Calculation method

First, you should take measurements of the roof and calculate the area of each slope, then add these values and get the total area. If the roof has a complex shape, for example a hip roof, formulas from geometry are used for calculation to find the area of the figures: two triangles and two trapezoids.

For example, we will use a traditional rectangular slope measuring 6 by 9 meters. Its area will be 6 x 9 = 54 square meters. meters.

Original Ondulin Smart sheets are available in only one size: length 1950 mm, width 950 mm, wave width 95 mm, thickness 3 mm. There are 10 waves on one sheet. Installation of ondulin is carried out with lateral and longitudinal overlap between adjacent sheets, which depends on the angle of inclination of the roof. We talked about this in more detail in the article about the installation of sheathing.

The outermost sheets on the slope extend outward, behind the wind board at one wave. The bottom row of ondulin, in the absence of a drip, is released outward by 5 - 7 cm.

Taking into account all overlaps, the effective area of the Ondulin sheet will be from 1.25 to 1.56 square meters. m. The effective area is the product of the width and length of the sheet minus any overlap allowances. It is based on this indicator that the number of sheets will be calculated.

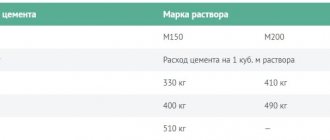

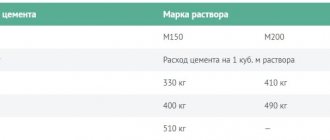

| Roof inclination angle, degrees | Effective sheet area, sq. m |

| from 15° and above | |

| 10 — 15° | |

| 5-10° |

For an example of roof calculation, we will assume that the slope of both slopes is 20 degrees (many roofs are made with exactly this angle). Accordingly, the effective area of the sheets will be 1.56 square meters. m. To get the exact number of sheets per slope, you should divide the measured area by the effective size:

Nl = Ssk / Sef where Ssk is the area of the slope; Seff is the effective sheet area taking into account the slope of the roof.

Then the exact quantity will be: Nl = 54 sq. m / 1.56 sq. m = 34.61 ≈ 35 sheets Total for covering one slope with an area of 54 sq. m will need 35 sheets of Ondulin + it is recommended to take a few pieces in reserve.

[my_custom_ad_shortcode1]

Roof sheathing

The choice of sheathing scheme depends on the angle of the roof:

- If the roof slope is 5-10 degrees, you will need a continuous sheathing , which can be made from plywood or boards.

- If the slope of the slope is 10-15 degrees , the sheathing is constructed from edged boards or timber with a section of 50x50 or 45x50 mm in increments of 0.45 m.

- If the slope exceeds 15 degrees , the distance between the sheathing parts should be 0.6 m.

To ensure that the arrangement of the sheathing parts corresponds to the technology, the step size is calculated based on the distance between the central axes of the bars. Read about how to attach ondulin to the sheathing here.

Calculation of additional elements

The useful length of the ridge part is 0.85 m. In our example, the length of the slope is 9 meters, you need to divide by 0.85 and round up, you get 11 elements. To decorate the pediment, we will calculate the required number of wind slats (tongs). To do this, the height of the slope is 6 meters, multiply by their number 2 and divide by the useful length of the part 0.95 m, we get 14 elements.

Ondulin is the most popular roofing material, consisting of bitumen, rubber, special fillers and cellulose fibers. Since the mid-90s, it has been widely used in private and suburban construction. Before purchasing material, calculation work must be carried out - this allows to reduce material consumption and excess coating. The calculator for calculating ondulin for the roof allows you to perform all calculation operations based on the parameters of the roof and material.

None In order to find out how many sheets of ondulin you will need, you need to set the parameters of the roofing material and the amount of overlap. After the calculations, the corresponding field will display the total amount required to cover the roof area.

When entering parameters in the “Overlap” field, you should take into account the angle of inclination of the roof. With an inclination angle of 10°, the overlap should be no more than 40 cm in width and 30 cm in length of the sheet. For angles of 10-15° approximately 20 cm in width.

At an angle of inclination above 15°, the overlap in width is 20 cm, in length - 17-18 cm. These values are important, since with an increase in overlap, the useful area of the roofing material decreases.

[my_custom_ad_shortcode4]

Designer capabilities

The KALK.PRO service is a universal assistant for beginners and professional craftsmen, with the help of which you can make a truly reliable and safe design. However, it is necessary to understand that the program calculates the roof based on the entered data and does not take into account their correctness, except in exceptional cases when the structure is guaranteed to be unstable.

When building a roof (especially for the first time), we recommend paying attention to the following regulatory documents: SNiP 2.01.07-85 (SP 20.13330.2010) “Loads and impacts”, SNiP II-26-76 (SP 17.13330.2017) “ Roofs", TSN 31-308-97 "Roofs. Technical requirements and acceptance rules. Moscow region", SP 31-101-97 "Design and construction of roofs".

READ MORE: Calculator for calculating bathhouse roof insulation

We currently provide calculations for the following roofing structures:

- roof is pitched;

- gable roof (gable, gable);

- hip roof;

- The roof is hipped (hipped).

We also have separate simplified calculators for calculating the rafter system of a gable and single-pitch roof - try it, maybe this is exactly what you need!

Among the main features of the designer, it is necessary to highlight (– only on KALK.PRO):

- Units. You can select the most convenient units of measurement (mm, cm, m, inches, feet), and the program will automatically convert all values in the calculator fields and calculation results.

- Roof type. When using a soft roof, it becomes possible to take into account the substrate in the form of OSB sheets.

- Roof parameters. You can specify the expected height of the structure, side outlet and overhang. In some roof calculators, the extreme position of the rafters (on the edge, against the wall) is also selected.

- Dimensions of the house. You can set the dimensions of the house: width, length of the house box and wall thickness (the latter affects the layout of the rafters, since the thickness of the gables is taken into account). The height of the walls is only needed to create a correct 3D model.

- Mauerlat. Only from us you get a separate calculation of the Mauerlat for the side and end slopes.

- Calculation of rafters. In addition to entering standard values for width/thickness and the distance between adjacent elements, for a more correct calculation of the rafter system, we can also specify the cutting depth.

- Insulation. The amount of insulation is automatically substituted into the results, the thickness of the material is taken equal to the thickness of the rafters and fills all the space between them.

- Vapor barrier. A block for entering the characteristics (width, length) of a waterproofing material with the ability to take into account overlaps from the sides and top.

- Lathing and counter-lattice. There is functionality for taking into account the parameters of the lathing and counter-lattice - you can enter the width/thickness of the board and the distance between them.

- OSB sheets. In the case of using a soft roof, the parameters of OSB sheets are taken into account in the calculations.

- Roofing materials. This block allows you to calculate metal tiles, corrugated sheets, ondulin and any other roofing material using known sheet parameters.

READ MORE: Plastic air ducts for ventilation, calculation, selection and installation

Our professional roofing calculators are used by many professionals - if you want to use them for commercial purposes, you can remove our watermark and upload your logo.

How to do the calculations yourself

Ondulin from one of the domestic manufacturers You can calculate the number of ondulin sheets without using special online calculators. This approach, while observing basic mathematical rules, is more accurate.

Standard ondulin slate sheet has fixed parameters. Length – 2 meters, width – 0.95 meters. The sheet area is 1.9 m2.

Tiled ondulin is slightly smaller - 0.21 m2. Calculation technology from the following:

- the total area of the roofing surface must be divided into simple geometric shapes: square, rectangle, triangle;

- Next, using trigonometric formulas, you will need to calculate the area of each individual section;

- after this, the results obtained should be added up, taking into account the error from the tilt;

- the resulting amount must be divided by the area of one sheet.

This diagram is simple and is used to calculate the material for any type of roof. Additionally, during calculations you can measure the length and width of the ridge.

In order to enter into the calculations the amount of material spent on an overlap or overlap, you will need to determine its size and calculate the area. Next, you need to subtract the overlap area from the obtained value. The resulting value will show the usable area, that is, the size that will cover the roof surface.

A similar technology was used to create an online ondulin roofing calculator.

[my_custom_ad_shortcode5]

Advantages and disadvantages

Online roof calculation calculator with drawings

Before revealing the advantages and disadvantages of ondulin as a roofing material, it is worthwhile to more clearly outline the range of its application - these are temporary roofing coverings. Precisely temporary, since a 15-year warranty on the coating is nothing more than a guarantee against leaks of the material itself, and a sufficiently long time to find a more durable and reliable coating for the building.

The positive qualities of the material, of course, include:

- The material is environmentally friendly, because it does not contain asbestos, which makes ondulin more attractive compared to ordinary slate.

- Lightness of the material and, accordingly, savings on the roofing structure.

- Ease and simplicity of installation.

- Relative cheapness of the material.

- Availability of all necessary accessories and additional elements to facilitate the installation of the roof.

But such a long list of positive qualities and advantages of the material is largely offset by the fact that ondulin, due to the presence of natural fibers and bitumen impregnation, is, unfortunately, quite a flammable material; this disadvantage is largely reduced by covering the sheets with special mineral compounds, but this is not solves his main problem.

Another problem, although less dangerous from a consumer point of view compared to flammability, is the burning of the material due to exposure to ultraviolet radiation on the coating; this is very noticeable in the first year of operation of the coating, but subsequently, the color change will not be so noticeable.

Calculation technology for a conventional pitched roof

As an example, we will calculate ondulin for the simplest type of roof - a gable roof with a slope angle of 20°. The length of the roof is 7 m, the width is 4 m. The overlap in length will be 20 cm, in width 17 cm. Ondulin will have standard dimensions, with a total area of 1.9 m2.

Calculations using the example of a gable roof and veranda The calculation process will consist of the following steps:

- The area of roofing material that will be used as an inlet is calculated. 2 – 0.2 = 1.8 m – useful length. 0.95 – 0.17 = 0.78 m – usable width. 1.8 x 0.78 = 1.4 m2 – useful area of the ondulin sheet;

- The total roof area for a gable roof is calculated. 7x4 = 28 m2. 48 m2 – total roof area;

- Next, we calculate the number of sheets that will be required to cover this surface. 48/1.4 = 34.3 sheets.

As a result, it turns out that for this roof you will need 35 whole sheets of ondulin, excluding the ridge and overhangs. To avoid material defects due to damage or defects, you should add 2-3 sheets to the obtained value.

The calculation of the ridge is carried out based on the length of the roof. The standard total length of an ondulin ridge is 1 m. The useful length is 0.85 m, since 15 cm is allocated for overlap with the adjacent element during installation. For our example, the number of ridge elements will be equal to: 7 / 0.85 = 8.2 pieces.

The spike (edge of the pediment) is calculated by analogy with the ridge. The total length of the element is 1.1 m with a useful length of 0.95 m. 7 / 0.95 = 7.4 pieces.

The covering apron and other additional elements are calculated based on the structure of the roof. The technology and sequence of actions are similar to the options described above.

[my_custom_ad_shortcode6]

Useful tips

Online calculator for calculating the angle of inclination, rafter system and sheathing of the hip roof of a house.

Some tips for installing roofing material.

- During the installation of the roof, the ondulin has to be cut. To lay the material around the chimney, it is necessary to cut the sheets into very small fragments. In case of excessive overlaps, experts also recommend cutting the material. It is strictly not recommended to use an electric jigsaw for cutting. Too small teeth on this power tool will become clogged with cellulose.

- To cut ondulin, it is better to use a regular stationery knife. With its help, smooth cuts are made, without crumbled edges. Cutting is done starting from the front side of the material. Next, the sheet is folded along the resulting line and turned over. The incision is extended further.

- If the sheet is cut to width, then it is better to use a classic wood hacksaw. Features of the work include the mandatory application of preliminary markings. The sheet is then cut exactly along the line. A chemical marker is used for marking; some craftsmen use wax crayons. To mark the entire cornice row, it is better to use a cord.

- If a large number of sheets are to be cut, then it is more advisable to use a circular saw. Using the tool, a smooth, beautiful cut is made. Sometimes the teeth of a circular saw become clogged with cellulose. For cleaning, it is enough to make a one-time cut of a wooden block.

Experts recommend using a grinder with caution when cutting material. Typically, in this case, melted edges are obtained at the cut points.

The temperature of the material increases due to the high speed of the working circle. Sometimes melted edges appear due to the fact that work is carried out in the sun, so it is better to cut in the shade or in a cool room. To fasten ondulin, nails with special heads are used. They are equipped with plastic plugs. If you use self-tapping screws or roofing nails, you can disrupt the installation technology. In this case, no manufacturer will accept your claims in the event of emergency situations. It is more convenient to hammer nails with a regular hammer. One sheet should require about 20 nails. First, nails are driven into the bottom of the panel, into each wave. Subsequently, fastening is done through one wave in a checkerboard pattern.

- Experts advise closing the caps on the fasteners immediately after fixing them, otherwise difficulties may arise during subsequent work on the roof.

- To lift ondulin onto the roof, you can use a special strong twine. There are hooks on its edges. If the roof is not high, then the sheets can be delivered manually, without special equipment, since they are quite light.

- Some owners of houses covered with ondulin complain that the material gets wet over time due to frequent rains. To prevent this from happening to your roof, you should be vigilant when choosing a manufacturer. Some low-quality companies sell ordinary pressed cardboard, which is coated with coloring substances reminiscent of ondulin coating.

- The original ondulin does not get wet, it has the properties of the usual slate. Like slate, it has the ability to break. To prevent damage to the material on the roof, you should move along its surface only on special ladders.

The procedure for performing work when covering a roof with ondulin can be represented in several stages.

Laying the sheathing. It is recommended to use bars with a cross section of 40x60 cm. The pitch between the bars is directly related to the slope of the slopes. Typically this value ranges from 45 to 61 cm

The beams require fastenings in the form of long self-tapping screws. The evenness of the sheathing for ondulin is not an extremely important characteristic. The material will look great on uneven roofs

Slate can crack under the same conditions.

- To mark the stacking of sheets, a pencil and a measuring tape will be useful. Laying begins on the leeward side. In this case, an overlap of three waves is created at the corner joint. The second row of coating should begin with ondulin cut into two parts.

- A professional installation scheme involves a staggered order of installation of rows. Vertical seams between sheets should not match. This will serve as additional protection. A special waterproofing tape is also useful for the same purpose. It must be used at the junction with the valley, cornices and other additional elements.

To learn how to properly coat a roof with ondulin, see the following video.

General installation provisions

Ondulin is a roofing material in sheets, so it is very convenient to lay it on pitched roofs without complex architectural elements. The abundance of junctions, pipes, protrusions and protruding parts leads to the need for constant trimming, which is fraught with high waste of material.

Scheme for attaching the material to the sheathing. General recommendations for installation are as follows:

- The slope of the slope determines the useful area of the sheet. The larger the angle, the larger the area the sheet has after laying;

- the bottom or outer row has its own area, since 5 or more cm is allocated to the eaves overhang. For an overhang of more than 5 cm, special rafter padding must be used;

- Each next row should start with half a sheet. A similar pattern is called “running” and is widely used when laying roofing and floor coverings;

- when connecting ondulin to all additional elements of the roof, special accessories must be used;

- the top or last row is trimmed flush with the ridge. During installation, it is not recommended to change the technological inlet for the sake of the last row, since the flowing water will get under the casing.

To install the sheathing, a beam with a cross-section of 50x50 mm is used, which is mounted in increments of 60-80 cm. If possible, the wood can be protected with an antiseptic or special impregnations for wood. Calculating ondulin for a gable roof is not difficult. For hip or hip roofs, we recommend using an online calculator - this will significantly speed up the process and reduce the likelihood of errors.

Any roofing work with ondulin begins with calculating the amount of material required. And the point here is not to avoid overpaying for an extra sheet or two. A much more unpleasant situation is when, during the installation of ondulin, it turns out that there is not enough of it, and the purchased material differs from the original color in a subtle shade. This is how you get a new roof with a new patch.

[my_custom_ad_shortcode1]

Roofing pie device

The roofing pie is an integral part of the roof structure, which includes a layer of thermal insulation, as well as waterproofing protection and vapor barrier. Waterproofing protects the insulation from the accumulation of condensation in it , as well as from moisture that can penetrate into it from the outside (rain, melt water). The vapor barrier layer protects the insulation from the effects of fumes coming from inside the building.

Important: a small gap (about 5 cm) must be left between the insulation and the roof covering. This will provide ventilation, which will prevent condensation from accumulating in the under-roof space.

Roofing pie diagram

The roofing pie is usually arranged according to the following scheme:

- rafter system;

- vapor barrier layer;

- thermal insulation layer;

- waterproofing membrane;

- counter-lattice and sheathing;

- roofing covering.

The essence of the calculation method

In order not to make mistakes in calculations when determining the required number of ondulin sheets, it is necessary to take into account the following circumstances:

- For a simple gable roof, the required number of ondulin sheets can be determined as the quotient of dividing the total area of the slopes by the area of one sheet, but in reality the number of standard wave euro slate will be greater, since, in addition to overlaps, it will be necessary to take into account the costs of arranging overhangs, the ridge zone and zones adjacencies;

- Calculation of the amount of material for options for broken, hip, and hip roofs is often performed using a more complex graphical method using diagrams and sketches. If necessary, the obtained data can be checked using any online calculator program or using trigonometry formulas.

Important! Having obtained the amount of ondulin for a complex multi-slope roof using a graphical method, it is necessary to take into account that the actual number will be greater due to the overlap.

[my_custom_ad_shortcode2]

Features of Euroslate

Corrugated bitumen slate is made from pressed cellulose. In addition to bitumen impregnation, the roof covering is equipped with a protective and decorative layer using thermosetting resins and ceramic granules or mineral chips. The structure of ondulin determines the ease of its installation

:

- the sheets are light in weight (about 6 kg);

- Euro slate 3 mm thick can be easily cut with standard tools (wood saw, electric saw);

- the corrugated sheet covering is secured using roofing nails with a sealing gasket or self-tapping screws.

The roofing material developed by Onduline allows you to create a coating that perfectly protects the building from atmospheric influences. A properly installed roof deck successfully withstands heavy snow loads, strong gusts of wind, and does not allow moisture to pass through during rains. The warranty period for ondulin coating is 15 years, the actual service life can reach 50 years

.

In the production of Euro slate, high-quality components are used that are completely safe for human health. The appearance of the coating to a certain extent depends on the characteristics of the mineral pigments, so different batches of the material may vary slightly in shade. To ensure that the roof has an even color, it is advisable to use ondulin from the same batch. It is necessary to correctly make preliminary calculations in order to accurately determine the required number of euroslate sheets

.

Graphical calculation methods

The essence of the method is to use large-scale plans of the roof of the house. The difficulty of using standard mathematical formulas for calculation is that simply multiplying the dimensions of, for example, a trapezoidal roof slope made of ondulin, will give the exact surface area of the roof, but this is not enough. Dividing the area of the trapezoid by the size of one sheet of ondulin, we obtain an equivalent number of ondulin sheets in area. In reality, this number does not give us anything, since the calculation is performed for conditions when the roof surface is covered with all the ondulin material, even with trimmings and waste.

To ensure maximum calculation accuracy, you must first draw a sketch of each roof slope. Next, we cut out rectangles to scale, the proportions and scales of which correspond to the dimensions of the ondulin canvas. From rectangles we lay out a geometric figure, in size and shape as close as possible to the geometry of the roof slope. Some amount of roofing material will extend beyond the area of the slope, but in any case, it is necessary to obtain the minimum number of whole rectangles covering the image of the roof slope. In this way, a graphical count of the material is performed.

A similar calculation procedure must be performed with each roof slope separately.

[my_custom_ad_shortcode3]

Properties of ondulin

Before calculating ondulin for the roof, let's talk about the properties of this material. Ondulin is made from cellulose fibers, which are impregnated with bitumen under pressure and then treated with resins and minerals.

Ondulin has a number of undeniable advantages:

- low price;

- easy installation;

- a large number of useful properties.

If we consider the beneficial properties in more detail, among them we can highlight the following:

- Reliable waterproofing. The special arrangement of the fibers and the fact that the material is impregnated with bitumen almost completely protects the ondulin roof from water getting inside.

- Large temperature range. Ondulin is used in many countries, regardless of the climate of the area, as it can easily withstand temperatures from -40 to +80 degrees Celsius.

- Strength of the material. Ondulin will withstand many loads, from snow drifts in winter to strong winds and thunderstorms in summer.

- Noise insulation. The special structure of the fibers inside ondulin blocks a large number of external sounds.

- Practical to use. The flexibility of the coating will allow it to be used on roofs of any complexity.

Simple calculation of ondulin sheets for the roof

When calculating a conventional gable roof, you must take into account:

- The angle of inclination of the slope. Depending on the steepness of the slopes, the amount of overlap of one sheet onto the edge of another is selected; accordingly, the initially obtained number of sheets must be increased to take into account the area eaten up by the overlap;

- Please note that the calculations take the useful square footage of the roof, and not the geometric dimensions tied to the dimensions of the house box;

- If the roof structure contains complex elements such as a valley, additional zones of abutment to vertical walls, projections, non-standard overhangs and canopies, the calculated number of ondulin sheets must be increased by 10%.

[my_custom_ad_shortcode4]

Advantages of ondulin, a popular roofing material

This roofing material has high thermal insulation and good sound insulation. Consequently, the house will be quiet even when it rains. Ondulin does not delaminate and does not change color due to a negative environment. It doesn't need to be constantly repainted.

What is ondulin? This is a reliable roof that does not rust, does not rot, and is resistant to corrosion. It can be noted that ondulin is protected from processes that could destroy it. The properties of ondulin are preserved for many years. Ondulin meets all fire standards because it is not flammable. Such a roof will not harm your health at all and is safe for residents.

Ondulin has less pressure on the roof structure than other roofing building materials. In addition, ondulin is used when it is necessary to repair the roof of a dilapidated building that cannot withstand significant loads. The material also stands out for its flexibility, which is why it is used in arches and other structures where this property is required.

Calculation of the number of sheets depending on the angle of inclination

The area of a standard sheet of ondulin is 1.9 m. The conditions for laying the roof covering require that the sheets overlap at low slope angles of 300 mm, for higher ones 200 mm. The lateral overlap of the wave for small angles is two waves or 200 mm, for high slopes - 100 mm. Accordingly, when calculating for small angles, the useful area of the ondulin is taken to be 1.7x0.85 m, which is 1.5 m, and for large angles of inclination the useful square footage will be 1.65 m.

Thus, for a building with two pitched surfaces, dimensions 6x9 m and a total area of 108 m, 72 sheets will be required if the angle of inclination does not exceed 20°, and 68 sheets for angles of inclination from 20 to 60°.

In a theoretical calculation, we increase the resulting number by 10% to meet the need for ondulin for non-standard and complex roofing units. We will add another 2% for excess material consumption associated with damage during fastening, errors during cutting and defects. A couple more sheets are added for repair purposes. Most often, these additional data are not taken into account, and they are remembered only during the process of laying the roof with ondulin.

[my_custom_ad_shortcode5]

Alternative roofing coverings

An alternative to an ondulin roof can be a roof made of galvanized iron, corrugated sheets, galvanized iron, roofing felt, tiles and the most important material of today - metal tiles.

A roof covered with galvanized iron looks neat and can protect against moisture and precipitation for many years.

Snow does not stay on a galvanized roof, so you can use thinner rafters for a galvanized roof and save money.

- Classic roofing felt is a star among roofing materials. It is easy to transport, inexpensive at all, easy to stack - it is in deserved demand. Now improved roofing felt of more modern brands has appeared, it has become even more popular. It is mechanically resistant to impacts, durable, has high elasticity - it is not for nothing that they cover the roofs of residential buildings, at least many Soviet-built houses are covered with roofing felt.

- Corrugated sheeting (corrugated sheet) is a high-quality modern material, pressed from rolled steel. Very strong, lightweight, easy to install, environmentally resistant and durable.

- Metal tiles are the king of the roof. Metal with tiles combines the advantages of both, eliminating their disadvantages. It looks better than just metal, and the properties are better than tiles. Provides ease of installation and durability, it is very popular among builders. Why is there a place for other materials like ondulin? The issue is the price.

- The tiles can be made from baked clay (ceramic tiles), thermoplastic composite, a solution of sand and cement (cement-sand tiles) or lime and sand with heat treatment (silicate tiles). The most famous clay tiles are made from plastic clays with a low melting point (sometimes a material such as fireclay is added to it). Classic tiles are fragile and heavy. The roof underneath should have a steep slope to allow water to flow down. Modern models can also be installed on flat roofs (10°).

- There is also slate, but, of course, they are no longer considering it seriously. And in European countries it is prohibited for use due to asbestos. Although our sheds can still be covered with it. The manufacturer is also important here - now they manage to make it unevenly.

Characteristics of ondulin and method of its attachment

There are many ways to cheat the practical calculation of the number of ondulin sheets. For example, if you nail the material according to the pattern shown in the photo.

In this case, the ondulin is nailed and at the same time straightened or settled in height. The calculation is quite simple - you cannot pierce a sheet in this way; if the required impact force is exceeded, the material will not be damaged, but will simply straighten the wave. A simple calculation shows that with each wave settling by only 5 mm, the total increase in the width of a sheet of ten waves will be 50 mm. And when laying 10 sheets in a row, the error will reach 0.5 m.

Ondulin cannot be attached in this way, and one should not hope for such changes in geometry. It is correct to fasten and uniformly align the roofing sheet on the plane of the sheathing.

[my_custom_ad_shortcode6]

Typical mistakes when installing an ondulin roof

How mandatory are the installation rules and what happens if they are not followed?

Typical installation mistakes:

- Using the wrong nails.

The absence of a special cap will allow moisture access to the sheathing, and it will begin to rot.

Nails less than 70 mm long will not provide reliable fastening of sheets.

- Saving on sheathing.

A section of bars that is smaller than required will cause the sheathing to bend under load. And the sheathing pitch greater than recommended will give the ondulin sheets the opportunity to sag. The sheet becomes deformed, breaks, and the seal is broken.

- No additional sheathing for the ridge and valley.

The elements will move in waves and atmospheric moisture will penetrate the inner layers of the roof. Irreversible processes will begin: mold and mildew will settle on the wooden elements of the rafter system. The thermal insulation layer will not work effectively when wet. Eventually there will be a need to replace the entire roof structure.

- Incorrect sheet overhang size.

The eaves (transverse) overhang over the drainage system pipes should be no more than 50 mm, and the free longitudinal edge of the sheet should be no more than 35 mm.

An overhang greater than the specified dimensions in winter can lead to breakage of the sheets.

- Lack of eaves and gable trim.

It will cause wooden elements to get wet during side rain and cause them to rot.

- Incorrect installation of the valley.

The valley must be located strictly under the roofing sheets. Otherwise, it will not be possible to protect the junction of the slopes from rain and snow. As a result, the load-bearing wooden elements of the rafter system and insulation become wet.

- Incorrect placement of sheets.

- Neglect of roof ventilation:

- There is no gap between the waterproofing film and the sheathing, air circulation is disrupted, condensation does not evaporate, resulting in rotting of the wooden elements. It is imperative to install a block under the sheathing along the plane of the rafter board, measuring 20x30, 30x30 mm, to attach the waterproofing layer. The gap between the waterproofing film and the insulation is ensured by choosing the correct size of the rafter leg. The width of the rafters should be greater than the thickness of the thermal insulation layer.

- The waterproofing is very stretched. It is correct to lay the protective film under the ondulin horizontally, starting from the eaves strip to the ridge line, with a sag of no more than 10-20 mm between the rafters (but not touching the insulation) and an overlap of 100-200 mm. Strong tension can lead to film rupture.

- Incorrect installation of the vapor barrier membrane or its absence will lead to the accumulation of moisture in the thickness of the insulation and will reduce its heat-protective properties. The vapor barrier film is installed as an absorbent layer inside the room.

- Lack of ridge vent. The waterproofing layer should start 40-50 mm below the ridge. Otherwise, condensation cannot be avoided.

The technology for installing the rafter system, laying layers of heat, hydro, and wind protection is similar for pitched roofs with various types of coating up to the stage of lathing installation . What types are there and how to choose the right rafter system for a roof made of bitumen sheets, sheet profiled covering (metal tiles, metal profiles), seam and soft roofing, ceramic tiles, you will find at the link.

How to calculate the roof area of a rectangular slope

Suppose the size of a rectangular slope is 10 m x 5 m, the roof slope is 35 degrees. The total area of the slope is 50 sq. m.

Stove and ventilation pipes reduce the total area slightly and do not affect the consumption of ondulin. With this slope, Ondulin Smart is mounted with a side overlap in one wave, the end overlap is 12 cm. The useful area of one sheet is 1.56 square meters.

You can calculate the number of sheets of ondulin “N” in two ways: 1. Quick method.

We divide the area of the slope by the useful area of the sheet, multiply the result by a correction factor of 1.1...1.2, taking into account unused trimmings: N = 1.15 x (50: 1.56) = 37 sheets.

2. Exact method. We calculate the number of sheets in one row:

– useful sheet width: 0.96 m (full sheet width) – 0.095 m (overlap) = 0.865 m; – number of sheets in a row: 10 m (length of cornice): 0.865 m = 12 sheets.

We calculate the number of rows: – useful sheet length: 1.95 m – 0.12 m (overlap) = 1.83 m;

– number of rows: 5 m (length of slope): 1.83 m = 3 rows. The number of sheets and rows is rounded up to whole numbers. Cutting sheets 61 cm long, formed during installation of the top row, are not used.

Required amount of ondulin: 12 sheets x 3 rows = 36 sheets.

[my_custom_ad_shortcode2]

Recommendations and notes on roofing

This collection provides recommendations on the construction of roofs and roofs, in particular. We hope you find this information useful for general information and when working with our calculators.

General

- The area of any classic roof can be calculated using the formulas for the area of a rectangle, triangle, parallelogram, trapezoid: S = a×b, S = (a×h)/2, S = a×h, S = (a+b) × h/ 2, where a, b are the lengths of the sides, h is the height.

- The optimal roof angle for constructing a full attic is 45°.

- The angle of inclination of the roof directly depends on the climatic conditions of the region: in snowy areas there should be steep roofs, in windy areas - flat ones.

- The angle of the roof depends on the roofing material: a rigid roof requires a steeper slope.

- The angle of the roof affects the final cost of the structure: a steep roof costs more than a flat one.

- The height of the roof is derived from the formula for the height of an isosceles triangle: H = a × sin α, where H is the height directed towards the base, a is the side (the length of the rafter along the slope), α is the angle at the base (applicable for gable roofs).

- The optimal value of the eaves overhang of the roof is in the range of 50-100 cm, but not less than the width of the blind area.

- The optimal size of the gable roof overhang should be in the range of 40-70 cm.

- Roof calculations must be made based on a load of at least 200 kg/m2.

- It is recommended to equip the roof with through ventilation holes from the eaves overhang to the ridge.

- All fastening materials (especially external ones) must be galvanized or made of stainless steel.

- All wood must be treated with fire retardants, antiseptics and antifungal agents.

- The wood moisture content for all structural elements should not exceed 18-22%.

- It is recommended to use wood of at least class 2, and for load-bearing elements - only class 1.

- The ideal roofing pie is in order from the inside out: vapor barrier, insulation, waterproofing (membrane), counter-lattice, sheathing, tiles (or other material).

Mauerlat

- The optimal size of timber for the Mauerlat is 150x150 mm, sometimes 50x150, 100x150 mm are used.

- It is recommended to fasten the Mauerlat to the armored belt using studs. However, the timber must be insulated so that it does not come into direct contact with the concrete.

- The pitch of the studs for attaching the Mauerlat should not exceed 150 cm.

Rafters

- The depth of the cut should not exceed 1/3 of the width of the board (optimally 1/4).

- The recommended width and thickness of the board for most designs is 150-180 mm and 50-60 mm, respectively. The section of the board is selected depending on the pitch of the rafters and the potential load on the roof.

- The distance between the rafters should not be less than 60 cm and more than 120 cm.

- It is recommended to fix all connections in two different ways.

- To increase the reliability of bolted connections, it is recommended to use metal plates and angles.

- When the span width is more than 10 m, the mandatory installation of additional supporting structures (rails, struts, racks) is required.

Lathing

- The recommended board for sheathing is 25x100 mm, in the case of heavy roofs - 40x150 mm.

- For hard roofing materials, it is recommended to install dense sparse lathing, for soft ones - with a wider pitch, since OSB sheets will be installed on top.

- The pitch of the lathing is selected individually for each material and is specified by the manufacturer. On average, for a soft roof - 1-10 cm, ceramic tiles - 30-35 cm, metal tiles - 30-40 cm, corrugated sheets - 30-65 cm.

Insulation and insulation

- It is recommended to buy rolled thermal insulation, since slab insulation is difficult to fix (especially alone) and is more likely to crumble.

- The recommended thermal insulation thickness is 15 cm, the minimum is 10 cm.

- It is recommended to lay the vapor-waterproofing in an overlap (10-20 cm) with subsequent gluing of the joints.

- It is better to lay waterproofing in two layers.

- The permissible deflection of waterproofing is no more than 15 mm.

The online roofing calculator from KALK.PRO is the most effective way to obtain design documentation for the manufacture of a reliable roof truss system and other structures.

Source

How to calculate the roof area of a slope in the shape of a polygon

The intersection of the two roofs is shaped like a triangle. Suppose the length of the base of the triangle B = 3 m, the height of the triangle H = 5 m. The roof area is calculated in the following sequence: – determine the total area of the slope: 10 m x 5 m = 50 sq. m;

– the area of the triangle formed by the inset is calculated by the formula: Str. = 0.5 x (H x H) = 0.5 x 3 m x 5 m = 7.5 sq. m;

– ramp area: 50 sq. m. – 7.5 sq.

m. = 42.5 sq. m.

1. Fast way. We divide the area of the slope by the usable area of the sheet, and multiply the result by a correction factor of 1.2.

. . 1.3, taking into account unused trimmings:

N = 1.25 x (42.5 sq. m: 1.56 sq. m) = 31 sheets. The number of sheets is rounded up to whole numbers.

2. Exact method: – we make an exact drawing of the ramp on a suitable scale;

– fill the slope with sheets of ondulin (sheet size taking into account overlaps – 1830 mm x 865 mm); – we measure the sizes of the fragments per area of the triangle and check the possibility of their use;

– recalculate the number of sheets. By analogy with the previous slope, the savings will be 2-3 sheets.

[my_custom_ad_shortcode3]

Dimensions of roofing sheeting

Roofing corrugated sheeting is a metal profiled sheet made of high-strength steel by stamping and protected with special substances. It comes in various types, which differ significantly from each other. This also applies to their sizes, which can be completely different in order to satisfy the needs of customers as fully as possible.

Thanks to the technical capabilities of modern machines, factories can produce roofing corrugated sheets up to 14 meters in length. This allows the client to purchase materials whose dimensions will best suit the size of the building itself.

NOTE! It is important to remember that each sheet of corrugated sheets has two types of width. One defines the total objective width, while the other characterizes the useful value.

It represents a slightly smaller parameter of the material, since it takes into account the fact that there should be an overlap between the vertical sheets

It represents a slightly smaller material parameter, since it takes into account the fact that there should be an overlap between the vertical sheets.

Long products can significantly reduce the number of joints, which primarily concerns their horizontal position

This is important because this, in turn, has a direct impact on the tightness of the roof itself. If the length of one slope is less than 14 meters, horizontal joints can be completely avoided

Profile dimensions

The use of long profile products also makes it possible to reduce material consumption, since short corrugated sheets need to be overlapped.

The most commonly used for roofing is corrugated sheeting 6 meters long. This is due to the fact that it is quite easy to deliver it to the construction site, while 14-meter products need to be loaded into special vehicles

The smallest length that a sheet of profiled metal can reach is only 0.5 meters. No less important is the width of the corrugated sheet, the standard size of which is only 1250 millimeters. Often wider sheets are placed on the machine, but due to bending they lose their width

The higher the height of the corrugation, the narrower the material itself will be. That is why the profile of the C8 brand has a width of 1200 millimeters, and the H75 brand has a width of 800 millimeters.

Dimensions

In order to calculate the amount of material, you need to know the size of the ondulin sheet for the roof that needs to be covered. The dimensions of Euro slate are standardized and have the following parameters:

- the length of the sheet is 2,000 mm with an error of 5 to 10 mm, which is not critical, since the overlap during installation is about 200 mm;

- the width of the ondulin is 950 mm with an error of 5 mm, with the necessary overlap of one or two waves, depending on the angle of inclination of the slope;

- standard material thickness is 3 mm with an error of 0.2 mm;

- the wave pitch is 95 mm with an error of 2 mm;

- wave height is 36 mm with an error of less than 2 mm;

- weight is 6.5 kg and has non-critical errors;

- one sheet has an area of 1.9 m2 with a usable area of 1.6 m2, taking into account overlaps.

Based on these parameters and knowing the effective dimensions of the ondulin sheet, you can easily calculate the required amount of material for your roof.

The easiest to calculate the amount of material are single- and double-pitched roofs, but more complex roofs can be calculated with confidence. Knowing the correct dimensions of the ondulin sheet and carefully measuring the roof area, you can minimize material loss and save significantly. Let's consider the principles of calculating the number of sheets required to cover a roof with ondulin.

What to consider when calculating

When calculating the number of ondulin sheets per roof, you need to take into account many factors. Without them, it will be impossible to make correct calculations. First of all, it is worth remembering that the sheet area indicated in the characteristics is total. To calculate the amount of material you need to know the useful value of this parameter. The fact is that ondulin is laid with an overlap. Therefore, the usable area will be less than that indicated in the specifications.

The amount of overlap depends entirely on the angle of the roof slope. Experts recommend considering the following:

- if the angle of inclination is less than ten degrees, then there is a high risk of water stagnation. For this reason, ondulin sheets should be laid with large overlaps, at least 30 centimeters. This applies to the vertical. The overlap on the sides should be in two waves;

- when tilted from 10 to 15 degrees, the flow rate will be slightly less. In this case, the ondulin is mounted with a lateral overlap of one wave, and a vertical overlap of at least 20 centimeters;

- if the roof is steeper, then the overlap on the sides remains in one wave. From above, one sheet of ondulin should extend at least 15 centimeters onto another.

Knowing the angle of inclination of the slope, you can calculate the usable area. Doing this using a regular calculator is not difficult. In the first case, the useful area of one sheet of ondulin will be approximately 1.3 square meters. In the second and third cases, 1.5 and 1.6, respectively.

In addition, depending on the angle of inclination of the slope, one or another version of the sheathing is selected. If the roof has a slope of less than 10 degrees, then the base is made solid. In other cases, the lathing for laying ondulin can be made of boards mounted in increments of 20 to 45 centimeters.

Material selection

The branch in Russia produces products of three standard sizes:

| Characteristics | SMART | DIY | Roof tiles |

| Size, m | 1,95/0,95 | 1,95/0,76 | 1,95/0,96 |

| Thickness, mm | 3 | 3 | 3 |

| Number of waves | 10 | 8 | 7 |

| Wave height, mm | 38 | 38 | 38 |

| Step between vertices, cm | 9.5 | 9.5 | 144 |

| Weight, kg | 6,5 | 5 | 5,9 |

| Weight 1 m2, kg | 3,4 | 3,4 | 3,15 |

| Roof inclination angle, degrees | Usable area at slope, m2 | ||

| 5-10° | 1,25 | 0,94 | 1,56 |

| 10-15° | 1,5 | 1,16 | |

| > 15° | 1,56 | 1,22 | |

The prices and characteristics of SMART and DIY are almost identical. A sheet with a smaller width creates a larger number of stiffeners at the joints - the reliability of the structure increases, but it will cost more.

The cost of tiles is 20-30% higher, depending on the markup of the selling organization.

What is usable area? The material is laid overlapping, so its covering (visible) part is smaller. The manufacturer has special requirements for the installation technology of SMART and DIU ondulin. The useful area of the sheet depends on the slope of the roof.

| Tilt angle | Lathing pitch, mm | overlap | ||

| Degree | Ratio | End, mm | Side | |

| 5-10 | 1/11-1/6 | Solid | 300 | 2 waves |

| 10-15 | 1/6-1/4 | Interval 450 | 200 | 1 wave |

| > 15 | > 1/4 | 600 | 170 | 1 wave |

The overlap sizes and lathing method in the table are based on average statistical calculations of the required structural strength. Russia has different climatic conditions. For areas with increased snow and wind loads, either/and is required:

Calculating the roof angle

If there is no data on the slopes of the slopes, you can determine them yourself. It is necessary to measure the height of the ridge (H) and the position (A).

An example of calculating the relative value of the slope: H/A = 3/5 = 1/1.67. This fraction is greater than 1/4 - for such a design, ondulin sheets have a useful area (m²):

To determine the angle in degrees, you must use trigonometric functions and Bradis tables or an engineering calculator. Calculating the relative magnitude of the slope is easier.

Determining the roof area

A house project is a good help for calculations. But the drawings and the actual structure are not always identical. Corrective measurements taken independently guarantee more accurate results.

From the school course:

Amount of roofing material

1. The first method for calculating the amount of ondulin:

Nl = 1.1 x Scr / Sl, where:

The result is rounded up.

Example of roof calculation

Additional elements (pcs):

Universal filler along the extensions (pcs):

Material calculation program

An online ondulin roofing calculator is an assistant for craftsmen who doubt their abilities. You need to enter in the “windows”:

The calculations are quite accurate; a 10% reserve for waste and defects is included.

The calculator for calculating ondulin sheets for the roof greatly simplifies the process, but it is better to use the program to check your own calculations. Drawing up an estimate yourself will allow you to study the features of roof laying technology and eliminate installation errors.

Source