, due to its similar size, its price per square meter may be higher than that of similar sheets of shorter length. In addition, it is difficult to purchase sheets of this length in stores - most likely, you will have to contact the manufacturer directly.

Read on topic:

Fastening corrugated sheets to the fence

How to properly attach corrugated sheeting to a fence? What screws should I use? How often? How much overlap should there be? The answers to all these questions are in the article.

Foundation for a fence made of corrugated sheets

Types of foundation for a fence made of corrugated sheets. How to make a columnar, strip and columnar-strip foundation for a fence from corrugated sheets in numbers and diagrams.

Prices for a fence made of corrugated sheets

Types of foundation for a fence made of corrugated sheets. How to make a columnar, strip and columnar-strip foundation for a fence from corrugated sheets in numbers and diagrams.

Sheet sizes

Kiln brick size

Currently, three variants of ondulin sheet roofing are supplied to the Russian market. They differ in:

- appearance;

- design features;

- usable area.

For example, Smart tiles have special locking systems. At the same time, DIY has fewer waves than a standard sheet. And the Compact version has a small area compared to other products.

The useful area is the area of the roofing material without taking into account overlaps, both end and side. Knowing this value allows you to most accurately calculate the amount of ondulin for your particular roof.

It is only worth noting that the usable area of the same material may differ, depending on the slope angle of the roof slopes. The larger it is, the smaller the overlaps need to be made.

On steep roofs, ondulin is placed on top of the previous sheet by 1 wave, while on flat roofs - by 2. This approach is needed in order to protect the house from leaks to the maximum, because water drains quickly from a sharp roof, and from those whose slope angle minimal - very slow.

This rule does not apply only to Smart tiles. It is equipped with a special lock that ensures tightness in any case. The size of the sheet mentioned above is 1.95 meters by 96 centimeters. The area, respectively, is 1.56 square meters (1.9 by 0.864 m).

Ondulin DIY has dimensions of 2 by 0.76 meters. The usable area varies depending on the steepness and slope. So, if the angle is more than 15 degrees, then:

- longitudinal overlap – 1 wave;

- transverse – 170 mm;

- usable area – 1.22 sq. m.

More than 10 degrees and not less than 15:

- 1 wave;

- transverse overlap – 200 mm;

- area – 1.2 square meters.

The slope is gentle from 5 degrees to 10:

- two waves;

- 300 mm;

- 0.97 m.

For standard ondulin, the size of which is 760 × 1950, the calculation of the usable area is carried out in the same order.

Ondulin Compact has a length of 1 meter and a width of 76 cm. Its usable area is:

- 27 or more degrees of slope - only 57 cm2;

- from 17 to 27 – 53;

- 10-17 – 50;

- 5-10 – 40 cm.

It is also necessary to mention that the height of the ondulin wave is 3.6 centimeters. There are 10 bends in a standard sheet, each with a step of 9.5 centimeters.

For those who do not want to bother with calculations, it is possible to calculate the exact amount of ondulin on the official website. There is a special calculator that will also indicate the number of all necessary additional elements:

- valleys;

- nails;

- skates;

- filling seals;

- waterproofing tapes, etc.

About the benefits of ondulin

- Let's start with the already mentioned water resistance of this material. As mentioned above, ondulin sheets are impregnated with a special composition, which provides 100% protection from moisture and does not allow it to penetrate deep into the material. We also note that the nails in the ondulin are driven into the highest point of the wave, so rain cannot wet the roof in this place. Its droplets will simply flow down, as if from a slide. Moreover, the ondulin sheets are laid overlapping, which adds tightness to the coating.

- Ondulin is highly environmentally safe and hygienic.

- This roofing coating is not afraid of either alkalis or acids, or products made from petroleum (for example, gasoline). And industrial gases cannot spoil it. Manufacturers claim that microorganisms and fungi also do not live in ondulin, but this is not entirely true.

- Another advantage of this coating is its light weight. A standard sheet of ondulin, two meters long and almost a meter wide, weighs nothing - 6.5 kg. That is, it is 4 times lighter than a slate sheet of approximately the same area. Therefore, it is not difficult to transport ondulin, and lifting it onto the roof will not be difficult. Moreover, you can do this alone, without waiting for your partner.

- The installation itself can be done quickly - after all, the layout of ondulin sheets is not at all complicated. And the rafter system for them does not need a particularly strong one.

- You can cut ondulin into pieces of the desired size with a simple hacksaw. And if you lubricate it a little with oil, then you can do it in no time.

- By bending the material, you can give it any shape. Therefore, you can cover the most fancy roof with it.

- It is also worth noting the low price of the material - approximately $5 per sheet. It is cheaper than metal tiles. We will not compare thin (0.35-0.45 millimeters) metal coatings - they are very fragile. Slate is a third cheaper than ondulin, but let’s not forget about the harmful asbestos it contains.

- The advantages of ondulin include its noiselessness. Indeed, in the case of a metal coating, there is no way to do without sound insulation. Otherwise, you will hear not only the annoyingly loud patter of rain, but even the stomping of birds on the roof.

Installation instructions

What kind of pillows can a child choose, filler and size?

If you have figured out how to calculate ondulin, then focus your attention on some aspects of its installation. The installation of ondulin is carried out in the same way as the installation of conventional slate:

- Install the roof sheathing, taking into account the slope of the slope and the direction of the wind. It is recommended to start work from the leeward side. The sheathing bars are located at the same distance. With a roof slope of 20 degrees, the distance between the bars is 600-800mm. If the distance increases, additional slats are installed;

- The first row of ondulin is laid from the lower right corner. For the second row, you need to make a longitudinal cut on the sheet and start laying from half the sheet;

- The foxes are fastened horizontally with special nails (20 pieces per sheet). The first row of fastening is placed in each wave. Subsequent fastening is at every second wave crest. When installing the second row, an overlap of the required size is made on the first row;

- In the vertical direction, the sheets are attached to the bar. The longitudinal overlap must be at least 1 wave, and the transverse overlap must be at least 15 cm;

- The installation of ridge elements completes the work of laying ondulin. They are mounted overlapping and fastened along the crest of the sheet. On gable roofs, corner ridge elements are used;

- To equip the valley with ondulin, it is necessary to install additional sheathing.

For high-quality roof installation with ondulin, additional roofing accessories are produced for this material:

- ridge elements;

- nails;

- valley;

- ventilation tube;

- cornice filler;

- tong element;

- self-adhesive sealing tape.

Calculating ondulin and installing it is not difficult. But, if you have doubts about the correct understanding of working with this material, then seek help from experienced roofers.

Production technology

Ondulin is made from cellulose fibers - a safe and inexpensive raw material. Unlike ordinary slate, it does not contain asbestos fibers, which are harmful to human health.

During production, raw materials are cleaned of impurities and mixed with water and chemicals. The finished substance, called pulp, is driven through a special conveyor with a press to remove moisture. Paint mixed with water-repellent resin is applied to the resulting canvas. This substance improves the waterproofing of the product.

The fabric is then given a wavy shape, after which it is sent to the drying chamber. Here, at a temperature of 270 degrees, it dries completely. Sheets are cut using a guillotine.

At the last stage, they are impregnated with molten bitumen, giving the product absolute waterproofness. This action does not spoil its appearance at all, as you can see if you look at the photo of ondulin sheets.

Technical characteristics of ondulin

Ondulin first appeared on the construction market in the first half of the 20th century. This material is a more advanced and convenient analogue of slate.

Ondulin is made from high-quality components that give it many advantages. Let's talk about the main characteristics of such a material as ondulin.

Ondulin sheet dimensions

Ondulin is manufactured and sold in the form of sheets, the thickness of which is approximately 3 mm, and the width and length parameters are 95 * 200 cm. The sheet has a corrugated surface, the height of the waves is 36 mm.

During installation, ondulin sheets are overlapped, so the useful area of the material is reduced to 1.6 m. This fact should be taken into account when performing calculations aimed at calculating the amount of material required.

Each sheet of ondulin is created by pressing cellulose fiber and then coating the finished sheets with a bitumen composition. The last layer of ondulin sheets is applied to mineral components and hardening resins.

Their technical characteristics will depend on the correctness of the technology for creating ondulin:

- Protective qualities;

- Length of service life;

- Attractive appearance.

Most manufacturers of ondulin sheets adhere to standard parameters, and the permissible dimensional error ranges from 2 to 5 mm. The area of one ondulin sheet is approximately 1.92 sq.m.

When calculating the amount of material required to cover the roof, it is necessary to take into account the useful area of ondulin and the number of overlaps and overlaps.

Ondulin sheet weight

Ondulin is made from lightweight materials, which ensures its light weight. One sheet weighs about 6 kg. The basis of ondulin is the following components:

- Cellulose fibers;

- Refined bitumen;

- Resin polymer impregnation;

- Natural pigments made on the basis of harmless mineral components;

- Mineral filler.

The cellulose base of ondulin sheets is impregnated with polymer and bitumen compounds under high pressure, thanks to which the finished product has a large margin of safety.

The addition of various mineral dyes allows you to obtain different shades of ondulin sheets.

The low weight of ondulin greatly facilitates its installation. To lay the sheets, there is no need to involve additional expensive construction equipment, and, therefore, no additional money will be required.

In addition, transportation of ondulin sheets to the construction site is also carried out without problems.

Ondulin service life

The popularity of such roofing material as ondulin is increasing every year. There are several reasons for this. This material has excellent technical characteristics, is easy to install, and versatile.

In addition, ondulin has a very long service life. Manufacturers who have been producing ondulin for a long time provide buyers with guarantees on the material for up to 15 years. In fact, the service life of ondulin is much longer.

If the sheets were laid correctly and the roof is used in accordance with the recommendations, then the ondulin coating can serve the owners of the house for 20 or even 30 years without repair.

The service life of ondulin is determined by the high resistance of the material to temperature changes

This is especially important in the off-season, when the ambient temperature changes quite often and sharply

Ondulin is not susceptible to severe frosts or scorching sun rays. Under the influence of such unfavorable factors, the material does not crack or melt.

Another important advantage of ondulin is its ability to withstand heavy loads. However, there is one caveat here

The material will be able to withstand the load created, for example, by a large amount of snow, only with the correct arrangement of the sheathing (it is this element that is responsible for the correct distribution of loads).

Alternative roofing coverings

An alternative to an ondulin roof can be a roof made of galvanized iron, corrugated sheets, galvanized iron, roofing felt, tiles and the most important material of today - metal tiles.

A roof covered with galvanized iron looks neat and can protect against moisture and precipitation for many years.

Snow does not stay on a galvanized roof, so you can use thinner rafters for a galvanized roof and save money.

- Classic roofing felt is a star among roofing materials. It is easy to transport, inexpensive at all, easy to stack - it is in deserved demand. Now improved roofing felt of more modern brands has appeared, it has become even more popular. It is mechanically resistant to impacts, durable, has high elasticity - it is not for nothing that they cover the roofs of residential buildings, at least many Soviet-built houses are covered with roofing felt.

- Corrugated sheeting (corrugated sheet) is a high-quality modern material, pressed from rolled steel. Very strong, lightweight, easy to install, environmentally resistant and durable.

- Metal tiles are the king of the roof. Metal with tiles combines the advantages of both, eliminating their disadvantages. It looks better than just metal, and the properties are better than tiles. Provides ease of installation and durability, it is very popular among builders. Why is there a place for other materials like ondulin? The issue is the price.

- The tiles can be made from baked clay (ceramic tiles), thermoplastic composite, a solution of sand and cement (cement-sand tiles) or lime and sand with heat treatment (silicate tiles). The most famous clay tiles are made from plastic clays with a low melting point (sometimes a material such as fireclay is added to it). Classic tiles are fragile and heavy. The roof underneath should have a steep slope to allow water to flow down. Modern models can also be installed on flat roofs (10°).

- There is also slate, but, of course, they are no longer considering it seriously. And in European countries it is prohibited for use due to asbestos. Although our sheds can still be covered with it. The manufacturer is also important here - now they manage to make it unevenly.

Ondulin sheet weight

Ondulin is made from lightweight materials, which ensures its light weight. One sheet weighs about 6 kg. The basis of ondulin is the following components:

- Cellulose fibers;

- Refined bitumen;

- Resin polymer impregnation;

- Natural pigments made on the basis of harmless mineral components;

- Mineral filler.

The cellulose base of ondulin sheets is impregnated with polymer and bitumen compounds under high pressure, thanks to which the finished product has a large margin of safety.

The addition of various mineral dyes allows you to obtain different shades of ondulin sheets.

In addition, transportation of ondulin sheets to the construction site is also carried out without problems.

Advantages and disadvantages

Before revealing the advantages and disadvantages of ondulin as a roofing material, it is worthwhile to more clearly outline the range of its application - these are temporary roofing coverings. Precisely temporary, since a 15-year warranty on the coating is nothing more than a guarantee against leaks of the material itself, and a sufficiently long time to find a more durable and reliable coating for the building.

The positive qualities of the material, of course, include:

- The material is environmentally friendly , because it does not contain asbestos, which makes ondulin more attractive compared to ordinary slate.

- Lightness of the material and, accordingly, savings on the roofing structure.

- Ease and simplicity of installation.

- Relative cheapness of the material.

- Availability of all necessary accessories and additional elements to facilitate the installation of the roof.

But such a long list of positive qualities and advantages of the material is largely offset by the fact that ondulin, due to the presence of natural fibers and bitumen impregnation, is, unfortunately, quite a flammable material; this disadvantage is largely reduced by covering the sheets with special mineral compounds, but this is not solves his main problem.

Features of the material

The provided guarantee for water resistance is 15 years, durability reaches 25-50. This roofing covering is attached to boards or old flooring using nails with special cast heads; at least 10 pieces are needed per 1 m2. The pitch of the sheathing depends on the angle of inclination of the roof, with its range within 5-10 ° it is continuous, 10-15 - no more than 45 cm, over 15 - 61 cm. The sheet is laid with an offset of 1 wave at a minimum, the presence of a Smart Lock strip along the edges prevents moisture from penetrating inside.

The relationship between the slope of the slope and the usable area of the ondulin is shown in the table:

| Brand Onduline | Standard dimensions, mm | Useful area/recommended overlap values at tilt angle, ° | ||

| 5-10 | 10-15 | >15 | ||

| Onduline Smart | 1950×960 | 1,39 | 1,56 | |

| Number of waves at the side junction | 2 | 1 | ||

| Amount of end overlap, cm | 12 | |||

| Onduline DiY | 2000×750 | 0,97 | 1,2 | 1,22 |

| Number of waves at the side junction | 2 | 1 | ||

| Amount of end overlap, cm | 30 | 20 | 17 |

The given values are taken into account when calculating the material; the measurement results of the slopes are divided by the useful, and not by the standard area of one sheet. As the roof slope decreases, the size of the end overlaps of conventional brands (without a lock at the edges) increases in order to protect against leakage and wind; for Onduline Smart it remains unchanged. In areas with high snow loads, it is recommended to make the sheathing continuous (or reduce its pitch), but the main requirements are put forward to the rafter structures rather than to the covering itself.

Thermal stability is improved artificially by introducing special additives. But ondulin is susceptible to softening in hot weather and becomes brittle in cold weather. In practice, this means a ban on moving through it during periods of peak temperatures; it tolerates the changes themselves without consequences. Taking into account the cellulose and bitumen base, it has a low fire safety class and ignites when heated to 230-300 °C. With increased requirements for fire resistance, use is permitted only if there are special cuts on the roofs that divide the coating into separate zones.

The scope of use includes simple pitched and complex roofs, including hip, mansard, multi-gable and round; the material can be easily processed and cut with a regular hacksaw. The characteristics of bitumen slate allow it to be used on structures with a bending radius of 5 m; if necessary, it can easily take a curved shape. Due to the low requirements for the condition of the sheathing, it is used both in the construction of new roofs and in the reconstruction of old ones.

This coverage cannot be classified as budget; the minimum cost, taking into account transportation costs, is 400 rubles. It is recommended to purchase Ondulin when:

- Arrangement of residential attics. With a small thickness, cellulose-bitumen sheets perfectly absorb noise, clearly outperforming noisy metal tiles or steel roofs.

- Independent delivery and installation of materials on your own. Ondulin weighs no more than 3 kg/m2, thanks to its convenient dimensions it can be unloaded and lifted onto the roof without any problems. The range offered by the manufacturer includes all the necessary accessories: nails with cast heads, aprons, pliers, valleys, seals, ventilation elements; a special program helps to calculate the required quantity.

- Low load-bearing capacity of rafter structures.

- Reconstruction without dismantling the old coating.

Cost of roofing corrugated sheets

| Variety | Suggested Colors | Dimensions, mm | Thickness, mm | Weight, kg | Number of waves | Price for 1 piece, rubles |

| Tile Ondulin | Red, green, brown | 1950×960 | 3 | 5,9 | 7 | 470 |

| Smart | Red, green, brown, black | 6,3 | 10 | 390 | ||

| DiY (narrow) | Red, green, brown | 2000×750 | 5 | 8 | 340 |

The correct sheets are marked, including the name of the material, the company code, the batch number and the date of its production, the same applies to all additional elements: valleys or skates; in order to save money, it is better to buy them at the same time as the coating. The only manufacturer producing Onduline in the Russian Federation is a plant in Nizhny Novgorod; in addition, it is supplied from France; indicating any other Russian cities as official manufacturers is a sign of a fake. Correct products do not have deviations in size or weight above the permissible norm; characteristic features also include a matte and rough surface and coloring by weight throughout the entire thickness of the sections.

Who produces: brief information about the manufacturers

You may be surprised, but there are only 9 specialized enterprises in the world that produce Euro slate, which in all respects falls into the “ondulin” category. The vast majority of these factories are located in Europe and this fact alone is a kind of guarantee of high quality. Historically, Russian people have become accustomed to trusting foreign manufacturers.

On the other hand, not everything is so simple, because the technological line for the production of ondulin is also available in Russia, or more precisely, in Nizhny Novgorod. As it turned out, the domestic manufacturer produces the material no worse and at a more attractive price.

Characteristics and production process

Ondulin is a French product that has been produced for over 70 years. The composition includes only components that are safe for health, environmentally friendly, this distinguishes it from asbestos-cement slate, of which it is considered an analogue. It is made from purified cellulose impregnated with petroleum bitumen and ether resins, natural pigments, and modifiers. Ondulin production occurs in several stages:

- First, the cellulose is cleaned of debris and impurities, and then water with a coloring pigment and modifiers is added to it. The resulting wet substance is called pulp.

- The pulp enters a special conveyor, where it is extruded into a layer 3 mm thick, and then, during the drying process, hardens, acquiring a wavy surface.

- Then the cellulose base of ondulin, the area of which is 1.9 m2, is treated with petroleum bitumen on both sides.

- The finished material is stacked in packs, packed in shrink film, and then a label with information about the material is attached.

Ondulin leaf

Ondulin laying diagram

Choosing a roof: ondulin, flexible tiles or metal tiles?

Each of these materials has its pros and cons. Many people prefer metal tiles, as they are considered stronger. Indeed, during a hailstorm, euro slate can be damaged, while galvanized metal will remain intact. But chips appear on its surface throughout the roof, which will soon begin to rust. It is easier to replace a damaged sheet of ondulin.

Flexible tiles are a stronger material, but their price is much higher than Euro slate, and installation is more difficult.

It’s easy to buy ondulin in Minsk using the TAM.BY catalog, and after studying the special offers, you can make a purchase with pleasant savings.

Technical characteristics of ondulin

- Service life: if you rely on manufacturer warranties, a bitumen roof should last 15 years without problems. In fact, this period can increase to 50 years, subject to compliance with operating rules.

- Fire resistance: Euro slate is a flammable material. Ignition temperature is 250 - 300 degrees. This parameter somewhat limits the scope of ondulin. For example, when constructing public buildings (schools, preschool institutions and clubs, etc.), it will be necessary to either abandon this material or provide fire barriers to localize fires and protect the remaining structures of the building from fire

- Overall dimensions of the ondulin sheet: length - 2000 mm; width - 960 mm; material thickness - 3 mm; wave height - 36 mm; wave pitch - 95 mm

- The weight of one sheet of bituminous shingles is only 6.5 kilograms: it is not the last among lightweight roofing materials

- The useful area of a sheet of bitumen shingles ranges from 1.29 to 1.56 square meters in accordance with the slope of the roof slope

Technical characteristics of ondulin

Physical properties of ondulin

Strength: this parameter for ondulin is: not less than 1800 kPa according to the NFQ 03-054 standard; not less than 170 kPa/m according to the OFIC standard.

- Heat resistance: without load, ondulin retains its shape when heated to 110°C

- Noise insulation: this figure, according to DIN 52210, reaches 40 dB. The soundproofing properties of ondulin are its absolute advantage compared to metal tiles

- Thermal conductivity: this indicator for ondulin is low. According to DIN 52612 it is only 0.19 - 0.2 Kcal/mh°C

- Frost resistance: ondulin is a frost-resistant roofing material. During testing (cyclic freezing/thawing in water to a temperature of -25 degrees), no damage or changes in the geometric parameters of the sheet were detected

- Environmental safety: Ondulin does not pose a threat to human health and cannot harm the environment. Rainwater flowing from the roof can be used for drinking by animals and watering plants. The smell that bitumen impregnation emits in hot weather is somewhat alarming - but it’s just a smell, it’s not harmful

- Color fastness: high-quality ondulin retains its original color for a long time. Its rapid fading in the sun is evidence of a violation of the European slate manufacturing technology.

Of course, with such characteristics, ondulin is a good roofing material. However, we should not forget that the modern market is not limited to it; there are metal tiles, corrugated sheets and others. What is better: ondulin or metal tiles? It all depends on what is more important to you. If fire safety is a concern, then you should definitely choose metal tiles.

Also, after reading this article, you can find out which is better: ondulin or corrugated sheeting? The detailed technical characteristics of each material will help you make the right choice.

Color range and price

Ondulin, unlike metal tiles, cannot boast of bright colors. Its color range is not rich, the sheets are painted in discreet shades of red, green, brown and black. However, you can see many cottages where the color and texture of the facades are in perfect harmony with the color of the ondulin roof.

Although price does not relate to the operational or technical characteristics of ondulin, this factor is one of the decisive ones when choosing a roofing covering. Ondulin with the appropriate technical characteristics has a price from 320 to 430 rubles per sheet, which may also vary depending on the color you choose.

Video about the production of ondulin and its technical characteristics

The technology for the production of ondulin has already been mentioned above. You can find out how this happens at the factory by watching the video.

In this video, ondulin is tested, thereby confirming its main properties.

Pros and cons of ondulin roofing

Advantages:

- Ease. The weight of one sheet of ondulin and its overall dimensions allow it to be used for transportation in a passenger car. Bituminous slate is easy to carry, install, and if you decide to make the roof yourself, one assistant is enough.

- Manufacturability. The lightness of the products and ease of fastening significantly speed up the installation process.

- Economical. Cheaper than other roofing materials. The small size of the ondulin sheet reduces the waste area when cutting.

- Availability. You can use a hand or circular saw to cut the sheets, and a hammer to fasten the sheets.

- Flexibility. Bitumen slate is used for roofs of non-standard shapes (spherical and arched).

- Chemical resistance. Onduline does not corrode and does not interact with gases.

- Biological resistance. Euroslate is not afraid of microorganisms and fungi.

- Durability. Ondulin roofing can last up to 50 years.

- Noise absorption. The ondulin roof is quiet. The sound of rain will not disturb your peace.

- Environmental friendliness. The roofing material, manufactured in accordance with the requirements of the standards, does not harm human health (which cannot be said about asbestos cement, which is banned in many countries).

- Multifunctionality. Bituminous slate is used in the construction of new and reconstruction of existing facilities. There is no need to dismantle the old sheet or roll material and spend money on temporary protection of a residential building from precipitation during repair work.

- Completeness. Along with the sheets, you can buy related products (ridge, valley, ventilation pipe, nails) in the color of the roof.

Flaws:

- The scarcity of shapes, textures and colors. You can choose from only 4-5 matte finish colors. In comparison with the same different-textured (gloss, matte) and multi-shaped (“Monterrey”, “Maxi”, “Cascade”, etc.) metal tiles, ondulin definitely loses.

- Flammability.

- Discoloration.

- Roughness. Over time, such a roof can become dirty from dust particles raised by the wind.

- Snow retention. The surface of the sheet traps snow on the roof.

Ondulin roofing price

The price of ondulin per sheet is only part of the cost of installing a roof. Before starting work, we recommend ordering a cost estimate for a turnkey ondulin roof from roofing specialists.

Roof costs include:

- lumber costs. The cross-section, pitch, length (over 6 meters is always more expensive) of rafters and sheathing, complexity of the rafter structure, volume and delivery distance all play a role.

- costs for roofing materials. Price for Ondulin sheets, membrane, insulation, roof components with delivery to the construction site.

- prices for roofing work. The cost of installing a new roof or repairing an existing roof is a different amount of work. In order not to throw money away, be sure to enter into a contract for construction services with a team of roofers and request a price list with prices.

On the websites of ondulin roof sellers, the cost of roofing covering per square meter, or the price of ondulin per sheet, is indicated. And when determining the amount of costs, you need to be guided by the cost per 1 m2. A table with prices for roofing materials will allow you to compare prices for ondulin, metal tiles, flexible and ceramic tiles.

Table 1 - Price for roofing materials in construction stores*

| Type of coverage | Price per 1 m2 of usable area |

| Ondulin | From 60 thousand Bel. rub. |

| Metal tiles | From 80-100 thousand Bel. rub. |

| Flexible tiles | From 60 thousand Bel. rub. |

| Ceramic tiles | From 100-150 thousand Bel. rub. |

*Average prices for roofing materials based on information from Belarusian websites of construction stores and roofing shopping centers at the time of writing.

The current price of ondulin per sheet is here.

Ondulin roofing is a durable, high-quality, economical option without unnecessary antlers. Ondulin bitumen roofing sheets for roofing are chosen by practical owners of private property.

Nuances of installing Euro slate

When laying the covering, the sheets are mounted overlapping: the length of this section is 30 cm, and the width corresponds to two waves. The technology for fixing sheets may vary depending on the slope of the roof. If the slope is less than 10°, a solid base of plywood slabs is made under the ondulin. If the slope is up to 15°, then timber is used for the sheathing in increments of 45-50 cm. For a slope of more than 15°, you can make a gap between the sheathing elements of 55-60 cm.

The process of covering a roof with ondulin: installation of a roof hatch

The sequence of fastening the sheets is as follows:

- The cornice strip is installed.

- The initial row is fixed strictly along the eaves overhang.

- Installation of the first sheet is done on the side opposite to the one from which the wind most often blows. The sheet is attached flush with the gable overhang and 5-6 cm of the sheet is left behind the cornice.

- To fix one sheet, nails are used, driving them first in the corners, then fixing the bottom of the sheet, and then grabbing the sheet in the center and on top.

- The second and subsequent sheets are laid overlapping the previous ones and so on until the end of the row. The next row begins with a sheet cut in half so that the joint of the sheets of the second row falls in the middle of the sheet of the first row. All even rows are performed in this way.

To install one sheet of ondulin on the roof, you need from 15 to 20 special nails

When covering a roof with ondulin, you should pay attention to the following points:

- If during installation a situation arises in which it is necessary to step on the laid material, try to place your foot on the highest point of the wave, and not in the groove. In this case, it is desirable that the shoes have soft soles;

- It is recommended to carry out installation work at temperatures from -5 °C to +25 °C;

- the first sheet is laid on the side opposite to the one from which the wind most often blows;

- Sheets of material must be fastened with branded nails. The instructions call for using 20 nails per sheet. The wide heads of such nails contribute to strong fixation, making the coating wind-resistant. It is with this fastening technology that the manufacturer provides a guarantee for the durability and excellent performance of the coating;

- During installation, you should not strain the material too much, taking advantage of the fact that ondulin is plastic. The sheets must be placed as evenly as possible both vertically and horizontally.

The process of covering a roof with ondulin can be handled without any special construction skills.

Ondulin sheets are used both for covering new roofs of cottages, country houses, outbuildings, and for reconstructing worn-out roofs. Moreover, during repair work, ondulin can be attached directly on top of the old coating. The plasticity of Euroslate allows you to fill any surface (even with a large radius of curvature). Ease of processing, the possibility of rational cutting, a virtually waste-free process and an affordable price make ondulin one of the most popular roofing materials.

How to cut ondulin

NOTE!

It is strictly not recommended to use an electric jigsaw for cutting ondulin due to the fact that its teeth are too small and they will become clogged with cellulose .

During the installation process, ondulin often has to be cut, sometimes into small pieces, in order to lay the material around the chimney pipe or other difficult areas of the roof. It is often necessary to cut off the excess if the overlap is excessive.

Cutting a sheet with a stationery knife

Remember: the ondulin is cut from the “facade”, that is, the front side, the top of which is laid towards the sky. And they also cut not along the wave, but along the depression between the waves.

How to cut ondulin? The cutting technique is as follows:

- An incision is made . That is, cutting begins with making a cut from the front side. Then the sheet is folded, turned over, and it is cut further.

- How to cut ondulin? stationery knife is perfect for these purposes . It allows for smooth cutting without leaving “crumbled” edges, everything will be clear and even.

- This is if cutting along the sheet is meant. If it is across, then there is nothing better than a classic hacksaw for wood. But there are certain features here. This cutting also occurs on the front side. But you need to make high-quality markings first in order to cut exactly along the line.

- If you need to cut a lot of sheets, you can use a “circular saw,” that is, a circular saw. A circular saw gives a smooth, regular cut.

- As for cutting with a grinder, you can use it, but be careful. It is necessary to ensure that the edges of the cut do not melt, since when cutting with a grinder at high speeds, due to friction, the temperature of the material at the place of the cut from the circle increases.

CAREFULLY!

If during operation the teeth of the circular saw become clogged with cellulose fibers, then to clean it you will need to make at least one cut in wood . You should not cut ondulin in the sun. It is necessary to do this in the shade, and best of all - in a room where it is cool.

Specifications

Ondulin

- Ondulin is a wavy sheet with a wave height of 34 mm.

- Wave pitch – 95 mm.

- The standard sheet size is 2x0.96 meters (or 1.92 square meters).

- The thickness of the material is 3 mm.

- One sheet weighs 6.4 kg (that is, the weight of 1 square meter is 3.3 kg).

Metal tiles

The geometric dimensions of metal tiles, depending on the manufacturer, differ slightly from each other.

- The thickness of metal tiles, taking into account polymer coatings, is on average 0.55 mm.

- Wave height – up to 50 mm (low wave) and over 50 mm (high wave).

- Sheet width – 1100 mm.

- Sheet length is from 0.7 to 8 m (the most optimal size is 4.4 meters).

- The weight of one square meter is 4.5 kg.

Conclusion: metal tiles are heavier than ondulin, but they have an advantage in terms of the area of a standard sheet: the larger the sheet, the simpler the roofing process.

Raw materials for production

Ondulin

For the production of ondulin, glass fiber is used, pre-impregnated with bitumen mixed with curable resins and paint. Quite quickly, under the influence of sunlight, the paint fades and becomes dull.

Metal tiles

For the production of metal tiles, thin-sheet steel, hot-dip galvanized, is used. A thin layer of polymer protective coating is applied to its surface. In addition to its protective functions, the polymer is responsible for the color scheme of metal tiles. The color of the material remains practically unchanged for a long time: the influence of sunlight on it is negligible.

Conclusion: metal tiles are more durable than ondulin. In addition, from an aesthetic point of view it has a clear advantage.

Lathing

Ondulin is laid only on a solid sheathing; metal tiles feel great on sparse sheathing.

Conclusion: lathing for ondulin will cost more.

What is more expensive and what is cheaper - metal tiles or ondulin?

Ondulin

A square meter of ondulin costs about 13 thousand rubles. Taking into account additional elements, the cost of one square meter of ondulin roofing is approximately 18 thousand rubles.

A square meter of metal tiles will cost 23 thousand rubles. Together with additional elements, a square meter of roofing costs about 34 thousand rubles.

Conclusion: metal roofing costs almost twice as much as ondulin roofing.

Fire safety

Bitumen sheet, unlike metal, is easily flammable and contributes to the further spread of fire.

Material consumption comparison

Ondulin

Due to the fact that the length of the ondulin sheet does not exceed two meters, for every 100 square meters of roof area, an additional 30 square meters of material will be needed for overlaps. But ondulin has a significant advantage: it does not contribute to the formation of condensation. Therefore, the installation of a waterproofing layer under it is not required.

Metal tiles

The length of the sheet can be chosen so that the number of overlaps is minimal. You can even order an overall size equal to the length of the slope. But metal tiles have two drawbacks: they are too noisy, and condensation forms on their inner surface. Therefore, there is a need to arrange hydro- and sound insulation of the roof.

And finally, the main trump card: durability. Without a doubt, a material based on metal will last much longer.

Does ondulin have any disadvantages?

But what about without them - nothing ideal exists. However, some of the shortcomings appear due to improper installation, excessive savings or trivial laziness. So, let's start listing the disadvantages of ondulin.

1. Durability. Some reviews complain about its low strength. They say that you cannot step on the roof without the risk of breaking it, and such a roof cannot withstand heavy snowfall. But often the reason lies in improper installation of the rafter system and violation of the material installation technology. After all, to fasten one sheet you need at least 20 nails, and some save them, reducing the number by almost 2 times. But if the required sheathing pitch is observed - 0.6 meters with a slope of more than 15 degrees - ondulin can easily withstand almost a ton of load per square meter. Therefore, snowfalls are certainly not scary for him.

An example of deformation of an ondulin roof due to a violation of the sheathing installation technology.

Another example of a violation of the rafter system installation technology.

This photo clearly shows that an insufficient number of nails were used when installing the Ondulin sheets.

In the summer heat, you should not walk on a softened ondulin coating - it may not withstand the weight of steps. In addition, in extreme heat, the unpleasant smell of bitumen fumes can be clearly heard.

2. Fire hazard. Another disadvantage is the fire hazard. Well, yes, ondulin is essentially organic, and that’s why it burns. But what to compare with - with expensive metal tiles of the best varieties? And a cheap “tin” roofing covering is not a hindrance to fire - it will burn out instantly.

Video. Flammability of ondulin

3. Durability. For some, the ondulin coating is destroyed in a couple of years. But there are also homeowners who cannot get enough of such a roof for 15-20 years. Firstly, it depends on the operating conditions. If they are extreme, and only the best metal tiles can withstand them, then ondulin will soon collapse. Secondly, you should not skimp on installation and quality of fasteners, doing everything according to the rules.

4. Loss of color. Over time, an ondulin roof loses its color, fading in the sun and becoming dull. If this happened quickly, then it is likely that it was not real ondulin (which is painted before impregnation with bitumen) that was used, but its analogue. However, over time, this also happens to the original coating.

And this is an example of the fading of an ondulin roof and the protrusion of bitumen sheets onto the surface.

6. Biological stability. After 2-3 years, the roof surface begins to be attacked by mosses and various fungi. As a result, poorly lit areas turn green. The same drawback - flowering - is also inherent in slate.

Famous manufacturing companies

Ondulin is produced almost all over the world. The most popular companies whose products are in particular demand include the German brand Bituwell. Cardboard is added to Euroslate sheets, which significantly increases rigidity. The brand produces two versions of the material: matte and glossy.

The Nuline company is located in the USA and produces ondulin, the size of which is 2000x1230 mm. Glossy material is less susceptible to fading in the sun, as it has an additional colorful coating.

The Aqualine brand was founded in Belgium. During the manufacturing process, the surface of ondulin sheets is covered with a layer of acrylic, thanks to the high density of which the material does not fade from direct sunlight. No less popular are the products of the Turkish company Corrubit. The sheet size is 2000x930 mm with a thickness of 2.4 mm. The covered area is 1.57 square meters.

Technological features of ondulin production

Roofing was invented more than a century ago and today the principles of production have been preserved. In the manufacture of products, cellulose fiber is used, which goes through the processes of heating, pressing and corrugating at a temperature of +120 C. After this, the elements are coated with paint and impregnated with bitumen compounds with polymer additives.

We advise you to study - How to make a sandbox with a lid: drawings, photosIn essence, ondulin is a type of slate, but with higher practical and quality characteristics. The production process produces an environmentally friendly material with high levels of water resistance and strength. When exposed to sunlight, thin cellulose fibers are welded together, guaranteeing excellent waterproofing.

Features of laying ondulin roofing

As such, there is no difference between the installation of Euroslate sheets and roofing made from traditional asbestos-cement materials. Note that, due to the presence of a wavy surface, noise absorption is ensured, as well as good thermal insulation of the under-roof space for many decades.

To attach the covering to the rafter system, it is enough to arm yourself with a drill and the required number of nails; self-tapping screws can also be used. The procedure is standard: drill holes and screw in screws.

Remember that nails or screws must have special seals to prevent water from penetrating under the coating layer.

The cost of ondulin is slightly higher than its cheap analogues, however, the end result is a roofing covering with a presentable appearance and excellent quality characteristics.

Sparse lathing: precisely calculated step

For roofs with a slope of 10 degrees or more, it is allowed to install sparse sheathing specifically under the ondulin. We will try to cover all the technical aspects of this process.

Let's start with the fact that in order for the step to be perfectly accurate, make a wooden template and apply it from block to block:

Make the same template as in the illustration, or just a flat piece of timber that will be convenient to place between the sheathing boards.

Second point. The eaves overhang itself is provided with a fillet - a special board that is nailed to the lower end of the rafter. And on gable roofs, using the overhang of the laths and the length of the filly, you can increase or decrease the size of the entire roof slope.

In this way, a minimum number of ondulin scraps is achieved. That's why make the slats and fillets a little longer, and then saw off all the excess:

Let's tell you one more secret: when laying sparse lathing, carefully ensure that there are not many knots on it. Because when the nail gets into such a place, then you have to tinker. After all, the wood at the knot has a completely different density.

In this case, some craftsmen act simpler: they fold a stack of sheets, simultaneously make a thin hole in all of them, and then hammer nails into the roof at precisely located points, as if using a stencil.

This has its advantages: you can insert a nail into the hole and immediately feel for a piece of sheathing there, and then punch it.

The next important requirement: the sheathing itself must be level. Of course, ondulin is one of the few materials that perfectly hides all the unevenness of the roof

But this does not mean that you can not worry about this and prepare the foundation somehow. Any such errors in the plane geometry always result in future deformation of the roofing sheets.

But checking the evenness of the mounted sheathing is quite easy - using a stretched thread. If unevenness is found in any place, then make special pads from plywood. For this, take pieces about 4 and 8 mm thick and stuff them in the right places. Very comfortably!

How much does one sheet of soft roofing weigh?

If a mandatory standard is observed with the standard size, then the actual weight of the ondulin sheet may vary depending on the manufacturing company. It is worth clarifying that weight discrepancies are not a defect. Here we can highlight the following mass indicators:

| Name | Unit | Sheet type | Magnitude |

| Weight | kg | SMART | 6,3 |

| COMPACT | 3 | ||

| DIY | 6 | ||

| Weight 1m2 | kg/m2 | SMART | 3,36 |

| COMPACT | 3,95 | ||

| DIY | 4 |

When making calculations, you need to take into account that to securely fix the ondulin to the sheathing, at least 20 fasteners , which adds approximately 200 grams . With a large roof area, these values, which are insignificant at first glance, can significantly increase the load on the supporting structures.