High-quality thermal insulation of a house helps not only to save money, but also to increase comfort in the home. You can insulate walls both outside and inside, especially if funds for repairs are limited. There is an excellent 100% method of insulating walls from the inside with polystyrene foam + video instructions, after studying which it will not be difficult to do all the work yourself.

Method of insulating walls from the inside with foam plastic

External or internal insulation: what to choose?

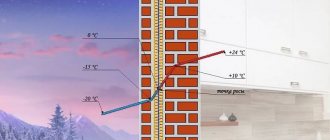

When choosing one of the methods, you should pay attention to the fact that external insulation shifts the dew point, so that moisture cannot penetrate deep into the wall, where it usually freezes and destroys the material from the inside. The disadvantages of this method include a much larger volume of work, the need to carry out high-quality waterproofing of all surfaces and, as a result, the high cost of the event.

Internal insulation will cost much less. In addition, work can be carried out in any weather, while work outside can only be done on days of the year when there is no precipitation.

Slab size

Foam boards are produced mainly in three sizes: 0.5 * 1, 1 * 1 and 2 * 1 m. It is immediately worth noting that this insulation is easy to cut, so no problems should arise during the installation process. So, it is better to choose the material that is most suitable for the area of the insulated surface. As a rule, for insulating balconies, loggias and apartments in apartment buildings, the choice is made on slabs measuring 0.5 * 1 m : they are most convenient to work with, they are more economical, and it will be easier to insulate all kinds of complex facade details with such material. But if you need to insulate a private house, the walls of which have a regular flat surface, then it makes sense to use slabs measuring 1 * 1 m. The largest material, slabs measuring 2 * 1 m are used least often for particularly large buildings.

Why foam plastic?

This material is one of the most common, so acquiring it will not be a difficult problem to solve. Moreover, polystyrene foam has characteristics that are important for the intended purpose. Such as:

- Good sound insulation.

- Excellent thermal insulation properties.

- Light weight.

- Easy to process and install (easy to cut and attach to wall surfaces).

- Resistant against mold and fungal organisms.

- Durability. The material is not afraid of severe frosts, heat, and temperature changes.

- Moisture resistance. Polyfoam does not absorb moisture, so it does not need additional waterproofing. The moisture resistance of the material is easy to check - to do this, just immerse the sheet in water for 7-10 days. During this time, it will absorb moisture no more than 0.3-0.4% of the volume of the sheet.

The disadvantages of polystyrene foam include its low strength, so when using this material it will be necessary to protect the material from a variety of mechanical damage.

Another disadvantage is the flammability of the material. It can withstand temperatures no higher than 600°C. A simple example will help you understand how little this is: the flame of a lighted match has a temperature of 750°C. In addition, the material has low adhesive properties, therefore, in addition to glue, it will need to be additionally fixed to the insulated surface.

What is important is that the use of polystyrene foam will reduce the usable area of the room, which is also a disadvantage.

Finishing

After the glue has dried, the wall is primed again, puttyed and painted with acrylic paint or a decorative finish is applied.

To quickly complete the work, you can use another type of finishing - plasterboard cladding: in this case, reinforcing mesh is not used.

After securing the vapor barrier film with a stapler, beams with a cross section of 25x40 mm are attached to the main frame, and plasterboard is attached to them. The drywall seams are protected with construction mesh, the surface is puttied and finished as desired.

By using plasterboard cladding, you reduce the area of the room, but gain time savings since you do not use a long-drying adhesive.

Features of choosing the right foam

Polystyrene foam is a gas-filled or foamed plastic in which air occupies the main volume. It is the presence of air in a larger volume that gives the material excellent thermal insulation characteristics. Depending on the raw materials used and the method of manufacturing the canvases, there is a division of foam into the following varieties:

- Polyurethane.

- Polystyrene.

- Phenol-formaldehyde.

- Polyvinyl chloride and others.

The most popular polystyrene foam today is polystyrene. It is produced in unpressed and pressed ways. For insulation, polystyrene material made without pressing is used. When choosing insulation, you must pay attention to its labeling. For example, the designation PSB-S-15 should be read as follows:

- PS – polystyrene type;

- B – non-pressed manufacturing method;

- C – self-extinguishing;

- 15 is an indicator of density, which is measured in kg/m³.

This brand of polystyrene foam is intended for insulation of roofs without attics and attics. To insulate residential premises, facades, loggias, balconies, it is worth using material with a density of 25 kg/m³ (PSB-S-25). Foam plastic with a density of 35 kg/m³ is designed for thermal insulation of foundations, durable and resistant even to harsh weather conditions. Insulation with a density of 50 kg/m³ has the highest strength and stability. It is used for thermal insulation of floors in basements, garages, industrial premises, etc.

Based on this, it can be noted that density is the main criterion for choosing foam insulation. But there are several more important criteria on which the quality of the material depends, namely:

- Storage conditions. If at the point of sale the insulation lies directly in the sun, its thermal insulation properties will be impaired.

- Appearance. The material must only be white. If there are yellow spots on it, this is evidence that poor quality raw materials were used for production or storage conditions were violated.

- No foreign odors. If there are any, then this indicates a violation of the manufacturing technology.

The quality of the material is also indicated by the presence of a manufacturer’s marking or sticker. A reliable manufacturer, for whom its reputation is important, will certainly provide the necessary conclusions and certificates. If the seller cannot show them, this is already a reason to think about the advisability of purchasing insulation from this supplier.

Myth 1: Insulating a façade is expensive

It is believed that insulating walls with foam plastic is an expensive pleasure. This cannot be answered unequivocally. For example, an owner living in the southern regions can choose an inexpensive material and get good thermal insulation, while an owner living in northern latitudes will have to look for a type that is more resistant to low temperatures, and therefore more expensive.

Maintaining the thermal insulation properties of foamed plastic mass depends on the operating temperature. If they exceed the value of its destruction, that is, destruction, it will be impossible to use the material for insulation.

In general, foam plastic allows you to save energy resources. In just a few years, it is possible to recoup the costs of insulating wall facades with this material.

Preparing the walls

If there are remnants of previously applied finishing on the walls, it is completely removed. Next, the surfaces are inspected to identify and mark the largest cracks, depressions, and protrusions. Using a level or plumb line, mark the places with the greatest difference in unevenness.

If the house was built with high quality, the errors are insignificant and can be easily eliminated by applying a thicker layer of adhesive. If the errors are significant, then the depressions are leveled with plaster, and the bulges are trimmed off with an ax or other tool. If this is not possible, you will have to cut a notch on the foam sheet in the place opposite the convexity.

If there are cracks near the window openings or near the door, they must be filled with putty, otherwise the insulation work may be useless. In order for the glue to better adhere to the wall surface, it is necessary to apply 2-3 layers of deep penetration primer. Experts also recommend applying an antifungal additive first. How to prepare and apply the mixture is indicated on the packaging.

Pros and cons of insulation from the inside

Before doing the work yourself, you need to study all the nuances. Thermal insulation of indoor walls is not the right solution from the point of view of such a science as heating engineering. This method becomes only acceptable if it is impossible to use another. The disadvantages of insulating the walls of a house from the inside are as follows:

- reduction of usable area of internal premises;

- the measures taken do not prevent the walls from freezing, and therefore do not protect them from destruction;

- the point of dew (condensation) appears inside the load-bearing wall of the house (there is a high probability of moisture accumulation).

The dew point is at the junction of the wall and the foam, so to avoid condensation it is extremely important to apply a vapor barrier

Insulation with foam plastic from the inside can only be done if there is a serious need for it. Most often, DIY work should be done in the following cases:

- Thermal insulation of premises in a multi-storey building. To insulate an apartment with polystyrene foam from the outside, you will need to hire industrial climbers. Such services are expensive, so an alternative option is to use protection from the inside.

- Insulation of house walls with new cladding. When doing work with your own hands in a private house, it is necessary to take into account the condition of the facade finishing. If the external work was completed relatively recently, dismantling the cladding is not practical from an economic point of view. In this case, it is also possible to fix the thermal insulation from the inside of the walls.

Installation of foam plastic

First of all, prepare the adhesive according to the instructions. Then they begin to glue the foam sheets in small areas: the spaces above and below the windows, behind the radiators, etc.

To do this, carefully measure the surface and, based on the data obtained, cut out the desired element, check its accuracy by applying it to the wall. Glue is applied to the entire area of the foam sheet in a thin layer or dotted in the center and along the entire perimeter, applied to the surface, firmly pressed against the wall and lightly tapped on its surface.

The sheets are laid in a checkerboard pattern, starting from the bottom of the wall. This must be done extremely carefully in order to get the surface as even as possible - this will save you from the work of further leveling them. At the same time, they carefully monitor that the foam sheets fit one to the other as tightly as possible.

Doweling

After the glue has dried, the insulation boards are additionally secured with dowels, at least 5–6 per standard 600x1200 mm slab.

Then a vapor barrier film is laid out over the surface and secured to the frame with a stapler.

IMPORTANT: Polyethylene film has a short service life, about 5 years, and therefore is not suitable for use as a vapor barrier.

Conclusion

To perform high-quality insulation of walls from the inside, you don’t have to turn to specialists for help: all the work can be done yourself if you have experience working with simple materials and tools.

You can carry out work on laying polystyrene foam both in the house and in utility rooms that are not heated. If heat leakage continues, it is necessary to insulate the ceilings and floors: only a set of measures will help protect the house from the penetration of cold.

Briefly about the main thing

Foam plastic is actively used as insulation for walls due to its lightness, low thermal conductivity and relatively low cost.

The technology for installing PPS and EPS boards includes preliminary leveling of the working base, gluing the sheets and then fixing them on special dowels. If necessary, the joints are filled with low-expansion polyurethane foam.

It is considered more practical to use two-layer insulation with overlapping seams of the previous one. The slabs are shifted to the side in a row.

Before painting, it is enough to prime the finished coating after filling the voids and recesses from the fasteners.

Before plastering and cladding, polystyrene foam is reinforced with fiberglass mesh, which is attached to a special adhesive for polymer materials.

The ventilation facade is made with a layer of waterproofing membrane.

Ratings 0

Calculation of insulation thickness

It is necessary to make correct calculations of the thickness of the material. This will save usable space in the room and provide thermal insulation.

The indicator that determines the measurement is thermal resistance. If there are several layers of insulation, then the indicators for each material are summed up. The thickness of the foam is calculated by multiplying the coefficient of thermal conductivity and thermal resistance. You can use tables indicating the characteristics of thermal insulation materials or a special calculator on the Internet.

Table for calculating the thickness of insulation.

Distance to green spaces

Since the land plot can contain not only buildings, but also green spaces, there are regulations for this case too

Leaving a gap between the fence of the site and flower beds is not as important as between trees and bushes. Here, too, it is necessary to comply with the rules in order to avoid penalties and claims from neighbors with possible legal proceedings.

Distance to trees

Tall trees growing close to the border of two plots of land are another subject of dispute between neighbors. To avoid legal disputes with residents of neighboring houses on this basis, maintain the recommended interval of 2 meters between medium-sized trees and the fence, and 4 meters if the trees are tall. The distance is calculated from the center of the trunk.

You need to maintain a distance not only from buildings, but also from trees to the fence

How to understand which trees grow on the site - medium-sized or tall? This is not stated in the laws, however, there is an unspoken rule - tall trees with a height of more than three meters. There are no restrictions or additions depending on the type of tree - apple trees, cherry plums, birches, tall pines, as well as wild or exotic trees can grow at the permitted distance.

Distance to bushes

The minimum gap between shrubs and the fence at the border of the site is 1 meter. The distance regarding flower beds and flower beds is not mentioned at all in the building rules and regulations. This means that you can plant flowers even close to the fence - this is legal. As with trees, there are no restrictions on the types of shrubs - the main thing is to keep your distance.