Rust

- is a general term for iron oxides.

Colloquially, the word applies to the red oxides formed by the reaction of iron with oxygen in the presence of water or moist air. There are other forms of rust, such as a product formed when iron reacts with chlorine in the absence of oxygen. This substance is formed, in particular, in the reinforcement used in underwater concrete pillars, and is called green rust

. Several types of corrosion are distinguishable visually or using spectroscopy, and they form under different environmental conditions. Rust consists of hydrated iron (III) oxide Fe2O3 nH2O and iron metahydroxide (FeO(OH), Fe(OH)3). Given oxygen, water and enough time, any mass of iron will eventually convert completely to rust and break down. A rust surface does not provide protection for the underlying iron, unlike the formation of a patina on a copper surface.

Rust generally refers to the corrosion product of iron and its alloys such as steel. Many other metals also corrode, but it is iron oxides that are commonly referred to as rust.

Chemical reactions

A thick layer of rust on chain links near the Golden Gate Bridge in San Francisco. The chain is constantly exposed to dampness and salty splashes, causing surface destruction, cracking and peeling of the metal.

Causes of rusting

If iron, which contains any additives or impurities (such as carbon), is in contact with water, oxygen or other strong oxidizing agent and/or acid, it will begin to rust. If salt is present, for example, there is contact with salt water, corrosion occurs faster as a result of electrochemical reactions. Pure iron is relatively resistant to the effects of pure water and dry oxygen. As with other metals, such as aluminum, a tightly adhered oxide coating on the iron (passivation layer) protects the bulk of the iron from further oxidation. The transformation of the passivating layer of iron oxide into rust is the result of the combined action of two reagents, usually oxygen and water. Other destructive factors are sulfur dioxide and carbon dioxide in water. Under these aggressive conditions, various types of iron hydroxide are formed. Unlike iron oxides, hydroxides do not protect the bulk of the metal. As hydroxide forms and flakes off the surface, the next layer of iron is exposed and the corrosion process continues until all the iron is destroyed or the system runs out of all oxygen, water, carbon dioxide or sulfur dioxide.

Reactions that take place

A bolt covered in rust and dirt.

Pitting corrosion and gradual surface deformation caused by severe oxidation are noticeable. Rusting of iron is an electrochemical process that begins with the transfer of electrons from iron to oxygen. The rate of corrosion depends on the amount of water available, and is accelerated by electrolytes, as evidenced by the effects of road salt on vehicle corrosion. The key reaction is oxygen reduction:

O2 + 4 e− + 2 H2O → 4 OH−

Since this produces hydroxide anions, the process is highly dependent on the presence of acid. Indeed, corrosion of most metals by oxygen is accelerated by lower pH. The supply of electrons for the above reaction occurs through the oxidation of iron, which can be described as follows:

Fe → Fe2+ + 2 e−

The following redox reaction occurs in the presence of water and is critical for rust formation:

4 Fe2+ + O2 → 4 Fe3+ + 2 O2−

In addition, the following multi-stage acid-base reactions affect the course of rust formation:

Fe2+ + 2 H2O ⇌ Fe(OH)2 + 2 H+ Fe3+ + 3 H2O ⇌ Fe(OH)3 + 3 H+

which leads to the following reactions maintaining the dehydration balance:

Fe(OH)2 ⇌ FeO + H2O Fe(OH)3 ⇌ FeO(OH) + H2O 2 FeO(OH) ⇌ Fe2O3 + H2O

From the above equations it is clear that the formation of corrosion products is due to the presence of water and oxygen. With the limitation of dissolved oxygen, iron (II)-containing materials, including FeO and black magnet (Fe3O4), come to the fore. High oxygen concentrations are favorable for ferric iron materials, with the nominal formula Fe(OH)3-xOx/2. The nature of corrosion changes over time, reflecting the slow reaction rates of solids.

In addition, these complex processes depend on the presence of other ions such as Ca2+, which serve as an electrolyte and thus accelerate the formation of rust, or in combination with iron hydroxides and oxides to form various precipitates of the form Ca-Fe-O-OH.

Moreover, the color of rust can be used to check for the presence of Fe2+ ions, which change the color of rust from yellow to blue.

Damage, damage...

Everyone has seen those orange-brown or yellowish rust spots on metal parts. The economic damage from metal corrosion is enormous. In the USA and Germany, the estimated damage from corrosion and the costs of combating it amount to approximately 3% of GDP. At the same time, metal losses, including due to the failure of structures, products, and equipment, amount to up to 20% of the total steel production per year. For Russia, exact data on losses from corrosion have not been calculated.

It is known for certain that it was rusted metal structures that caused the collapse of several bridges in the United States, including with numerous casualties. Environmental damage is also extremely unpleasant: leakage of gas and oil due to the destruction of pipelines leads to environmental pollution.

Rust Prevention

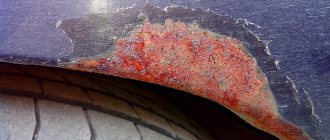

Peeling paint exposes areas of rusty sheet metal surface.

Rust is permeable to air and water, so the underlying iron continues to corrode. Preventing rust therefore requires a coating that prevents rust from forming. A passivating layer of chromium (III) oxide forms on the surface of stainless steel. A similar manifestation of passivation occurs with magnesium, titanium, zinc, zinc oxide, aluminum, polyaniline and other electrically conductive polymers.

Galvanization

A good approach to preventing rust is the galvanization method, which typically involves applying a layer of zinc to the object to be protected, either by hot-dip galvanizing or electroplating. Zinc is traditionally used because it is inexpensive, has good adhesion to steel, and provides cathodic protection to the steel surface if the zinc layer is damaged. In more aggressive environments (such as salt water), cadmium is preferred. Galvanization often does not reach the seams, holes and joints through which the coating was applied. In these cases, the coating provides cathodic protection to the metal, where it acts as a galvanic anode, which is primarily affected by corrosion. Aluminum is added to more modern coatings; the new material is called zinc-aluminum

. The aluminum in the coating migrates, covering scratches and thus providing longer lasting protection. This method relies on the use of aluminum and zinc oxides to protect surface scratches, as opposed to an oxidation process such as a galvanic anode. In some cases, in very aggressive environments or long service life, both zinc galvanization and other protective coatings are used simultaneously to provide reliable protection against corrosion.

Cathodic protection

Cathodic protection is a method used to prevent corrosion in structures hidden underground or underwater by introducing an electrical charge that inhibits electrochemical reactions. If used correctly, corrosion can be stopped completely. In its simplest form, this is achieved by connecting the object to be protected to a sacrificial anode, resulting in only a cathodic process occurring on the surface of the iron or steel. The sacrificial anode must be made of a metal with a more negative electrode potential than iron or steel, usually zinc, aluminum or magnesium.

Paintwork and other protective coatings

Rust can be prevented by using paint and other protective coatings that isolate the iron from the environment. Large surfaces divided into sections, such as the hulls of ships and modern cars, are often coated with wax-based products. Such treatments also contain corrosion inhibitors. Coating steel reinforcement with concrete (reinforced concrete) provides some protection for steel in high pH environments. However, corrosion of steel in concrete is still a problem.

Metal coating

Rust can completely destroy iron. Pay attention to the galvanization of non-rusted areas.

- Galvanizing (Galvanized Iron/Steel): Iron or steel is coated with a layer of zinc. The hot-dip galvanizing method or the zinc blowing method can be used.

- Tinning: Mild steel sheet is coated with a layer of tin. Currently, it is practically not used due to the high cost of tin.

- Chrome Plating: A thin layer of chrome is electrolytically applied to steel, providing both corrosion protection and a bright, polished appearance. Often used in shiny components of bicycles, motorcycles and automobiles.

Blueing

Blueing is a method that can provide limited corrosion resistance to small steel objects, such as firearms, etc. The method consists of obtaining a layer of iron oxides 1-10 microns thick on the surface of carbon or low-alloy steel or cast iron. To add shine, as well as to improve the protective properties of the oxide film, it is impregnated with mineral or vegetable oil.

Humidity reduction

Rust can be avoided by reducing the humidity in the air surrounding the iron. This can be achieved, for example, using silica gel.

Inhibitors

Corrosion inhibitors, such as gaseous or volatile inhibitors, can be used to prevent corrosion in closed systems. Some corrosion inhibitors are extremely toxic. One of the best inhibitors are salts of technicic acid.

Specialized drugs

If folk life hacks don’t help or the rust gets too deep, use a special anti-corrosion substance. You can purchase the product at any hardware store. During handling, be sure to wear protective gloves and a mask. Strictly follow the manufacturer's instructions so that you do not damage the metal while removing rust.

1. Neutralizers and converters

Chemicals should be used in complex and advanced cases

Chemicals that prevent the spread of corrosion. After applying the product to metal, the substance reacts with iron and forms a protective layer on the surface of the material. The film will remain on the product for a certain period of time, and then the procedure will have to be repeated. The products protect the material from the negative effects of oxygen and moisture.

2. Paint

Paint will prevent rust from spreading

You can use oil paint or a special rust stain. Regular paint should be applied to a surface that has been previously cleaned of corrosion. However, the disadvantage of this method is the possibility of rust progression under the painted layer. It is better to use special paints that can be applied directly to areas with corrosion. The product prevents the spread of rust by stopping the oxidation of the metal.

3. Primer

Primer enamel converts rust into a protective layer

In addition to regular primers, there are also varieties for working with rust. The operating principle of the product is to convert corrosion into a protective film. Prime the surface to level it, and treat it with special paint on top.

Economic effect

Rust causes degradation of products and structures made from iron-based materials. Since rust has a much larger volume than the original iron, its buildup leads to rapid destruction of the structure, increasing corrosion in adjacent areas - a phenomenon called rust eating

. This phenomenon caused the destruction of the Mianus River Bridge (Connecticut, USA) in 1983, when the bearings of the lifting mechanism completely rusted from the inside. As a result, this mechanism caught the corner of one of the road slabs and moved it from the supports. Rust was also a major cause of the collapse of the Silver Bridge in West Virginia in 1967, when the steel suspension bridge collapsed in less than a minute. 46 drivers and passengers who were on the bridge at the time were killed.

Kinzu Bridge after destruction.

The Kinzu Bridge in Pennsylvania was torn down by a tornado in 2003, in large part because the central support bolts connecting the structure to the ground had rusted, leaving the bridge supported only by gravity.

In addition, corrosion of concrete-coated steel and iron can cause the concrete to split, creating serious design difficulties. This is one of the most common failures of reinforced concrete bridges.

Types of corrosion and its causes

Before talking about rust on iron, let's briefly look at its other types.

Not only metals, but also non-metallic products are susceptible to corrosion. In this case, corrosion is also called “aging”. Plastics, rubbers and other substances are subject to aging. For concrete and reinforced concrete there is a term "fatigue". They are destroyed or their performance characteristics deteriorate due to chemical and physical exposure to the environment. Metal alloys - copper, aluminum, zinc - also corrode: during their corrosion, an oxide film is formed on the surface of the product, tightly adhering to the surface, which significantly slows down the further destruction of the metal (and the patina on copper also gives it a special charm). Precious metals are such not only because of their beauty, valued by jewelers, but also because of their resistance to corrosion. Gold and silver are still used to coat particularly sensitive electronic contacts, and platinum is used in the space industry.

The metal can corrode in some areas of the surface (local corrosion), cover the entire surface (uniform corrosion), or destroy the metal along the grain boundaries (intercrystalline corrosion). Corrosion accelerates noticeably with increasing temperature.

Table 1. Metal compatibility

| Metals for which data are presented in the table on their susceptibility to corrosion | Ratio of metal area to other metals table | Magnesium | Zinc | Aluminum | Cadmium | Lead | Tin | Copper | |||||

| Magnesium | Low | WITH | WITH | WITH | WITH | WITH | WITH | ||||||

| High | U | U | U | WITH | WITH | ||||||||

| Zinc | Low | U | U | U | WITH | WITH | WITH | ||||||

| High | N | N | N | N | N | N | |||||||

| Aluminum | Low | U | N | N | WITH | WITH | |||||||

| High | N | U | N | WITH | WITH | WITH | |||||||

| Cadmium | Low | N | N | N | WITH | WITH | WITH | ||||||

| High | U | N | N | N | N | N | |||||||

| Carbon steel | Low | N | N | N | N | WITH | WITH | WITH | |||||

| High | N | N | N | N | N | N | N | ||||||

| Low alloy steel | Low | N | N | N | N | WITH | WITH | WITH | |||||

| High | N | N | N | N | N | N | N | ||||||

| Cast steel | Low | N | N | N | N | WITH | WITH | WITH | |||||

| High | N | N | N | N | N | N | |||||||

| Chrome steel | Low | N | N | N | N | U | U | WITH | |||||

| High | N | N | N | N | N | N | |||||||

| Lead | Low | N | N | N | N | N | N | ||||||

| High | N | N | N | N | N | ||||||||

| Tin | Low | N | N | N | N | N | |||||||

| High | N | N | N | N | N | ||||||||

| Copper | Low | N | N | N | N | U | WITH | ||||||

| High | N | N | N | N | N | U | |||||||

| Stainless steel | Low | N | N | N | N | N | N | ||||||

| High | N | N | N | N | U | U | N | ||||||

Column 1 of the table presents metals that are or are not subject to corrosion with the metals indicated in the remaining columns of the table and the proportion of the ratio of the areas of the metal indicated in column 1 to the metals in the remaining columns of the table. The short designation S, U, N in the table means:

| |||||||||||||

Classification of corrosion processes according to the conditions under which corrosion occurs.

- Gas corrosion occurs in the gas phase with a minimal amount of moisture. This corrosion occurs when metals come into contact with aggressive gases (halogens, oxygen, sulfur oxide).

- Atmospheric corrosion occurs in an atmosphere of air or other moist gas.

- Liquid corrosion is corrosion that occurs in various types of liquids.

- Underground corrosion is metal corrosion that occurs as a result of inhomogeneities in the soil.

- Corrosion under cryptoclimate conditions occurs in confined spaces.

- Radiation corrosion is caused by exposure to radiation.

- Marine corrosion occurs due to the depassivating properties of chlorine ions.

- Structural corrosion is associated with the structural heterogeneity of metals.

- Corrosion caused by stray currents.

Video description

Rust destroyer-killer WD-40, or life hack with WD-40

Folk remedies

If there are no chemical compounds or it is impossible to work with them, you can try to remove rust from metal products using household chemicals and other effective solutions. Some of them you will have to prepare yourself.

Cilit

The gel is designed to remove rust in the kitchen and bathroom. It is often used to clean taps, mixers, metal appliances, and other iron products. Before using the composition, it is important to consider that it can corrode the paint.

Silite is a fast-acting product; it cannot be left on the treated surface for more than five minutes Source cdn.comfy.ua

Kerosene and paraffin

The recommended ratio of ingredients is 10:1. After connecting the components, the product must be left for 24 hours, then applied to the elements damaged by rust. After 12 hours, the treated area should be wiped with a dry cloth. This method is perfect for building materials and tools.

The specific smell of kerosene does not allow you to treat exposed surfaces covered with rust in the kitchen or bathroom Source ritualica.ru

Protection methods

To protect metal surfaces from corrosion, various techniques are used. Each of them is unique and has certain characteristics.

Application of protective coating

Protective coatings can be of two types - metallic and non-metallic. Types of non-metallic coatings:

- Chemical layer. More often these are oxide films that form on the surface under the influence of steam and air. One of the oxidation options is to immerse parts in a solution of nitric acid heated to 140°C.

- Paint and varnish coatings. The main disadvantage of paint and varnish coatings is their low resistance to temperature changes and mechanical damage.

- Powder paints. They are applied using specialized equipment in closed painting booths.

- Various polymer coatings.

Table 2. Compatibility of steel with metals

| Metals for which data are presented in the table on their susceptibility to corrosion | Ratio of metal area to other metals table | Carbon steel | Low alloy steel | Cast steel | Chrome steel | Stainless steel | |||||||

| Magnesium | Low | WITH | WITH | WITH | WITH | WITH | |||||||

| High | WITH | WITH | WITH | WITH | WITH | ||||||||

| Zinc | Low | WITH | WITH | WITH | WITH | WITH | |||||||

| High | N | N | N | N | N | ||||||||

| Aluminum | Low | U | WITH | WITH | |||||||||

| High | N | N | U | U | U | ||||||||

| Cadmium | Low | WITH | WITH | WITH | WITH | WITH | |||||||

| High | N | N | N | N | N | ||||||||

| Carbon steel | Low | U | WITH | WITH | WITH | ||||||||

| High | N | N | N | N | |||||||||

| Low alloy steel | Low | N | N | WITH | WITH | ||||||||

| High | N | N | N | N | |||||||||

| Cast steel | Low | N | U | WITH | WITH | ||||||||

| High | N | N | N | ||||||||||

| Chrome steel | Low | N | N | N | WITH | ||||||||

| High | N | N | N | N | |||||||||

| Lead | Low | N | N | N | N | ||||||||

| High | N | N | U | N | N | ||||||||

| Tin | Low | N | N | N | |||||||||

| High | N | N | N | U | |||||||||

| Copper | Low | N | N | U | |||||||||

| High | N | N | N | N | |||||||||

| Stainless steel | Low | N | N | ||||||||||

| High | N | N | N | U | |||||||||

| Column 1 of the table presents metals that are or are not subject to corrosion with the metals indicated in the remaining columns of the table and the proportion of the ratio of the areas of the metal indicated in column 1 to the metals in the remaining columns of the table. The short designation S, U, N in the table means:

| |||||||||||||

Rye solvents

All of the products listed below are in great demand (everything is simple and affordable) and effective. Each of the compositions necessarily contains a certain type of acid that effectively copes with and prevents corrosion.

What should those who purchase solvents remember? They are produced for outdoor use and hidden surfaces. The difference is in the method of use, the indicator of aggressiveness towards various products - paintwork, rubber, plastic. We recommend that you read the review: how to remove glue from a sticker from plastic.

Specialized solvents have excellent deep penetrating ability (even for microcracks), an increased degree of adhesion to the base, and do not harm paints and varnishes. We recommend a review: can varnish be applied to nail polish? Rye destroyers are produced in the form of: sprays, aerosols, liquids, gels.

Let's look at the most popular ones:

- "LOCTITE 8019 400 ML" - spray. The best option when you need to disconnect rusted fasteners. It has a convenient elongated spout for application in hard-to-reach places.

- "Neomid 570" - liquid, concentrate. Designed for external and internal processes on concrete, ceramics, stone, metal, paint and enamel.