Since ancient times, metal has been one of the most important materials, both in production and in everyday life. At the same time, despite the strength, reliability and very long service life, even metal structures can be exposed to negative environmental factors.

Forged products are various metal structures that are assembled using any methods from individual elements. These include different types of wickets, fences, gates, railings on stairs and balconies, and many other products.

Before painting them, the surface must be primed. Moreover, you can use paint and varnish material and primer in tandem.

Properties of patina

The name “patina” was invented by the Italians. Patina was originally thought to be a naturally occurring coating on copper. It did not always look like a work of art, but over time it became fashionable to have “antique” forged products in homes. Demand creates supply and patina began to be applied to metal artificially, using acids and oxidizing agents . As a result, the interior items looked great.

But in addition to purely decorative properties, patina also has important practical meaning:

- protects the metal from external influences;

- protects against rust;

- gives the surface water-repellent properties.

How to protect forged products from corrosion?

Painting the gate with blacksmith's paint will help protect the forged beauty from corrosion. Before painting the gate, you need to carry out work to prepare the surfaces for painting.

Painting wrought iron gates

Algorithm for performing work on anti-corrosion protection of forged gates.

- Cleaning from rust.

- Primer for surfaces to be painted.

- Application of special blacksmith paint to the gate, followed by protection of the painted surface with special substances.

The main thing is to clean the metal from rust. Under no circumstances should you paint over rust! Our task is not to disguise rust, but to get rid of it. Here are some ways:

- Sandblasting. Purchasing a sandblasting machine is very important if you become the owner of a forged gate. Experience shows that if painting the gate is done once every year or two years, renting a sandblasting machine can cost quite a significant amount. In general, the final choice is yours.

- Clean with a stiff wire brush.

- Using sandpaper. This is also a fairly effective method, but you need to keep in mind that to clean the gate from rust, you should use the harshest types of rust.

List of materials and tools

Patination should be carried out in a well-ventilated area or in the open air to protect the respiratory system from harmful influences. You will need:

- patina of the required color;

- solvent;

- a synthetic brush or sponge if you need to treat a small surface;

- small containers made of plastic or glass (for example, you can use cut bottoms from plastic bottles);

- item made of metal;

- varnish;

- alcohol.

- palette.

Important! Patination should always be carried out wearing thick gloves. You will need to work with oxidizing agents and therefore, if safety precautions are not followed, there is a possibility of getting a chemical burn.

Types of patina

Patinas are sold in stores in the form of pastes, liquids and varnishes.

- Acrylic. It is made on a water basis. Suitable for metal, wood and plaster products. Differs in versatility and ease of application. Protects metal from external influences

- Oily. Does not hide the natural shade of the metal and emphasizes its pattern.

- Chemical _ It is made by combining water-based paint and an oxidizing agent. Due to a chemical reaction, the forged product “ages” in a few hours. Thus, the metal actually changes.

Important! During operation, the patina in a jar or in a special container must be stirred periodically.

General information

Thanks to the artistic method of forging, you can make metal objects not only practical, but also aesthetic. All this helps make artistic forging an ideal option for decorating interiors and exteriors. But under modern conditions, painting forged products with your own hands is the best method of preventing corrosion, thereby increasing their service life.

Special preparation of metal products before painting

Initially, primary treatment of metal surfaces should be carried out, and only then paint and varnish material should be applied. If forged products have been under the direct influence of environmental factors for a long time, then a lot of attention will need to be paid to their preliminary processing. Thus, you should remove the paint that has already begun to peel off, and also get rid of the loose layer of rust. All this can be done with coarse sandpaper, a sander or a metal brush. In this case, when there are large quantities of metal products or elements, a sandblasting machine is used.

Degreasing process

So, the second stage will be degreasing. When cleaning new forged elements, be sure to follow certain rules. Thus, ferrous metal products straight from the factory may have grease or oil stains. Various lubricants may also remain on their surface. Under such circumstances, you can get rid of this by using any type of solvent or a 5% solution of a synthetic detergent to wash off. Metal products that have smooth and shiny surfaces require sanding with P-40 or higher sandpaper to remove dust.

Please note that in this case, zinc surfaces are washed off under a huge pressure of water, and while aluminum ones will not be cleaned at all, they are simply degreased.

Coloring of forged products

In order to achieve reliable, beautiful and wear-resistant painting, it is necessary to carry out all finishing work in calm and dry weather. The air temperature should be within +20...+36 degrees, and the composition should not be lower than +17 degrees. Humidity parameters should be from 40% to 85%. So you should make sure that direct sunlight does not fall on the coating, which has not yet had time to dry. The final coat of forging paint is applied two hours after coating, although the duration will directly depend on the composition used.

The edges and corners should be painted with the greatest care because they are most susceptible to corrosion. There are several stages of painting forged products:

- The use of materials to transform rust. Once such a composition has been applied, the rust will begin to transform into a chemically neutral coating of the composition with high strength, resulting in increased anti-corrosion properties of the primer composition.

- Application of primer. Before painting forged products, it is necessary to use a high-quality primer that prevents the appearance of rust, is highly resistant to moisture, and promotes a high degree of adhesion to metal structures and future coatings. Traditional priming has low wear resistance and minimal decorative properties. But at the moment they produce special “3 in 1” primer-enamels, which can provide the product with a beautiful appearance and provide maximum protection from corrosion. The primer composition can be universal or special - for work only outside or only inside a room/building. For this reason, you should read the label carefully when choosing a primer.

- Painting stage - the paint and varnish material should be applied over a layer with a primer. It will protect the surface from the aggressive influence of environmental factors, namely precipitation, sunlight, and large temperature changes. In order to enhance protection and increase the degree of wear resistance of paints, special varnish compositions can be used as an additional layer.

It is thanks to the latest technologies that it is possible to combine the properties of layers. For example, a rust-transforming substance can be added to the primer layer, and components that have an anti-corrosion effect can be added to the paint composition. Thus, the combined paint and varnish material for forging imparts efficiency to products made by forging for decades and at the same time increases their service life, protecting them from negative corrosive effects.

Specialized compositions for painting forged products

Preparing metal for patination

- Prepare a smooth surface on the forged product. Remove uneven areas with a file and sandpaper, and then coat the item with a special metal primer. Check that there are no rust stains left.

- Before decorating a forged item, paint the product, and then be sure to let the paint dry . The paint will cover the primer layer and create a spectacular background for the future patina. Gold or silver patina looks especially good on dark tones.

Which primer should I choose?

A primer is needed to protect the wrought iron gates from corrosion and to ensure that the paint layer adheres smoother and better. Some types of primers add substances that transform the chemical composition of rust.

Types of gate coverings

An integral part of others are inhibitors (substances that slow down the oxidation process of the metal). According to manufacturers, the use of such primers allows you to at least double the service life of paints applied over the primer.

Secrets of patination

The choice of patination method depends on the result you require.

If you apply patina with a sponge, the layer will come out very heterogeneous and light. Suitable if your goal is only to emphasize some place on the product.

Apply paint to kinks and corners. Thus, a “time imprint” will appear on the item.

Important. When working with a sponge, apply light strokes to the material. Otherwise, a trace of foam rubber will appear on the item, which will have to be washed off or covered with a new layer.

What nuances should you consider if you decorate metal with a brush?

- The brush bristle must be dry and clean. Otherwise, dirty spots will remain on the metal and instead of the desired effect you will get a “painted fence”.

- Apply a little patina to the palette and rub it in with a brush. After this, start covering the material with sweeping movements.

- The brush is suitable for applying deeper layers of patina when the effect of light strokes is not enough.

- If you need to make the paint more transparent, dilute it with a solvent. Adjust the proportions to your taste.

- Didn't the plot work out? Wipe the area where the patina was applied incorrectly with a cloth and brush again.

Applying patina (1 video)

Alkyd

They are produced on the basis of modified alkyd resins, so such dyes are elastic and durable. Manufacturers produce the product in cans.

| pros | Minuses |

|

|

Preparatory work

Preparation for painting the gate must be carried out in strict sequence. The following work steps must be completed:

- Washing or cleaning from dirt. Contaminants are removed, as well as other substances adhering to the canvas are washed away. The most thorough work can be done using a hose. Pay special attention to corners and hard-to-reach places.

- Surface cleaning. At this stage, it is necessary to remove peeling paint from the canvas. If the layer of the previous coating is large, then the entire thickness of the old paints must be removed. The work can be done either with a metal brush or with a hair dryer. It is possible to use a grinder or a drill with a special attachment – a “brush”.

- Grinding. It is done with fine-grained sandpaper, regardless of the method of doing the work - manually or using a drill that has a special attachment. The mechanized method speeds up the work. However, you cannot do without manual grinding in hard-to-reach places.

- Degreasing. Performed with a solvent after cleaning and sanding. It is important to treat the entire surface without gaps, not forgetting hard-to-reach areas. The quality of adhesion of further coatings to metal depends on this.

Of course, changes and additions to the work order are possible. Some gate owners wash them after cleaning and polishing, using detergents. This allows you to save on degreasing products. But it should be remembered that these works must be performed especially carefully, and detergents cannot replace solvent.

Dyeing technologies

So, it is clear: the surface is painted after preliminary priming. Many experts recommend using primer and paint in pairs.

Experience shows that if you paint a metal product with hammer paint, the effect will be truly amazing.

Varieties of colorful coatings for gates

However, it should be noted that the name “hammer paint” is not entirely correct. Rather, the effect of its use can be called hammer. Dyes are known as acrylic (alkyd-acrylic).

You can paint wrought iron gates in the following ways.

- Painting with a brush. The best option is a rounded brush with a stiff brush. The process is simple, but requires a certain degree of accuracy. If you do not approach your work very responsibly, the result, to put it mildly, will not live up to expectations.

- Aerosol painting – special dyes are used in cans.

- Powder painting. Recommended for use when no welding was used during installation.

- Electrostatic painting. Perhaps the most durable and reliable type of painting. The disadvantage is the high cost, since special equipment must be used.

- Patination is the application of a small amount of patina to give the metal an antique effect. It is applied to the surface with very small strokes (this creates a scuffed effect).

The main advantages of painting with hammer paint:

- Painting with hammer paint does not require too scrupulous surface preparation. Cleaning from dust and rust is quite enough.

- Painting gates with hammer paint is a combination of three-in-one work: simultaneously priming, painting and applying a protective anti-corrosion coating for the metal.

- If you paint the surface correctly, you don’t have to worry about frequent repairs.

- Very good appearance.

As you know, metal paints have three effects: matte, glossy and hammer (the hammer effect, due to its aesthetics and characteristic pattern, is the most common).

When using dyes with matte and glossy effects, such a pattern does not occur.

Among the ingredients included in hammer paint are silicone additives, substances that cause chemical transformation of rust, paint enamel, tiny particles of glass, and aluminum powder.

Using silicone filler and tempered glass particles, protection against the harmful effects of water is created. Aluminum powder creates the opportunity for better adhesion of paint to the surface being painted.

The hammer paint option is therefore ideal for painting wrought iron gates.

How to choose blacksmith paint

Choosing a wrought iron fence – what to look for?

To produce gratings of this decorative type, ferroalloys, steel alloys, cast iron and iron are used. Depending on the type of material, a forged lattice can stand in an open space without damage from corrosion for a certain number of years, and with care and proper timely painting, the guarantee for the service life of the fence can reach 50-70 years.

When choosing, take into account this fact - cast iron grates are those that use cast iron only for the manufacture of cast elements, while forged grates are never made of cast iron. Therefore, when you offer a “forged cast iron fence from the manufacturer at a low price,” you may immediately suspect a catch. Additionally, to decorate the lattice with thin elegant details, titanium, aluminum, copper or other metal alloys are used, which increase the cost of the fence section by several orders of magnitude. Sometimes precious metals are also used for such parts, so when calculating fence gratings, pay attention to this part of the cost estimate.

To increase the strength of the fence, at your request, craftsmen can increase the number of elements in the intervals of the main sections; the optimal height of such a fence will be 2-2.5 m.

The design of the pattern is developed in 3D form, so you can see and evaluate the appearance of the fence from all sides. Pay attention to the fact that the fence is beautiful and aesthetically pleasing from all sides, and not just from the face. If you don’t have your own sketches or ideas, the craftsmen will offer you to choose one of the ready-made solutions for forging a floral, geometric, medieval or abstract design. We recommend that you take a closer look at the options from this catalog, since ready-made solutions will save money and you will not take risks with the development of an untested fence.

If you are afraid of disturbing yourself and your loved ones with the transparency of your new fence, you can always let climbing plants correct this problem. But make sure that they do not “occupy” the grille, hiding its beauty underneath.

How to paint a fence so it doesn't rust

Well, there are no special tricks here:

- We always paint from top to bottom - no one has canceled the laws of gravity, so moisture will always flow down and not rise.

- We always paint in the direction from the center to the periphery of the structure: this way you can always correct shortcomings and flaws.

- We always paint in the direction of the rays of sunlight: paint layers will be less visible, especially if we do not use a spray bottle.

- When painting, you should use a micrometer to determine the minimum layer thickness: it should not be less than 10 microns.

- Since exterior paint is a quick-drying type, we try it on the inside of the fence

Have you gotten the hang of it? Go ahead and don't let the weather stop you!

After looking at the works of my neighbors, I came to the conclusion that it is better to order wrought-iron fences on a turnkey basis. Painted, oxidized, blued. But not welded! What do you think?

Primer-enamel

They are designed specifically to cope with existing rust. They cover the metal with a dense layer and reliably protect it from any negative influences.

| pros | Minuses |

|

|

Powder paints for forged items

The advantages of powder paints over others are undeniable: they are environmentally friendly, economical and durable. Powder painting technology differs significantly from other methods. The name of the paint speaks for itself: painting is done by applying powder on a special resin base to the metal. Advantages of powder paints:

- Wide range of colors and shades;

- High strength and wear resistance;

- Contains only environmentally friendly components;

- Low percentage of material waste during painting;

- No need for special preparation of painted surfaces;

- High anti-corrosion qualities.

Like any materials, powder paints have a number of disadvantages:

- The impossibility of “finishing”, which allows them to be used only on finished, solid products;

- Limitation of use on non-standard forms;

- Difficult to apply at home.

As a rule, powder paints are applied to finished products, such as wrought-iron furniture, in a factory.

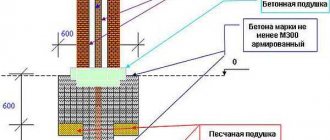

Repair of metal mesh fences

Metal mesh (chain-link, welded) is often used to make fencing for sports areas and fences for private areas (summer cottages, agricultural enterprises, etc.). Due to increased loads or for natural reasons, the pillars may become loose and the mesh may sag. In these cases, the following repair work is carried out:

- Strengthening supports. The pillars are pulled out and the pits are cleared of cement residues. Then the supports are reinstalled and filled with quick-hardening mortar. While the cement hardens, the pillars are fixed with supports and clamps.

- Tensioning the mesh. To eliminate its sagging, the supporting wire is tensioned using an auxiliary cable.

How to beautifully paint a gate?

The airbrush method allows you to beautifully paint the gate. To work, you will need an airbrush - a device similar to a spray gun, but more functional.

Photo No. 8: this is what working with an airbrush looks like

Before drawing, stock up on a sketch and paints. Where can I find the sketch? You can choose an image online or design it yourself.

Sequence of work.

- Draw the contours of the future image according to the sketch. To do this, use paper templates.

- To convey the depth of the picture, alternate light and dark shades of paint.

- Work out the small details.

- Cover the design with varnish to add shine and realism.

Examples of work performed using the airbrush method are presented below. Such designs can be applied to sliding, swing and sectional garage doors.

Photo No. 9: sports car on the garage door (airbrushing)

Photo No. 10: sea waves on the garage door (airbrushing)

No artistic talent? Here is an option that is available to everyone, regardless of skill level.

Photo #11: Canadian flag on the garage door

For the work, a simple spray gun and a paper stencil were used.

Sequence of work

We paint metal gates sequentially from top to bottom, following the following recommendations:

- cover surfaces that do not need to be painted with masking tape or tape;

- overlap one layer with another to hide transitions;

- wait for the layer to dry and paint over the missing areas;

- paint the hinges, grooves and latches with a thin brush;

- Apply a second coat after the first has completely dried (the recommended time is indicated on the paint packaging).

Important! Don't apply more paint than necessary. A thick layer reduces the strength properties of the material. The optimal number of layers is 2.

Temperature

The recommended temperature for applying paint is from +10 to +20 degrees. It is advisable that the weather be calm and the sun's rays do not fall directly on the surface to be treated.

Image No. 1: properties of enamels and varnishes

What happens if you ignore temperature advice? In 8 cases out of 10:

- the paint will swell;

- the color will turn out dull, with transitions;

- drips and sagging will appear.