Rust, which inevitably occurs on exposed metal, is a serious problem, as it gradually begins to spread over the surface, destroying the structure. In order to prevent the spread of corrosion and maintain the integrity of the structure, it is necessary to use a rust converter (neutralizer). It can be applied to any corroded area of the car body.

The converter is available in the form of a spray, paste, as well as gel and liquid; thanks to this variety, it is easy to apply to any area, including hard-to-reach places. As for the composition of the components, the basis of most products is phosphoric acid, supplemented with thickeners and auxiliary substances.

How cars are chewed

Today, corrosion has greatly weakened its position - galvanized body parts and more advanced primers and paints have appeared.

In addition, the automaker’s long-term warranty against through corrosion reassures the car owner: they say, it’s enough for my lifetime. And since cars today are replaced quite often, it would seem that there is no point in their anti-corrosion treatment. But this is only at first glance. In reality the picture is different. Firstly, the initiator of corrosion is not only the age of the car. It can actively develop even on new cars in places where there are deep chips from stones, when the paintwork is pierced to the metal. Secondly, its appearance can be triggered by body repairs after a minor accident. It’s no secret that when carrying out repair work, craftsmen often use body parts produced by their eastern neighbor. And their elements corrode much more readily than their “native” ones. Finally, the active life of a huge number of cars begins not at all with the first owner, who is accustomed to frequently updating his “garage,” but with the second and subsequent ones. All these cars are far from brand new, and their owners have no extra money. Therefore, they are interested in maximizing the safety of the purchased transport.

The word “corrosion”, as you know, comes from the Latin corrode, that is, “gnaw”. We are talking about the corrosion of the material when it interacts with the external environment. Classic methods of combating corrosion have been known for a long time, but new ones are also emerging.

How to make a converter with your own hands

Some craftsmen prepare anti-rust products on their own. This is possible with the availability of certain consumables and equipment. The procedure will be as follows:

- take a battery (12–30 V), zinc in any form, a self-tapping screw, soldering acid, wire, cotton wool and a rag;

- wrap a piece of zinc with cotton wool, then with a rag, attach a self-tapping screw with a wire to it;

- wet a rag with soldering acid, working with strong gloves;

- connect the wire to the battery;

- apply zinc wrapped in a rag to the rust area, wait 10 minutes;

- wash off the acid and accumulated plaque.

A rust converter is one of the most effective means of combating existing corrosion and an excellent method of preventing its occurrence. You should choose a high-quality composition and apply it correctly, and the result will be no worse than when the work was done by a professional.

Ways to combat corrosion

Metal corrosion is a destructive, lattice-destroying, redox chemical process. It is most often caused by the high chemical activity of the metals themselves - many remember from the school chemistry course the “line” of the activity of elements. It can be activated when unfavorable conditions are created, for example, high humidity and low temperatures, in an aggressive salt, acidic or alkaline environment.

Most often we have to deal with corrosion of ferrous metals, that is, various types of steel and cast iron, used literally everywhere, in all spheres of human activity. The process begins to reveal itself by the appearance of red stains or stains on the metal surface.

If corrosion is not dealt with, it can show its extremely destructive power - metal products quickly become unusable.

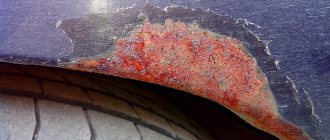

If no steps are taken, the outbreak begins to grow, capturing more and more areas. And sometimes this happens unnoticed. Thus, many areas of mechanisms, instruments, etc. - are simply hidden from view, and can only be seen when the unit or entire device is completely disassembled. And other pockets of corrosion may be hidden under a layer of paint for the time being, and only when the process has gone very far - first appear in the form of swellings, and then as rust breaks out.

Some owners try to deal with identified pockets of corrosion mechanically. That is, by grinding the damaged area with sandpaper or special discs, reaching the “healthy” metal.

However, such a technique, if it can be applied, should be done with extreme caution, and only as a preliminary step, before applying special compounds. Only mechanical cleaning is a very ineffective means.

Spot corrosion showing through the paint layer

It is especially difficult to remove small pinpoint rust using this method, since during the cleaning process they become clogged with finely dispersed corrosive dust, and they become practically invisible. But the trouble is that they don’t go away, and will definitely show themselves in the future, even after coloring. Therefore, chemical treatment is more reliable.

In addition, if thin metal is affected by rust, then during cleaning, under the pressure of brushes or abrasive material, it can be damaged down to a through hole.

In this regard, it is recommended to use chemical compounds that clean the metal and prevent the occurrence of corrosion in the future. Moreover, with their help, you can even successfully deal with outbreaks in hard-to-reach areas, where you cannot reach the affected area by any other means without disassembling the mechanism.

Basic ways to combat body corrosion

| Way | Algorithm | approximate cost | Applicability | pros | Minuses |

| Service visit | Washing, drying, applying the drug | From 15000 ₽ | Most often - the second owner who took the car for a long time | Proven technology, turnkey work | Expensive |

| "Classic painting" | Stripping, priming, painting | Correction of several paintwork defects - from 4000 ₽ | On the exterior panels of the car to give a great look | The car looks almost like new. | Considerable labor intensity, selection of paint is required, but on external panels this is practically the only way |

| "Classic" with rust converter | Rust converter treatment, stripping, priming, painting | From 1000 ₽ when working on your own | On the external surfaces of cars that have nothing to lose, and all invisible surfaces | The rust will disappear | The surface will have an uneven appearance and an unclear color. |

| "Classic" with galvanizing | Zinc-rich primer | From 500 ₽ when working on your own | It is very noticeable on the external surfaces of any car except silver ones. | Zinc will provide protective protection | Poor adhesion of zinc particles to the treated surface |

| Electrochemical | Electrochemical stripping and galvanizing | From 800 ₽ when working on your own | In places where the paintwork is damaged and corrosion has begun. | Allows you to completely eliminate the source of corrosion | A stain the color of a “galvanized bucket” remains |

| Self-treatment with Movil with zinc | Apply to areas with damaged paintwork | From 1000 ₽ when working on your own | In places where the paintwork is damaged | A high-quality product provides lifelong body protection | Movil, made using simplified technology, does not give the desired effect |

| Self-treatment with Movil with rust converter | Apply to areas with damaged paintwork and incipient corrosion. | From 1000 ₽ when working on your own | In places where the paintwork is damaged and corrosion has begun. | A high-quality product provides lifelong body protection | Movil, made using simplified technology, does not give the desired effect |

Selection rules

If the buyer wants to save money, then he should opt for neutralizers from a domestic manufacturer. Since the factories are located in Russia, companies are able to reduce prices by saving on transportation costs.

For non-professionals, it is better to purchase aerosol formulations , as they are more convenient to use. With their help you can quickly process a small surface.

If you need to clean a large area of rust, then it is more rational to purchase a liquid product. They are convenient for processing removable parts.

The choice should be made in favor of the gel when the treatment area is impressive , but it is impossible to remove the part. Such compositions do not spread over the surface.

Why does rust form?

We all remember from our school chemistry course that only iron and its alloys can rust. Rust itself is nothing more than oxidized iron. Corrosion of a metal surface is an electrochemical process that occurs only in the presence of water or moisture in the air. Salts and other road reagents only add speed to the process.

Based on this, it is clear that the body is painted not only for aesthetic reasons. The primary function of paintwork is to protect the metal from oxidation. Partly for the same reason, polishing a car body with wax. As an additional protection against corrosion, automakers often galvanize the body. The protective layer of zinc reliably prevents oxidation of the metal surface.

Types of corrosion protection products

There are several types of compounds designed to combat corrosion. These are rust converters, special primers and anti-corrosion coatings:

- One of the most commonly used and effective products are the so-called rust converters. These compositions are capable of not only removing at the chemical level, but transforming the resulting corrosion products into a protective, fairly strong film, a kind of surface primer. Such compositions are economical in consumption and perfectly perform the functions assigned to them.

An example of a quality rust converter

Converters are sold in liquid form (solutions or suspensions), and you can choose the optimal form of application, depending on the location of the damaged area - whether it will be applied with a brush, or whether using a spray is more convenient.

The converters are suitable for processing any metal parts, but provided that the thickness of the affected layer does not exceed 15÷20 microns. The composition will not penetrate deeper - it will simply cover the damaged area with a phosphate film, and the corrosion center remaining underneath will continue to corrode the metal.

- Metal primers are no less popular than rust converters. You can find different versions of these chemicals on sale - these are passivating, phosphating, protective, insulating, as well as transforming (that is, in many ways similar to the converters mentioned above) and others.

- Another group of materials for protecting metal from rust are special anti-corrosion coatings used in combination with the other materials mentioned above.

Comparison of the presented funds

The table below contains brief characteristics of the samples discussed above.

| Model | Type | Expiration date (months) | Production | Price, rub) |

| Chemist | liquid | 12 | Russia | from 77 to 199 |

| ASTROhim | spray | 36 | Russia | from 119 to 136 |

| Autoprofi | liquid | 12 | Russia | from 150 to 297 |

| "Omega PolyComPlast" | powder | 24 | Russia | from 98 to 132 |

| DINITROL RC800 | liquid | 12 | Germany | from 448 to 621 |

| KUDO 150 | gel | 36 | Russia | from 90 to 150 |

| Nanoprotech "Super Anticorrosive" | aerosol | 60 | Russia | from 272 to 339 |

Ratings on the topic: Rating of the TOP 7 best hearing aids for the elderly: which one to choose, reviews, price

Removing rust from metal surfaces

If we are talking about cars, then corrosion most often appears on the car body. It is clear that any car owner is interested in the “health” of his “pet”, and regular updates of anti-corrosion protection are entirely on the owner’s conscience. But it also happens that corrosion finds loopholes, or due to some circumstances, vulnerable areas appear on the protective layer.

If the slightest signs of damage are detected, it is necessary to take immediate action, otherwise the focus of active oxidation will not only expand, but also go deeper into the metal. If the metal sheet is eaten through by rust, then other, more expensive repair methods will have to be used.

Here you need to act quickly: if you come to your senses in time, you can still return the damaged area to its original appearance (provided you choose the right shade of paint).

Removing rust from a car body - applying converter with a brush

Any of the selected rust removers must be used in the prescribed sequence. Only in this case can you achieve the desired effect:

- The first step is to carefully clean the damaged area from loose rust using a wire brush and then sandpaper of the desired grain size.

- Next, the surface is treated with a rust converter;

- The next step is to wash the treated area several times (if specified in the instructions for the rust converter, since sometimes this is not required.)

- After this, the metal surface is dried with a rag or using a hair dryer;

- Once the surface is ready, they move on to painting work.

When cleaning, you may find that rust has already made a through hole in the metal. If it is very small, then you can try to seal it with putty using fiberglass. If the hole has reached a significant size, it is impossible to do without welding a patch, and this will require special equipment and, naturally, stable skills in carrying out such repair and restoration work. In order not to let things get to this point, you should carefully monitor the state of the car’s anti-corrosion protection in order to stop the onset of metal corrosion at an early stage.

Restoration of an area damaged by corrosion using a converter and soil is carried out in approximately the following sequence:

- Cleaning metal from loose layers of rust.

- Degreasing the cleaned area.

- Rust converter treatment.

- If necessary, the next step is puttying, and after it dries, sanding.

- Then the surface is degreased again.

- The next stage is the application of protective primer in one or two layers.

- Next comes two or three layers of adhesive primer;

- After this, the repaired area is painted in several layers.

- A special varnish is applied on top of the paint.

When performing all work using anti-corrosion chemicals, it is necessary to comply with safety regulations. A prerequisite is the use of protective equipment - rubber gloves, goggles and a respirator. If necessary, the metal surface surrounding the damaged area should be covered to eliminate the possibility of contact with the converter, primer, and finishing paints and varnishes.

It must be said right away that the complete restoration of a heavily damaged area with its subsequent finishing painting is a rather difficult task, and not everyone can do it. That is, if you have doubts about obtaining an acceptable result, it is better to turn to specialists. This is not cheap, and therefore the best solution is to try not to bring your equipment to a state that requires such intervention. That is, to nip the appearance and development of areas affected by corrosion, as they say, “in the bud.” There are a lot of resources for this.

Next, we will present a rating of the best compounds that can effectively combat the corrosion process that has arisen on the surface and in the hidden cavities of the car.

A large number of products from domestic and foreign manufacturers are on sale (both in hardware stores and in auto parts, auto chemicals and cosmetics stores, and in hardware stores). An interesting fact is that users especially highlight formulations made by companies in Russia and the USA. Products from many European brands also perform well.

The quality and efficiency of the presented products have been tested by practical application - all of them, if the technology of use is followed, give the expected result. Therefore, they are readily used by both repair service workers and home craftsmen.

It is also pleasantly surprising that consumers put domestic formulations in first place. Most likely, because they were developed taking into account Russian climatic and road conditions.

Corrosion Removal Methods

Corrosion can be eliminated in the following ways:

- Mechanical – used for severe corrosion, it involves removing rust by stripping down to metal, followed by priming, puttying and painting the area of the body being repaired;

Advantages of the method: elimination of large and deep stains, damage under swelling paint, as well as low cost and availability of the necessary materials.

Disadvantages: length of the process.

- Chemical - involves using rust removers. Such reagents are widely represented on the modern market.

Advantages of the method: elimination of corrosion in hard-to-reach places, higher process speed.

Disadvantages: inability to use on heavily damaged areas.

Step-by-step instruction

Before starting repair work, it is necessary to inspect the body and identify all problem areas. Assess the degree of damage and decide on a method to eliminate corrosion.

Before starting work you need to prepare:

- grinder;

- sandpaper;

- degreaser;

- putty;

- primer;

- paint;

- car varnish;

- rust converter;

- masking tape;

- clean cloth.

Removing rust stains mechanically is carried out in several stages:

- cleaning corrosion down to metal with sandpaper. The work can be done manually or using a power tool, such as a grinder. The stain should be cleaned gradually and carefully, avoiding rough scratches. It is important not to damage entire areas of the paintwork and to carry out 100% complete stripping down to “bare” metal.

- treating the prepared area of the body with a rust converter in order to eliminate the smallest corrosion residues that are not always visible to the eye.

- degreasing the surface after the converter ends (on average after half an hour);

- putty (carried out in several layers if necessary) and grinding of the treated surface;

- painting in body color (before painting, protect adjacent parts of the body with newspapers and masking tape and apply an anti-corrosion primer in 2-3 layers). Painting is also carried out in 2-3 layers, each thoroughly drying.

- application of clear varnish (if desired) for more reliable protection and a beautiful appearance.

The result of the work will depend entirely on compliance with all instructions and the correct execution of the work. If the technology is violated, for example, due to poor-quality cleaning or insufficient drying, the result of the work may be completely short-lived.

Watch a video on how to remove rust from a car in 10 minutes:

Chemical method

The significant difference between this method and the previous one lies only in the first stage - cleaning from rusty stains. Instead of mechanical cleaning, specialized chemicals are used. It can remove rust and prevent its further spread without damaging the metal.

As a rule, such preparations are applied to the problem area in accordance with the manufacturer's instructions for the specified time, after which the remaining product is wiped off or washed off.

However, to obtain an excellent and long-lasting result, you will also have to putty, sand and paint. When eliminating minor damage to the body, you can do without these steps.

Operating principle of converters and their composition

There are various products on sale that belong to the group of rust converters. All of them, despite the different components in their composition, work on a similar principle - they transform iron oxide into chemically inert substances. Most often, the composition of the converters is represented by orthophosphoric acid - the antipode of rust, or other acids. Such chemical elements actively react with the corrosion layer and convert it into salts, which can be easily removed from the surface of the metal product. Acid products have one disadvantage: if they are not washed off the surface after work, they themselves can become a source of corrosion.

To get rid of rust on metal and prevent its development in the future, more advanced compositions have been developed. These may include:

- Corrosion inhibitors. They protect metal bases from water, temperature changes, and aggressive chemicals for a long time. Most often, zinc acts as a corrosion inhibitor. This chemical element binds with oxygen atoms, resulting in the formation of a durable film that reliably protects carbon steel and stainless steel from destruction. In addition to zinc, manganese or tannin can act as a corrosion inhibitor.

- Thickeners. These synthetic substances are included in rust converters to facilitate application and retention on the surface. Without thickeners, the product will drain from a vertical or inclined base, and the effect will not be fully manifested.

The converters may contain additional substances - film formers, flavoring agents, various additives that enhance the effect of the main elements.

How to stop rust

If rust spots have already appeared, you need to start fighting them as quickly as possible and try to localize them. And since it is not possible to remove the process of natural oxidation, it is possible to slow down this process, as well as prevent its spread.

NITTRON is a neutral rust converter. Designed to modify corrosion on

First you need to thoroughly clean the surface of all contaminants, down to the metal. A wire brush or sandpaper will do.

This procedure must be approached very responsibly, since any small speck left will continue to oxidize the metal and you will soon have to clean everything again.

After this, you can already use the means at hand:

- Use vinegar. It is suitable for all types of metals, but you need to take into account that in this case only the most common, transparent one is used, since others can leave stains. Metal products are placed in a container with vinegar and left for several hours, but it is advisable to wait a day. After this, remove stains with a brush or sponge with an abrasive surface, rinse with water and dry the product. If it is necessary to remove rust stains from a large surface, use a sprayer.

- Use baking soda. It is necessary to dilute it with water to a thick sour cream and apply it to the contaminated area. Wait twenty to thirty minutes, then clean the surface with a brush, rinse with water and dry. This procedure can be carried out several times.

The most effective preparations for combating rust stains are the application of a chemical agent - a rust converter.

A special chemical composition, upon contact with corrosion, transforms it into a dense protective film. This helps stop the spread of rust and prepares the area for painting.

Before applying such preparations, the surface must be cleaned from dirt with a brush.

In addition to the rust spots themselves, the areas around them are treated.

After this, the converter is applied using a spray or brush, and the surface is dried naturally for a certain time specified in the instructions, which can be up to twelve hours.

The procedure can be repeated several times until the rust is completely removed.

These products are available both with and without the formation of a primer.

If you choose products without formation, then it is necessary to apply a layer of primer to the dried surface before further painting.

Do not forget that all work carried out must be carried out in well-ventilated areas, and if they take place outdoors, the area must be protected from possible precipitation and winds.

Sealing rust

Remove one of the elements of the electrochemical reaction and rust will not form. You can remove oxygen from the metal and corrosion will not spread.

In theory, if the coating seals rust well and its integrity is not compromised, then there is no reason to allow it to spread further.

Rust Encapsulator is a primer-like coating that can be applied to any material. It seals off air and water to stop further corrosion. It can be used separately from or after the converter to stop minor rust and prevent its further occurrence. This rust sealant primer has a urethane base and inhibitors to stop corrosion.

Theoretically, epoxy primer can be used to seal rust residues that have been treated with a converter and represent a stable, non-flaking base, since it creates a dense film and “cuts off” the supply of oxygen and moisture to the applied surface. However, manufacturers of epoxy primers always write in the instructions to apply them to clean metal, without traces of corrosion. Still, there is a positive experience of using epoxy primer for a minimal amount of converted rust (residues of the converter acid must be washed off and neutralized, see above). It is better to use a sealant primer specifically designed for this purpose.

Is it important to remove all rust before applying sealer primer? This is quite important, since rust is a weak link, so the coating on it will not adhere very well. A poor foundation will cause heterogeneity and damage to the integrity of the soil, which will allow moisture to enter and corrosion will reappear.

The rust sealant reacts to rust residues, neutralizes it and leaves behind a polymer coating that can serve as a primer for further coatings.

Again, any coating is not completely waterproof. Theoretically speaking, oxygen and water have a propagation speed that is not equal to zero even through a very dense paint film. This way, the rust can continue to spread, but at a much slower rate.

Rust sealant should be used:

- On thin surface rust.

- On rust of medium thickness, when it is larger than surface and spreads slightly into the metal, but does not yet affect its strength. In this case, you must first remove as much rust as possible by sanding or sanding. Next, apply 2-3 layers of sealant for better penetration.

- On bare metal. A rust sealant primer can be used on bare metal to prevent corrosion.

- On a mixed surface. Rust sealant is good to apply on surfaces with varying degrees of corrosion, mixed with normal metal and old paint.

Rust sealant does not need to be used:

- Over the rubberized surface on the bottom or over existing rust protection.

- In hidden cavities or hard-to-reach places. Rust sealant requires preliminary preparation before application (cleaning off flaking rust). The product requires full coverage to stop corrosion. In areas where preparation is not possible, it is not advisable to use rust sealant.

- Heavily corroded metal is a poor candidate for sealing.

Rating TOP 7 best rust converters

The best ranking included:

- Chemist.

- ASTROhim.

- Autoprofi.

- Omega PolyComPlast.

- DINITROL RC800.

- KUDO 150.

- Nanoprotech "Super Anticorrosive".

Let's look at each sample separately.

Chemist

Primer with zinc, which is designed to remove corrosion damage and protect metal surfaces from atmospheric and climatic influences. Forms a primer layer that ensures adhesion to any paint and varnish materials. Does not require subsequent rinsing with water. Forms a protective anti-corrosion coating. Prepares the surface for priming and painting. A bottle with a trigger allows you to apply liquid to the surface in measured doses with different spray positions, without contact with the skin.

| Production | Russia |

| Color | colorless |

| Type | liquid |

| Best before date | 12 months |

Price: from 77 to 199 rubles.

- does not require rinsing;

- reliably protects the treated surface from corrosion;

- prevents re-occurrence of rotting areas.

- eats away the paint.

I applied it several times a day and was simply delighted with the results! In place of the red one there was white soil! The mixture is good, but caustic, you need to be extremely careful not to criticize the product in vain. It gets the job done.

anti-rust Chemist

ASTROhim

Made from organic solvents. Contains a film former, tannin, functional additives and a gas-forming component. Designed for treating metal surfaces with existing rust and clean ones - to protect against its appearance.

| Shelf life | 3 years |

| View | spray |

| Color | colorless |

| Country of Origin | Russia |

Price: from 119 to 136 rubles.

- leaves no traces;

- easy to find on store shelves, thanks to the well-known name (ASTROhim);

- Can be used on bare metal due to adhesion.

- does not wash off well (2-3 approaches are required);

- strong, pungent odor.

This tool did a great job, for which I thank him very much. The only downside to this product is that it smells pretty bad when working with it. I recommend to everyone!

anti-rust ASTROhim

Autoprofi

The presented product is intended to remove severe rust and stop the corrosion process. The product is developed based on the interaction of iron oxides and phosphoric acid. Easily stops the corrosion process and creates a phosphate protective coating on the surface of metals and iron before applying primer or paint. Effectively transforms rust, stops the corrosion process and creates a durable protective coating on the metal surface.

| Suitability | 1 year |

| Manufacturer | Russia |

| Color | colorless |

| View | liquid |

Price: from 150 to 297 rubles.

- creates a durable protective coating on the metal surface;

- eliminates the effects of corrosion and prevents the appearance of new formations;

- Convenient to use, you can get to the most inaccessible places.

- none.

It actually transforms rust, and quite effectively. For more important tasks, I used drugs of this kind that are much more expensive, perhaps their protection lasts longer, but this composition is quite working. For this type of work I recommend it for use.

anti-rust Autoprofi

"Omega PolyComPlast"

Rust removal and metal phosphating occur at room temperature under normal conditions. During phosphating, a chemical interaction between the metal and the components of the rust remover occurs, resulting in the formation of a durable protective layer of insoluble phosphates on the surface, which also ensures maximum adhesion of paint and varnish coatings.

Ratings on the topic: Review of the best ovens: advantages and disadvantages of the best models

Allows you to remove rust and phosphate vertical and inclined surfaces, provide a high level of protective properties of paint and varnish coatings by inhibiting the development of under-film corrosion and increasing adhesion to metal.

| Manufacturer country | Russia |

| Release form | powder |

| Shelf life | 24 months |

| Color | white |

Price: from 98 to 132 rubles.

- Suitable for processing car parts;

- thanks to the powder form of release, it does not flow down from a vertical surface;

- provides reliable protection of the paintwork.

- if the depth of metal damage is more than 2 mm, it is necessary to re-treat.

The rust disappears miraculously. Unless, of course, you have a very thick layer. Here, processing alone will not do. The product is very effective. I recommend to buy!

anti-rust Omega PolyComPlast

DINITROL RC800

Solvent-free, water-based rust converter. The composition includes a latex copolymer with an organic complexing agent. Actively binds rust into a stable organic complex. After drying, a reliable oxygen and moisture barrier film is formed, providing effective protection against further corrosion.

| Color | white |

| Type | liquid |

| Shelf life | 1 year |

| Manufacturer | Germany |

Price: from 448 to 621 rubles.

- convenient packaging (tube with dispenser);

- thick composition (quickly applied);

- a reliable barrier film for oxygen and moisture is formed.

- none.

Anyone who wants to carry out high-quality repairs to a corrosion source and who values their time, use this product. Efficient and effective especially in local areas of corrosion. It does not corrode corrosion, but rather transforms it!

anti-rust DINITROL RC800

KUDO 150

Converts rust and forms a protective coating. The gel formula adheres well to the surface until washed off. Convenient application with a brush allows you to quickly and accurately apply the product to the damaged area.

| Manufacturer | Russia |

| Color | black |

| Release form | gel |

| Best before date | 36 months |

Price: from 90 to 150 rubles.

- forms a reliable protective coating;

- simple and convenient application with a brush;

- well suited for surface treatment for painting.

- none.

Acted according to instructions. Even after time, the paint did not swell and rust did not reappear. I recommend this product for purchase and use.

anti-rust KUDO 150

Nanoprotech "Super Anticorrosive"

Powerful protection against any aggressive influences. A durable invisible nano-coating will reliably protect external and internal surfaces of all types of transport, industrial, agricultural and construction equipment from corrosion for at least 1 year! It has pronounced protective, anti-corrosion, lubricating and penetrating properties, confirmed by technical certificates, laboratory tests and tests. The coatings have a unique composition, are high-tech and very practical.

| View | aerosol |

| Manufacturer | Russia |

| Best before date | 5 years |

| Color | transparent |

Price: from 272 to 339 rubles.

- easily penetrates into hard-to-reach places;

- works on wet surfaces;

- invisible durable coating;

- is universal (passenger cars, trucks, motorcycles, construction, agricultural equipment).

- none.

My husband applied the anticorrosive agent according to the instructions, the result is good, it really protects against moisture and corrosion. He is satisfied with the products of this manufacturer and has used them more than once. Can be used not only on cars, but also on other things.

anti-rust Nanoprotech Super Anticorrosive

Removing rust with potent agents

There are chemicals for removing rust (rust remover or rust dissolver - rust remover or solvent). Rust remover removes rust using a strong, concentrated acid. This can be hydrochloric, oxalic, phosphoric (higher concentration than in the rust converter) or other acid.

Of course, rust removal is a better option than converting or sealing it, and is a concrete answer to the question “how to remove rust from a car?”, but this remedy has its own characteristics and disadvantages.

Features of rust remover:

- Rust remover is most often used as a product that requires soaking a rusty part, so it is mainly used to remove corrosion on small parts. However, this product can also be used on large surfaces. For stationary parts with a large area, it is necessary to apply the product, then cover it with plastic film to prevent its evaporation.

- Hydrochloric acid and oxalic acid, as the main active ingredients of rust remover, are very toxic, so rust remover must be used with extreme caution.

- Strong acids have an adverse effect on metal, especially if the action is too long. After this action, the corrosion resistance of the metal is weakened.

Considering all the above features of rust removers, they are still used when removing rust on the body. An important point after using such a product is to wash off the acid and neutralize its residues.