Insufficient thickness or poor choice of wall material often leads to undesirable consequences - the walls are cold, moisture condenses on them, heating costs become too high.

The solution to the problem is to insulate the walls.

The event is not too complicated, but it requires an understanding of the meaning of the actions, otherwise you can achieve the completely opposite effect.

Moreover, choosing the most correct method is sometimes impossible, but somehow you need to get out of the situation. Let's try to figure it out.

Brief characteristics of polystyrene foam

Expanded polystyrene is a hard, white, porous material. The peculiarity of its production is processing at high temperatures.

Styrene granules are filled with gas and the mass formed in the process is heated by steam. The air in the pores is reduced, the granules increase in volume.

Main characteristics:

- noise absorption;

- energy saving;

- water resistance;

- high strength;

- lightness of the material;

- resistance to chemicals and microorganisms;

- non-toxic.

Physical and technical properties of expanded polystyrene.

Styrene release

But the danger of material fire is not the only problem. After all, the main component of polystyrene foam is styrene. And it turned out to be very toxic. And although manufacturers claim that it is almost completely exhausted through technology, what remains is quite enough for polystyrene foam to cause irreparable harm.

Crafts made from polystyrene foam Source solitrade.by

After all, styrene can appear already at room temperature. And with its increase, the release only intensifies. Therefore, the biggest danger may lie in a foam-insulated kitchen. The room can warm up to high temperatures, and it is not without reason that in some cases it is compared to a bathhouse.

High concentrations of styrene can lead to:

- to dizziness;

- irritation of the mucous membrane of the eyes;

- to pulmonary poisoning;

- disruption of the liver and kidneys;

- failure of the hematopoietic system;

- to the occurrence of cancer.

But officially styrene is classified as a third group of hazardous substances. And they are considered moderate. This means that the toxin is on a par with copper, aluminum and alcohol. And only high concentrations of these substances are truly dangerous.

Defenders of expanded polystyrene compare the toxin to nuts and berries. After all, he is present in them. And if a person consumes a moderate amount of them in food, then they even bring benefits. Besides the pleasure of their taste. When the norm of use is violated, then too much always leads to negative consequences.

Packaging corners made of polystyrene foam Source tiu.ru

But in addition to high temperatures, the release of styrene is no less affected by light. And especially infrared radiation. And also the sun's rays. And also oxygen and ozone. Yes, and moisture. And if you simply bring polystyrene foam into the house and leave it near an uncurtained window, then after a very short period of time the concentration of styrene in the room will be 10 times higher than the permissible limit. And if you raise the temperature in the room to 75 °C, then by 150 times.

Types of expanded polystyrene

Expanded polystyrene varies depending on the manufacturing method, properties and scope of application:

- Expanded polystyrene foam. There are pressed and non-pressed ones. Pressed foam is more durable.

- Extruded foam. A synthetic material that is used in the construction of roads, sports facilities, and the manufacture of food packaging.

- Extruded polystyrene foam. High-strength waterproof material with low thermal conductivity, used for insulating houses.

- Polyurethane foam. A common example is foam rubber.

- Polyethylene foam. Elastic material used for packaging fragile items.

- Polyvinyl chloride foam. Included in construction products and materials.

Surface priming

The choice of primer depends on the scope of the intended work. The best choice would be products with deep penetration. When planning to prime, you need to run your hand along the wall with slight resistance. If it is dusty after this, the wall must be thoroughly washed and dried. You can reapply the primer after a day. A white coating indicates the presence of mineral deposits that occur during weathering of the top layer.

If there is a white coating, the surfaces are treated with a stiff wire brush. Now you can apply the primer. Concrete and brick walls with deep erosion leave a gray, brown or red coating on the hand. Such walls are treated with a metal cord brush until the wall has a smooth surface and integrity. To remove the damaged top layer, you can use a hammer drill with a chisel, after which the wall is rubbed with cement putty on concrete until completely level.

Advantages of polystyrene foam

Polystyrene foam is widely used in building insulation work. In terms of its technical characteristics, it differs positively from other thermal insulation materials.

Price

The price of polystyrene foam in construction stores may vary depending on the density of the insulation, the size of the material, brand and manufacturer.

Compared to analogues on the market, polystyrene foam is an inexpensive material.

Ease of installation

Polystyrene foam is lightweight. This advantage is due to the fact that it consists of more than 90% air. The material can be easily cut with a knife or hacksaw, and the necessary holes can be made in it. The elements fit together without any extra effort, the surface has good adhesion. Installation does not require the use of complex equipment.

Polystyrene foam is easy to install.

Life time

The practice of using polystyrene foam indicates its durability. It can withstand physical stress and does not collapse under pressure. If the insulation is of good quality, the rules of installation technology are followed and protection from negative factors is carried out, it can last more than 30 years.

Environmental friendliness

Polystyrene foam is an environmentally friendly building material. It is odorless and does not emit harmful substances. The polystyrene foam contains no carcinogens. It almost does not interact with air and water.

The material is safe for human health and must be completely recycled.

Hydrophobicity

Due to its structure, the hydrophobicity of the foam is minimal. When immersed in water for a day, the absorption of liquid by the material does not exceed 3%. When interacting with water, the foam does not change shape and does not collapse.

How to protect walls from dampness

As has already become clear, with such insulation, the formation of dampness is almost inevitable. Therefore, you should consider the basic rules that will help you cope with the question of how to get rid of dampness that appears as a result of freezing of the wall.

Thus, in order to eliminate dampness in the wall, it is necessary to use only vapor-tight insulation. This is where the first, most serious mistake of many people arises, namely, insulation with mineral wool using an additional layer of vapor barrier (which in reality is practically useless).

In addition, the complete absence of seams or joints during insulation becomes an important factor, since they also allow steam to pass through, and even in greater quantities than the material itself. And also any joints are a risk of condensation entering the room.

Thus, only good, and most importantly, proper insulation and ventilation will help in solving the question of how to remove dampness. In this case, the following absolutely do not fit the category of good and correct:

- Warm plaster.

- Cork covering.

- Mineral wool.

- Liquid ceramics.

The first two options can only be used as the last element of insulation, nothing more. Let us repeat, any insulation that is performed with vapor-permeable materials is absolutely not suitable.

Almost the best option for insulating walls from the inside in a panel house is to use polystyrene foam. Of course, it is also difficult to achieve maximum tightness with it, especially without using additional solutions, but it wins compared to other materials. Penofol is also a good choice, we will also talk about it a little.

Thus, in order to get rid of dampness in the house, as has already become clear, it is necessary to carry out high-quality insulation. And then we will look at how to make it and what you need for this.

Disadvantages of polystyrene foam

There are few significant disadvantages characterizing the material:

- Not resistant to direct sunlight.

- Refers to flammable materials. When ignited, it releases toxic substances.

- Absorbs moisture, so is not suitable for cold and damp rooms.

- Has a fragile structure.

- Forms a vapor barrier. If there is insufficient ventilation in the rooms, humidity may increase.

- It is a favorable environment for rodents.

The main disadvantage of polystyrene foam is its susceptibility to open fire.

Do you need hydro- and vapor barrier?

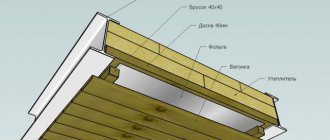

The presence of waterproofing in a wall pie using EPS is not required . Vapor barrier is present in the form of the insulation itself, which in itself is an excellent insulator, although in exceptional cases, when the room has a high content of water vapor, a layer of vapor barrier is laid on top of the EPS layer.

At the same time, simultaneously with laying a vapor barrier or insulation, it is necessary to take care of high-quality ventilation in order to organize the replacement of internal air and the removal of steam to the outside. Then the house will become much more comfortable, in addition, the passage of vapors through the cake material will be reduced.

Areas of application

Expanded polystyrene is a building material that has a wide range of applications:

- In renovation work as external and internal insulation of buildings, houses and apartments.

- During the construction of bridges and floating structures.

- In gardening.

- In the production of building materials and furniture.

- In architecture to create decorative elements.

- For packaging equipment and food products.

- In mechanical engineering. Polystyrene foam is used to create structures for casting.

Construction

In construction, expanded polystyrene is used to insulate roofs, water pipes, floors and walls.

To create a high-strength thermal insulation layer with low water absorption, extruded polystyrene foam is used.

Insulation of walls using the electric floor method

If you decide to abandon the installation of extruded polystyrene foam, replacing this method with wall insulation using the electric floor method, you must weigh all the positive and negative aspects of this technology. Experts say that good heat transfer cannot be achieved. The heating components will be located in the wall, and the heat will have to work its way through the trim or drywall. In this case, the space only a few tens of centimeters from the wall will warm up, while the heated air will immediately begin to rise upward. The result will be the need to install an additional electric heating device, which will entail costs.

If wallpaper and decorative tiles are pasted on the walls as a finishing touch, you may encounter the fact that the materials will move away from the surface under constant heating. With such a heating arrangement, it will not be possible to place furniture or electrical equipment against the wall, as they will quickly fail and, in addition, will block the air flow.

Having installed such a heating system, you will be faced with impressive heat losses, because energy will go not only inside the room, but also outside the house. Foil thermal insulation is placed under the infrared fabric (to prevent such phenomena), but this only aggravates the situation, and heating is even reduced. Such walls, where the electrical cable is laid, can no longer be used for hanging equipment and furniture. The same condensation will form between the warm and cold surfaces of the wall, which cannot but become a serious obstacle to installing such a heating system.

Calculation of insulation thickness

It is necessary to make correct calculations of the thickness of the material. This will save usable space in the room and provide thermal insulation.

The indicator that determines the measurement is thermal resistance. If there are several layers of insulation, then the indicators for each material are summed up. The thickness of the foam is calculated by multiplying the coefficient of thermal conductivity and thermal resistance. You can use tables indicating the characteristics of thermal insulation materials or a special calculator on the Internet.

Table for calculating the thickness of insulation.

Embedding fiberglass reinforcement mesh

After applying the adhesive solution to the mesh, it is necessary to carefully press it down, starting from the top, pressing it along its entire width. The mesh should be evenly stretched over the entire surface, without waves, humps or bulges. To ensure proper functioning of the layer, the reinforcing mesh must be recessed in the middle of the thickness of the solution. It is not allowed to attach reinforcing mesh directly to umbrellas or glue applied with a trowel. Immersion of the mesh too deep or too shallow can lead to cracking and the formation of humps in the reinforcement layer. The thickness of the solution layer when using one mesh should be from 3 to 5 mm.

When embedding the mesh into the mortar layer, you should pay attention to ensure that the vertical and horizontal edges of the mesh overlap each other by at least 10 cm. It is necessary to strictly follow the rules for wrapping the mesh on slopes and window sills and on wall corners - in the case of using protective corners without grids - move the grid onto the adjacent wall by about 15 cm

If the walls of the building are subject to impacts and mechanical damage, given their location, it is necessary to use a double fiberglass mesh along the entire height of the walls of the first floor. After the adhesive solution in which the first layer of fiberglass mesh was immersed has hardened, a second layer of solution should be applied and another layer of mesh should be sunk into it. The thickness of the layer reinforced with a double layer of mesh should be 6-8 mm.

The mesh must be carefully filled, since the leveling of the surface affects the final appearance of the facade. If irregularities occur, they must be sanded with sandpaper - otherwise they will be visible in the structure of the thin-layer plaster. Grinding can be done when the mortar layer is not yet too hard.

Sequence of work

When carrying out work on insulating a room from the inside, it is necessary to follow a certain sequence. Each stage has a number of features. Knowledge and implementation of technological requirements and recommendations during the work process will ensure high-quality installation of insulation and preservation of heat in the room.

Wall cleaning

Warming a room from the inside begins with preparatory work. It is necessary to thoroughly clean the walls, removing previous coatings, mortar deposits or paint. It is recommended to remove old plaster from the slopes of doors and windows. If fungal infections are detected, the plaster should be removed to the base of the wall and the damaged areas should be treated with antifungal agents. Using a brush, you can clean the walls from dust, after which you need to rinse them with water.

Alignment

If irregularities, depressions, or cracks are found on the walls, leveling should be carried out. For this purpose, the surfaces are treated with a special primer. It can be applied with a brush or a paint roller.

The walls are dried during the day and the resulting irregularities are eliminated using a spatula and sanding mesh.

Installation of insulation under windows and radiators

One of the methods of thermal insulation in areas where heating systems are located is to install a reflective screen under the radiators. It can be purchased ready-made or made independently from materials that include aluminum foil. The screen dimensions must be larger than the battery area, and the thickness must be at least 5 mm. The screen should be attached so that the surface is directed with a layer of foil into the room.

A reflective foil screen is an effective way of thermal insulation in areas where radiators are located.

The distance between the window sill and the wall can be filled with insulation, polyurethane foam or sealant.

Wall insulation

To install foam plastic, it is necessary to apply a fastening solution containing a moisture-proof layer to the slabs. The adhesive mixture is applied to all fields of the sheet and distributed evenly over its surface. To ensure a reliable connection when applying the solution, a needle roller is used. The product is attached to the wall in a checkerboard pattern. Gaps should remain minimal. The slabs are pressed against the wall, and the joints are taped with aluminum tape.

If a second layer of foam is needed, it is placed on top of the first and moved halfway across the slab.

Sealing seams and fastening with dowels

It is advisable to secure the heat insulator with dowels. Polypropylene umbrellas (fungi) are hammered into the prepared holes with a rubber hammer in the center and corners of the blocks with an insertion into the wall of at least 60 mm.

Next, you need to seal the seams between the foam plates. Deep seams are filled with pieces of insulation and treated with polyurethane foam and adhesive solution. The remaining mass is removed with a knife or spatula.

Scheme for fastening insulation with dowels.

Reinforcement and plaster

To protect the insulation from damage, ensure the strength of the finishing coatings and better adhesion, reinforcement is performed. The evenness of the walls can be determined by running a wide spatula over the surface. The joints between the insulation sheets should be located at the same level.

The fastening process begins with measuring the area to be treated. The reinforcing mesh is cut into pieces and mounted to the primed surface using nails. An adhesive solution with the addition of an antiseptic is applied in a thick layer to the pre-moistened walls and leveled.

Perforated corners are used to level corners and slopes.

Special building mixtures are used in plastering work. The mass is thrown onto the walls using a metal spatula and distributed evenly over the surface. Construction beacons are used to control evenness. If necessary, several layers of plaster are applied, after which the walls are cleaned until all irregularities are eliminated.

Finishing

The plaster is applied in layers until the desired evenness of the wall is achieved. After drying, the surface is treated with a primer, which finally eliminates defects. Next, you can paint, wallpaper or other finishing.

Finishing includes plastering and priming of insulated walls.

Internal and external thermal insulation - which is better?

In practice, internal and external (external) methods of wall insulation are used. If we consider both methods from a physical point of view, we can get an amazing conclusion: only the external method can rightfully be called insulation.

There are several options for insulation:

- mineral wool;

- Styrofoam;

- penoizol;

- extruded polystyrene foam;

- penoplex;

- polyurethane foam.

IMPORTANT!

The reason for cold walls is the lack of thermal energy to warm them up due to large heat losses. If the insulation layer is located outside, then the wall is separated from the external space, causing heat loss to be significantly reduced.

The temperature of the inner surface of the wall rises, eliminating the possibility of moisture condensation, and the dew point - the area with a temperature that causes condensation - is moved outside the wall. Thus, all problems with heat retention and wetting of the wall material are solved.

Insulation from the inside works in the opposite way. A layer of insulation cuts off the wall from contact with the warm air of the room. It becomes even colder, the outside temperature meets virtually no resistance and cools the wall.

At the same time, water vapor present in the internal air, under the influence of partial pressure, gradually passes through the insulation layer. When it encounters cold wall material, it immediately condenses, causing the wall to get wet, which threatens subsequent freezing and destruction.

Differences in insulation methods

Thus, insulation from the inside is, rather, cutting off the wall from contact with warm air . The method is insidious in that the sensations indicate that the house has become warmer - the wall is not cold to the touch, the presence of moisture between the insulation and the wall cannot be seen, and it does not become noticeable immediately.

It may seem that the issue is resolved. At the same time, steam escape through the wall material has not stopped, it is simply not noticeable. However, the use of this method is quite common, since work is possible at any time of the year and everything can be done with your own hands.

If insulation from the outside is not possible, then you should choose the most vapor-impenetrable insulation, which is expanded polystyrene (EPS). It to some extent eliminates the problem of the presence of steam, creating a barrier to contact between the wall and penetrating particles.

User reviews

Arsen, 38 years old, Moscow: “I used polystyrene foam to insulate the inside of the balcony and the corner wall of the children’s room. I completed the job in 3 days. The material is easy to attach. The surface was plastered and wallpapered. The heat is retained much better than before.”

Vladimir, 49 years old, Voronezh: “I insulated the wall in the toilet with polystyrene foam. After a few years, black spots began to appear through the wallpaper. I realized that during the repair I did not pay attention to the composition of the soil, which should contain antifungal components.”

Finishing

Frame method

The foam inserted into the grooves between the frame does not affect the finishing work in any way.

Panels, forcing, drywall and other finishing materials are fixed to the frame in the most common way - with self-tapping screws using a screwdriver.

You can then continue finishing as you wish.

Glue method

After applying the glue to the reinforcing mesh, time must pass until it dries completely. Then rough irregularities and glue deposits are removed. The surface is sanded using sandpaper.

Now you can use decorative plasters or paint. To hang wallpaper, the surface is primed again.

An option with preliminary application of drywall is also possible, but if the surface turns out to be smooth, you should not weigh it down with an additional layer.

Release of other toxins

But styrene isn't the only toxin released from foam. Scientists have proven the presence of phenol and formaldehyde in vapors.

The latter can cause very serious damage to a person:

- Inhalation causes bronchitis and asthma.

- Ingestion of the substance can lead to stomach bleeding and kidney and liver failure.

- When it comes into contact with the skin, the toxin provokes dermatitis, rashes and eczema.

Phenol is more dangerous because it is a strong poison. And poisoning can even lead to death if you do not seek medical help in time. And in order to save a person’s life, it is often necessary to administer an antidote.

Saving a person from poisoning Source toksikolog.com