At the very beginning, you need to find out how much primer solution and paint you need to use to paint the battery. This can be found out by calculating the area of the heating radiator. Next, look at the recommendations indicated on the paint can. They always indicate how much paint can be used per 1 square meter. m . It is impossible to measure the battery area yourself. This does not need to be done, because manufacturers indicate the heating surface area of the section. Since every square centimeter of the section is heated, this area and the area of the entire surface of the section. One edge of the MS-140-500 battery has an area of 0.244 square meters. m. A modification of this model with an interaxal distance of 300 mm has sections with an area of 0.208 sq. m.

To determine the total surface area of a cast iron battery, you must:

- Find out the model name of the installed battery and preferably the manufacturer (this is because sections produced by manufacturers of the same models have different depths and widths).

- Set the heating area of 1 rib.

- Multiply the number of sections by the area. If the MS-140-500 radiator has 10 fins, then the surface area will be 2.44 square meters. m.

Having made the calculation, they determine the amount of composition and primer, buy them and paint. Paint should be taken with reserve, because everyone applies a layer with a different thickness.

Procedure for calculating area

A problem such as the poor appearance of old cast iron appliances can be easily solved by painting their surface. First of all, you need to figure out how much primer mixture and paint you should buy.

This can be found out by determining the painted area of cast iron radiators. Then they study the recommendations that are on the jar with the coloring composition. They always contain information regarding paint consumption per square meter.

It is impossible to independently find out the area of a section of a cast iron radiator for painting. This is not required, since heating equipment manufacturers provide this information in the instructions supplied with the products. More precisely, the documentation indicates the size of the heating area, and since every centimeter will be heated, this value is the size of its entire surface.

It is known that the edge area of the MS-140-500 product is 0.244 square meters. m, and the modified section of this device, having an interaxial distance of 300 millimeters, has an area of 0.208 square meters. m.

To calculate the entire surface of a cast iron radiator, you should:

- find out the name of the model and, if possible, its manufacturer, since the same modifications of devices manufactured at different enterprises have different parameters - width and depth;

- determine the heating area of the fin;

- multiply this value by the number of sections.

For example, in the MS-140-500 radiator there are 10 fins, then the surface area will be 2.44 square meters. m. After this, they determine how much and what kind of building materials will be needed. When calculating paint consumption for heating radiators, it is necessary to take into account that it must be purchased with a reserve, since each layer of the paint composition will have a different thickness.

Coating process

Initially, it turned out that domestic heating radiators look a little rough and old-fashioned, but if you properly treat the surface and choose an interesting design, the devices will please the eye for a long time. The following instructions will help you carry out the work without professional help.

General provisions

First, preliminary recommendations should be considered to ensure a high-quality coating application, after which one should proceed to study the sequence of actions.

As for tools, you will need a simple painting kit for the work.

Painting: a – use a brush, b – use a special spray can.

- As the main equipment, it is recommended to use a small smooth roller made of foam rubber and a brush necessary for treating hard-to-reach places. If necessary, the battery can be removed to provide access to certain areas.

- The paint coating is applied only to a cold device, otherwise problems with peeling off the dried composition cannot be avoided. Therefore, it is advisable to carry out such activities when the heating season is not in progress. However, you can always close the valves, stopping the flow of hot water.

- To determine the approximate painting area of cast iron radiators, you need to multiply the length by the width and multiply by two, then add ten percent to the result. The final number will be the approximate square footage of the cast iron panel.

- It is best to apply paint to fixed batteries from above, this way you will be able to avoid accidental smudges. Experts recommend not limiting yourself to one layer, because in two passes it is easier to provide high-quality surface protection.

Removing a cast iron heating radiator for painting.

Attention! Heating of heating radiators is permitted only after the paintwork has completely dried, otherwise streaks, stains or small bubbles may appear.

Procedure

When the area to paint the cast iron radiator section has been determined and the necessary materials have been purchased, you can begin the main work, which cannot be classified as complex work. It is enough to adhere to a certain sequence of actions, and also be able to use a brush and roller.

When removing a heating device, you can use a spray gun.

This is how the treatment is carried out using a spray gun.

- The first stage usually involves cleaning the surface of the deteriorated coating using chemical solvents or a wire brush. In the first case, the dried layer is washed off with a special mixture, and in the other, mechanical removal is performed, in which a drill can be used.

- After successfully removing the old paint, the battery surface is subjected to a degreasing process, which removes organic contaminants from the device. An ordinary solvent can be used as the main agent.

- Next, the heating device is treated with a primer, which ensures high-quality adhesion. That is, the adhesion of paint to the surface becomes much better. This composition is applied using traditional painting tools.

- Using a foam roller, the main planes of the sections are first processed, after which hard-to-reach areas are passed with a brush. If a spray gun is used during the work, then the listed equipment is not required. After the first layer has dried, the next one is applied.

Note! When using mechanized equipment, the coating is applied to a higher quality, but the price of such devices is usually quite high, so many craftsmen use a brush and roller in the process.

Preparatory activities

They involve cleaning the battery surface from old paint and dirt:

- Wipe off the dust thoroughly with a damp cloth so that no dirt remains in the recesses. To clean hard-to-reach areas, place a rag between the ribs and move it back and forth.

- Remove the layer of old paint. When using a chemical method, Dufa, SP-6, B52, ACE products are used, but they are not able to cope with oil compositions that were produced in the mid-20th century. The physical method requires the use of a drill with a metal brush attached. You can also use a file and sandpaper.

- Apply a layer of primer mixture. It must not only withstand elevated temperatures, but also match the type of paint, it’s good if they are the same brand.

Remove from wooden surface

The main feature of working with wood is that it is a soft material that is easily damaged if treated carelessly.

Having decided to remove the old paint layer from furniture or another wooden surface, first of all you need to understand whether this is necessary

If the old coating is applied in a thin layer and does not have serious damage, you can simply apply a protective primer on it and start painting. Attention! If the coating is in poor condition, it must be removed. This must also be done if it differs in composition from the new paint and is incompatible with it.

If these rules are not followed, both layers may eventually be destroyed.

Old one from the floor

Methods for removing old paint from a floor vary depending on what material it is made of and whether the coating has had time to dry.

So, the most effective way to remove dried paint from linoleum is to cut it off with a sharp knife. If the layer is too thin, use a wire brush or scraper. In this case, you need to act carefully so as not to damage the floor. To make the paint come off easier, cover the stain with a cloth soaked in acetone and leave for 10 minutes.

There are two methods used to clean porcelain stoneware:

- Mechanical;

- Chemical.

The first involves scraping off the paint using a knife, spatula or other tools by hand.

In this case, do not use sandpaper, metal brushes or other abrasives that can scratch the material.

In the second case, chemicals are used that are designed to remove such compounds.

Today there are special cleaners for porcelain tiles on sale that allow you to remove traces of a wide variety of stains.

This is interesting: How long can you store various foods in the refrigerator?

If you need to get rid of old paint on laminate flooring, use White Spirit, solvent or another product with a similar effect. However, keep in mind that they can also have an aggressive effect on the laminate itself, leaving marks on it. Therefore, they should not soak contaminants.

Also, when removing paint, do not use wire brushes or scourers to avoid damaging the finish. Also, laminate does not tolerate moisture. It can only be wiped with a damp cloth, but under no circumstances should it be filled with large amounts of water.

With doors and window frames

Before painting doors and windows, the surface must be properly prepared, otherwise the time spent on the work may be wasted.

Don’t forget, proper pre-treatment prevents the development of mold and mildew, ensuring a longer product life.

One of its mandatory stages is removing the old paint, especially if it has long been cracked and began to peel off.

Information. To remove long-applied coating, in most cases a regular spatula is sufficient. They can remove the largest pieces. When final cleaning the surface from small particles of paint, it is convenient to use a dish net or sandpaper.

However, sometimes it is quite difficult to remove old paint using this method. Heat treatment of the coating helps simplify the task.

It is best to use a heat gun for this, since it is the safest and, moreover, has various attachments that make the work process more convenient.

After removing the old paint, do not forget to treat the surface with special anti-fungal compounds and let it dry. Then you can start applying a new layer.

Acrylic

You can also remove acrylic paint from the lining mechanically. Use a spatula, wire brush or special scraper. To complete the surface treatment, you can use sandpaper or a grinding machine, or pumice.

Alcohol or acetone are also suitable for this purpose. Apply it to the cloth and rub the surface until any remaining paint particles are removed. Then treat the lining again with a damp cloth and let the material dry.

If necessary, the procedure can be repeated after 24 hours. If the paint does not come off well, preheat it with a hair dryer.

Battery painting

You can cover the radiator painting area with any coloring composition, the main thing is that it is resistant to high temperatures. The work is done using a curved or regular brush. First, gloves are put on your hands, and a rag or gauze is placed nearby to erase traces of paint on the handle of the brush.

Sequence of the dyeing process:

- Renew the look of hard-to-reach places between pipe sections using a flexible brush.

- If the paint has not touched the cast iron, use gauze folded into a rope. It is laid between the sections, a coloring composition is applied to the middle and the ends are pulled in turn.

- Paint the top and easily accessible places.

- You should move from top to bottom, applying paint in several layers.

Taking into account the characteristics of the room

The technical characteristics of different types of radiators are not the same. Heating specialists recommend using cast iron radiators in private homes; bimetallic or aluminum products are more suitable for apartments.

Calculation of the size of sections takes into account not only the square footage, but also the probable heat losses occurring through windows, doors, walls, ceilings and floors, as well as through ventilation ducts. For each type of unproductive heat consumption, its own coefficients are applied, denoted by the letter Q.

The following parameters must be included in the calculation of heat losses:

- The difference in temperature between outside and inside a room, denoted as DT.

- The area of doors and windows and other similar structures is S.

- The thickness of the partitions or walls is V.

- The value of thermal conductivity of walls, depending on the nature of the material and the insulating materials used - Y.

The ratio for calculation looks like this:

Q = S x DT / R layer,

where R = V : Y.

All calculated coefficients must be summed up, and in the presence of ventilation shafts, the resulting indicator increases by up to 40%.

Depending on the location of the rooms in space, additional coefficients are introduced for verticals facing north, northeast and northwest. It is 10%, and for those facing southeast and southwest – 5%. For the south direction the correction does not apply. For a corner room with two walls facing outside, the additional coefficient is taken equal to 5%.

If the height of the wall is more than 4 meters, an additional factor of 2% is introduced. A reduction in heat loss parameters can be obtained by insulating the ceiling on the attic side and the roofing pie.

Painting area of cast iron radiators: how to calculate paint consumption

Heating radiators that have served for a long period require revision. If repairs have been made, then it is quite possible that the appearance of the structure needs to be slightly refreshed, that is, painted. To do this, you need to know the paint area of cast iron radiators. High-quality heat-resistant paint is not cheap, so by calculating its consumption, it is easier to save on repairs.

A restored and repainted cast iron radiator looks no worse than new

Additional features

In country houses and apartments located on the upper floors of multi-storey buildings, a circulation pump NTs 32/4 (power 72 W) is usually installed. Such a device will guarantee warmth and comfort even in the severe frosts of central Russia.

The correctly calculated amount of power of a cast iron radiator and the number of sections ensures normal air temperature and comfortable living conditions in residential or industrial premises of any type. Therefore, calculations must be made very carefully, taking into account the various features of the room and other amendments.

Why do paint cost estimates for radiators vary?

Not everyone wants to get rid of old cast iron batteries after upgrading their apartment. They are practical and reliable, and if the heating system is cleaned and rusty pipes are replaced, old radiators after painting will last at least another decade.

Advice! You should not cover yellowed, crumbling or cracked layers of paint with a new coating. This should be done only after removing old layers of paint and exposing the metal with a primer.

Calculations for paint consumption are complicated by the variety of models of heating devices, differing in many respects:

- mass (weight);

- aesthetics (design);

- format (dimensions of the section and the entire battery);

- power (heat transfer);

- volume of coolant (water);

- connection method (side, bottom, diagonal), etc.

Improved battery designs may require more paint than regular batteries

New models are also being produced that imitate old cast iron accordions. They exactly imitate the general structure of classic heating equipment. They have an improved design with artistic casting or designer soldering and comfortable legs at the bottom - for floor placement. They require a little more paint and primer, materials need to be taken in reserve.

What color is better to paint and why?

The color of the battery does not affect the quality of heat transfer into the room, and therefore sticking to the traditional white color for a radiator is unnecessary.

What color to paint a cast-iron radiator depends on the overall color scheme of the room or kitchen. For a nursery, it can be multi-colored, bright and even funny colors; in the living room, the color of the radiator can be matched to the color of the upholstered furniture or, conversely, this element can be highlighted in contrast to the overall tone of the wallpaper and flooring.

You can endlessly figure out how to beautifully paint a radiator, how to turn an ordinary object into a bright, designer piece. For ancient cast-iron sectional batteries, a picture in the form of an accordion suggests itself, and for modern bimetallic and aluminum radiators it is fashionable to use ombre painting technology, when the dominant color is smoothly laid out horizontally into halftones.

When planning a design for a battery, you should consider how noticeable this element will be in the overall picture of the room. If the radiator is constantly hidden by curtains or furniture, there is no need to waste effort and invite expensive specialists to draw an original picture; in this case, a single-color coating in the general style of the room is sufficient.

How to independently calculate the coverage area and paint consumption

There are various ways to calculate the painting area of cast iron radiators, but there is no use in “reinventing the wheel”.

Attention! Manufacturers of thermal equipment reflect this information in the technical description for the model. This value is usually indicated as “heating area”; other options and translations are possible if these are imported models.

When calculating the paint area of a cast iron radiator MS-140 as a classic model, we take into account the area of one section or “accordion fin”. It is approximately equal to 0.244 m2. A more modern or modified section with a slightly larger center distance (300 mm) has a painting area of about 0.208 m2.

The radiator can be painted in any color that matches the overall interior

Models of cast iron batteries can vary greatly, so for calculations we take the heating area of one section from the documentation (product data sheet). Next, we multiply by the total area of all ribs with a small margin (adapters, taps, couplings, legs). For example, in the standard MS-140-500 there are 10 ribs, multiply by 10 the section area of 0.244 sq.m. We get 2.44 m2. Round up to 3 m2 - for all adjacent parts. Next we decide how many layers of painting there will be.

Innovative methods for determining the painting area of cast iron radiators - special computer programs and calculators. The following parameters are entered:

- radiator marking (according to technical documentation).

- number of sections, their length and height.

Only with proper pre-cleaning of the battery will the paint lie perfectly evenly

In the output we have the actual painting area. After receiving the information, a “reset” is entered to clear the window and enter new data.

Calculations depending on the type of heating devices

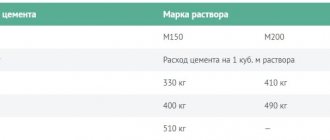

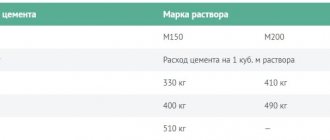

When choosing a model, keep in mind that the thermal power depends on the material from which they are made. The methods for calculating the sizes of sectional batteries are the same, but the results will be different. There are statistical averages. It is worth focusing on them when choosing the optimal number of heating devices. Power of heating devices with sections of 50 cm:

- aluminum batteries - 190 W;

- bimetallic - 185 W;

- cast iron heating devices - 145 W;

Table for calculating the number of battery sections

In order to correctly calculate heating radiators based on the area of the room, it is important to know not only the power, but also how many squares one section heats; the value of this parameter depends on the metal:

- aluminum - 1.9-2 square meters;

- aluminum and steel - 1.8 sq. m.;

- cast iron - 1.4-1.5 sq. m;

Here is an example of calculating the number of sections of aluminum heating radiators. Let's assume that the size of the room is 16 square meters. It turns out that for a room of this size you need 16m2/2m2 = 8 pcs. Use the same principle for cast iron or bimetallic appliances

It is only important to know exactly the norm - the above parameters are correct for models with a height of 0.5 meters

Types of heating radiators

At the moment, models are produced from 20 to 60 cm. Accordingly, the area that the section can heat will differ. The lowest-power models are curb ones, 20 cm high. If you decide to purchase a heating unit of non-standard sizes, then you will have to make adjustments to the calculation formula. Look for the necessary data in the technical passport.

When making adjustments, it is worth considering that the size of the batteries directly affects the heat transfer. Consequently, the smaller the height with the same width, the smaller the area, and with it the power. For correct calculations, find the ratio of the heights of the selected model and the standard one, and use the data obtained to correct the result.

Calculate how hot the battery should be

Let's say you chose models with a height of 40 cm. In this case, the calculation of the number of sections of aluminum heating radiators per room area will look like this:

- Let's use the previous calculations: 16m2/2m2 = 8 pieces;

- calculate the coefficient 50cm/40cm = 1.25;

- correct the calculations using the basic formula - 8 pcs * 1.25 = 10 pcs.

Calculating the number of heating radiators by volume begins first of all with collecting the necessary information. What parameters need to be taken into account:

- Housing area.

- Ceiling height.

- Number and area of door and window openings.

- Temperature conditions outside the window during the heating season.

Heat loss

The norms and rules established for the power of heating outlets regulate the minimum permissible indicator per square meter. meter of apartment - 100 W. Calculation of heating radiators based on the volume of the room will be more accurate than one in which only the length and width are taken as a basis. The final results are adjusted depending on the individual characteristics of a particular room. This is done by multiplying by the adjustment factor.

When calculating the power of heating devices, the average ceiling height is taken - 3 m. For apartments with a ceiling of 2.5 meters, this coefficient will be 2.5m/3m = 0.83, for apartments with high ceilings 3.85 meters - 3.85m/3m = 1.28. Corner rooms will require additional adjustments. The final data is multiplied by 1.8.

Calculation of the number of heating radiator sections according to the volume of the room should be adjusted if the room has one large window or several windows at once (coefficient 1.8).

Heating radiators with bottom connection

The lower connection will also require some adjustments. For this case, the coefficient will be 1.1.

In areas with extreme weather conditions, where winter temperatures reach record lows, power must be doubled.

Plastic double-glazed windows, on the contrary, will require a downward adjustment, using a coefficient of 0.8 as a basis.

The above data shows average values, since they were not additionally taken into account:

- thickness and material of walls and ceilings;

- glazing area;

- flooring material;

- the presence or absence of insulation on the floor;

- curtains and curtains in window openings.

How to clean cast iron batteries before painting

High-quality painting requires:

- preliminary cleaning from dust, rust and dirt;

- removing all layers of old oil;

- coating with a metal primer, preferably heat-resistant;

- painting in 2 layers gives the highest quality and smoothest surface (one layer can be slightly diluted with a solvent to save composition).

Many actions can be easily carried out using available tools, including brushes for cleaning and washing. Old paint can be removed using different methods (can be done in a complex way):

- chemical;

- mechanical (special attachments for grinders and universal tools);

- thermal (hair dryer, blowtorch);

- manually.

Advice! Use a metal brush to clean the surface before applying primer to remove loose particles that may then stick to the brush or roller.

Old radiators after painting will last at least another decade

Not every paint is suitable for painting cast iron radiators. Only non-toxic heat-resistant enamels for interior use. They are sold in different forms - cans, jars, buckets. If you paint without a primer, you can degrease it with a solvent suitable for its chemical composition. Even if the enamel is “environmentally friendly”, when painting the area of a cast iron radiator MS-140 (another model) use:

- respirator,

- work gloves;

- work clothes and shoes.

It is recommended to ventilate the room at each stage of processing, especially after the paint has set a little. All calculation data are adjusted to suit any modern model or an old one. The area of the heated surface varies slightly for 1K60P-60x500 “Barelief”, Standard-90, RD-90s, 2K60P-300, B-Z-140×300, MR-2KP140 “Bekard”, etc. How to carry out calculations, by the number of sections , on a “calculator” or through a program, decide for yourself. There won't be any big differences.

Methods for assessing heat transfer

Before purchasing heating batteries, we will consider ways to calculate the number of their elements.

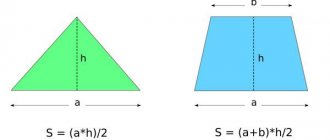

The first method is based on the area of the room. Construction standards (SNiP) state that for normal heating 1 sq. m. requires 100 W. thermal power. By measuring the length and width of the room, and multiplying these two values, we get the area of the room (S).

To calculate the total power (Q), we substitute our value into the formula, Q=S*100 W. The passport for heating radiators indicates the heat transfer of one element (q1). Thanks to this information, we will know the required number. To do this, divide Q by q1.

The second method is more accurate. It should also be used with a ceiling height of 3 meters or more. Its difference lies in measuring the volume of the room. The area of the room is already known, let's measure the height of the ceiling, then multiply these values. We substitute the resulting volume value (V) into the formula Q=V*41 W.

According to building codes, 1 cubic meter. m. should be heated by 41 W. thermal power. Now let's find the ratio of Q to q1, obtaining the total number of radiator nodes.

Let's sum up the interim results and bring out the data that will be needed for all types of calculations.

- Wall length;

- Wall width;

- Ceiling height;

- Power standards for heating a unit of area or volume of a room. They are given above;

- Minimum heat transfer of the radiator element. It must be indicated in the passport;

- Wall thickness;

- Number of window openings.

Area of cast iron radiator section for painting

How to convert radiator sections to kW

Bilta

: Dear Colleagues! I have long wanted to ask you about how many kW is 1 section of a cast iron radiator, I don’t have reference data, but I come across different numbers everywhere. And also in the technical part of the DBN there is an interesting wording regarding the calculation of the amount of work on painting radiators. If anyone knows how to calculate the paint area of cast iron radiators, please tell me.

Guest

: 1 section is 0.31-0.35 ecm, 1 ecm is 0.56 kW

Sergey

: I may not agree with the Guest, heat transfer depends on the material of the radiator, so I check it with the manufacturers (suppliers).

L.D.

: I have the following data: 1 section = 0.77 kW/0.35 eqm/0.297 m2

Sergey

: Sorry for the previous answer, I didn’t finish reading the question, one section of a cast iron radiator is rated at 120 W

Guest

: It was said that the radiators are cast iron.

Marisha

: I have data (MS-140 MC) 0.184 kW

Sergey

: Gentlemen, don’t bother yourself, call Bolshevik and find out, I just received information from them - 100-140 W.

Guest

: Read reference books! It's all said there. Regarding painting, the same reference books say that cast iron radiators MS140 AO - 0.3 m2, MS140 - 0.244 m2

L.D.

: I went online and searched: sectional cast iron radiators. I found the following data - cast iron heating radiators type MS-140M-500-0.9-4 - 0.64 kW; MS-140M-500-0.9-7 - 1.12 kW

LUDMILA

: I still have data from old reference books - 1 section -0.35 ecm-0.57 kW.

Inna

: And I kept counting - 0.23 kW, and the color is 0.244 sq.m.

Bilta

: I thank all participants, but as I see, we have not come to a consensus, so I will try to choose one of the options. I myself always counted 1 section - 0.177 kW

ECT

: Designer's Handbook. Internal sanitary installations. (edited by Candidate of Technical Sciences I.G. Staroverov). Part 1. Heating. Moscow, Stroyizdat, 1990. page 295: Cast iron sectional radiators (GOST 8690-75) MS-140-108 area - 0.244, nominal heat flow - 0.185 kW MS-140-98 area - 0.240, nominal heat flow - 0.174 kW

Alexander

: Always took 7 sections - 1 kW

Andru

: By the way, Staroverov is still popular among designers

Alexandra_K

: I always considered 1 section - 0.175 kW, coloring - 0.254 m2 (M-140)

Bdgenka

: My dad is a heating engineer, and he says 0.165KW

Heat transfer from bimetallic radiators: device design, methods and location of connection

This will depend on the type and quality of the material used in the manufacture of radiators. The main varieties include:

- made of cast iron;

- made of bimetal;

- made of aluminum;

- of steel.

Each of the materials has some disadvantages and a number of features, so to make a decision you will need to consider the main indicators in more detail.

Made from steel

They function perfectly in combination with an autonomous heating device, which is designed to heat a significant area. The choice of steel heating radiators is not considered an excellent option, since they are not able to withstand significant pressure. They are extremely resistant to corrosion, lightweight and heat transfer performance is quite satisfactory. Having an insignificant flow area, they rarely become clogged. But the working pressure is considered to be 7.5-8 kg/cm2, while the resistance to possible water hammer is only 13 kg/cm2. The heat transfer of the section is 150 W.

Steel

Made from bimetal

They do not have the disadvantages that are found in aluminum and cast iron products. The presence of a steel core is a characteristic feature, which made it possible to achieve colossal pressure resistance of 16 - 100 kg/cm2. The heat transfer of bimetallic radiators is 130 - 200 W, which is close to aluminum in terms of performance. They have a small cross-section, so over time there are no problems with contamination. Significant disadvantages include the prohibitively high cost of the products.

Bimetallic

Made from aluminum

Such devices have many advantages. They have excellent external characteristics and do not require special care. They are strong enough, which means you don’t have to worry about water hammer, as is the case with cast iron products. The working pressure is considered to be 12 – 16 kg/cm2, depending on the model used.

Features also include a flow area that is equal to or less than the diameter of the risers. This allows the coolant to circulate inside the device at tremendous speed, which makes it impossible for sediment to deposit on the surface of the material.

Most people mistakenly believe that too small a cross-section will inevitably lead to low heat transfer rates.

Aluminum

This opinion is erroneous, if only because the level of heat transfer from aluminum is much higher than, for example, that of cast iron. The cross section is compensated by the area of the fins. The heat output of aluminum radiators depends on various factors, including the model used, and can range from 137 to 210 W.

Contrary to the characteristics given above, it is not recommended to use this type of equipment in apartments, since the products are not able to withstand sudden temperature changes and pressure surges inside the system (during the run of all devices).

The material of an aluminum radiator deteriorates very quickly and cannot be subsequently restored, as is the case when using other materials.

Made from cast iron

The need for regular and very careful maintenance. A high rate of inertia is almost the main advantage of cast iron heating radiators. The level of heat transfer is also quite good. Such products do not heat up quickly, and they also give off heat for quite a long time. The heat output of one section of a cast iron radiator is equal to 80 - 160 W. But there are a lot of shortcomings here and the main ones are considered to be the following:

- Tangible weight of the structure.

- Almost complete lack of ability to resist water hammer (9 kg/cm2).

- There is a noticeable difference between the cross-section of the battery and the risers. This leads to slow circulation of the coolant and fairly rapid contamination.

Heat transfer from heating radiators in the table

Parameters of bimetallic radiators

The technical parameters of bimetallic radiators are determined by the specifics of their design - in a lightweight aluminum casing there is a rod made of anti-corrosion steel in contact with the coolant. This symbiosis of materials gives them anti-corrosion resistance, high heat transfer and low weight, which makes the installation process easier.

The disadvantages include high cost and low throughput.

Cast iron heating radiators MS-140

Cast iron radiators MS-140 made in Belarus have been known to domestic consumers for many years. Of course, now their design has changed and has acquired a completely modern look. The front surface is made flat, different colors are possible.

The technical parameters of MS-140 radiators are in no way inferior to the best European models: operating pressure - 9 atm, test pressure - 18 atm.

Cast iron radiators MC-140 are supplied in lengths from 4 to 10 sections and are equipped with two blind plugs with left-hand threads and two through plugs with 1/2-inch right-hand threads. The number of sections is selected based on at least 1000 W of radiator power per 10 sq.m. under standard conditions of heated area (1 window, 1 door and ceiling no higher than 3 m).

Cast iron radiators MS-140M-500-0.9

The type of cast iron radiator is sectional two-channel. Section length - 93 mm, height - 588 mm, depth -140 mm. The heating surface area of one section is 0.244 m2, the nominal heat flow is 0.160 kW. The capacity of one section is 1.45 l. The weight of one section is 7.1 kg (including nipples and plugs). Nipple hole thread - G 1 1/4". The material of the radiator section and plugs is gray cast iron SCh-10, the material of the nipples is malleable cast iron KCh30-6-F, steel 08 KP or 08 PS GOST 1050. =>> passport for MS-140M-500-0.9

MS-140 radiators are supplied in packages (a package contains 9 seven-section and 1 four-section cast iron radiator, stacked and tied with steel tape).

Cast iron radiators MS-140M-300-0.9

Designed for heating systems of residential public and industrial buildings with low window sill heights, coolant temperatures up to 130° C and operating excess pressure up to 0.9 MPa.

Radiator type: sectional two-channel. Section length - 93 mm, height - 388 mm, depth -140 mm. Nominal heat flow - 0.120 kW. The capacity of one section is 1.11 liters. The weight of one section is 5.7 kg (including nipples and plugs). Nipple hole thread - G 1 1/4". The material of the radiator section and plugs is gray cast iron SCh-10, the material of the nipples is malleable cast iron KCh30-6-F, steel 08 KP or 08 PS GOST 1050.

Radiators are supplied in packages (in a block package there are 16 seven-section and 2 four-section cast iron radiators stacked and tied with steel tape).

Design of cast iron radiators MS-140.

The cast iron radiator consists of sections made of high-quality cast iron, connected by nipples made of malleable cast iron.

Cast iron radiators are supplied coated with a primer or hot-drying epoxy polyester enamel.

A good example

Let's say there is a need to calculate the radiator power for a room whose area is 15 sq.m. and the ceiling height is 3 meters. Using simple calculations, we obtain the volume of air filling the room, which is heated by the heating system - 45 cubic meters. The next stage is calculating the required power. The previously obtained figure is multiplied by the power spent on heating a cubic meter of air in a particular region. For example, for the Caucasus and eastern countries this figure is 45 W, and for the northern regions - 60 W. For example, let's assume that the appropriate figure is 45 W. Thus, we obtain the power that the heating system expends to heat a room of 45 cubic meters - 2025 W.

Radiator selection

To select the optimal type of radiator, namely steel, there is a special table for calculating the power of steel radiators. Having the calculated power spent on heating the room and such a table, you only need to look at it to see what the width and height of the equipment should be, as well as its type. An example of such a table is given below.

For the current case, consider type 22, which is the most popular and has decent advantages. According to this table, the optimal battery dimensions are 600x1400, the power will be 2015 W.

What determines the heat transfer of heating radiators?

Typically, such tables are provided by equipment manufacturers or store salespeople. It will also be useful to consider the following nuances:

- It is necessary to find out the temperature of the coolant. The higher it is, the more the radiator will heat up, therefore, the level of heat transfer is also higher. This temperature should be compared with the characteristics of the product being purchased. Only if they coincide will the work be safe.

- Battery size matters. The larger its dimensions, the more time the coolant spends in it. That is, the more, the hotter.

- We take thermal conductivity into account. Steel heating radiators are made of sheet steel, the thickness of which is about 1.5 mm. Thanks to this, the heating system heats up quickly.

All these parameters affect power, so you should pay attention to them when choosing

Features of steel batteries

Panel radiators are made of two sheets of steel connected to each other. Inside these sheets there are 5 channels: 2 horizontal (top and bottom) and 3 vertical (every 10 cm of length)

The big disadvantage is the fact that these channels are too narrow, so it is important that there are no impurities in the coolant. Unfortunately, this cannot be achieved with a centralized system, therefore, when buying steel radiators, a special filter is usually purchased along the way

The power of steel radiators differs for different types, its average is 0.1-0.14 kW per section.

- 11 – single-section, has one convector, power is 1.1 kW.

- 22 – has two sections and two convectors, power is 1.9 kW.

- 33 is three-sectional and has three convectors. The power of such a radiator is 2.7 kW.

Consequences of incorrect battery selection

Firstly, overheating can be achieved. This means that the room becomes so hot that the window is opened and kept open constantly. This is unfavorable for the body, and is also fraught with exorbitant electricity bills.

Secondly, if the selection is made incorrectly and the battery power is below the required level, then even at the peak possible load in the room there will still always be a low temperature.

And thirdly, if the batteries are weak, then pressure changes will very soon render them unusable, which can cause an accident.

The calculation has been completed - what next?

Every person feels comfortable living in a warm place

And in order to provide this warmth, you will have to treat the heating system with maximum attention and responsibility. Manufacturers offer a lot of options for batteries, pipes, taps and boilers, all you have to do is choose the right one

And in order to do this, you need a little knowledge.

Calculation of the painting area of a cast iron radiator

Heating systems are available in every apartment. There are many types of heating devices. They are distinguished by weight, design, dimensions, heat dissipation and other properties.

Radiators made of cast iron are reliable and convenient. Houses commissioned during the Soviet Union were equipped with batteries that perfectly manage their own functions and heat the apartment space during the cold season. What sets today's heating systems apart from cast iron is that they are lighter and more interesting on the outside. But most people do not want to exchange their own old cast iron radiators for good and attractive today's heating devices.

Diagram of a heating radiator.

The advantages of cast iron radiators are high heat transfer, resistance to rust, and durability.

Once upon a time, batteries were painted with oil-based paints. Under the influence of constant high temperatures and significant changes, they burn out, deteriorate, and crumble; The batteries take on an unattractive, sloppy appearance. The question arises about their reconstruction.

So, you need to paint an old cast-iron radiator battery. What does that require? 1. Preparation work: removing dust and outdated paint using a chemical method. First of all, wipe off the dust using improvised means, you can use a brush for cleaning dishes, wet gauze folded into a rope. One end of it is threaded through the internal transverse plates of the heating devices; The 2 ends of the tourniquet are taken naturally with the left and right hands; The device is cleaned of dust by alternately pulling the gauze from the left hand to the right. Then you can remove layers of flaking, outdated paint and traces of corrosion. If the area of the old paintwork is small, the paint can be removed mechanically (by manual stripping).

For this you need:

- Sanding paper;

- File;

- Iron bristle brush.

You can also use:

- Bulgarian;

- A specialized attachment for a drill.

Cleaning cast iron batteries before painting is a mandatory process, because... Paint cannot hide the unevenness of heating devices.

The positive quality of the mechanical method is its versatility: it can be performed on functioning warm batteries, on cool ones connected and not connected to the heating system; We use it for any paint and varnish coatings (thermal spray enamels, oil paints, nitro paints, paints based on various resins, etc.)

If the surface area of the outdated paint is not small, it is possible to remove the entire layer using chemical means. They are solvents, acids and alkalis. For this method of removing outdated paint you will need:

- Gloves;

- Respirator;

- Specialized curved brush;

- cycle;

- Iron bristle brush;

- Putty knife.

Using a brush, the substance is applied to the paint to be removed. The application process is sometimes repeated a couple of times at intervals of 5-30 minutes. After some time, the coating, which is already outdated, completely dissolves or softens. It is removed with a spatula, brush, or scraper. The cleaned surface of cast iron radiators is washed with water and dried. It is much better to do such actions on a cold battery or on one that is not connected to the heating system. But for any individual case, you must follow the instructions for using the selected chemical. Precautionary measures include using chemicals away from open flame sources, in a well-ventilated area, using gloves and a respirator. 2. Thermal method of removing outdated paint , degreasing, calculating the area of the surface to be painted

, primer

Diagram of a repair hair dryer.

When selecting a thermal method, the battery should not be connected to the heating system; it should be disassembled. The method is suitable for removing strong layers that do not peel off. The surface of the heating device is heated. For this use:

- Soldering lamp;

- Construction hair dryer.

Heating is carried out until the paint begins to bubble. Afterwards it is cleaned with a spatula. If not all of the old paint is removed in this way, mechanical, chemical or combined methods are used. Precautionary measures include observing safety precautions when working with devices that create a jet of open flame, using:

After work, you should leave the room for a couple of hours and carefully ventilate it, because during work, toxic substances are released that have a detrimental effect on the body.

The cleaned battery is washed with water and dried. Then degrease with a simple solvent. Now she is ready for painting.

First of all, it will be primed. The primer is selected so that its properties best meet the requirements of the decorative paint used. To find out how much primer and paint is required, calculate the area of the plane to be painted

.

To do this, the area of one part is multiplied by the number of sections in the battery. To calculate the area of one part, you need to multiply the height of the part by the length. It is much better to use reference books or the technical data sheet of the device, which contains the values of such quantities. The MS-140M-500-0.9 brand device with a part length of 93 mm and a height of 588 mm is considered very popular. The area of one part is 0.24 m2. We multiply this quantity by the number of sections in the heating device and obtain the final quantity equal to the area of the painted surface

of the cast iron radiator. 3. Selection of decorative paint and painting of a cast iron radiator

Variations of brushes for painting: a, b – flute brushes; c – round brush; d – radiator brush; d – maklovitsa.

After the primer has dried, painting of cast iron radiators

.

Today, the industry recommends a large number of decorative paints for painting metal surfaces. These are anti-corrosion epoxy acrylic enamels, chemically resistant paints, resistant to high temperatures. If possible, choose paints that do not require special preparation of surfaces for painting. One of these paints is considered “Hammerite”; it can be used on warm, functioning batteries. Among its varieties there are those that form stylish patterns on the painted surface

, which creates a beautiful radiator design that matches the interior design of the room.

To paint the heating device you will need:

- Gloves;

- Curved or regular brush;

- Available means (gauze, rags or foam rubber mounted on a metal rod).

When working with brushes, the internal components of the battery may become poorly painted, sometimes leaving unpainted areas. The deficiency can be eliminated with a simple intervention. As described at the beginning of the publication, the gauze is folded into a tourniquet. It should be dipped in paint. Then follow the same steps as when removing dust. You can use foam rubber or rags attached to a rod. The working principle with this tool is similar to working with a brush; its advantage is that when painting the surface inside cast iron radiators

has greater maneuverability than the hand. The pyron can be bent if necessary, which provides greater maneuverability in hard-to-reach areas.

The painted battery is left to dry.

Today's paints for metal surfaces are great for cast iron radiators ; they create a beautiful radiator design.

Right choice

The quality characteristics will depend on the correctly selected material, but during the purchasing process one should not forget about the aesthetic component, because heating devices are usually in plain sight. You can make no mistake when purchasing if you know the basic operating conditions.

- The coating used must withstand temperatures above 90 degrees, otherwise peeling is possible.

- You should purchase only formulations that do not contain harmful impurities, since they will be used in the internal environment.

- The purchased products must be suitable for painting metal surfaces.

Having considered the above requirements, you can understand that only heat-resistant and environmentally friendly paint for cast iron heating radiators is suitable for processing.

Previously, oil paints were actively used, but their time has passed, and they have been replaced by more effective analogues.

An example of applying a pattern to radiator tubes.

- Alkyd enamels have a uniform structure and are able to withstand high temperatures. In addition, they are quite resistant to abrasion. However, a strong and unpleasant odor can persist for a long time.

- Water-dispersion compositions for special purposes are ideal for coating heating devices. During the work, no harmful substances are released, and drying occurs quite quickly.

- Acrylic enamels create a glossy shine on the surface, thereby improving the external characteristics of the coating. The disadvantage may be the unpleasant odor of organic solvents.

Addition! Fire-retardant paints for metal Polistil have proven themselves well when painting batteries, allowing the formation of a thermally resistant and fairly durable coating.

Color solution

The classic version involves covering the device with silver or white enamel, which does not provide the widest possibilities for design. Currently, shades are selected in accordance with the overall style of the home. Various designs and patterns are often applied to the surface of cast iron products.

Design with a smooth transition of colors.

- The performance of heating devices should be 10% of the area of the room if its ceiling height is less than 3 m.

- If it is higher, then 30% are added.

- For the end room you need to add another 30%.

After determining the heat losses, you need to determine the performance of the device (how many kW should be in a steel radiator or other devices).

- For example, you need to heat a room with an area of 15 m² and a ceiling height of 3 m.

- We find its volume: 15∙3=45 m³.

- The instructions say that to heat 1 m³ in the conditions of central Russia you need 41 W of thermal output.

- This means that we multiply the volume of the room by this figure: 45∙41=1845 W. The heating radiator must have this power.

Number of ribs

Next, you need to calculate the number of sections in the battery. The instructions for the products indicate the parameter of each edge.

From it you will find out how many kW are in one section of a bimetallic radiator and an aluminum analogue - this is 150-200 W. Let's take the maximum parameter and divide the total required power in our example by it: 2214_200=11.07. This means that to heat the room you need a battery of 11 sections.