One of the thermal insulation materials that is suitable for insulating a house yourself is ecowool. It is made on a cellulose basis, namely from wood fibers impregnated with brown and boric acid. Technological features of production make it possible to make the final insulation product wear-resistant, environmentally friendly, and energy efficient. When working, you can apply ecowool yourself. The structure of the substance ensures the necessary degree of filling the space of the treated surface. In view of these features, this type of thermal insulation should be considered in more detail.

Application methods

Cellulose wool has a loose composition. It contains grayish fibers. Cellulose insulation consists of 4/5 of used waste paper or newsprint and 1/5 of non-flammable substances that tend to reduce the likelihood of fire (usually borax and boric acid). The fibers are bonded together by lignin, which, when moistened, ensures reliable attachment of the composition to the surface being treated.

There are two methods by which ecowool is installed: wet and dry. They are used depending on the design features of the insulated surfaces. The dry method is different in that it does not require the use of a compressor.

The ability to evenly fill all the voids of frame buildings is an advantageous advantage of the dry technology of applying insulation, so during insulation work it is important to ensure the tightness and wind protection of the room. The insulation composition is supplied to the equipment hoses in a fluffy form. The process is not complicated, but requires compliance with a number of safety measures.

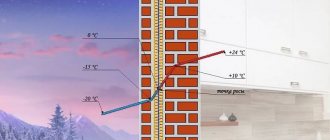

Cellulose insulation is suitable for insulating both internal and external walls, which makes this material universal.

There are two technological methods for installing thermal insulation:

- Blowing out. With this technique, the insulation composition is used to fill horizontal and inclined voids in frame walls. Thermal insulation is supplied through hoses through special holes in the wall. Ecowool fills the cavities inside, making insulation more effective.

- Open laying. A method that allows you to quickly fill open horizontal areas with insulation. Floor insulation with ecowool is often done using this method. The thermal insulation product is distributed evenly over the surface to be treated using a pump hose.

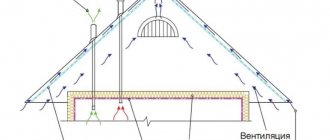

The wet method of applying ecowool is used when working on insulating external vertical sections and insulating interfloor ceilings. Roof insulation with ecowool can also be done using the wet application method. This technology differs from the dry method in the insulation composition. Dry raw materials are diluted with an adhesive or water base.

During installation, the need to carry out hydro- and vapor barrier measures in such places as:

- underground space;

- exterior walls;

- roof;

- ceilings between the attic and the lower floor.

Using special equipment for installation instead of manual installation will provide better thermal insulation, so hiring specialists to carry out the work will be the right decision. Organizations working in this area will provide prices for services that include both the cost of work and the cost of products. The consumption of ecowool can be assessed independently. It ranges from 40 to 65 kg per cubic meter depending on the surface. When applied horizontally, the consumption is minimal, when applied vertically – maximum.

Areas of use of the material

Ecowool is a universal insulation material, which allows it to be used for insulating country houses, private houses, multi-storey residential and public buildings, industrial buildings, for arranging warehouses and retail outlets, as thermal insulation for saunas, baths and swimming pools. Due to its excellent soundproofing properties, this material is used in the arrangement of acoustic rooms and recording studios.

When insulating the walls of a house, dry and wet installation methods can be used. The attic, floors and roof are insulated using manual dry installation of insulation. To reduce heat loss in the attic, two methods of thermal insulation can be used: dry blowing of the walls with special equipment and manual laying of the material on the floor.

Dry plaster mixtures can be made on the basis of ecowool, which can be used to treat concrete, brick and gas silicate walls to improve their sound and heat insulation characteristics.

Preparation for insulation using the blowing method

Insulation of walls and ceilings using the blow-in method begins with preparation for this process. If you plan to do the thermal insulation work yourself, then you need to purchase all the necessary equipment, calculate the material and prepare the working surface. Knowing the consumption of the substance per cubic meter and the thickness of the walls, you can determine what the consumption of ecowool is per 1 square meter. m.

Calculating the amount of cellulose wool required for insulation is an important procedure. Mistakes at this stage will lead to unnecessary costs for raw materials.

The consumption of ecowool per square meter of walls and ceilings varies, which must be taken into account when calculating the amount of ecowool required for work. Ecowool is transported in bags. One bag contains 0.14 cubic meters or, in terms of weight, 15 kg of thermal insulation composition. For a house with a base area of 60 m2, with an ecowool consumption of 50 kg per m2, you will need about a hundred of these bags. The amount of insulation depends on the thickness of the walls or floor slabs.

Recommendations

*

To ensure a continuous process of installing ecowool, it is recommended to have an assistant who will add thermal insulation material to the equipment.

For safety reasons, it is advisable to use a respirator.

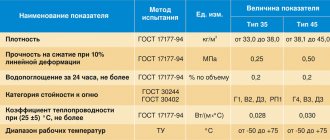

When laying cellulose wool manually, the density of the insulation should be taken into account. For walls, the density should be about 65 kg / cubic meter. m, and for the attic and floor it is in the range of 40-50 kg/cu. m.

When laying thermal insulation on the floor, you should not step on the insulation, as the material loses its properties under pressure.

Ecowool laying process

Wet method

Applying ecowool using a wet method is difficult to do with your own hands. Wet insulation is carried out only using expensive equipment. In a private home, the volumes are not so large that it would be economically profitable to carry out such work yourself.

The technology of laying ecowool using the wet method is applicable for thermal insulation work on the facade or under the roofing. On the facade, the technique is applicable only if finishing is possible. To supply wet adhesive-based composition, equipment with special nozzles is used to ensure uninterrupted supply of the composition under pressure. Drying time for insulation is 12 hours. Ecowool consumption when using the wet application method is 70-75 kg per square meter.

Due to its characteristics, ecowool eliminates the possibility of deformation of the thermal insulator during installation using the wet method. Condensation does not accumulate in the walls. Removal of excess material is done in a simple way - with a scraper and hands. After drying, the thermal insulation is hidden in the body of the wall with finishing materials.

Insulating the ceiling with ecowool using the wet application method will save time. Installation of insulation is carried out after installing a vapor barrier. Traditional methods of ceiling insulation are inferior to this method for several reasons. When insulating with ecowool, there are no microgaps between the main structures of the building and the insulation. In a wooden house, the wet application method can also be used to insulate the floor with ecowool.

Are there any disadvantages?

- In fact, the main disadvantage of ecowool is that additional equipment is required for its convenient installation. Moreover, it is required not only for the wet method of insulation, but will also be very useful for the dry method. Plus we need sufficiently qualified workers.

- In addition, the drying time for wet installation is 2-3 days. And, as you know, not everyone likes to wait.

Let's sum it up

The technical characteristics of ecowool described above show that it is no worse than any other materials for thermal insulation. In addition to this, it is undoubtedly environmentally friendly and durable. The use of technological equipment allows us to insulate a building or room of any size or shape in the shortest possible time.

Dry method

The dry method is also applicable for insulating ecowool walls on the indoor and outdoor sides. As a rule, it is used when necessary to fill the voids in the walls of frame houses. Insulating the roof with ecowool using a dry method is also possible, but only if there is a frame to fill it with heat-insulating material. Ecowool consumption with this method is 10-15% more economical than when applying insulation using the wet method.

Before you start applying insulation, you need to prepare it. The raw materials arrive in pressed form, so it will be impossible to apply ecowool in a commercial form. Modern equipment has the function of fluffing raw materials with a built-in mixer, but if this is not available, then the composition will need to be fluffed manually. Subsequently, under the influence of high air pressure in the hose, the composition will reach the required state. The degree of “fluffiness” of the raw material affects the penetration of insulation into all corners of the cavity, providing maximum coverage.

How to lay insulation manually

If you want to save on installation work to insulate your home, you can apply the insulation yourself. Do-it-yourself ecowool takes a lot of time to install. Blowing in the wall ensures greater density of insulation and filling of cavities with ecowool. When laying insulation manually, the consumption of ecowool is correspondingly reduced.

Before direct application, the insulation is laid out from the bags into a specially prepared trough, after which it is mixed with a mixer to give the material the required density and consistency. To do this, you will need to purchase a construction mixer or drill with a suitable attachment. Thermal insulation should be installed using personal protective equipment to protect the respiratory tract and mucous membranes of the eyes from dust.

conclusions

In the article we talked about the key points for using stone wool aspiration. Let's summarize what has been said. So, the advantages of mineral wool crumbs:

Disadvantages of insulation obtained from stone wool production waste:

We recommend a topic that describes in detail the use of mineral wool aspiration - Decagon, or the path from the sphere to the coaxial yurt.

Source

Installation equipment

If insulation is not done manually, then you should purchase the necessary equipment for installing ecowool. The installation for blowing ecowool is assembled on the basis of a vacuum cleaner. If necessary, you can assemble the entire blowing device for ecowool with your own hands. A detailed list of what equipment is needed for applying ecowool is given below:

- Vacuum cleaner Elitech BC 2000 power 2 kW/

- An electric drill or construction mixer with an attachment for mixing paint or dry mixtures.

- Container for mixing insulation raw materials 200 liters.

- Corrugated pipe for electrical cables with a diameter of 63 mm.

- Special electric roller scissors for trimming excess insulation

- Roll of tape.

Manual styling

This material can be used for insulation in various ways. One of them, industrial, consists of spraying pre-moistened ecowool onto the surface requiring treatment using specialized equipment, as well as pumping dry material into the insulated frame with a powerful compressor.

In addition, you can install the material manually, but this will increase its consumption. This process will take an order of magnitude longer.

The manual method of installing the material is labor-intensive, increased time costs, and the impossibility of completely filling all existing cavities, voids and cracks. But many people prefer this option, since it turns out to be much cheaper.

If you intend to insulate a shed, outbuilding or garage, follow the given procedure:

- Since the material is in a compressed state, it is necessary to fluff it well. You can do this using a drill and a paint attachment. The fluffed material can begin to be used.

- The briquette with insulation is opened, the mass is poured into any suitable container.

- This method of using the material can only be used for filling it into floors (when laying it from above), or for dry laying it into a wall space.

- When filling into floors, the mass should be evenly distributed between the joists and rafters. It is used to fill all the required places until a surface with a slide is formed. When the floorboard is subsequently used, the material will be compacted to the required volume.

- When dry filling the mass into vertically located structures, it should be carefully compacted: the density of the material should become only two times less than the original one inherent in the factory briquette.

Ecowool: do-it-yourself insulation

When preparing to independently insulate a house with ecowool, you can use a kind of calculator to calculate the needs for cellulose wool, based on consumption data for each section of the building structure. The table below shows data on insulation consumption when insulating roofs, walls, and ceilings with ecowool. The table shows data on insulating structures of various thicknesses with insulation.

| Installation location Layer thickness | 50 mm | 75 mm | 100 mm | 150 mm |

| Horizontal designs | 2 kg | 3 kg | 4 kg | 6 kg |

| Vertical and inclined structures | — | 4.13 kg | 5.5 kg | 6 kg |

| Wet, wet-adhesive application | 3.5 kg | 5.35 kg | 7 kg | 10.5 kg |

The total volume of material is calculated by multiplying the surface quadrature by the consumption per 1 sq. m. It is important to take a reserve of 10% for unforeseen expenses. The area of the walls is calculated by multiplying the perimeter of the room by the height of the ceilings minus the area of window and door openings.

Ecowool or penoizol

Among insulation products there are several products that do not form seams during installation. Many people ask themselves what is better: ecowool or penoizol. Both substances have many advantages. However, it is worth noting that the first of them is a truly natural material made from wood. In addition, this insulation helps in the fight against rodents. Boric acid repels many pests, which is very important for residents of private homes. Penoizol has one drawback - when applied, it releases formaldehydes that are harmful to humans, which can also be released during a fire. But the right to choose still remains with the buyer.

What are the advantages of cellulose wool? Its components are low-toxic: antiseptic and antispirin are characterized by moderate harm to health. Eco-friendly cotton wool does not rot, does not burn in fire, and has high heat and sound insulation. It is capable of concentrating in the upper layers of the composition and retaining up to 20% moisture, which does not affect the consumer properties of the product. Without contacting substances on the surface, cellulose insulation does not corrode.

Insulation of a frame structure with ecowool: Advantages and disadvantages of the material

Let us consider in more detail the advantages of the material, which ensure its excellent performance when insulating various buildings.

- Ecowool can retain up to twenty percent moisture in the surface layer, and at the same time it does not lose its insulating properties, unlike, for example, mineral wool;

- The structure of this material allows it to dry quickly after water gets on it, without losing its working qualities. The use of e- wool for home insulation helps maintain a normal microclimate in the house, keeping the humidity level at a level that is comfortable for humans;

- The material has low breathability, but is very elastic and perfectly absorbs sound waves. Together, these qualities provide ecowool with excellent sound and noise insulation properties;

- Ecowool is a homogeneous, fairly loose mass. After laying it in prepared frame cells or inside ceilings, it forms a monolithic seamless fabric that fills the intended volume completely, without voids and cold bridges that impair functional qualities;

- The material does not contain toxic or harmful substances: it can be installed and operated without any danger. The natural lignin it contains is absolutely safe, while borax and boric acid do not evaporate and are not volatile, so they cannot cause harm to health.

- Despite the peculiarities of composition and production, the material is only capable of smoldering, without catching fire or igniting. It is not afraid of mold and rot, does not emit an unpleasant odor, is chemically inert, and does not cause corrosion of contacting metals;

- The use of traditional materials for thermal insulation usually results in the generation of a significant amount of waste. The use of ecowool, on the contrary, ensures the recycling of unnecessary materials.

Like any material, in addition to its advantages, ecowool also has some disadvantages:

- To use the material, it will not be enough to simply purchase it. Use requires special equipment, and this cannot but affect the final cost of the work;

- The structural properties of the material, namely its flowability, can cause some inconveniences when using it: for this reason, vertical backfilling should be preferred;

- Anyone who intends to use the dry installation method will encounter a significant amount of dust when working;

- If the material is fastened poorly, it can settle, so the work process must be carefully controlled;

- You should not use ecowool to insulate floors located above the basement, where there is a consistently high level of humidity.