0

8475

05.01.2014

Insulating the roof of a bathhouse is an important task, the correct implementation of which determines the temperature and humidity in the steam room and other rooms of the bathhouse. First of all, for proper insulation of the bathhouse roof, it is important to decide whether the bathhouse will have an attic floor or a ventilated attic. The sequence and choice of materials for insulating the roof of a bathhouse largely depends on this.

Bathhouse roof insulation

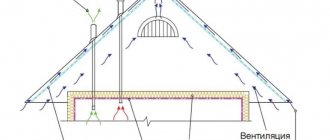

There are two main stages of thermal insulation of the roof in a bathhouse: insulation of the ceiling of the steam room and dressing room and insulation of the roof slopes. The feasibility of the second stage for a bathhouse with an unheated and well-ventilated attic is very controversial - if the temperature in the attic is close to the street temperature, there will be no problem of condensation, and therefore rotting of wooden structures. Therefore, in a bathhouse with a cold attic, the roof slope is usually not insulated - this is a waste of money. Ventilation is provided by installing attic windows, and the attic itself is used for drying and storing brooms and other necessary items.

When insulating the roof of a bathhouse with an attic floor, it is necessary to insulate both the ceiling and the roof slope. This will make it possible to arrange a full-fledged recreation room on the second floor. In such a bathhouse, it is necessary to pay close attention to the vapor barrier of the floors in order to avoid an increase in humidity on the second floor. Otherwise, the principles of insulating a bathhouse roof are no different and are performed using similar technology.

Roof insulation

Before you begin to insulate the roof of the bathhouse, it is necessary to treat the surface of the roof, rafters and beams with antiseptics and fire retardants to protect the structures from rotting and high temperatures.

If low-quality, rotten elements are discovered during the process, they must be replaced.

Next, waterproofing material is strengthened over the entire surface of the roof. As such, a membrane film is usually used, but polyethylene can be used.

The film is spread before installing the sheathing, the rafters are wrapped along its entire length. The film is attached without tension, with an overlap of 10 cm. Seams and joints are insulated with tape, preferably foil.

After this, the installation of insulation begins. If you have chosen a material in the form of slabs, it is installed between the rafters at random. The best option would be to lay the slabs in two layers, so that the second layer overlaps the joints of the first. In this case, the likelihood of cold bridges appearing between the joints will be reduced.

https://youtube.com/watch?v=1oq77y9dl6M

Each layer should be at least 10 cm thick. If the width of the rafters does not allow laying a layer of such thickness, they will have to be increased by nailing a beam of the required thickness to them on top. You can try to save on insulation by reducing the layer thickness to 5 cm. However, this will require laying an additional layer of vapor barrier.

The insulation is secured using lathing, which is placed on the rafters every 30-40 cm. You can use a cord or fishing line as fastening, which is pulled across the insulation.

This method of fastening will help, among other things, to create the necessary air gap between the insulation and the next layer of the roofing cake - vapor barrier.

Vapor barrier materials

Vapor barrier materials can be foil, roofing felt, or membrane coatings. You can do without a vapor barrier if you use foil-coated mineral wool slabs as insulation.

The vapor barrier layer is attached to the rafters using a construction stapler. Laying is carried out without tension, overlapping, preferably in two layers. The joints must be taped to protect them from damage.

Roof insulation is carried out if it is necessary to use the attic space. Therefore, it will not be possible to do without interior decoration. Lining or any wall panels are suitable as a finishing material.

Expanded clay of various fractions

Environmentally friendly insulation, available in the form of clay granules of various sizes. The advantages of the material are:

- low thermal conductivity; fire resistance; immunity to high humidity; resistance to mold and fungi.

Among the disadvantages of expanded clay, it should be noted that it is necessary to backfill a sufficiently high layer of insulation, which can lead to an increase in the weight of the floor.

In addition, the top layer of granules is capable of absorbing water, especially if the technology was violated during the production process. Wet material loses its insulating properties and takes a very long time to dry. Therefore, the presence of hydro- and vapor barrier is necessary.

Insulation technology

In order for bath procedures to be comfortable, it is necessary to follow the bathhouse roof insulation technology:

- A vapor barrier layer is installed. To do this, you need to purchase special materials. The vapor barrier is attached between the beams. Foil tape is glued to the knocks.

- A sheathing is nailed on top of the vapor barrier. As a rule, the distance between the sheathing bars is 60 cm. However, the dimensions of the selected insulation should be taken into account.

- The insulation is laid or filled in, and there should be no free space left. The thickness of the layer depends on the climatic conditions of the area where the bathhouse is located. Thermal insulation characteristics are directly dependent on the thickness of the layer, that is, the thicker it is, the better the thermal insulation. But there is no need to make the layer excessively thick. In most cases, 15-20 cm is sufficient.

- The cracks should be filled with foam.

- Thermal film or polyethylene is spread over the thermal insulation. A waterproofing layer is required; if it is missing, the insulation will quickly become unusable. The film is fixed using a construction stapler.

- The ceiling is sheathed with finishing material. The best option is eurolining, but you can also use regular boards.

Here is a general plan of action for insulating the roof of a bathhouse. The insulation technology can be changed depending on the type of ceiling structure.

Video description

One of the options for insulating a brick bath is shown in the video:

Bathhouse made of timber

If small timber was used to construct the building, then not only the steam room in the wooden bathhouse is insulated, but also all other rooms. Complex thermal insulation is also carried out when the structure was originally built from low-quality materials.

If the timber bathhouse was built in strict compliance with the technology, then all the cracks are caulked. In addition, the wood is treated with special substances that prevent the formation of fungi and mold. In this case, to insulate a steam room, basalt wool, which has a foil coating, is usually used. Fiber insulation and foil can also be used separately.

Expanded clay concrete bath

If the structure is built from expanded clay concrete blocks, then insulation is carried out using moisture-resistant heat-insulating material. After all, the walls in this bathhouse have a porous structure. Therefore, they themselves will retain heat perfectly. However, such structures are negatively affected by high humidity.

One of the options for moisture-resistant heat insulator Source cs.petrovich.ru

For baths made of expanded clay concrete blocks, basalt wool is also often used. At the same time, a vapor barrier layer and waterproofing are laid. Additionally, it is recommended to install a ventilation system.

On a note! If a foil thermal insulator is used, the insulating layer may have a small thickness. However, in any case, it is additionally necessary to install waterproofing.

Why is it worth insulating the roof of a bathhouse? Interesting for dummies

In order for the roof of the bathhouse to well protect the room from external adverse factors, become vapor-tight and have good ventilation, it must be insulated. It is this solution that will allow you to retain heat in the steam room for a long time, which will make the process of staying in it comfortable. Of course, when choosing a method of insulation, it is worth considering how often visitors will be in the room. If the bathhouse will be used only occasionally, then you can use thinner and cheaper insulation materials, but for a room in which you will be constantly steaming, you need to do more serious insulation.

You can insulate the roof, both when building a bathhouse and an already finished room, by choosing appropriate high-quality materials for this. To insulate the roof of a bathhouse with your own hands, you will have to stock up on strength, materials and tools that will be useful for carrying out the work.

Briefly about the main thing

Thanks to the heat insulator in the bathhouse, it is possible to organize effective circulation of steam and moisture, reduce the amount of firewood used, and significantly increase the level of comfort in using the premises.

In such buildings, basalt wool, polystyrene foam, foil insulation material, penoplex and even polyurethane foam are often used. However, the most popular material is still fiber insulation. However, it is recommended to mount a layer of foil along with it.

If the bathhouse is built from timber, following the technology, then usually only the steam room is insulated. When the walls are made of bricks, the structures are thermally insulated in 2 layers. If expanded clay concrete blocks are used, then a moisture-resistant heat insulator is used.

Ratings 0

Thermal insulation of deck ceiling

The flooring method allows you to erect a ceiling without the use of beams. In such a situation, the flooring of the boards is carried out on the strapping or on the upper crowns. Great for steam rooms with attic space.

The most budget-friendly and easiest ceiling option to install yourself. With this method, the insulation on the roof side is not covered, so it will not be possible to use the attic in the future. In addition, any repair work related to the ceiling will require replacing the insulation, which is not entirely convenient.

Direct thermal insulation work begins with the fact that a rather thick layer of clay is first laid on the ceiling boards. Next, you need to wait until the clay is completely dry, lay the selected insulation on top and cover it with a layer of loose vapor barrier. Before starting work, you need to place a box around the perimeter of the attic, which will serve as a fence for loose thermal insulation.

Insulation can be done using wood chips mixed with cement. This material will allow you to fill all hard-to-reach places and obtain thermal insulation of maximum quality.

Selection of materials

Regardless of whether the attic space will be used, it must be vapor-insulated. Click on photo to enlarge.

If the attic space of the bathhouse is not used in any way, special insulation of the roof will not be required. It will be enough to provide steam and heat insulation of the bathhouse ceiling and attic floor.

If you want to use the attic as a place to relax, or dry clothes and store bath equipment, you will need major insulation.

Almost any insulating material is suitable for insulating the roof of a bathhouse - polystyrene foam, glass wool, mineral wool, synthetic insulation materials such as "Ursa".

It would be good to use mineral wool with a foil side.

When choosing how to insulate the roof of a bathhouse, pay attention to materials that are resistant to high temperatures and high humidity

Steam and waterproofing

Before starting insulation work, all roof elements must be treated with antiseptics and fire retardants.

Membrane coatings are usually used as waterproofing materials.

The waterproofing film is laid on the rafters before installing the sheathing. The film, which serves as a vapor barrier, is installed between the lining and the ceiling insulation.

The film is laid loosely, without tension, with an overlap of strips of 10-15 cm. The seams and joints are taped to seal and prevent stretching and tearing in the event of deformation of the film due to temperature.

Ecowool

Completely environmentally friendly insulation based on cellulose impregnated with sodium tetraborate and boric acid. The advantages of using the material are:

- low thermal conductivity of the coating; resistance to temperature changes; light weight; long service life; almost complete resistance to attack by insects, microorganisms, fungi.

Among the disadvantages, it is worth noting the complexity of installation. If it is produced by the so-called “wet” method, and this happens most often, the use of special equipment is required.

These are not all coatings that are used for insulation. Sometimes environmentally friendly materials, which have been successfully used by home craftsmen for decades, are chosen as an insulator. This is clay with sawdust or leaves.

The composition of the mixture may vary. Wood shavings, cement, peat, black soil, straw, etc. are added in various proportions.

The procedure for insulating the ceiling

Insulating the roof of a bathhouse requires the installation of a vapor barrier layer. The vapor barrier is fixed between the beams. Special ready-made materials are available for sale, so you won’t have any problems with the purchase. The joints must be taped with foil tape.

Vapor barrier

A sheathing is installed over the vapor barrier. The standard step between the sheathing bars is 60 cm. You also need to focus on the dimensions of the selected insulation.

When choosing the thickness of the layer, the determining parameter is the climatic conditions of the area in which the bathhouse is located. The thicker the layer, the higher its thermal insulation characteristics will be. However, there is no need to make it too thick, there will be no point in doing so. Usually a layer of 15-20 cm is sufficient.

The laid thermal insulation is covered with thermal film or polyethylene. This is a mandatory moisture-proofing layer, without which the service life of the thermal insulation will be significantly reduced. To secure the film, it is most convenient to use a construction stapler. At the end, all that remains is to sheathe the ceiling with the selected finishing material. It is best to use eurolining for this, but simple wooden boards will also work.

Bathhouse roof insulation

This is what the process of insulating a bathhouse roof looks like in general terms. Depending on the design features of the ceiling in your bathhouse, the thermal insulation technology may undergo certain changes.

Stages of roof insulation work

First of all, it is necessary to treat all wooden elements of the roof structure with an antiseptic. This will increase the resistance of the rafters to moisture. You can also treat wooden structures with fire retardants. To save money, such treatment can be done within a radius of several meters from the chimney opening.

Installation of insulation

After treating the rafters with appropriate compounds, you can begin insulating the roof of the bathhouse. In the process, you need to follow the following sequence of work:

- For laying between beams, if necessary, the insulation is cut with your own hands to the appropriate size.

- In this case, the width of the sheet should be 2–3 mm greater than the distance between the rafters. This is done to ensure a tighter fit of the material to the beams.

- After this, a vapor barrier membrane is laid on the insulation.

- The insulation is covered with boards along the rafters. It is possible to use other sheet materials: chipboard or plywood.

Particular attention is paid to do-it-yourself insulation around the chimney pipe. At this point it is better to do the following:

- Build a frame around the chimney pipe from a galvanized iron plate 25–30 cm wide.

- The resulting space between the chimney and the frame must be filled with non-flammable and fire-resistant material. For these purposes, asbestos inserts of suitable size are used.

- The same manipulations must be performed at the place where the pipe passes through the ceiling of the bathhouse.

At this point, the roof itself is considered insulated, but there are still some nuances.

Don't forget about the ceiling

In order for the insulation of the bathhouse roof to be truly done correctly, it is necessary to take care of the waterproofing and insulation of the bathhouse ceiling. There are several methods for this that differ from each other in how they solve the problem.

Application of vapor barrier. This method is more familiar and is more often used by young masters. Its essence is as follows:

- A layer of vapor barrier is laid on the pre-boarded bathhouse ceiling from the attic side. The use of foil material is recommended. In this case, a layer of foil is placed on the boards (face down).

- Then insulation is placed in the space between the beams. Pressed basalt wool is optimal for this, as it is the most natural material.

- Then boards or plywood are laid on the beams, thus forming the floor of the attic.

Waterproofing lock. This is a folk method, therefore less known. Used mainly by professional bathhouse attendants. It allows you to do more reliable waterproofing and insulation of the ceiling yourself. The essence of this method lies in the following actions:

- Ordinary clay is mixed with water until a homogeneous fatty mass without lumps is formed.

- Sawdust is added to this mass and thoroughly mixed to form a viscous mastic.

- The rough ceiling from the attic side is filled with this mass. The minimum required layer is at least 15 cm.

- The joints and seams between the walls and ceiling are especially carefully sealed.

- After applying this mass, it is covered with a layer of sawdust, shavings or straw on top.

Ventilation arrangement

Having dealt with the question of how to insulate the roof of a bathhouse, do not forget about the need to arrange ventilation for the attic space of the bathhouse. Proper ventilation can be done with your own hands in several ways:

- Equipment of several dormer windows (at least two).

- Install two ventilation pipes. Their installation should be done on different sides of the attic.

- You can also increase the ventilation gaps by installing the roof ridge a little higher.

The overall energy saving indicators of this room depend on the correct insulation of the roof of the bathhouse. And, although the process of insulating the roof itself is quite labor-intensive, it can be done with your own hands, without resorting to hiring specialists.

A few more recommendations

Where the chimney passes through the roof, only non-combustible insulation materials can be used. The chimney must be lined with refractory bricks.

The attic of the bathhouse must be ventilated; for this purpose, it is necessary to have dormer windows.

Waterproofing must be done on both sides, that is, on the steam room side to protect the insulation from steam and on the roof side from precipitation.

To obtain reliable, durable and effective thermal insulation, it is necessary to follow all the recommendations and sequence of work for insulating the roof of the bathhouse.

How to choose insulation

If construction deadlines are not pressing, and you want to save money, you can use traditional methods of insulation. For example, coat the ceiling with a mixture of sawdust and clay.

Or line the attic floor with moss and sprinkle wood ash on top. The reliability of such insulation methods has been tested for centuries.

However, today there are modern materials that are more convenient to install. Unfortunately, not every one of them is suitable for insulating a bathhouse.

When deciding how to insulate the roof of a bathhouse, take into account the following properties of the material:

- Thermal insulation characteristics.

- High temperature resistance.

- Sensitivity to moisture.

- Environmental friendliness of the material.

The last point is especially important. When exposed to high temperatures, synthetic materials can begin to release toxic substances, which will negatively affect the health of bathhouse users.

To insulate the roof, it is most often recommended to use mineral wool (preferably foil-coated), Penoplex boards, extruded polystyrene foam, basalt boards, and felt. Expanded clay chips are suitable for insulating the attic floor.

Mineral wool

A general name for a group of insulation materials with similar properties. To insulate the ceiling you can use:

- Glass wool, which is made from glass fibers. Slag wool, made from blast furnace slag. Rock wool, made from molten rocks.

Their common advantages include low thermal conductivity, good resistance to temperature changes and fire resistance. The average service life of materials is 40-50 years, which is due to their high resistance to rotting and the proliferation of pathogenic microflora. The main disadvantages are the loss of insulating properties even when slightly wet and the fragility of the fibers, which leads to heavy dusting.

Comparative characteristics of mineral wool are presented in the table

Variety Thermal conductivity coefficient Fiber length, mm Possibility of combustion Glass wool 0.04215-50 Absent Slag wool 0.0416 Sintered at high temperature Stone wool 0.04616 Absent

Cotton insulation is produced in the form of slabs and rolls. The first ones are more convenient to install. Some manufacturers produce foil coatings, which is very convenient, since the metallized layer reflects heat rays and retards evaporation.

Steam and waterproofing

The first stage when carrying out roof insulation work is treating the structures with antiseptic preparations that prevent wood rotting. To prevent fires, the roof is treated with fire retardant compounds. For waterproofing, membrane films are often used to protect against moisture; the film is laid on the rafters before installing the sheathing, and is intended for vapor barrier between the ceiling insulating material and the ceiling lining. The film material is laid without tension, overlapping with an allowance of 20-25 cm. The film sheets are connected with strips of adhesive tape, due to which there is no stretching, tearing, or deformation when the temperature rises.

Scat

It is also recommended to insulate it.

The technology for insulating the slope is similar to that used for the roof. You can use foam or fiber insulation for this work. The work can be done before or after the roofing is laid.

During the event, you should ensure that materials that could catch fire are kept at a considerable distance from the chimney. There you need to build a metal box and fill it with non-flammable substances.