Corrosion processes that occur on products made of metal are completely natural and logical. They begin on steels and other metals in areas where the protective coating is damaged due to contact with water, as well as various aggressive media such as acids or alkalis. Serious temperature changes and atmospheric factors play an important role in their appearance. In order to fight corrosion, as well as to get rid of existing defects, a so-called rust converter was developed.

Additional 5% discount on Ozon Express products on the table when purchasing over 1,500 rubles using promotional code OZONHBP235 for products from this page!

Today there are quite a lot of varieties of a similar composition - with their help you can significantly extend the service life of a metal product. Products can differ greatly from each other in chemical composition, principle of action and a number of other factors. In our review of the best rust converters, we will try to figure out on what basis you should give preference to one or another product, and we will also provide a list of the most popular products indicating the main performance characteristics.

What are rust converters, what is it used for, how does it work?

A rust converter is a chemical compound.

How it works? Once applied to the damaged area, phosphoric acid, which is part of most modifiers, acts on iron oxides, especially iron (III) oxide.

As a result of a chemical reaction, a protective barrier is created due to the transformation of corrosion products.

If the converter contains zinc compounds, the operating principle is different. Zinc atoms combine with oxygen to form a film. Provides protection and prevents further rust formation.

Additional components also take part in the chemical reaction, ensuring the inactive state of the protective layer formed on the surface.

Types of rust modifiers

The industry produces the following types of car rust converter:

- Zinc. All zinc preparations are popular. A layer of zinc applied to the body prevents corrosion from reoccurring. Before the operation, the rusty surface is cleaned, ground and treated with an electrolytic zinc solution. Experts note that the optimal time to apply a zinc rust converter is when a gray coating appears on the metal.

- Acid. Such drugs suppress the development of corrosion at an early stage. This is important because the car body is usually made of thin metal. If the rusting process begins, the part quickly rots and pitting can form. Consequently, expensive elements will have to be redone. If a part of the body is coated with this modifier, a layer of corrosion simply does not form, and the driver does not need to change the fender liners or hood over time.

- Rust converters into soil. These are new generation modifiers. Unlike phosphoric acid-based products, they do not create a protective layer on the metal, but rather convert the rust into a primer. These primers are popular abroad, but in Russia motorists tend to choose between zinc-based and acid-based products.

Selection rules

Before purchasing a rust modifier, it is recommended to analyze the purpose of its further use, since each drug interacts with metal differently.

To restore the damaged surface of the body, it is recommended to opt for a primer. If you need to treat areas that are not prone to further staining, then the best option is products with the addition of special stabilizers.

When choosing a converter, the manufacturer also plays an important role. A trusted brand serves as a guarantee of the quality and effectiveness of the product.

The cost, as a rule, is slightly higher, but the result is an order of magnitude higher than that of little-known companies. This is explained by constant testing of products, control of all stages of product creation by well-known manufacturers.

The release form should also be taken into account. Before painting, it is recommended to use a concentrated composition. If the area to be treated has a large surface, it is recommended to choose an aerosol. This will make the application process much easier.

Comparison of presented products

Based on the rating compiled above, we have organized a table containing the main technical parameters of each model.

| Model | Volume (ml) | Type | Weight, kg) | Price, rub) |

| ASTROhim | 140 | aerosol | 0. 600 | 135 |

| Phenom | 110 | solution | 0.615 | 150 |

| Permatex 81773 | 120 | solution | 0.645 | 200 |

| Hi-Gear | 370 | aerosol | 0, 830 | 300 |

| Autoprofi | 410 | aerosol | 1 | 150 |

| ABRO RC-1000 | 400 | solution | 0,850 | 350 |

| LIQUI MOLY | 380 | aerosol | 0.800 | 350 |

Best Liquid Rust Converters

Fenom FN956

This rust to earth converter protects the metal surface of your car before painting. The action of the drug is carried out by creating a film of ferromanganese phosphate, due to which the adhesion of the treated metal to the applied paint or bitumen coating increases three times.

Fenom FN956 applied to the surface does not interfere with the welding process and does not impair the quality of the seams. Without compromising the technology of applying the drug and the rules of painting, the manufacturer guarantees protection of the car from corrosion for a period of 5 to 7 years, depending on the operating conditions of the vehicle.

Dignity

- Effectively removes rust;

- After anti-corrosion treatment there is no need to rinse off;

- Long-playing;

- Dries quickly;

- Well absorbed.

Flaws

- Small volume;

- Expensive.

Opinions about this drug are very different, for some it completely coped with removing corrosion, for others it did not help at all. But all consumers agree that the cost of the drug is too high given its small volume, only 110 ml.

Chemist

This liquid zinc converter is designed to remove corrosion damage and protect the metal of the car from external negative environmental influences. The product is used to prepare the surface of the car for applying primer or paint. When using this composition, a whitish zinc coating appears on the affected area and a primer layer is formed, which helps improve the adhesion of the treated metal to the paint. Available in 500 ml plastic bottles.

Dignity

- Acts quickly;

- Does not require rinsing;

- Effectively removes rust;

- Reliably protects the treated surface from corrosion;

- Prevents the reoccurrence of rotting fire.

Flaws

- Poisonous;

- Slightly blurs the paint.

Car owners who have used “Chemist Rust Converter” recommend applying the product very carefully and only to a specific surface, since there have been cases of damage to headlights and car paint when the product gets on them.

“Eltrans”, 500 ml. EL-0702.02

Eltrans is made using a simple recipe: one part water, one part phosphoric acid, plus a small inhibitor. Rust can be turned into neutral soil with just a small thickness of oxide, so sanding cannot be avoided. When the reaction takes place and the surface is completely dry, the iron is covered with a light phosphate film. Protects against repeated corrosion.

Professionals

- actively interacts with rust;

- creates a neutral phosphate layer on the surface.

Flaws

- not found.

"Astrohim"

The Astrochem product works thanks to a solution of phosphoric acid. In conditions of small thickness of rusty deposits, it forms foam upon contact with the converter and after about an hour turns into a solid layer of chemically neutral soil. The product formula includes particles of a protective metal - zinc, which, after drying on the steel, provides additional protection against “red flaking”. At the same time, the manufacturer does not recommend delaying painting, which means there is no guarantee of resistance to rain and condensation.

Professionals

- not so expensive;

- The main function works without any glitches.

Flaws

- it is necessary to wash off the residue with water;

- leaving it without paint for more than a day is risky.

DINITROL RC800

Water-based, solvent-free rust converter. The composition includes a latex copolymer with an organic complexing agent. Actively binds rust into a stable organic complex. After drying, a reliable film, impermeable to oxygen and moisture, is formed, which provides effective protection against further corrosion.

| Color | white |

| View | liquid |

| Shelf life | 1 year |

| Director | Germany |

Price: from 448 to 621 rubles.

- convenient packaging (tube with dispenser);

- thick composition (applied quickly);

- a reliable barrier film for oxygen and moisture is formed.

- missing.

Those who want to carry out high-quality repairs to the very essence of corrosion and value their time will use this tool. Efficient and effective, especially in local areas of corrosion. It does not corrode, but transforms!

anti-corrosion DINITROL RC800

LAVR Rust remover

The “10 minutes” series liquid is suitable for treating heavily corroded surfaces. LAUREL quickly penetrates the rust layer.

The formula consists of:

- mixtures of organic and inorganic acids,

- Non-ionic surfactants,

- phosphates,

- phosphonates.

According to the instructions, the sensor is spread over the surface with a sponge, rag or brush. If the bottle has a spray bottle, spray the product from a distance of 15-20 cm. After a quarter of an hour, the remaining chemicals and rust are wiped off. Rinse the metal with water and dry.

A 500 ml bottle with a trigger costs an average of 200 rubles. There are practically no complaints in the reviews. The only caveat is possible irritation of the skin of hands without gloves. The effectiveness, ease of use, reasonable price, and cost-effectiveness of LAVR were unanimously recognized.

SONAX RostUmwandler & Grundierung

Sonax is designed to remove rust from metal surfaces. It can be used for body work and as a tool to help loosen rusty bolts through threads.

Sonax does not contain acids that would react with paints and varnishes. Despite this, the drug is very toxic. Once dry on metal, Sonax forms a polymer coating that can be used as a primer.

It can only be used with personal protective equipment.

Professionals:

- affordable price;

- good execution;

- no acids in the composition.

Flaws:

- insufficient volume for a large volume of work;

- price.

Step-by-step instruction

Before starting repair work, it is necessary to inspect the body and identify all problem areas. Assess the degree of damage and decide on a method to eliminate corrosion.

Before starting work you need to prepare:

- grinder;

- sandpaper;

- degreaser;

- putty;

- primer;

- paint;

- car varnish;

- rust converter;

- masking tape;

- clean cloth.

Removing rust stains mechanically is carried out in several stages:

- cleaning corrosion down to metal with sandpaper. The work can be done manually or using a power tool, such as a grinder. The stain should be cleaned gradually and carefully, avoiding rough scratches. It is important not to damage entire areas of the paintwork and to carry out 100% complete stripping down to “bare” metal.

- treating the prepared area of the body with a rust converter in order to eliminate the smallest corrosion residues that are not always visible to the eye.

- degreasing the surface after the converter ends (on average after half an hour);

- putty (carried out in several layers if necessary) and grinding of the treated surface;

- painting in body color (before painting, protect adjacent parts of the body with newspapers and masking tape and apply an anti-corrosion primer in 2-3 layers). Painting is also carried out in 2-3 layers, each thoroughly drying.

- application of clear varnish (if desired) for more reliable protection and a beautiful appearance.

The result of the work will depend entirely on compliance with all instructions and the correct execution of the work. If the technology is violated, for example, due to poor-quality cleaning or insufficient drying, the result of the work may be completely short-lived.

Watch a video on how to remove rust from a car in 10 minutes:

Chemical method

The significant difference between this method and the previous one lies only in the first stage - cleaning from rusty stains. Instead of mechanical cleaning, specialized chemicals are used. It can remove rust and prevent its further spread without damaging the metal.

As a rule, such preparations are applied to the problem area in accordance with the manufacturer's instructions for the specified time, after which the remaining product is wiped off or washed off.

However, to obtain an excellent and long-lasting result, you will also have to putty, sand and paint. When eliminating minor damage to the body, you can do without these steps.

The best gel rust converters

PERMATEX Rust Treatment

Rating (2021): 4.56 Reviewed 23 reviews from resources: Yandex.Market, Otzovik, OZON

The composition quickly penetrates the metal structure and turns rust into soil. On average, the reaction takes only 2-3 minutes. The second layer can be applied after 15-30 minutes.

- Characteristics Average price: 800 rub.

- Country: USA

- Scope of application: automotive, household

- Active ingredients: vinylidene acrylic copolymer mixture, barium sulfate, organic acid

- Operating temperature range: +10°C to +32°C

- Volume: 236 ml

High-quality gel transformer from a famous American brand. It boasts efficiency and simplicity. To get a good result, simply apply the product to the prepared surface and wait 2-3 minutes. In this case, there is no need to thoroughly clean the metal - it is enough to remove loose rust and remove dirt. If you believe the reviews, the modifier turns into an excellent primer and protects the base from destruction for a long time. Despite the fact that Permatex is practically non-toxic, it contains aggressive components. When working, you need to be as careful as possible: if the mixture settles on the car’s paint, it will be very difficult to remove it, and the coating may be damaged.

Advantages and disadvantages

- Virtually non-toxic and safe to use

- There is no need for extensive preliminary cleaning of the surface - it is enough to remove loose rust and dirt

- Can be applied to wet metal

- The resulting polymer film can serve as a primer for subsequent painting.

- Quick effect

- High price

- Very sticky: if it sticks to the paint, it will be difficult to clean

- Not suitable for car exterior parts

See also:

- 10 Best Scratch Removers

Agat-Avto "Tsinkar"

- Characteristics Average price: 213 rub.

- Country Russia

- Scope of application: automotive, household

- Active ingredients: phosphoric acid, zinc, manganese

- Operating temperature range: +10°C to +35°C

- Volume: 500 ml

An excellent product from a Russian brand, about which you can say “cheap and cheerful.” Suitable for car care and any metal structures. For 25 years, it has proven itself to be an effective product that can cope with any task. Zincar not only turns rust into soil, but also creates a special active protective layer that prevents further destruction of the metal. This is one of the most effective mixtures, and compared to its competitors, it is also very economical. Deep cleaning occurs due to the content of aggressive components that cause corrosion. They are toxic and precautions should be taken when training.

Professionals

- Effectively eliminates corrosion and forms an active protective layer

- Budget

- Large areas are also easy to manage

- Not temperamental at work

- Available in different volumes from 60 ml to 11.5 l

Against

- Requires thorough rinsing

- Complete cleaning takes a long time

- The surface must first be cleaned

- Toxic: precautions must be taken

- Incompatible with paints and varnishes

KerryGel formula KR-240

KR-240 gel uses phosphoric acid as an active ingredient, to which a so-called structure modifier is added. The last component destroys the crystal lattice of rust, giving way to the active substance deep in the corrosion products. After processing, the metal is coated with an iron-zinc phosphate film, which prevents the development of corrosion. But this does not mean that the iron can be left unpainted. In addition, the operating instructions provide for mandatory rinsing of acid residues and debris with plenty of water.

Professionals

sinks deep into the rust layer;

creates the effect of cold galvanizing.

Flaws

it must be washed off;

weakly resists relapse without further treatment.

Rust remover AKEMI 10814

This is a special preparation intended for use on acid-resistant surfaces - natural or patterned stone. The substance allows you to reliably protect the material from subsequent manifestations of corrosion processes. It comes in gel form, making it very convenient to apply and use.

The composition contains inorganic, non-inogenic acids, capable of self-decomposition under natural conditions, and all kinds of anti-corrosion additives. The composition does not contain hydrochloric acid, and there are no substances that can severely corrode the skin - you can work even without gloves, but the manufacturer still recommends taking care of the skin.

The principle of operation is approximately the same as that of compositions intended for metal processing: corrosion processes stop, and the rust layer itself quickly dissolves. In this case, the applied product turns into a full-fledged primer, which, when dried, forms a film through which air, water vapor and water cannot penetrate. The stone regains its original appearance and its service life increases significantly. Rust does not develop on the treated surface.

Advantages:

- Leaves no traces after use;

- Features high adhesion;

- Return natural and artificial stone to its original appearance.

Flaws:

- Strong odor so should only be used outdoors.

B-52 Vershina

>

The cheap gel has a viscous consistency, which is very convenient when applied to vertical plates. The composition does not drip and does not leave halos or puddles. The reaction with rust is quite strong, since the formula includes a mixture of mineral acids and corrosive salts. It should be understood that this is not a converter, but a destroyer of corrosion products. Therefore, after each course of treatment, contamination must be removed with an alcohol solvent. If you rinse with water, “mushrooms” will immediately appear on clean iron. As a result, metal cannot be left unpainted - relapse is inevitable.

Professionals

- inexpensive product;

- The gel is convenient to use.

Flaws

- does not convert oxide into soil, but only corrodes it;

- cannot be washed off with water - only solvent;

- does not create protective layers on the surface of the processed steel.

The Best Aerosol Rust Converters

Liqui Moly "Pro-Line Schnell-Rostloser"

Liqui Moly "Pro-Line Schnell-Rostloser" rust converter is an excellent product in every way. Despite its high cost (which is the only drawback), it has a subtle and targeted effect on corroded metal, allowing it to be completely treated in a few minutes.

The mechanism of action of this solution combines the principles of WD-40 and the modifier to which we are accustomed: by neutralizing rust, it cleans the moving joints (and allows them to unfold), and with subsequent washing it forms a protective film on the surface. The latter is the result of the action of filling materials, which contain zinc ions. Liqui Moly "Pro-Line Schnell-Rostloser" is neutral in relation to paint and therefore does not pose the slightest danger to it. Can also be applied to dirty surfaces - excellent penetrating action will remove both rust and dirt. In general, among other things on equal terms, this converter stands out favorably, thanks to which it takes a well-deserved first place.

Professionals

- neutral to paint, soil;

- high penetrating effect;

- a complex of additives ensures lubrication of moving parts and jams them (for example, WD-40);

- 400 milliliters volume;

- creating a durable film on a metal surface.

Against

- high price.

KUDO 150

Converts rust and forms a protective coating. The gel formula ideally adheres to the surface until washed off. Convenient application with a brush allows you to quickly and accurately apply the product to the damaged area.

| Director | Russia |

| Color | black |

| Release form | gel |

| Shelf life | 36 months |

Price: from 90 to 150 rubles.

- forms a reliable protective coating;

- easy and convenient application with a brush;

- Suitable for surface treatment for painting.

- missing.

I acted according to instructions. Even after some time, the paint did not swell and rust did not appear again. I recommend this tool for purchase and use.

Nanoprotech "Super Anticorrosive"

Powerful protection against any aggressive influence. A durable invisible nano-coating will reliably protect the external and internal surfaces of all types of transport, industrial, agricultural and construction equipment from corrosion for at least 1 year! It has strong protective, anti-corrosion, lubricating and penetrating properties, confirmed by technical documentation, laboratory tests and tests. The coatings have a unique composition, are high-tech and very practical.

| Visualization | aerosol |

| Director | Russia |

| Shelf life | 5 years |

| Color | transparent |

Price: from 272 to 339 rubles.

- easily penetrates into hard-to-reach places;

- works on wet surfaces;

- durable invisible coating;

- universal (cars, trucks, motorcycles, construction, agricultural machinery).

- missing.

My husband applied the anticorrosive agent according to the instructions, the result is good, it really protects against moisture and corrosion. I am satisfied with the products of this manufacturer, I have used them more than once. It can be used not only on cars, but also on other things.

Anticorrosive Hi-Gear HG5754

A powerful and effective rust remover that is very popular among domestic motorists. The modifier copes well with iron oxides and film corrosion. During the reaction of the active substances, a moisture-resistant protective coating is created, which also improves the adhesion of the metal to paints and varnishes. Before treatment, the surface must be cleaned of dirt and dried.

Professionals

- Efficiency

- Long-term corrosion protection

- Use as a primer

- Uniform distribution over the surface

- Speed reaction

- Ease of use

- Shelf life

Against

- Aggressively affects paint

- A complete alcohol rinse is required.

Eltrans EL-0702.06

Rust converter in the form of an aerosol made in Russia. The product contains highly dispersed zinc and natural tannins, which convert rust into a dissolved substance and create a reliable protective film that replaces soil. The composition easily penetrates into any cracks and micropores, even in hard-to-reach places, and improves the adhesion of metal to paints and varnishes.

Professionals

- Efficiency

- Fast drying

- No rinsing required

- Ease of use

- Acceptable price

- Versatility

- Replaces soil

Against

- Significant expenses

- Not applicable at temperatures below + 10 ° C

LIQUI MOLY Keramik Rostloser mit Kalteschock

An effective rust remover from a well-known manufacturer of auto chemicals. Before processing, the metal does not require preliminary preparation, and the product itself is neutral to the paintwork and plastic elements of the car. Rust dissolves very quickly due to the temperature difference and the high penetrating ability of the modifying active substances. After processing, a protective film with ceramic particles is formed on the metal, preventing the reappearance of the oxide.

Professionals

- High efficiency

- No metal pre-treatment required

- Dissolution rate

- Ease of use

- Neutral to paint and plastic

- Creation of an effective protective layer

- Preventing metal re-oxidation

Against

- Not found

ABRO RC-1000

The American composition RC-1000 from ABRO is available in aerosol cans of 283. The cost is a little high, since there are many analogues that are equally effective and inexpensive. The modifier quickly dissolves rust, turning it into a layer of soil.

In this case, a moisture-resistant protective coating is obtained that improves the adhesion of the metal to the paint. After treatment, the surface can be painted immediately. To avoid the formation of drops, the composition is applied in thin layers in 2-3 doses with intervals between applications of about 2 minutes.

Advantages:

- rapid transformation of the oxide layer into the soil;

- surface readiness for painting;

- ease of use;

- reliable protection against recurrence;

- no need to rinse off.

The only complaint from users is that it is a little overpriced. There are cheaper analogues on the market that are not inferior in effectiveness to the well-known American brand.

Autoprofi

The aerosol rust converter is produced not in a regular can, but in a spray bottle. Unfortunately, surface treatment with this product cannot be called very convenient. Primarily because drops are formed. This indicates that the modifier is wasted. Packaging capacity – 500 ml. The adjustable spray pattern allows the sensor to be used in a wide variety of locations, even in hard-to-reach areas. Manufacturers state that there is no need to rinse off after use. However, practice shows that this stage should not be missed. To better extinguish acid residues, use water with added soda.

Advantages:

- speed of action;

- classic components;

- preventing the emergence of new areas of corrosion;

- ability to manage hard-to-reach places;

- low price.

Flaws:

- wasteful waste (droplets on the surface);

- If you do not use a solvent, the paint will not adhere well.

AVS AVK-101

The spray is used to treat car parts to prevent repeated negative effects on them from the external environment. The composition transforms rust into a durable, moisture-resistant protective coating that can be used as a base for painting. The bottle capacity is 500 ml.

Advantages:

- ease of use;

- quickly and effectively convert a layer of rust into a protective coating.

Disadvantage - limited scope (the composition is used only for cars).

ASTROhim

An effective rust neutralizer from a domestic manufacturer. Available in the form of an aerosol and composition in cans. The latter option, according to many users, is more profitable. Firstly, because a 0.5-liter jar of solution is not much more expensive than a 250-milligram aerosol can. Secondly, aerosol is not always available for sale.

The low price of ASTROkhim does not mean that it is ineffective. It is able to successfully compete with expensive products from other companies. The heart of the product is phosphoric acid, which destroys the oxide layer. The composition is applied with a brush, then the rusty layer is removed with a special napkin. In this case, a film appears on the surface, providing good adhesion to coatings. Therefore, ASTROkhim is also used as a preventive agent on clean metal before painting.

Advantages:

- good quality of cleaning;

- low price.

Minus: you need to wash it as thoroughly as possible.

Ways to combat corrosion

Metal corrosion is a destructive, lattice-destroying, redox chemical process. It is most often caused by the high chemical activity of the metals themselves - many remember from the school chemistry course the “line” of the activity of elements. It can be activated when unfavorable conditions are created, for example, high humidity and low temperatures, in an aggressive salt, acidic or alkaline environment.

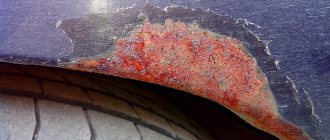

Most often we have to deal with corrosion of ferrous metals, that is, various types of steel and cast iron, used literally everywhere, in all spheres of human activity. The process begins to reveal itself by the appearance of red stains or stains on the metal surface.

If corrosion is not dealt with, it can show its extremely destructive power - metal products quickly become unusable.

If no steps are taken, the outbreak begins to grow, capturing more and more areas. And sometimes this happens unnoticed. Thus, many areas of mechanisms, instruments, etc. - are simply hidden from view, and can only be seen when the unit or entire device is completely disassembled. And other pockets of corrosion may be hidden under a layer of paint for the time being, and only when the process has gone very far - first appear in the form of swellings, and then as rust breaks out.

Some owners try to deal with identified pockets of corrosion mechanically. That is, by grinding the damaged area with sandpaper or special discs, reaching the “healthy” metal.

However, such a technique, if it can be applied, should be done with extreme caution, and only as a preliminary step, before applying special compounds. Only mechanical cleaning is a very ineffective means.

Spot corrosion showing through the paint layer

It is especially difficult to remove small pinpoint rust using this method, since during the cleaning process they become clogged with finely dispersed corrosive dust, and they become practically invisible. But the trouble is that they don’t go away, and will definitely show themselves in the future, even after coloring. Therefore, chemical treatment is more reliable.

In addition, if thin metal is affected by rust, then during cleaning, under the pressure of brushes or abrasive material, it can be damaged down to a through hole.

In this regard, it is recommended to use chemical compounds that clean the metal and prevent the occurrence of corrosion in the future. Moreover, with their help, you can even successfully deal with outbreaks in hard-to-reach areas, where you cannot reach the affected area by any other means without disassembling the mechanism.

Basic ways to combat body corrosion

| Way | Algorithm | approximate cost | Applicability | pros | Minuses |

| Service visit | Washing, drying, applying the drug | From 15000 ₽ | Most often - the second owner who took the car for a long time | Proven technology, turnkey work | Expensive |

| "Classic painting" | Stripping, priming, painting | Correction of several paintwork defects - from 4000 ₽ | On the exterior panels of the car to give a great look | The car looks almost like new. | Considerable labor intensity, selection of paint is required, but on external panels this is practically the only way |

| "Classic" with rust converter | Rust converter treatment, stripping, priming, painting | From 1000 ₽ when working on your own | On the external surfaces of cars that have nothing to lose, and all invisible surfaces | The rust will disappear | The surface will have an uneven appearance and an unclear color. |

| "Classic" with galvanizing | Zinc-rich primer | From 500 ₽ when working on your own | It is very noticeable on the external surfaces of any car except silver ones. | Zinc will provide protective protection | Poor adhesion of zinc particles to the treated surface |

| Electrochemical | Electrochemical stripping and galvanizing | From 800 ₽ when working on your own | In places where the paintwork is damaged and corrosion has begun. | Allows you to completely eliminate the source of corrosion | A stain the color of a “galvanized bucket” remains |

| Self-treatment with Movil with zinc | Apply to areas with damaged paintwork | From 1000 ₽ when working on your own | In places where the paintwork is damaged | A high-quality product provides lifelong body protection | Movil, made using simplified technology, does not give the desired effect |

| Self-treatment with Movil with rust converter | Apply to areas with damaged paintwork and incipient corrosion. | From 1000 ₽ when working on your own | In places where the paintwork is damaged and corrosion has begun. | A high-quality product provides lifelong body protection | Movil, made using simplified technology, does not give the desired effect |

Correct use of rust converter

Before starting work, read the operating instructions for the automotive rust converter. The rules established therein are binding.

Since most of the substances included in the complexes are toxic, safety rules must be followed.

The work execution algorithm consists of:

- clean the area damaged by corrosion;

- degrease the treated surface;

- applying the working composition;

- washing of working personnel;

- painting the treated surface.

Typically, zinc is used for body work, although other options are possible. The metal must be cleaned with a wire brush or sandpaper before application. They also remove loose body parts and bits of rust. Consequently, when using zinc, it takes more time to treat the surface before applying the composition.

Before using the solvent, degrease the surface to be treated with soapy water or degreasers. Instructions for using the degreaser are in the manual. Usually it is enough to apply the mixture to the surface of the car and then rinse.

After applying the converter to the surface to be treated, a chemical reaction should occur within 10-15 minutes. This time is enough for a protective film to form or for the corrosion to turn into a primer.

After this, it is necessary to thoroughly rinse the working solution from the body. When washing, do not use excessive force, as this may damage the protective layer formed on the metal. After washing, the treated surface is dried.

Then the body is primed and painted. The paint must be applied in three layers. You can start using the car after the paint has dried.

At first, it is advisable to avoid traveling in extreme conditions so as not to damage the protective layer.

The industry offers trucking owners a wide range of corrosion protection products. The driver needs to purchase a rust modifier and apply it correctly to the problem area of the body. If you cannot cope with corrosion, contact a car service.

Corrosion Removal Methods

Corrosion can be eliminated in the following ways:

- Mechanical – used for severe corrosion, it involves removing rust by stripping down to metal, followed by priming, puttying and painting the area of the body being repaired;

Advantages of the method: elimination of large and deep stains, damage under swelling paint, as well as low cost and availability of the necessary materials.

Disadvantages: length of the process.

- Chemical - involves using rust removers. Such reagents are widely represented on the modern market.

Advantages of the method: elimination of corrosion in hard-to-reach places, higher process speed.

Disadvantages: inability to use on heavily damaged areas.

How to wash it off?

Some rust converters do not need to be rinsed after application. However, most formulations require removal of residues from the treated surface. Otherwise, the opposite effect will occur - rust will appear.

Here are some useful tips on how and what to wash off the rust modifier:

- the converter must be washed off after the treated surface has dried;

- It is recommended to use special products: silicone solvent or white spirit;

- in the absence of a special product, you can use laundry soap to neutralize unreacted acid;

- after removing the converter residues, the surface must be thoroughly rinsed with water;

- moisture must be removed with a dry cloth.

It is advisable to prepare everything you need in advance in order to wash off the modifier in a timely manner. This ensures not only that rust is removed, but also that the converter does not leak. This article will tell you how to wash off rust converter.

Is it possible to make a rust modifier yourself?

If it is not possible to purchase a modifier, you can do it yourself. The easiest way is to mix phosphoric acid with water in a ratio of 6:4. However, sometimes it can be difficult to find the acid.

In this case, you can use the following recipe:

- 1.5-2 liters of boiled water;

- 1.5-2 liters of citric or oxalic acid;

- 15 grams of baking soda.

First you need to mix the first two ingredients. Next, add soda. The reaction lasts about 35 minutes. The converter is ready for use.

It is recommended to apply the resulting solution to the damaged area with a napkin made from natural materials. During the process, you need to ensure that the surface remains wet for at least 15-20 minutes.