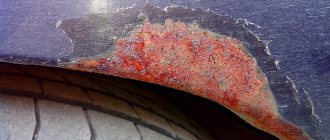

Motorists quite often encounter the problem of body corrosion. For long-term operation, the machine requires urgent troubleshooting. In everyday life, there is also often a need to remove rust from metal surfaces, which are quite difficult to clean mechanically. In this regard, to clean rusted parts and other elements, a rust converter is used, which will help preserve metal components from corrosive processes for a long time. For maximum effect, you need to know what a rust converter is, what types of compounds there are and the rules for their use.

Composition and main characteristics

A rust converter is a product based on special compounds that convert corrosion elements into a protective film that tightly covers the metal. The rust converter contains dissolved orthophosphoric acid, sometimes replaced by a zinc salt.

When the substance comes into contact with rust, a layer of zinc compounds is formed, which has a high corrosion protection rating when compared to ordinary metal. To know how to use the compositions correctly, how this or that mixture works, as well as which converter is better, it is important to carefully read the information provided by the manufacturers and consult with a specialist.

Anti-corrosion compounds for metal are available in 3 types:

- suspension;

- solution;

- emulsion.

High density and excellent protective properties allow the product to be used as a preliminary element before applying paint. The acid contained in the composition affects iron oxides, converting them into orthophosphate salt. Compositions based on zinc compounds combine with oxygen atoms, resulting in a film on the surface that protects the metal from repeated corrosion.

It is not recommended to use a rust converter in soil if the thickness of the corrosion is more than 0.1 mm. In such cases, you need to use special grinding machines or remove the damaged layer using coarse sandpaper.

Precautionary measures

Phosphoric acid contained in the converter is explosive and toxic. For this reason, you should work with the composition very carefully. It is imperative that the work area is well ventilated. Hands and face are protected with gloves and a respirator, respectively. Instead of a respirator, you can use a cotton-gauze bandage.

If the solution does get on the skin or mucous membranes, you should immediately rinse these areas with plenty of water.

If you experience a burn from the solution or an allergic reaction, it is better to immediately contact a medical facility.

Store this substance in places where children cannot reach it.

Types of product

The converter is available in different types. This is how sprays, pastes and liquids are presented on the market. The aerosol is also very convenient to use. Before using a rust converter, experts strongly recommend consulting with a specialist. This is primarily due to the fact that each paint has individual characteristics and a different chemical composition.

The most common compositions are the following:

- Primer with rust converter. Performs a modifier function, i.e. creates the base needed before painting.

- Stabilizing mixtures. Unstable components of corrosion, coming into contact with them, become more stable.

- Converting compounds. They influence rust, turning it into slightly soluble salts.

- Penetration. During processing, compaction of corrosive products is observed.

How to improve efficiency

To increase the effectiveness of this tool, you should consider the following recommendations:

- Prepare the surface for application as thoroughly as possible;

- do not use the product if there is high air humidity, or if the surface itself is not dried;

- Do not apply the composition in a thick layer;

- Do not neglect the washing stage.

Products from famous manufacturers

There are several brands of this product on the modern market. We will discuss below which rust converter to choose, as well as the distinctive characteristics of the compositions. The most popular brands of compounds:

- Rust converter Tsinkar is a fairly effective tool in the fight against corrosion. When applied, iron oxide is converted into phosphates, and zinc and manganese react. All this creates a durable protective layer on the metal surface.

- Hotex rust converter is a water-based composition; the operating principle is a combination of cold phosphating with surface passivation and further preservation with effective corrosion inhibitors. Suitable for processing ferrous and non-ferrous metal structures.

- Converter SF 1 is a phosphate-based composition, widely used for cleaning steel, cast iron, galvanized and aluminum surfaces before applying a coat of paint.

- Fenom rust remover – neutralizer increases the adhesion force of the coating to the treated area. When carrying out welding work, the film formed on the surface does not in any way affect the quality of the seam. As a rule, the composition protects well against corrosion for 6-7 years.

- Rust converter with zinc Chemist is a highly effective composition that is in considerable demand. Capable of removing corrosive processes and creating a reliable protective anti-corrosion coating. Use primarily before painting, without reducing the thickness of the metal.

Before choosing the best rust converter, it is important to study the composition and functional features of each. Tsinkar has the following advantages:

- economical consumption;

- acceptable price;

- Thanks to the shape of the bottle, the composition is convenient to use;

- The presence of a sprayer ensures uniform spraying of the product over the entire surface, also reaching hard-to-reach places.

In the video: how to remove rust from a car body using zinc.

Instructions for use

To achieve the greatest results from using Tsinkar, you should strictly follow the recommendations for its use.

Surface preparation

Before painting the surface, you should first prepare it for this process. If it is not cleared of rust, and that which has a loose structure and comes off on its own, Tsinkar will not be able to help. Moreover, in this situation its use is strictly prohibited.

To get rid of interfering factors, you should use any methods: brushes, abrasives, sandpaper and others. The best option is a specialized metal brush. But this is not for a large area. If you have a large surface to clean, it is better to use a grinder or drill with a special attachment.

If there is an old layer of paint, it can be scraped off or washed off. But this must be done.

Before using the Tsinkar product, you should shake it thoroughly, as sediment will form at the bottom.

If the solution was purchased in the form of a cylinder, then no additional items will be required to use it. If the product is purchased in the form of a container or canister, then it is better to stock up on several things: a small container, a brush and a roller. This is necessary for more convenient use.

If the surface is already quite old, then for greater effectiveness of the product, it should be primed in 1-2 layers.

Application

You can apply the product in any convenient way. But depending on it, the consumption of the converter also varies. For example, if you use a brush or roller, the consumption will increase.

To save money, you can use spray bottles.

If a large area requires treatment, then the best option would be to use a paint spray gun. Thanks to it, the layer will be thin and uniform.

Each subsequent layer is applied only after the previous one has completely dried.

Drying time

The average drying time for one layer is approximately 1.5 hours. It depends on the air temperature and its humidity.

The layer is considered completely dry if a grayish-white coating appears on it.

Fluid flushing

After applying the product, be sure to wait for it to dry completely. After this, the treated surface should be wiped with a dry cloth. The plaque remaining after the procedure is removed with a special remover. It is based on silicone and organic solvents. But you can also do this with a regular rag soaked in water. But the water must be warm.

You shouldn't get too carried away with the process. This has a negative effect on the applied layer. And if you overdo it, the resulting protection will be damaged.

When further painting the treated surface, nothing will need to be washed off.

Consumption rate

How much the solution will take to process depends on how many layers there will be, the area of the treated surface, and how the composition will be applied.

The more layers, the more money will be spent. On average, up to 350 ml of converter is consumed per m2.

The expenditure of funds also depends on the surface area. The larger the area, the more will be spent.

It is best to use a spray gun or a bottle with an existing sprayer, as they will help save money. But if it is not possible to purchase them, then you should use a regular paint brush or roller.

Application of the composition

Preparatory work and application of the composition is divided into several stages. To know how to use anti-corrosion substances, instructions for use are provided:

- Degreasing the damaged surface.

- Cleaning from dirt and dust.

- Apply to the affected area.

After 15 minutes, the rust turns gray and can be washed off with water. After the surface has completely dried, the area is primed and paint is applied. The consumption of one bottle of the composition (0.5 l) averages 80-100 ml/1 m². Usage on average is the same for all products, but you should carefully read the information on the packaging about consumption per 1 m².

If we talk about whether it is necessary to wash off the rust converter and how this can be done, it is best to use the rough side of a sponge, previously moistened with water, when washing off.

How can I wash off the converter?

Before using any product, do not forget about the instructions, especially if it is a rust converter. There are products that do not need to be washed off, these include Cortamine F and Phosphamite.

But it is still necessary to remove most of the converters from the surface. As a rule, information on how to wash off the composition can be found on the label. Experienced motorists use silicone remover or white spirit for these purposes, and some prefer to use ordinary water.

DIY making

The rust converter contains rather complex components and substances, but it can be made at home. Do-it-yourself rust converter is made on the basis of phosphoric or orthophosphoric acid, which are needed in certain proportions. Acids in the correct ratio are mixed with plain water.

There is also a less expensive method that involves the use of the following components:

- distilled water;

- baking soda;

- lemon acid.

You need to dissolve the acid in water, then add soda. The reaction that appears lasts 30-40 minutes, after which you need to dip a rag into the composition and soak it well in the solution. For safety reasons, the use of rubber gloves is highly recommended. The rag is placed briefly on the affected area, which is then better cleaned. We choose this composition for treating surfaces and removing even deep lesions.

Treatment of metal surfaces using transducers is possible if the affected area is no more than 30%. Otherwise, the use of an anti-corrosion composition will be ineffective.

The products are applied by roller, spray or brush, depending on the type and location of the surface being treated. When working, you must use protective equipment, as the components can adversely affect the eyes and respiratory tract.

Methods for removing rust at home (2 videos)

Converter of different brands (30 photos)

About metal corrosion

The most famous process for the destruction of metallic iron is electrochemical corrosion. The interaction between iron and the surrounding electrolytically conductive environment results in the formation of hydrated iron oxide or rust. This happens due to the desire of the metal produced from ore to return to a more stable state with less energy.

Electrochemical corrosion in action

The generally accepted mechanism of this type of corrosion is explained by the laws of electrochemical kinetics and is characterized by the speed of electrode processes - anodic and cathodic. When metal surfaces come into contact with electrolyte solutions, iron ions pass into solution (anode process) with their subsequent release on the metal surface in the form of neutral particles (cathode process).

The most common destruction of metals is under the influence of the atmosphere, since 80% of metal structures are located in the open air. The influence of water adsorbed from the air (the influence of air humidity) and oxygen penetrating the metal-water interface create conditions for electrochemical corrosion. Additional factors that enhance the effect of destruction are aggressive gases and mechanical impurities. Thus, in industrial areas with high humidity, the corrosion rate is higher.

Analogs

Not only Tsinkar, but also its analogues will help get rid of rust. Here are some decent options.

Sonax rostumwandler & grundierung

Designed for minor body work and protecting small areas on metal. It is good for loosening nuts and bolts.

Its main advantage is that it can be used even in places where there is paint. And this is despite its toxicity.

As soon as the product dries, a thin polymer film is formed, which plays a protective role. In addition, it is a kind of primer before applying paintwork.

One of its main disadvantages is that it is produced in small volumes. If you need to process a large surface, you will have to spend a large amount of money on its purchase. And one bottle costs about 230 rubles.

Chainmail

Chain mail is a Russian product. The composition contains zinc. This drug perfectly fights corrosion and performs its protective functions.

One of the features of “Kolchuga” is the absence of acids in its composition. This product can be used as a primer, but it does not require rinsing off.

Another advantage is the relatively low cost. One bottle can be purchased for 130 rubles.

Hi-gear rust treatment

When severe corrosion is found on the metal, conventional converters will not be suitable. Most likely, you will need the most powerful tool, which is Hi-gear rust treatment. The bottle of this product has a sprayer, thanks to which a large area is treated in a short time. The result of this product is the elimination of corrosion and the formation of a polymer layer on the surface.

When using this product you should be very careful. Respiratory protection is required. It is important that the composition does not get on already painted areas.

This composition should definitely be washed off. Moreover, this should be done not with water, but with an alcohol-containing solvent.

One of the disadvantages is the high cost - one bottle can be purchased for 700 rubles.

Video: comparison of rust activators

Comparative table of Tsinkar and analogues

| Means | Price |

| Tsinkar | from 40 rubles |

| Sonax growth umwandler grundierung | about 230 rubles |

| Chainmail | about 130 rubles |

| Hi-gear rust treatment | 700 rubles |

User reviews

Here is a review left by a buyer of this product:

“When I tried it for the first time, I was very pleased with the quality. Easily transforms rust with the release of gas bubbles, which indicates a rapid reaction. Naturally, you shouldn’t expect a miracle; rust won’t turn into metal, and don’t think that it can cope with a thick layer of rust. Therefore, if you want to do it efficiently, you should first work with a metal brush, and then only apply a converter that eats the rust out of the recesses, which cannot be done mechanically without damaging the good metal. There is also a container with a spray bottle for convenience, of course. There is only one drawback: in my opinion, the price of such a volume of the converter (0.5 liters) is too high.” – Gregory left his review.