In this article we continue to talk about fabric ceilings. Let’s talk about their features, consider what their advantages are and how to install a fabric stretch ceiling in your apartment with your own hands. Everyone knows that they have recently become more and more popular and have probably replaced old and traditional finishing methods forever; we will not focus on this.

Ceiling features

A DIY fabric ceiling is a perfectly smooth, strong and durable finishing material.

The material is a polyester fabric of synthetic origin, very thin and rough in texture. It does not exceed a quarter of a millimeter, but despite this, it is very durable and can withstand quite heavy loads, due to the fact that the base of this material is impregnated with polyurethane.

Available in rolls 5 meters wide.

This makes it possible to install on the ceiling surface without seams or joints. Unless, of course, its width exceeds 5 meters. Using such building materials, you will get a perfectly flat surface under which you can easily hide electrical wiring and other communication elements.

Installation – the most important thing is strength and practicality

To make a stretch ceiling we will use calico. Why?

The main difference between calico lies in the method of its production. Cotton threads are woven using a special linen method, which adds strength. Clothes made from calico are practical and can withstand numerous washes without loss of quality, shape and color.

The issue with the material has been resolved. Before purchasing it, you need to measure the ceiling to determine the amount of material to purchase.

Advice! Don’t try to simplify the task and measure the floor instead of the ceiling, hoping for the same results. Sometimes the walls have significant differences, which can play a cruel joke - fabric like PVC film cannot be stretched. We take a margin of 7-8 centimeters for each wall.

You need to purchase undyed calico, with a rough structure. This is much cheaper and better for further processing of the ceiling. Typically, specialized stores sell calico 1.5 meters wide.

Advantages of fabric ceilings

They are very light and do not create a load on the supporting structures of the room, but this is not the only positive feature that should be noted. They also have the following advantages:

- Easy to install. This creates the opportunity to use a fabric ceiling with all the components yourself in combination with other materials, if this is provided for in the design project.

- Withstands the weight of water when flooded, without creating streaks or other stains after drying. Moreover, after drying it takes on its original appearance.

- Fire resistant due to special treatment of the base material. Namely, impregnation with a polyurethane substance. It goes on sale with a certificate that confirms this.

- In addition to the fact that it does not burn, it is also not afraid of low temperatures. Able to withstand air temperatures down to (-300). This makes it possible to use it in rooms that are not heated or in private houses on verandas and terraces.

- If the surface is accidentally cut or punctured, they easily stick together.

- Since they are made from environmentally friendly materials, installing fabric stretch ceilings in children's bedrooms is quite possible.

- Under thermal loads it does not emit any substances harmful to human health.

- Warranty service. Long service life up to 50 years.

- They can also be used as panels with photographs or advertising on the walls of an apartment or building, restaurants, offices, and so on.

Also read: Draping the ceiling with fabric.

Vinyl - main advantages

Before describing fabric ceilings, let's first talk a little about its direct competitor made of vinyl. This stretch ceiling is essentially a vinyl film.

The fact that vinyl is not afraid of water is its undeniable advantage; it makes it easier to waterproof the ceiling. Imagine that after a renovation has just been completed, a leak appears in the apartment due to a forgotten open tap or a burst pipe in the neighbors above. The repair will be ruined.

Nervous tension when talking with neighbors, spoiled mood, household items and the need for new repairs - all this can be avoided if a high-quality stretch ceiling is installed. Water will simply collect on it, it will bend, and after the water is drained, it will return to its original shape.

Our information is that a stretch vinyl ceiling can withstand 100 kg per m2.

But of course, like any element, a vinyl ceiling is not without its drawbacks. First of all, this relates to certain skills when selecting and installing it.

Do-it-yourself fabric ceiling finishing

Since special devices and skills are not required for its installation, you can try installing fabric stretch ceilings.

First, as with any finishing, the ceiling must be prepared. If its surface is smooth without large cracks and crevices, without fungal stains, soot or rust, then simply rinse it thoroughly. If this is not the case, then you will have to putty, plaster, and sand everything so that the surface is smoother, without dirt and stains.

At the moment, there are two ways to install fabric panels; we will consider each separately.

New technologies - new opportunities

Like everything else in the world, construction technologies do not stand still. Many still remember the first proposals for the installation of suspended ceilings, and how the novelty soon became one of the standard decorative elements in the renovation and decoration of premises.

A huge advantage of such ceilings is the wide selection of shades and colors that allow you to select the canvas for different interiors and for almost any room. Possibilities of modern photo printing, which is used in the production of suspended ceilings. We have reached such a level that we can purchase ceilings of various styles.

Method 1

The installation steps in the first method are as follows:

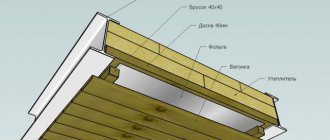

- We prepare and install the profile. It is best to take an aluminum profile, a molding for suspended ceilings, since it is almost eternal.

- We fix the fabric of the canvas in the middle of the profile, leaving a little material in reserve at the edge of our profile; 6 will be enough.

- Since stretching fabric coverings can sometimes be difficult, do it gradually and slowly. Try to keep its surface as smooth as possible.

- Start from the middle of the canvas, moving towards the corners on both sides at the same time. As we move, we secure the material into baguettes. Therefore, for this work you definitely need an assistant.

- After the ceiling has been stretched, secure it in the corners of the profile.

If after stretching you have small sagging, you can remove them with a hairdryer. Heat the sagging area at a distance of no less than 20 cm to the sag and at a temperature of 1800. After this, cut off the unnecessary ends of the edge and install decorative plugs.

Method 2

For installation you will need:

- wooden beams with a cross section of 2 × 3 cm. Their length should be 50 cm longer than the required length for processing corners;

- penatex;

- Velcro tape:

- metal corners 8 pieces.

First we make frames from wooden beams, which will then be attached to the ceiling itself.

Next, we’ll look at how to glue fabric to the ceiling. We attach the tape using a construction stapler to the part of the frame that protrudes beyond the edges. It is better to glue it with liquid nails.

The other part of the tape needs to be sewn to the perimeter of the base on the front side of the curtain itself.

Next is a very important point, since our frame will be located under the chandelier, you need to pay attention to this detail. If it is not of dense tones, then the chandelier will need to be installed with additional lighting lamps; 6 lamps will be quite enough.

Note: If the frame is transparent, then the glow of one lamp will be enough.

This completes the installation of the fabric tension covering frame with your own hands.

All that remains is to secure our frame. Adding decor such as chains and other pendants will look very unusual and beautiful. You can attach the frame to the ceiling surface using special pipe holders.

Existing varieties

Modern fabric ceilings may differ from each other both in the properties of the material they are made of, as well as in their functions and aesthetic properties. However, most models ideally combine several characteristics at once, being an ideal solution for any operating conditions.

The classification of fabric stretch ceilings is as follows:

- Standard models are white , which fit perfectly with any interior. Such coatings are characterized by increased durability, and they can be additionally decorated with various designs and photo printing.

- Colored ceilings. They have unobtrusive tones in pastel colors. Such products are painted exclusively with natural dyes, which makes them environmentally friendly.

- Sound-absorbing and anti-noise ceilings (acoustic). They are created using a special impregnation that has sound-absorbing properties. In addition, such models may contain special linings that provide ideal noise absorption. As an example, we can take the Cerutti Next canvas.

- Translucent tension models. Such products are based on light-scattering fiber capable of refracting light rays. The material is additionally impregnated with matte varnish and polymer material with increased light transmittance. Lighting fixtures are fixed inside the ceiling, resulting in light refraction. This principle allows you to create a feeling of weightlessness of the ceiling.

- "Starry Sky". It is a specific type of translucent ceiling that creates a romantic atmosphere in the house.

- Antimicrobial models. They are a relevant solution for medical clinics and health centers. The fabric surface is pre-treated with a special antimicrobial composition.

There are also canvases on the market that are resistant to moisture and dirt. They are characterized by increased service life and maximum strength.

Fabric stretch ceilings - how good are they?

The type of ceiling decor that interests us began to be actively used relatively recently.

Many people liked it immediately. Others treat it with caution, believing that the special advantages of tension structures are greatly exaggerated. The real benefits of using fabric ceilings are as follows:

- Possibility of creating seamless surfaces. Manufacturers produce canvases up to 5.1 m wide. This is more than enough to mount a ceiling without seams spoiling its appearance in any room. In cases where the ceiling surface is large, installing a fabric structure is impossible - its individual panels cannot be connected to each other.

- High resistance to temperature changes. You can install a fabric ceiling with your own hands on a loggia, veranda, and other unheated rooms. The canvas will feel great - without losing its performance qualities and geometry, at temperatures down to -40°.

- Excellent durability of decorative coating. Fabric canvases are very difficult to damage or scratch with objects with sharp edges.

Also, seamless structures do not become electrified during operation, do not burn, and can be painted up to 3-4 times with acrylic compounds.

Installation of such canvases requires minimal skills from a home craftsman. You don't even need to take particularly careful measurements of the ceiling and fabric. The main thing is to buy the canvas with some reserve, and then simply cut it to the required parameters.

Cold pull method

Today, there are many technologies for installing suspended ceilings. One of the possible ways is the cold stretching method, done with your own hands. This method is ideal for seamless ceilings based on fabric.

The advantages of this design:

- They are made from a whole cloth, its width can reach 5 m. This is a significant advantage, since you can make any pattern that suits your own taste preferences.

- The ceiling surface is “breathable”.

- The material is not afraid of temperature fluctuations. Thanks to this, such a ceiling can be made in the kitchen and bathroom. A ceiling surface of this type is an ideal option, as it is suitable for installation in various conditions. The same cannot be said about vinyl sheeting, which can easily become deformed under certain circumstances.

- There will be no problems during installation. Installation of suspended ceilings without heating can be done very quickly by installing another sheet. Such a need may arise in the following cases: flooding, damage to the fabric base, or a desire to change the design.

- Resistant to various damages. The material is very difficult to damage. Of course, if you deliberately cut it with a knife, it will be noticeable, but if you accidentally “scratch” it with a sharp object, not a hint will remain on the surface.

- The canvas can be painted in any color with acrylic paints. Also, using paints you can create a drawing or use photo printing technology.

- After installing the fabric, there is no specific smell in the room. After installing vinyl sheets, the chemical smell remains for several days.

There are also disadvantages:

- The price of the structure is higher than PVC sheets.

- Small selection of designs.

- The distance between the main surface and the tension seems larger. Therefore, if the room has low ceilings, this solution will not be very successful.

- It is much more difficult to remove dirt from a fabric surface than from PVC fabric.

Seamless fabric ceiling structure

Fabric tension structures are made from polyester (100% synthetic material), which is specially impregnated with polyurethane. There are several manufacturers that use natural fibers or fiberglass to produce canvases. But this base is in any case impregnated with polyurethane.

This means that tensile structures made of fabric cannot be called absolutely environmentally friendly. When heated, they do not emit any toxic compounds that are potentially dangerous to humans. But this, in principle, is where all their environmental cleanliness ends.

An important nuance.

Fabric ceilings are positioned as moisture-proof coatings. This is true. But it is worth understanding that fabric is characterized by a low degree of elasticity.

It stretches much worse than stretch PVC ceilings. This means that the fabric structure may well break out of the installed fastenings during severe flooding. Remember this.

Famous manufacturers

A significant part of the leading manufacturers of fabric ceilings are located in Germany, Russia, Switzerland and France. The list of the most popular manufacturers includes the brands Cerruti, Clipso and Deskor. Unsurpassed quality is emphasized by relevant certificates and the experience of tens of thousands of satisfied consumers. In addition, brands are trying to keep up with the times , discovering new trends in this direction. As a result, the quality of their products is only increasing, and the number of customers is increasing.

When choosing a model from a well-known brand, you need to be guided not only by its bright design and attractive price, but also by reviews of real customers, as well as the performance properties of the product. It is important to understand that purchasing a stretch fabric ceiling is a long-term solution that should last for many years without deformation. Therefore, it is better to take the choice seriously.

How are seamless structures attached?

You can install a fabric ceiling yourself without preheating the room to a certain temperature.

This ensures ease of work. The canvas is fastened to a baguette - a special profile element. It is made of aluminum or plastic and attached to the wall using self-tapping screws and dowels.

The baguette can be: U-shaped (otherwise it is called wedge); clip-on.

The U-shaped profile is installed really quickly. When installing it, precise measurements of the room are not required. Its installation is carried out using a decorative insert and glazing bead.

It is worth noting that a U-shaped baguette does not provide clearly defined boundaries of the canvas, which can cause deformation of the decorative ceiling covering and displacement of the lighting devices on it. But the clip fastener allows you to avoid these problems. Therefore, experts recommend doing independent installation of fabric ceilings with its help.

Hiding the seams

For this we will use tracing paper. But first, let's prepare the glue.

Our advice is to make the edges of the tracing paper and overlaps invisible, bend them when gluing so that they do not stick to the fabric. When the glue has dried, carefully tear off the edges so that the tracing paper on the edges becomes thinner and the seams become completely invisible.

A detailed examination of the video instructions about the installation of fabric stretch ceilings allows you to fully master all operations.

. If a question arises about attaching a chandelier or other lamps, then in this case everything is done exactly the same as in any suspended ceiling - first the thermal rings are glued with special glue, and then the fabric inside them is cut through.

Almost everyone can install fabric stretch ceilings with their own hands, the main thing is desire and accuracy in work. When the ceiling is ready, you can begin finishing it, but we will talk about this in other articles. Best wishes.

Fabric stretch ceilings

One of the varieties of suspended ceiling structures is fabric stretch ceilings. Pros and cons, photo instructions for installing such materials and a selection of ready-made projects will help you make a choice and purchase a truly high-quality product.

With the help of a modern fabric covering, you can not only decorate the interior in an original way, but also hide the shortcomings of the rough ceiling.

Knowing all the pros and cons of fabric stretch ceilings will help you make your choice.

This fabric is made on a polymer base, slightly reminiscent of the well-known satin. Due to the existing fine-grained surface, such ceilings have a mother-of-pearl effect. Under the influence of artificial light, the fabric literally sparkles, which adds some mystery to any room.

Useful advice! You can wash fabric ceilings using only mild detergents without abrasive ingredients.

The fabric covering is much stronger than PVC fabric. Different strength indicators are explained by the structural features of the materials. Air permeability. The fabric covering can be called breathable, since it allows air to pass freely and does not disrupt the air exchange between the main ceiling and the room.

In the manufacture of fabric tension structures, a rather complex technology is used. The threads used to produce this fabric are exclusively natural. They are used to weave a mesh, which is then treated with a solution that gives the finished fabric fire-resistant properties.

Helpful advice! The fabric does not contain harmful substances such as cadmium, phenol and others. Therefore, the material cannot have a detrimental effect on health.

Fire resistance. This high-quality material cannot ignite when exposed to high temperatures due to the above composition.

If the manufacturer has not saved on additional components, then the fabric will have high performance characteristics. Resistance to negative temperatures. All properties of this material are preserved even at temperatures below -40 degrees. This allows you to maximize the scope of application of fabric ceilings.

If you compare a fabric covering with a polyvinyl chloride film, it can withstand more severe physical damage. The fabric does not crack or sag over time. Possibility of painting. For these purposes, specialized acrylic paints are used.

Fabric ceilings are decorated with any patterns, which makes it possible to bring interesting fantasies to life. Such products can be repainted up to 4-5 times. With the help of modern technologies, entire paintings or even photographs can be transferred to fabric.

This indicator depends on the quality of installation of the tension structure. Assembled according to all the rules, with certain subtleties observed, the ceiling system will last more than 10 years. Simplicity and ease of installation. Unlike stretching polyvinyl chloride film, you can install a fabric structure alone, without the help of others.

One of the main disadvantages of fabric ceilings can be considered a poor color palette.

It is very difficult to find fabrics in original colors, but you can create them yourself. The disadvantages also include the complexity of this stage of work, since the fabric is painted only after it is completely installed. To paint the ceiling, you will have to call in experienced craftsmen who specialize in such activities.

Unlike PVC fabric, fabric covering is not capable of retaining water. If the neighbors accidentally caused a flood, a fabric ceiling will not prevent repairs.

However, modern manufacturers have begun to offer ceiling materials with moisture-resistant properties. Difficult maintenance can be added to the disadvantages of fabric products. Any fabric tends to absorb odors, so you should not experiment with such designs in the kitchen or other rooms where there are any odorous substances.

You should not use fabric in dusty rooms due to the lack of antistatic effect.

Experts recommend cleaning fabric ceilings with a vacuum cleaner. This needs to be done regularly. You may need to purchase an additional device for these purposes.

Fabric ceilings cannot be installed a second time.

If you had to dismantle an already installed ceiling, the only correct solution would be to buy new fabric. Another disadvantage is the inelasticity of the fabric, so it cannot be used in complex ceiling structures. It is impossible to install fabric in rooms wider than 5 meters, since such installation will require the creation of an additional seam, which is very noticeable.

It is quite easy to choose the appropriate option, knowing all the pros and cons of fabric stretch ceilings.

Photo installation instructions will help you understand the installation features. Just as when installing any tension coverings, the existing fabric is very tightly stretched onto a pre-prepared frame around the perimeter of the room. The profile used for these purposes comes in two types: aluminum U-shaped and the so-called clothespin.

In the first option, the fabric is practically not stretched; its tense state is determined only by the force of the profile. When performing installation, it is necessary to check the fastening strength of each element, since quite high pressure will be exerted on them. Special hardware and spacers can also be used, but this depends on the original quality of the walls.

Clip-on fastening is a cheaper option that does not require calling professionals. It is thanks to its simplicity and ease of installation that this method has become widespread.

Installation is carried out without a ceiling plinth using a special spatula. Recently, a new technology for fastening fabric ceilings using clips was patented in Germany. In this case, the work is done quite quickly; the minimum distance between the rough ceiling fabric can be only 2 cm.

You can begin installing the hanging system after understanding all the pros and cons of fabric suspended ceilings. Photo installation instructions include several steps:

Installation of a stretch ceiling with LED lighting

Useful advice! Before installing a tensile structure, you need to decide what type of lighting you plan to use. It is necessary to prepare in advance places for installing electrical appliances.

Well, now it's time to finish the article. All the material I wanted to share has been reviewed. I hope it will be useful to you, and you will use it if you need to make fabric stretch ceilings with your own hands. Improve your own practical skills and gain new knowledge, as they say: “It’s never too late to learn!” That's all, thank you for your attention, successful and easy repair!

U-shaped profile for installing a fabric ceiling

The clip-type fastening is made of high-strength plastic material. Its structure is such that you do not need to worry about additional decorative elements (a special insert when carrying out installation work using a P-baguette). Note! Clip fastening guarantees a long duration of trouble-free operation of the fabric structure.

The amount of profile required to install a ceiling without seams is calculated simply. It is equal to the perimeter of the room. When determining the amount of fabric needed, be sure to leave a small piece of material on each side.

Calculations of the area of a stretch ceiling are carried out according to the following formula - the length of the room plus 0.15 m * by the width of the room plus 0.15 m. The indicated 150 mm is the fabric supply we mentioned.

One more tip. Install spotlights on a fabric ceiling structure using a special thermal ring. It is made of plastic, which is not afraid of heat, and is fixed in place with glue.

Preparation and marking

The process goes as follows.

Preparation and marking: instructions

Step 1. Take measurements of the height from floor to ceiling in the corners of the room, make notes and, if necessary, notes. Additionally, you can take measurements in the middle of each of the four walls.

Step 2. Compare the numbers with each other and note the difference in ceiling height in different corners of the room. On average it is 1-5 centimeters. The height of the stretch ceiling should be 30 millimeters less than the height of the ceiling at its lowest point. The value can be changed if you plan to install spotlights.

Step 3. Using a level, tape measure and pencil, draw a line along which the baguette will be installed. Make sure that it is parallel to the floor and at the same height from it at all points.

Step 4: Prepare the surface. Remnants of the old finish - pieces of plaster, paint or wallpaper - should be removed from the rough ceiling and walls. All kinds of cracks and holes must be sealed. Don’t forget to putty the ceiling and treat it with a primer and antiseptic so that fungus or mold does not grow above the tension fabric.

Primer for walls and ceilings with Dufa antiseptic, 5 l

Step 5. If you plan to insulate or soundproof the ceiling, do it before fixing the baguettes. The same applies to the installation of electrical wiring and other communications.

Installation instructions for fabric ceilings

To complete the work you will need a minimum of tools. Stock up on dyeing upholstery thread, a water level or a more accurate and easy-to-use laser level, a hammer, an impact drill (or, as an option, a hammer drill), and a stationery (or better yet, a construction) knife.

The installation sequence is as follows:

- Determination of the level (horizontal) of the installed structure.

- Measuring the corners of the room to ensure perfectly even joining of profile elements.

- Installation of the baguette and its fastening.

- Pulling the fabric.

- Installation of a plug (decorative).

- Installation of lighting devices.

Level markings are carried out to determine the exact plane (in the horizontal direction) of the fabric structure being mounted. It is imperative to lower the ceiling level by 0.11–0.12 m if you plan to install spotlights.

What is required for installation

In addition to the stretch ceiling kit, before starting work, you must prepare the following tools:

- stepladder;

- hammer drill or impact drill;

- screwdriver or Phillips screwdriver;

- hammer;

- laser or water level;

- hacksaw;

- pencil and tapping cord (can be replaced with a tape measure);

- construction or stationery knife;

- screws and plastic dowels;

- spatula with rounded ends.

To install lighting you will need:

- chandelier;

- built-in lamps;

- thermal rings of suitable diameter;

- wires;

- platforms or plywood or timber for mortgages.

Installation of fabric ceiling structure

Marking is done using a level (water, laser). Place level marks on each wall - use a simple pencil.

Then pull the upholstery dyeing thread along the marked points, pull it back a little and release it. A clearly visible mark will remain on the wall. You will be guided by it when carrying out installation activities.

Along the line you have made, you need to drill holes with a cross-section of 6 mm (the distance between them is taken to be about 12–15 cm).

Plastic dowels are installed in them, into which a baguette is then attached using self-tapping screws. It is necessary to fix the profile as efficiently as possible. The durability of the ceiling structure depends on this.

Now start stretching the fabric according to the following diagram:

- tuck (sequentially) the corners of the canvas in the baguette;

- fix the fabric structure in the center of the wall;

- strengthen the canvas in the center of the intermediate sections;

- install a decorative trim.

It is convenient to thread the canvas using a spatula with a rounded end. You will not have any difficulties in carrying out such work. Provided that you perform them with a careful and understanding partner.

The final stage of work is the installation of lighting fixtures. Don't forget that they are installed using thermal rings. Important nuance! It is advisable to attach massive chandeliers to a mounting element (it is made from a piece of thick plywood or a wooden block, which is fixed with dowels to the existing ceiling).

The installation of textile stretch ceilings is characterized by some features. The result of professional installation will be a stylish, sophisticated and perfectly smooth ceiling surface.

Preparatory work

The surface of the rough ceiling does not need to be leveled. But if pieces of plaster, putty, etc. fall off, they will stick out unsightly on the tension fabric. And heavy parts can even damage the fabric. Therefore, the base ceiling is prepared before installation.

If the chandelier is already hanging, it needs to be removed. The apartment is first de-energized. The wires are removed from the ceiling.

Remains of paint and plaster are removed from the surface of the ceiling. If there is mold, the affected areas are removed. The surface is impregnated with a composition that will not allow the fungus to reappear. This is also useful for prevention. After drying, the ceiling is covered with a primer (preferably deep penetration). It strengthens the surface.

The next step is laying out the electrical wiring for lighting. The wires are laid in a corrugated pipe and secured with clamps and dowels. Putty is not used as it may fall off later.

As a rule, a chandelier is used for lighting, sometimes in combination with built-in lamps. But the fabric will not support the chandelier, so a mortgage is being prepared for it. Take a piece of plywood or a wooden block slightly larger than the chandelier mount. The mounting platform is mounted at such a height that the lower part is at the level of the future ceiling. If the thickness of the plywood or timber is sufficient, they are fixed with dowels. Otherwise, a frame is made of a metal profile, which is attached to the ceiling. And a mounting platform is screwed to its lower part. Recessed lights are also attached to pre-installed platforms.

Advantages of stretch fabrics

Textured polystyrene fabric or, as many people call it, fabric stretch ceiling has many positive characteristics:

- It easily tolerates multiple coatings of water-based paint. In this case, there is no need to use a primer, the canvas already acquires a deep and rich color.

- The service life of textile ceilings exceeds 10 years. They are durable and reliable.

- The fabric fabric does not deteriorate from low temperatures. It is not afraid of changes from +80C to -40C, and its strength is only slightly inferior in characteristics to traditional finishing.

- This ceiling is multifunctional. It can be used in premises for various purposes.

- Installation is easy and quick.

- The fabric is waterproof and fire resistant.

A correctly installed fabric stretch ceiling is visually practically indistinguishable from a plastered surface, which is recognized as one of its main advantages.

The disadvantages of this building material include the fear of sharp objects, although if you consider that everything requires careful handling, then this disadvantage ceases to be significant.

Tip: Lighting devices with a power of up to 50 W can be inserted into the stretched textile fabric, since deformation of the ceiling surface may occur as a result of heating. The restriction does not apply to LED or energy-saving lamps.

Installation - main difficulties

As for installation, this is not an idle question. Of course, a person who decided to install a vinyl stretch ceiling himself most likely has certain construction skills. It will not be difficult for him to drill holes for fastenings and mount baguettes.

Our advice is that we do not recommend that you install a vinyl ceiling in your home yourself, without preparation.

Technologies for installing fabric stretch ceilings

Installation of textile ceilings occurs without the use of a heat gun.

There is no need to heat the room, as is done when installing PVC ceilings. This feature of textured materials allows finishing even in unheated rooms in any season of the year and significantly saves time. The “cold” installation method is absolutely safe, practical and convenient.

There are two installation technologies.

They have fundamental differences. Both methods require installation of a frame around the perimeter of the room. But the first technology involves a U-shaped aluminum baguette, and the second - a clothespin profile.

Wedge technology with U-shaped baguette

Installation is carried out using a decorative insert and a wedge.

It does not require exact measurements of the canvas. The work is cheap and done quickly. But it has two significant drawbacks:

- Lighting fixtures mounted in the ceiling can move and the canvas can become deformed if the specialist does not have enough skills to work with such material.

- The service life of a stretch ceiling installed in this way is significantly less than that of a similar one installed using clip technology.

- Clip technology

Clip fasteners are made of durable plastic.

It is designed in such a way that it does not require any additional inserts, because the canvas fits as tightly as possible to the wall surface. However, it will not be possible to mount the ceiling surface in this way alone; the help of another person is needed. Clip installation has no disadvantages and guarantees a long service life, as well as the absence of deformation of the canvas.

Advice: if you want your textile stretch ceiling to serve you for a very long time, give preference to clip technology.

How to stretch a ceiling alone

It is accepted that before installing a suspended ceiling in a room, it is necessary to agree with the person who will participate in the installation process. However, the work is quite accessible for one master if the floor plan is a simple shape, such as a square or rectangle. Those who want to know how to install a suspended ceiling in several levels must take into account that it is unlikely that they will be able to make it level on their own. The good news is that you don't need to be a civil engineer.

If you decide to do everything yourself, you will have to buy or rent a laser level. The rod is attached directly between the ceiling and the floor. Before installing the structure, measure the middle of the room. After “shooting” the first point, a screw is screwed into the wall, to which a rope is tied. This is necessary to make it possible to independently install fasteners that are installed along a horizontal mark. Another problem is the heavy chandelier, because you have to hold it and screw it at the same time. If it is simple and easy, this can also be done.